Детали для лазерного оборудования высокая мощность 30 кВт 30000 Вт 2 0 Волоконно Лазерная режущая головка

- Категория: >>>

- Поставщик: Dongguan Dechuan Laser Technology Co. Ltd.

Сохранить в закладки 1601164038382:

Описание и отзывы

Характеристики

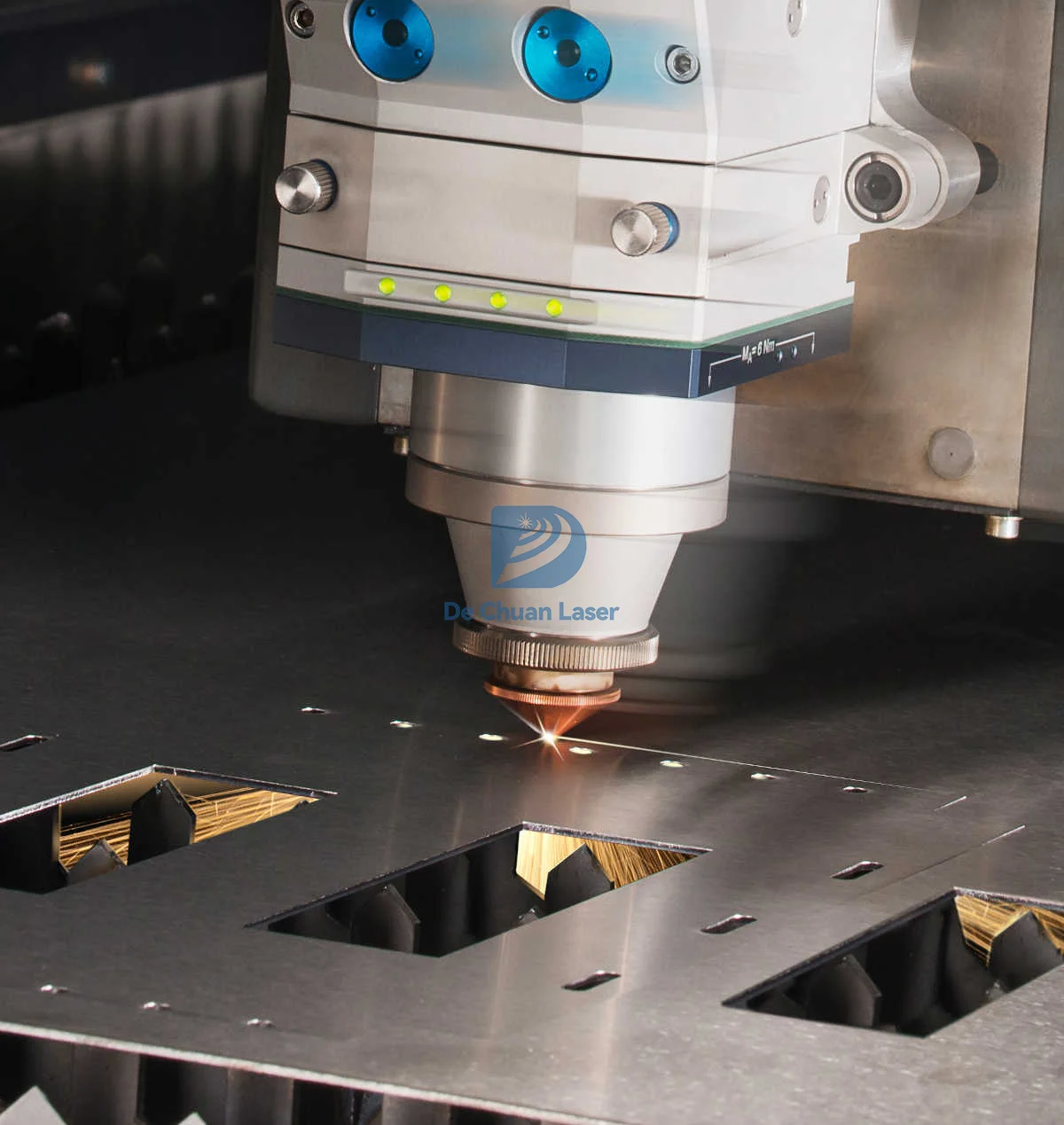

Laser Equipment Parts High Power 30KW 30000W Precitec ProCutter 2.0 Fiber Laser Cutting Head

Model | Procutter 2.0 30000W |

Max Laser Power | 30KW |

N/A | 0.13 / 0.18 |

Focusing lens focal length | 150, 200, 250, 300 mm |

Dimensions (WxD) | 96 x 134 mm |

Weight | 6.9 KG |

ProCutter 2.0

With ProCutter 2.0, previously hidden cutting processes can now be used in an industrially stable manner. It is no longer necessary to choose between high quality and high speed. Now both are possible - from an investment point of view, with increased machine utilization and a shorter payback period. Rework is reduced to a minimum.

