Grp напольные листы автоцистерна холодильник автомобильный фургон Rv

- Категория: >>>

- Поставщик: Tangshan Runfeng Composite Materials Co. Ltd.

Сохранить в закладки 1601160225852:

Описание и отзывы

Характеристики

FRP GELCOAT PANEL

Description:single or double gel coat, high gloss,smooth and even

Application:container inside wall,refrigerated truck,boat wall and roof

Product name Fiberglass rv panels

Panel thickness 1-3mm

Core thickness 10-100mm

Length ≤11.8m

Width ≤2600mm

Fiberglass contect ≥30%

1

FRP XPS sandwich panel

XPS has a perfect closed-cell honeycomb structure. The XPS board has extremely low water absorption, low thermal conductivity, high compression resistance, and anti-aging (almost no aging decomposition phenomenon in normal use).

Special materials for floor heating and insulation.

2

FRP PU sandwich panel

PU is the reaction product of polyisocyanate and polyether or polyester polyol in a certain proportion. From the comparison of the basic physical properties of materials, PU has advantages in thermal conductivity and temperature resistance.

3

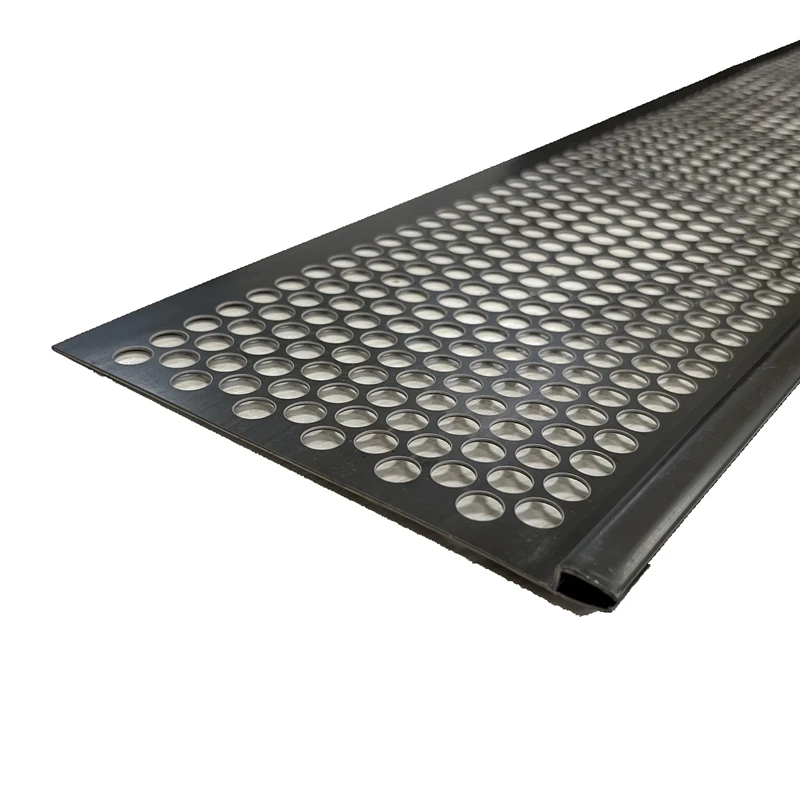

FRP PP Honeycomb panel

PP honeycomb panels are light in weight and high in strength, with honeycomb design and good sound insulation, which can reduce the load of transportation vehicles, increase transportation speed, and reduce transportation costs. It is suitable for interior decoration of shells, roofs, partitions, decks, yachts, cars, Floors of vehicles such as trains.

4

FRP Plywood panel

Plywood is very resistant to breaking, shrinking, twisting and generally high strength properties. If it is used indoors, generally cheaper urea-formaldehyde glue is used. This glue has limited water resistance. Outdoor and marine panels are often made from phenolic glue because it provides corrosion protection, prevents delamination and open holes in the plywood, and maintains strength in high humidity conditions.

COMPANY CERTIFICATE

Our company has got the certification based on ISO 9001:2000 standards, and was invited by AQSIQ(

General administration of quality supervision,inspection and quarantine of the people’s republic of china) and SAC in the year of 2005 as a participant in the compilation of the national standard GB/T 14206-2005 Glass Fiber Reinforced Polyester corrugated plate.

Runfeng lighting panels are widely used in the fields such as industrial factory,large warehouse,shopping malls,sports gym,greenhouses,aquaculture,the construction of steel structure roof and lighting and warm of walls etc.

COMPANY CULTURE

Based on the policy of credit first, quality first, service first, funfeng would like to try the best to cooperate sincerely with you and create a brilliant future.

COMPANY SERVICES

1your inquiry related to our products or prices will be replied in 12hrs.

2well-trained and experienced staffs to answer all your questions in fluent English

3 OEM&ODM any your customised we can help you to design and put into product,protection of your sales area, ideas of design and all your private information.

4 the ability of monthly develop new product can help you enlarge your market

5. we can offer you free sample.

TRADE TERMS

1 payment term: TT30% deposit before production 70% Balance before shipment

2 fob TIANJIN

3 production time:7-15days

4 MOQ 500-800 meters

5 other items can be negotiated if your quantity is big enough.

APPLICATION

Feature | weather resistance,high toughness,good impact resistance,and high light transmission rate. |

Surface treatment | Dupont Melinex301 anti-aging film |

Resin component | Ashland phenylene UP resin |

Fiberglass | Taian high quality glass fiber, the content no less than 30% |

Standard thickness | from 0.6mm to 5.0mm |

Light transmittance | lamina lucida≥80% ,basis of 1.5 mm thickness |

Operating temperature | -40℃-+130℃ |

Ultra-violet transmission | ≤0.01% |

Coefficient of thermal expansion | 2.1*10-5m/m/℃

|

CONTRACT ME

Our company has the following production capabilities:

1. Complete equipment: We have a series of advanced production equipment for fiberglass composite panels, such as automated molding machines, molds, presses, etc.

2. Efficient production process: Adopting advanced fiberglass composite plate production process, the product has high quality and performance.

3. Stable product quality: through strict quality control and testing methods, ensure that each product has stable quality and performance.

4. Flexible production method: Different specifications and sizes of fiberglass composite panels can be produced according to customer needs, and customized production can also be carried out according to customer requirements.

5. Mass production capacity: able to meet the requirements of orders of various sizes and batches, ensuring timely delivery.

FAQ

Q:How can I get a sample from you?

A: We offer the sample you want for free. After we know clearly about you inquiry about the product, we will prepare the samples and send to you immediately if they are available. What you need to do is just tell the detailed address, contact method, and your DHL or Fedex account.

Q: How long is the lead time?

A: Our lead time will be about a week after we received your advanced payment.

Q: What’s the payment terms?

A: We accept T/T, L/C, cash, West Union, Moneygram. 30% as advanced payment, and balanced should be cleared before shipping.

Q: I am interested in the product I saw on the website. I want to ask for more information. Do you have some customer service online that I can consult on time?

A: Please see the website of "Contact us" to get our information of MSN, QQ, TM, or yahoo manager. But sometimes because of the problem of time zone, if we can not answer your questions on time, please be patient. We will get back to you as soon as possible. Or you can send us email so that we can reply on time.

Похожие товары

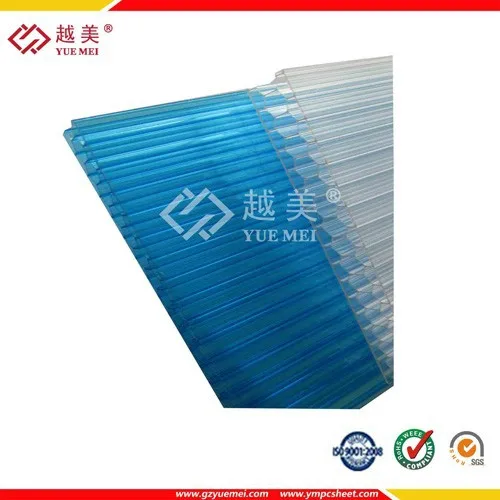

FRP гофрированный лист синтетическая смола GRP кровельные материалы прозрачная пластиковая кровельная плитка

Стекловолоконный армированный полиэстеровый Gelcoat Frp лист для стеновых панелей для душа

Пластиковые прокладки структурные подковы U-образные цветные Пластиковые оконные Упаковщики

Yuemei Сотовая панель из поликарбоната Сотовый лист

ПВХ дождевой желоб вешалка 6 дюймов 5,2 дюймов дренажная водосточная система пластиковые белые виниловые желоба монтажные кронштейны

Прямо с завода ПВХ вешалка для водосточных желобов, 5,2 дюймов, система для установки труб на крыше, пластиковые белые виниловые кронштейны для монтажа желобов

Белый ПВХ водосточный предохранитель для защиты листьев

Новые поступления

Новинки товаров от производителей по оптовым ценам