Изогнутая керамическая износостойкая облицовочная плитка из глинозема для оборудования добычи стального угольного цемента

- Категория: >>>

- Поставщик: Shanxi Huazhan Wear-Resistant Material Technology Co. Ltd.

Сохранить в закладки 1601164630016:

Описание и отзывы

Характеристики

Alumina liner

Products Description

Alumina wear-resistant ceramic liner is a new ceramic material with low wear, high specific gravity and high hardness. It uses alumina (AL0) as the main material and is sintered at a high temperature of 1500 ° C. It is widely used in thermal power, steel, chemical industry, and cement. In industries such as coal transportation, material transportation, pulverization, ash discharge, dust removal systems and other mechanical equipment with high wear and tear, products with different purity (defined by alumina content) can be selected according to different needs.

Product performance indicators | ||||||||

Performance / product | The 92 series | The 95 series | The 97 series | The 99 series | ||||

AL203(%) | ≥92 | ≥95 | ≥97 | ≥99 | ||||

Moh's hardness | 9 | 9 | 9 | 9 | ||||

water absorption(%) | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 | ||||

Breakingstrength(n/mm) | 40 | 42 | 44 | 48 | ||||

Bending strength(Mpa) | 255 | 257 | 285 | 300 | ||||

Bulk density(g/m3) | ≥3.63 | ≥3.68 | ≥3.73 | ≥3.83 | ||||

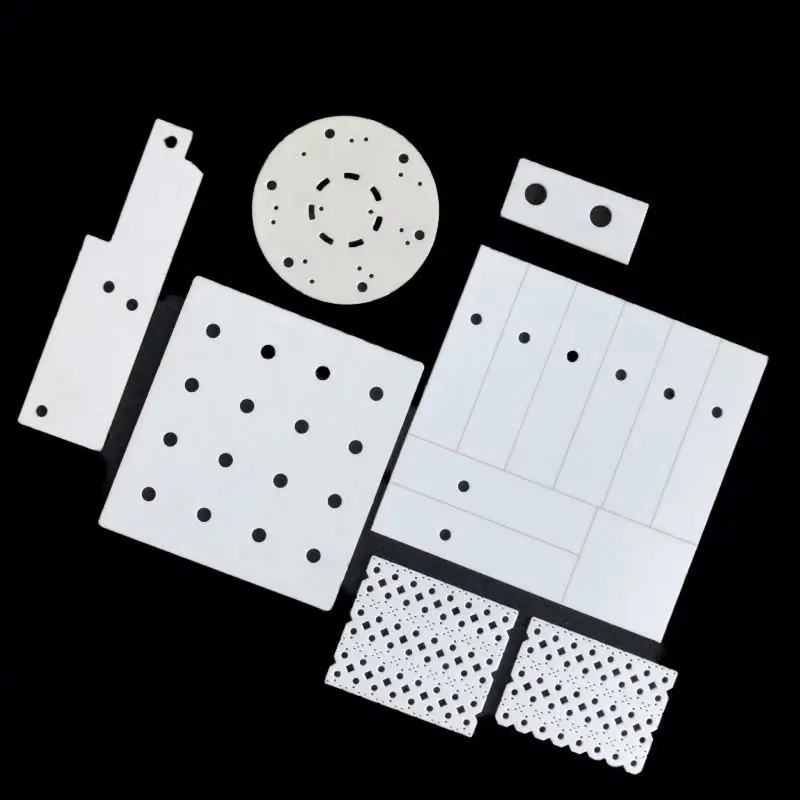

Product specification | ||||||

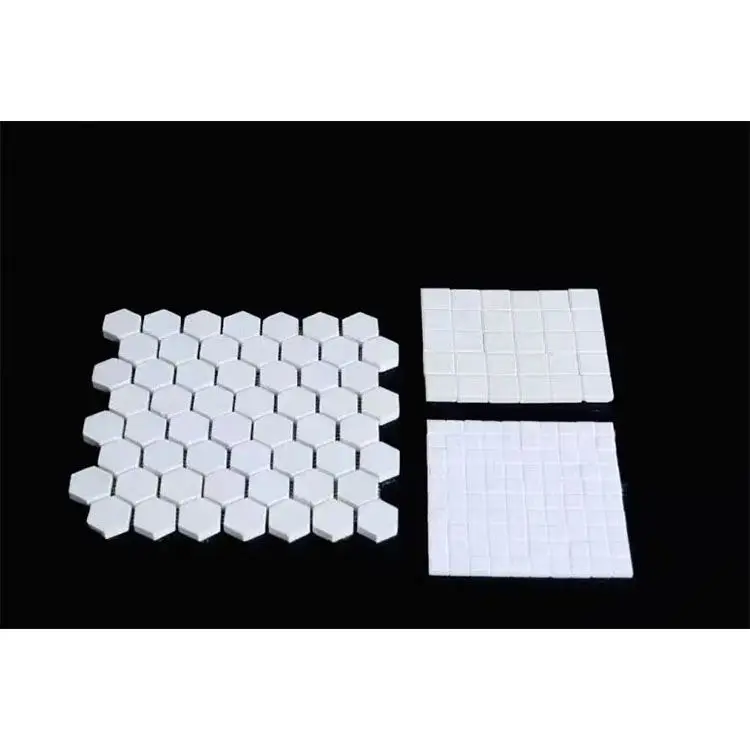

10x10Alumina liner | (L)mm 10 | (W)mm 10 | (H)mm 3-10 | |||

17.5*17.5 | 17.5 | 17.5 | 4-10 | |||