With the new generation ProCutter 2.0, previously unthinkable highest cutting speeds can be achieved. Thanks to its advanced cooling principle and extended stroke, the cutting head can operate trouble-free at laser powers of up to 60 kW. If the full laser power is not required, the cutting speed can still be increased by up to 25% compared to the predecessor, thanks to the optimized design.

Continuously stable cutting quality at high power

For higher laser powers, the beam quality and consistency of lasers from various manufacturers are limited. ProCutter 2.0 is truly compatible with all lasers in the field and offers a configuration option with a maximum NA of 0.16. This means that stable operation at full power is possible during the cutting process. The design of the cutting head has not changed for this, it remains compact and lightweight and is also suitable for bevel cutting.

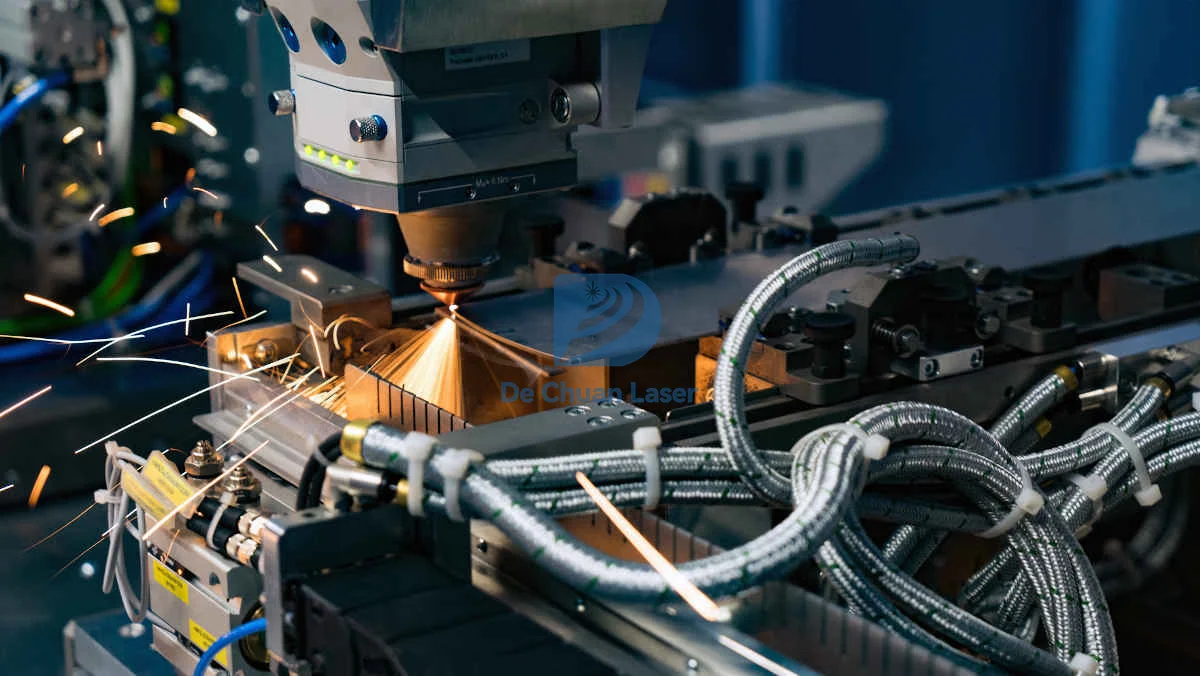

Smart sensors at their best

The quality of the components and process stability remain constant at all times: Fluctuations in the process or in the quality of the material to be cut can be compensated without intervention by the machine operator. With PierceTec (automatic piercing), you achieve consistent piercing and surface quality and reduce the amount of rework required. PierceTec saves cycle times and operating costs.

