Долгий срок службы энергосберегающая шаровая мельница Caco3 кварцевая гипсовая

- Категория: >>>

- Поставщик: Sino Mining Co. Ltd.

Сохранить в закладки 1601157647334:

Описание и отзывы

Характеристики

Ball grinder mills attritor ball mill 200 mesh advantages

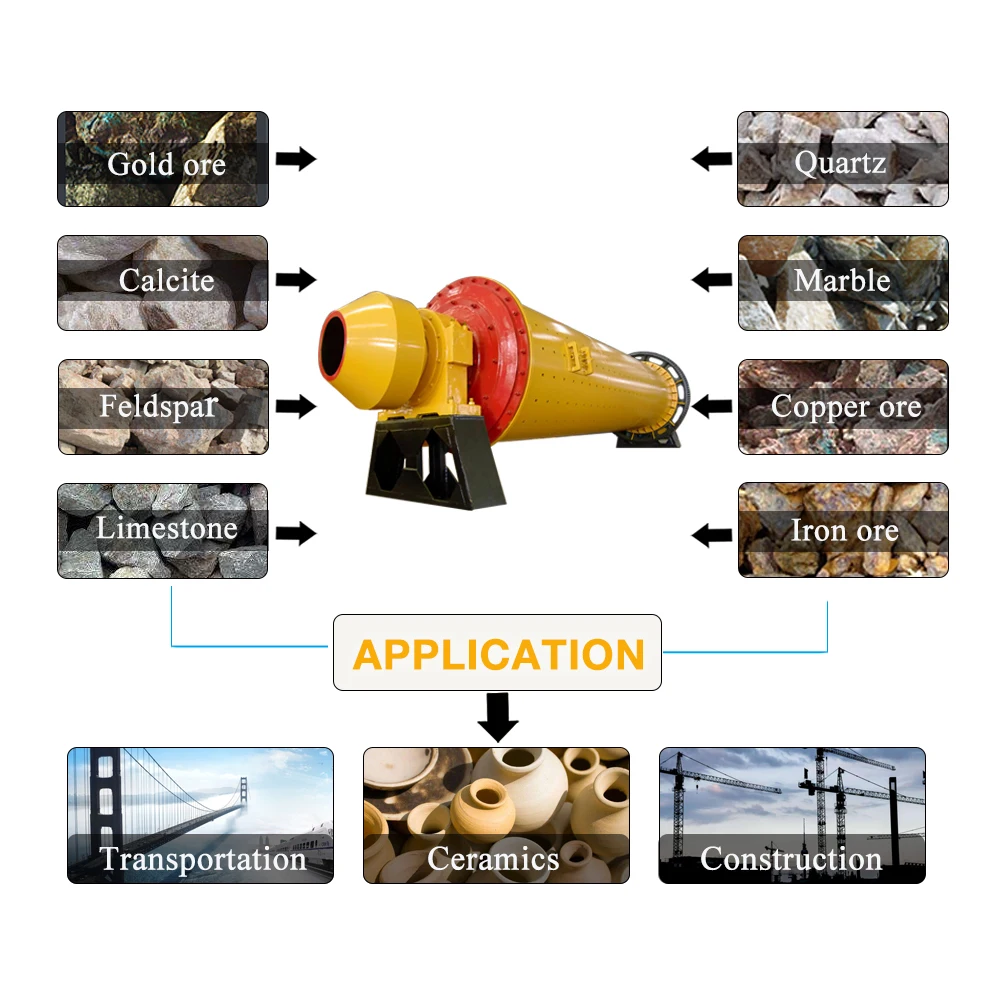

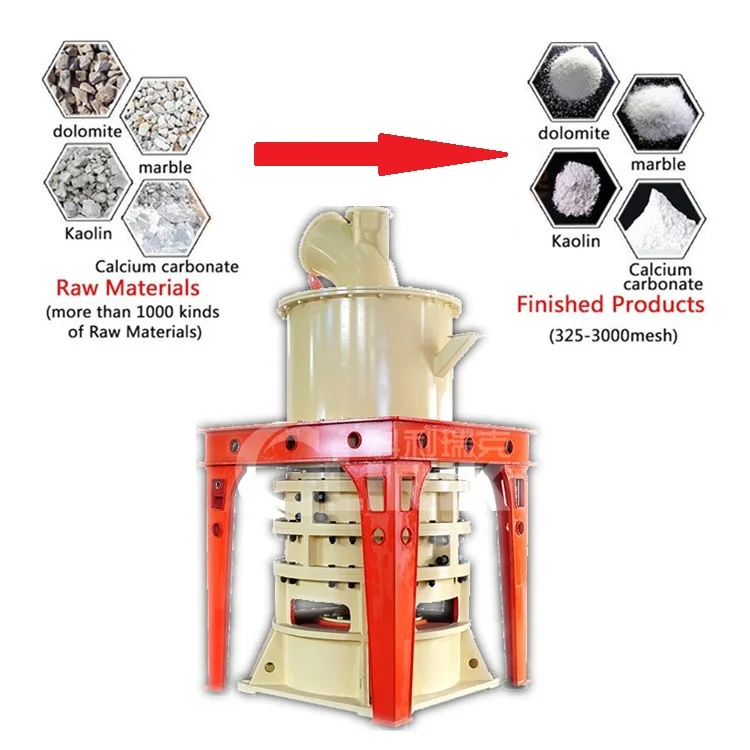

Energy-saving ball mill is a key equipment for material grinding after crushing process. It is widely used in powder-making production lines, such as cement, silicate, new-type building material, refractory material, fertilizer, glass ceramics and non-ferrous Metal etc.

| Model NO. | Balls Weight | Max. Feeding Size | Capacity | Output size | Motor Power | Weight |

| (t) | (mm) | (t/h) | (mm) | (kw) | (t) | |

| 900*1200 | 1 | 20 | 0.5-1.5 | 0.074-00.4 | 18.5 | 4 |

| 900*1800 | 1.5 | 20 | 1.1-3.5 | 0.074-00.4 | 22 | 4.8 |

| 900*3000 | 2.6 | 20 | 1.5-4.8 | 0.074-00.4 | 30 | 6 |

| 1200*2400 | 3.5 | 20 | 1.6-5 | 0.074-00.4 | 30 | 9.5 |

| 1200*4500 | 6.5 | 20 | 1.6-5.8 | 0.074-00.4 | 45 | 13.1 |

Main features

1. The lining can be replaced.

2. Mineral ball mill is an efficient tool for grinding many materials into fine powder.

3.Two ways of grinding: the dry way and the wet way.

4.Ultimate particle size depends entirely on how hard the material you’re grinding is.

5. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

Working principle

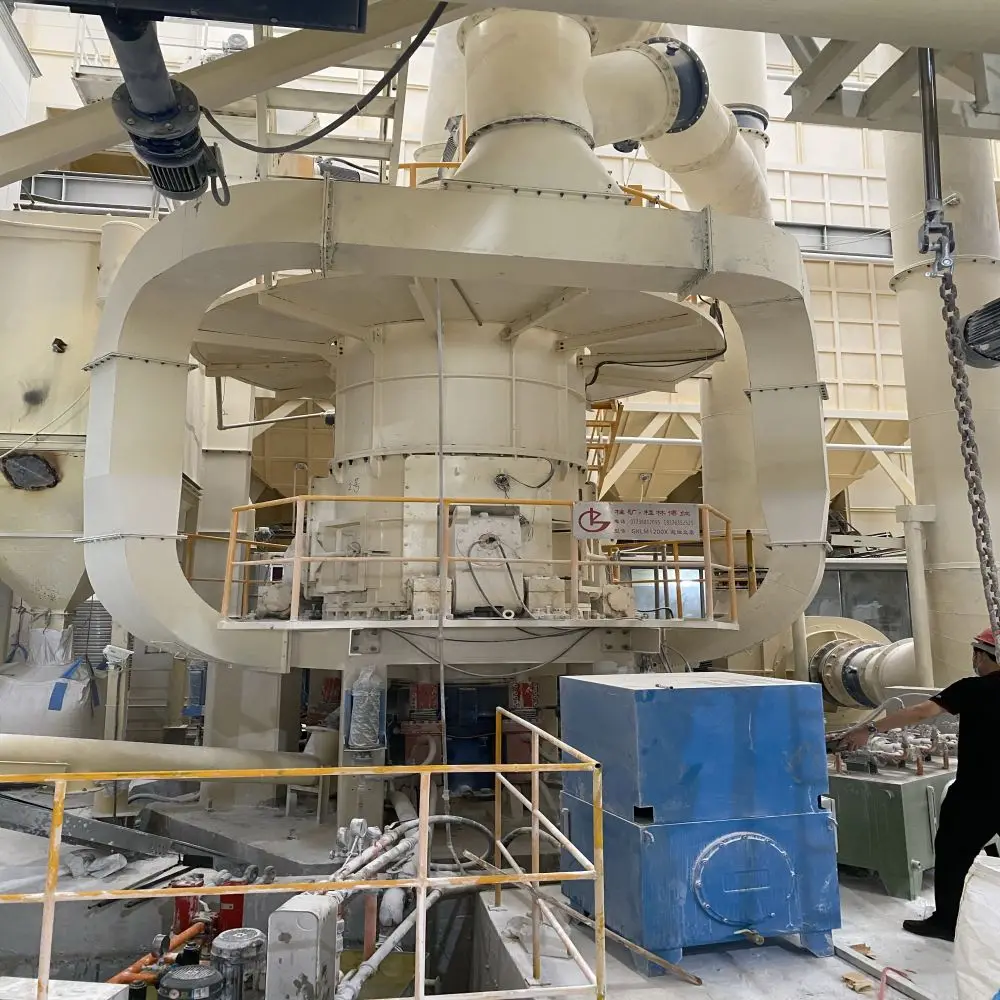

The ball mill is horizontal cylindrical rotation device,driving by brim gearwheel, there are two chambers and grid. Material goes into the first chamber through the feeding inlet, inside the first chamber, there are stage liners and ripple liners as well as steel balls with Various kinds. The shell rotates which generates eccentricity, this force brings balls to a certain height and then balls drop down by gravity, which will impact and grind the material. After the primary grinding in the first chamber, material goes into the second chamber through Segregate screen, in the second chamber, there are fiat liners and steel balls, after the secondary grinding, material is discharged through the discharge screen.

Q1: Are you factory or trade company?

A1: We are factory.

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3: Our senior engineer will guide the installation and commissioning as well as the initial production at

Q4: How about the wear parts supply?

A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our technicians to your place and you are therefore, responsible for all thecost involved.

Q5: What about the payment method?

A5:T/T, L/C Paypal is available

Q6: What about after-sale service?

A6:12 months warranty for all kinds of products.

Похожие товары

От 3 до 6 лет/ч Золотая Шахта 900x1800 900x3000 шаровая мельница шлифовальное оборудование с облицовкой и стальным шаром

Шлифовальное оборудование Золотая Руда шаровая мельница прайс-лист

Измельчитель Каолина оборудование для обработки минерального порошка измельчитель цена на Шри-Ланку

Оборудование для измельчения кварцевого песка извести 5 тонн в час малая минеральная обработка шаровая мельница роликовый шлифовальный станок

От A до Z 20000 тонн в год тальковая слюдяная магнезитовая порошковая мельница оборудование для обработки

GKH3000 30 роликовый гипсовый порошок производственная линия станок кольцевая роликовая мельница

Высококачественная Вертикальная роликовая мельница

Новые поступления

Новинки товаров от производителей по оптовым ценам