23.7*23.7 | 23.7 | 23.7 | 5-15 | |||

50*25 | 50 | 25 | 5-10 | |||

50*50 | 50 | 50 | 5-15 | |||

100*100 | 100 | 100 | 6.5-15 | |||

120*80 | 120 | 80 | 6-20 | |||

150*60 | 150 | 60 | 10-25 | |||

150*100 | 150 | 100 | 6-25 | |||

150*100 | 150 | 100 | 12-20 | |||

Application:

Widely used in various construction machinery, electronics, chemical industry, metallurgy, steel, petroleum, coal mining, mechanical equipment, textile fiberglass and ceramic composite pipes, cement cyclones, metal composite pipes and elbows, chute wear-resistant lining, pipe wear-resistant Grinding lining, preheater hanging piece, powder grinding disc, and other parts that require wear resistance, high temperature resistance, and corrosion resistance, as well as high-tech fields such as aviation, aerospace, automobiles, national defense, and environmental protection, and can be made into insulating devices and Excellent grinding media, etc. According to specific data requirements, alumina content, tolerances, drawings or uses, etc., support product customization.

Product Features:

* Acid and alkali resistance: The rubber adopts a new formula of acid and alkali resistant rubber, which can resist weak acid and weak alkali: 2. Wear resistance: alumina corundum ceramics, hardness above HRA85.

* Wear resistance: alumina corundum ceramics, hardness above HRA85.

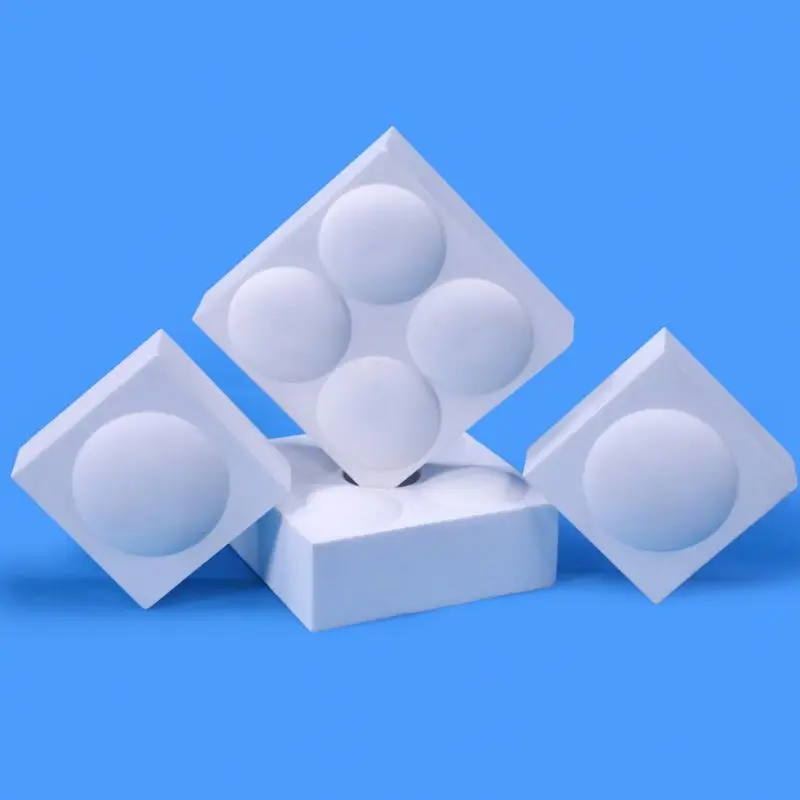

* Impact resistance: The toughened ceramic formula ensures that the ceramic is not easy to break, and the unique spherical design and high-quality buffer layer can resist the impact of large materials;

