Машина для производства бетонных плит легкая настенная панель Заводская Прямая сборка бетонная стеновая дома 3d линия детей и домашних животных

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.

Сохранить в закладки 1601165937681:

Описание и отзывы

Характеристики

Concrete slab/EPS Wall Panel Advantages

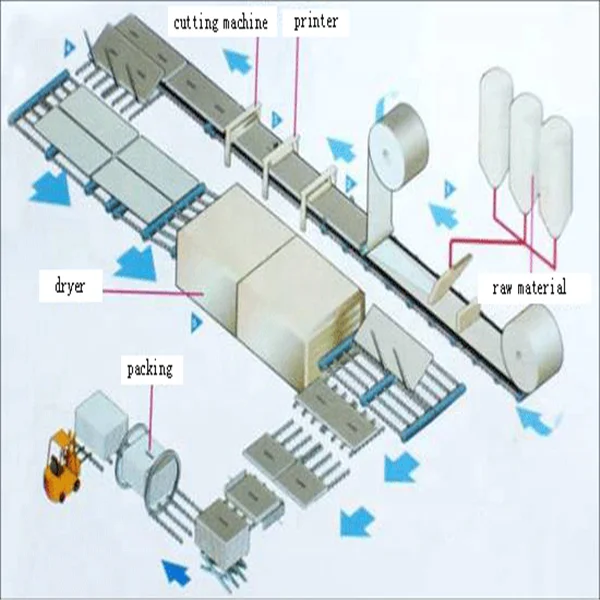

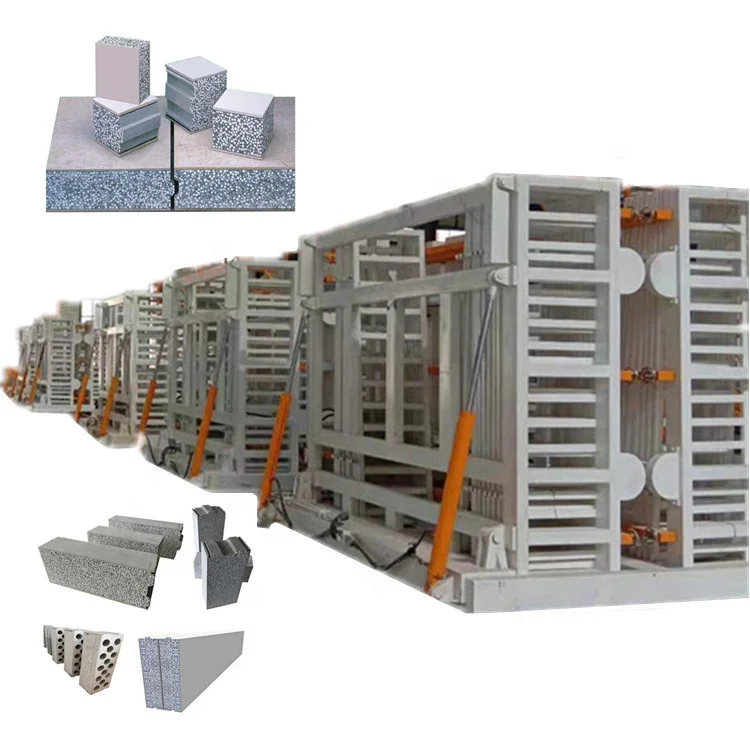

HONGFA one Lightweight Precast Concrete Wall Panel Making Machine, Sandwich Wall Panel Production Line, Fiber Cement Wall Board Machinery can produce kinds of wall panels and Concrete slab

Common Size of EPS cement wall sandwich panel

2440mm*610mm*50/60/75/90/100/120/150/180/200/250mm,other size such as length 3000mm, 3200mm, 3500mm, 4000mm can be customized .

Raw materials

1) Outside (with side board or without)

- Calcium silicate board , Cement fiberboard. MGO board.

- Also can be without the side board and adjustable.

2) Inside (core material)

- Cement, Foam EPS , Fly Ash, Sand , Saw dust, Perlite, Stone, Additives, etc.

Advantage of HONGA Wall panels production line

1. Patent protected product

2. Labor-saving and Advanced Technology

3. Double side opening and higher capacity

4. ISO9001-2015

5.Adopts touch screen control, automatic filling, electronic weighing, temperature

control, material level control to realize automatic production.

6. Easy to maintainence, Easy to clean.

HONGFA Machine

Hongfa group since 1990, We provide kinds of Lightweight Building Material Precast Concrete Wall Panels Machine for Prefab House Foam Concrete Wall Panels Making Machine

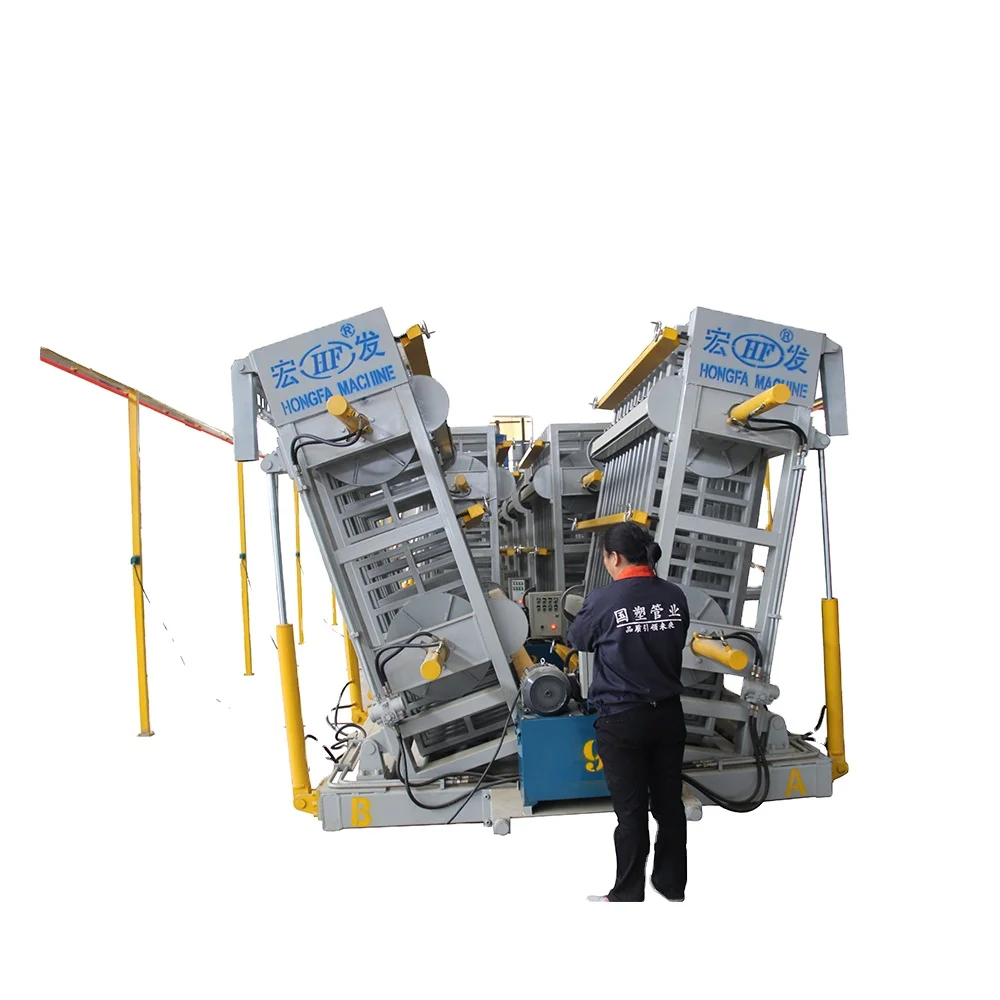

1.Automatic Horizontal Wall Panel Machine

2.Manual Vertical Wall Panel Machine

3.Automatic Vertical Double Layers Wall Panel Machine

Automatic operation, high output,fewer workers required.The most advanced patent

protected machine in China. Double capacity Higher working-efficiency.

It is automatic operation with double side opening,

High capacity and with fewer workers. The EPS lightweight wall panel machine is most

labor-saving and fastest now in China.

EPS Wall Panel Applications and Advantages

The Eps panel is widely used for partition board in non-bearing wall,exterior wall in steel structure,roof and floor.

It is popular for new construction or renovation and expansion building,such as house construction,fire wall,fences,footings,retaining walls,bungalows high-rise buildings,basements,walk-in fridges,hotels,schools,shopping malls,villas and etc

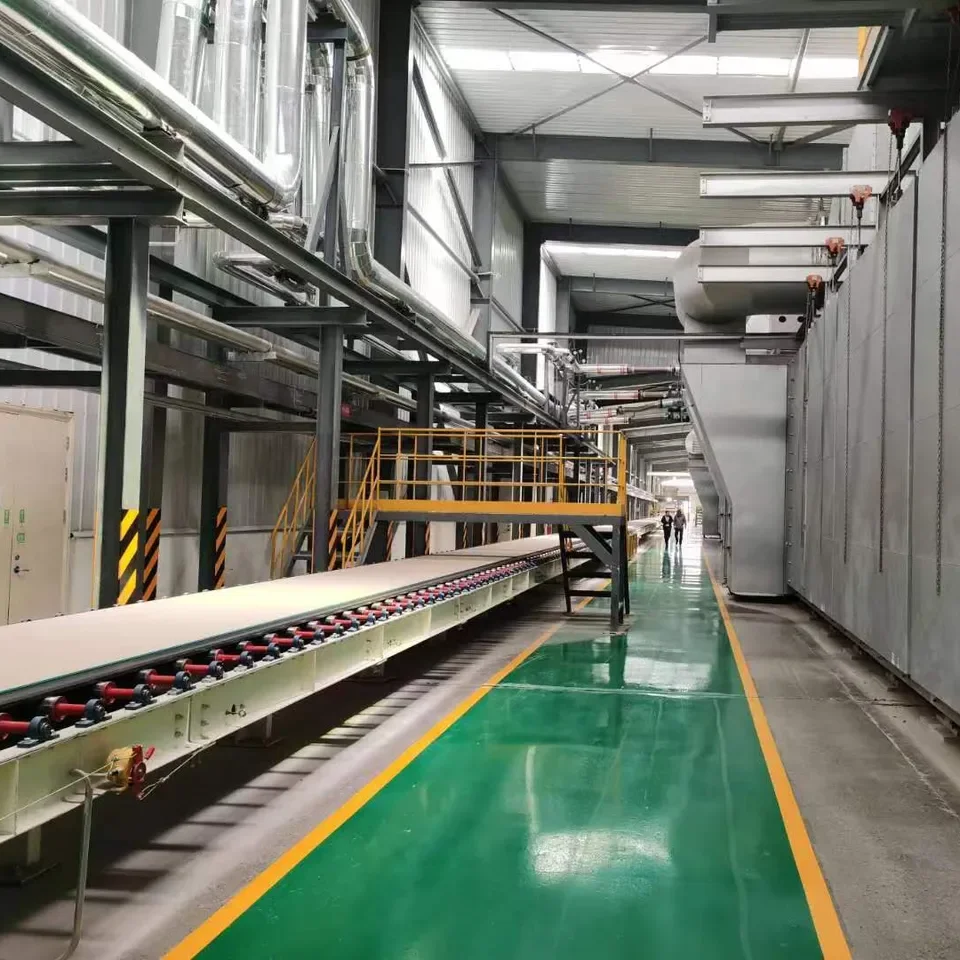

Our Sucessfull plant

Packing: Naked packing or stretch film packing or according to customers' requirements(We will send machine with plastic film package,parts with wooden case,if need, fumigation wooden carton also available.)

| Pre-sales Service |

| (1) Professional suggestions (raw material matching, machine selection, the condition of building factory, |

| feasibility analysis for brick machine production line) |

| (2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick) |

| (3) 24 hours on-line service |

| (4) Welcome to visit our factory and production line anytime. |

| (5) Introduce the company file, product categories and production process. |

| (6)Sample testing support. |

| In Sale |

| (1) Update the production scheduling in time |

| (2) Quality supervision |

| (3) Product acceptance |

| (4) Shipping on time |

| After-sale |

| (1) Training how to instal the machine, training how to use the machine. |

| (2) Engineers available to service machinery overseas. |

| (3) Recall clients regularly ,get feedback in time,keep well communication with each other |

More than 30 years experience. 1500 employee (50+engineers)

Main business Range & Products:

| Lightweight Wall Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, |

| Organic fertilizer equipment, hydroelectric power plant, Portland Cement Plant, Sugar cane sugar extraction equipment,Quicklime kiln equipment. |

| Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment,etc |

| Q1. Are you manufacturer or trading company? |

| We are Direct factory, not agent or trading company, and the quality and after-sale services is guaranteed. |

| Q2. When do you delivery the goods? |

| Normally 30 days after receipt of deposit and moulds confirmation from Buyer. |

| Q3. What about the payment? |

| 30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable). |

| Q4. how can we guarantee quality? |

| Always a pre-production sample before mass production; |

| Always final Inspection before shipment; |

We observe contract and keep promise!

We will provide the brick sample for free!

Get the best price, feel free to contact with me!

Похожие товары

Изоляция высокой Density6-8mm толщины, волокнистая цементная силикат кальция, вода-в-воде, панель для окраски наружных стен

Высококачественное оборудование для производства панелей для легких сэндвич-стенок Eps-панели для производства сборного бетона, цена пенопласта

2023, китайский известный бренд, небольшой гипс, машина для производства гипсовых плит

Машина для производства свиней HONGFA, Брудер для свиней, Камден, индийский пропан, материалы, необходимые для удерживания свиней

2024 простое в эксплуатации дешевое и тонкое оборудование для производства гипсокартона

Новая Автоматическая сборная линия по производству сборных зданий, сборная бетонная форма, сборная бетонная цементная стеновая панель для домов

Автоматическая изоляционная базальтовая машина, минеральная вата, волоконная плита, производственная линия

Новые поступления

Новинки товаров от производителей по оптовым ценам