Smart sensors integrated in the cutting head permanently monitor the condition of critical components or cutting process parameters. The sensors also provide the basis for planned maintenance and efficient utilization of spare parts. This ensures safer operation and reduces subsequent costs.

The data can also be accessed via mobile devices and the current status can be visualized in the ProCutter APP (link to shop) (link to PC APP) or error messages can be queried.

The ProCutter 2.0 has impressed the world with its high performance and automation features. Its reliability and load capacity have been perfected in flat sheet and tube cutting systems - with a laser power of up to 60 kW.

Superior technology for maximum productivityAdvantages

With ProCutter 2.0, previously hidden cutting processes can now be used in an industrially stable manner. It is no longer necessary to choose between high quality and high speed. Now both are possible - from an investment point of view, with increased machine utilization and a shorter payback period. Rework is reduced to a minimum.

With the new generation ProCutter 2.0, previously unthinkable highest cutting speeds can be achieved. Thanks to its advanced cooling principle and extended stroke, the cutting head can operate trouble-free at laser powers of up to 60 kW. If the full laser power is not required, the cutting speed can still be increased by up to 25% compared to the predecessor, thanks to the optimized design.

Continuously stable cutting quality at high power

For higher laser powers, the beam quality and consistency of lasers from various manufacturers are limited. ProCutter 2.0 is truly compatible with all lasers in the field and offers a configuration option with a maximum NA of 0.16. This means that stable operation at full power is possible during the cutting process. The design of the cutting head has not changed for this, it remains compact and lightweight and is also suitable for bevel cutting.

Smart sensors at their best

The quality of the components and process stability remain constant at all times: Fluctuations in the process or in the quality of the material to be cut can be compensated without intervention by the machine operator. With PierceTec (automatic piercing), you achieve consistent piercing and surface quality and reduce the amount of rework required. PierceTec saves cycle times and operating costs.

Smart sensors integrated in the cutting head permanently monitor the condition of critical components or cutting process parameters. The sensors also provide the basis for planned maintenance and efficient utilization of spare parts. This ensures safer operation and reduces subsequent costs.

The data can also be accessed via mobile devices and the current status can be visualized in the ProCutter APP (link to shop) (link to PC APP) or error messages can be queried.

Our company provides professional maintenance services and maintenance training services, and we are looking for laser and cutting head maintenance agents around the world. If you are interested, please contact us.

Похожие товары

1000 Вт 1 кВт Макс фотоника MFSC-1000X один модуль оригинальный CW лазерный источник для волоконно-лазерной резки

246 708,90 ₽ - 290 568,26 ₽

HanLi HL-6000 6000 Вт 6 кВт волоконно-лазерный станок для резки воды охладитель промышленного оборудования запчасти

153 507,76 ₽

Высокопроизводительный 395nm 350mW Волоконно-оптический лазерный модуль для изготовления печатных плат

8 223,63 ₽ - 8 771,88 ₽

Набор 12*31 с держателем и адаптером питания EU AU UK лазерное позиционирование красным светом регулируемый инфракрасный луч диодный модуль лазерная машина

866,23 ₽ - 1 085,52 ₽

Smartrey волоконный лазер ручной лазерный сварочный пистолет головка d20t2 d203 d18t2 Защитная линза для оптического прибора

Красный луч лазерного уровня мини портативные измерительные инструменты USB зарядный порт позиционирования прицел с функцией магнитной адсорбции

Объектив d22 5 * 17 толщиной 3 мм

Новые поступления

Новинки товаров от производителей по оптовым ценам

Ортодонтия Prophy мотор беспроводной

69 $

Недорогие коврики с 3D-печатью

7,20-7,99 $

Уличная Водонепроницаемая светодиодная лампа IP65 E27 фитинг для фермы патрон лампы со шнуром праздничная лента с колпачком ламп на солнечной батарее

6-8 $

Дезодоратор для домашних животных

4,70-8 $

Профессиональный пневматический гравировальный молоток

22,73-45,45 $

Специальные продажи экстремальное бездорожье Unimog Merce-des-Benz U530

6 000 $

Запасные части для мотоциклов сила 1 импульсная

Беспроводной велосипедный Спидометр Одометр ЖК-Смарт-подсветка

6,40-6,80 $