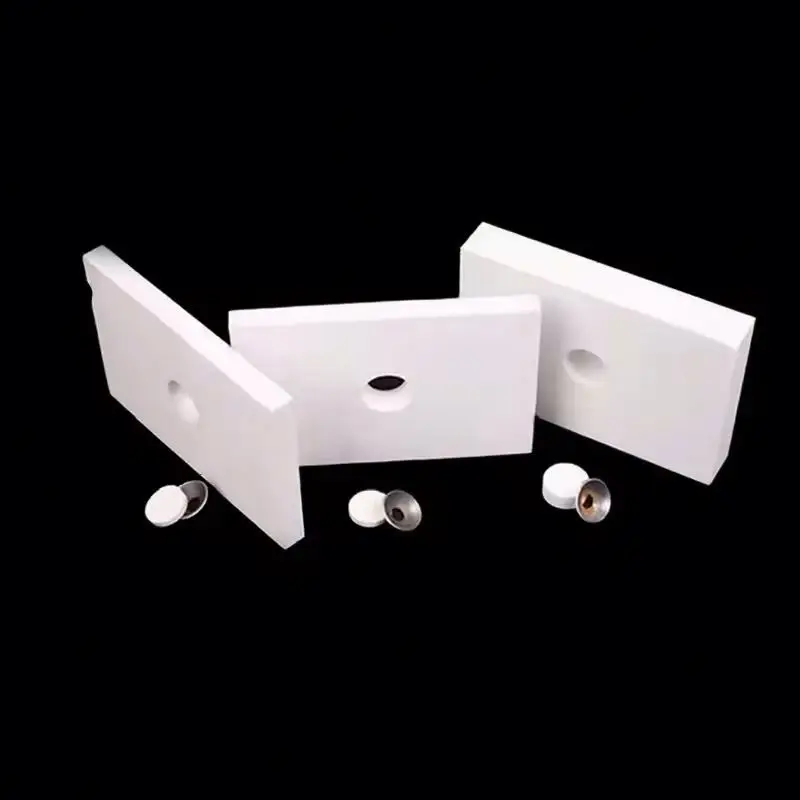

* Anti-shedding: The ceramic rubber steel plate is vulcanized in one piece, and the combination is very firm; each piece of ceramic has a penetrating bolt passing through the bottom steel plate, which is firmly welded and has good stability;

* High temperature resistance: it can operate at 0℃-300℃ for a long time;

* Easy installation and replacement: it is provided with a whole liner, which is convenient for replacement and installation, and reduces after-sales service:

* Easy installation and replacement: it is provided with a whole liner, which is convenient for replacement and installation, and reduces after-sales service:

* Reduced maintenance: super wear resistance greatly reduces the frequency of maintenance, saving costs and labor.

Company Profile

Shanxi Huazhan Wear-resistant Material Technology Co., Ltd. is located in Gudan Industrial Park, Taiyuan City, Shanxi Province. Covering an area of 25,000 square meters, there are more than 80 engineering and technical personnel.

In the past 20 years, we have been committed to the customization, production and service of wear-resistant steel products, professionally providing solutions for wear-resistant products in industries such as electric power, metallurgy, mining, steel mills, petrochemicals, and new energy. A major breakthrough has been made; advanced production technology has been introduced, the monthly output of wear-resistant pipes is 1,300 tons, and advanced testing equipment is equipped. Our products involve more than 110 varieties in 12 categories, and we are currently the largest manufacturer of wear-resistant pipe fittings in China.

The company has an independent research and development design team, 70% of the front-line employees have 10 years of casting experience, the products have passed the ISO9001 quality system certification, and have a number of invention patents.

The company has an independent research and development design team, 70% of the front-line employees have 10 years of casting experience, the products have passed the ISO9001 quality system certification, and have a number of invention patents.

Huazhan has always pursued the enterprise management policy of "quality first, reputation first", strictly controlled quality, and formed a strict quality control mechanism and a reliable quality assurance operation system. Because of reliable product quality, honest business philosophy, and scientific technical effects, it has won the trust of users, and the scale of the enterprise is developing rapidly. The products are sold to engineering projects in 31 regions across the country, and are widely used in mines, power generation, chemicals, etc. project.

Certification:

Service:

* Provide 7 * 24-hour service. Feel free to contact us by phone, email, instant messaging and social media.

* After receiving your inquiry, reply within 8 hours, and provide the price plan within 24 hours.

* After receiving your inquiry, reply within 8 hours, and provide the price plan within 24 hours.

* Review and monitor project details and progress at no cost by a professional team of sales, engineers

and QC personnel.

* In the cost, production, inspection, packaging, delivery and other aspects to provide a full range of intimate services.

* Provides professional support and assurance at all stages of sales.

and QC personnel.

* In the cost, production, inspection, packaging, delivery and other aspects to provide a full range of intimate services.

* Provides professional support and assurance at all stages of sales.

Похожие товары

Cnc Обработанные детали из алюминиевого сплава автозапчасти на заказ EJ25 шкив двигателя

4 934,18 ₽ - 10 964,84 ₽

Электрическая медная контактная пластина, электрические шинные соединители с ЧПУ, механическая обработка, медная шина

5 811,37 ₽ - 6 578,91 ₽

CNC переключатель из нержавеющей стали с логотипом автоматическая регулировка скорости маленький переключения

Высококачественные части центробежного маслоотделителя воздушный компрессорный насос автомобильные компрессорные части

Задний светодиодный фонарь для задних ворот, водонепроницаемый задний фонарь для поворота, для грузовиков, прицепов, грузовиков

712,72 ₽ - 822,37 ₽

Китайский производства RBSIC/SISIC высокой чистоты карбида кремния десульфурации сопла имеют хорошую износостойкость

10 964,84 ₽ - 15 679,73 ₽

OEM высокоточная медная штамповка LCP overmading газовый датчик Контактный блок селективное позолоченное изготовление на заказ услуги

109,65 ₽ - 131,58 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $