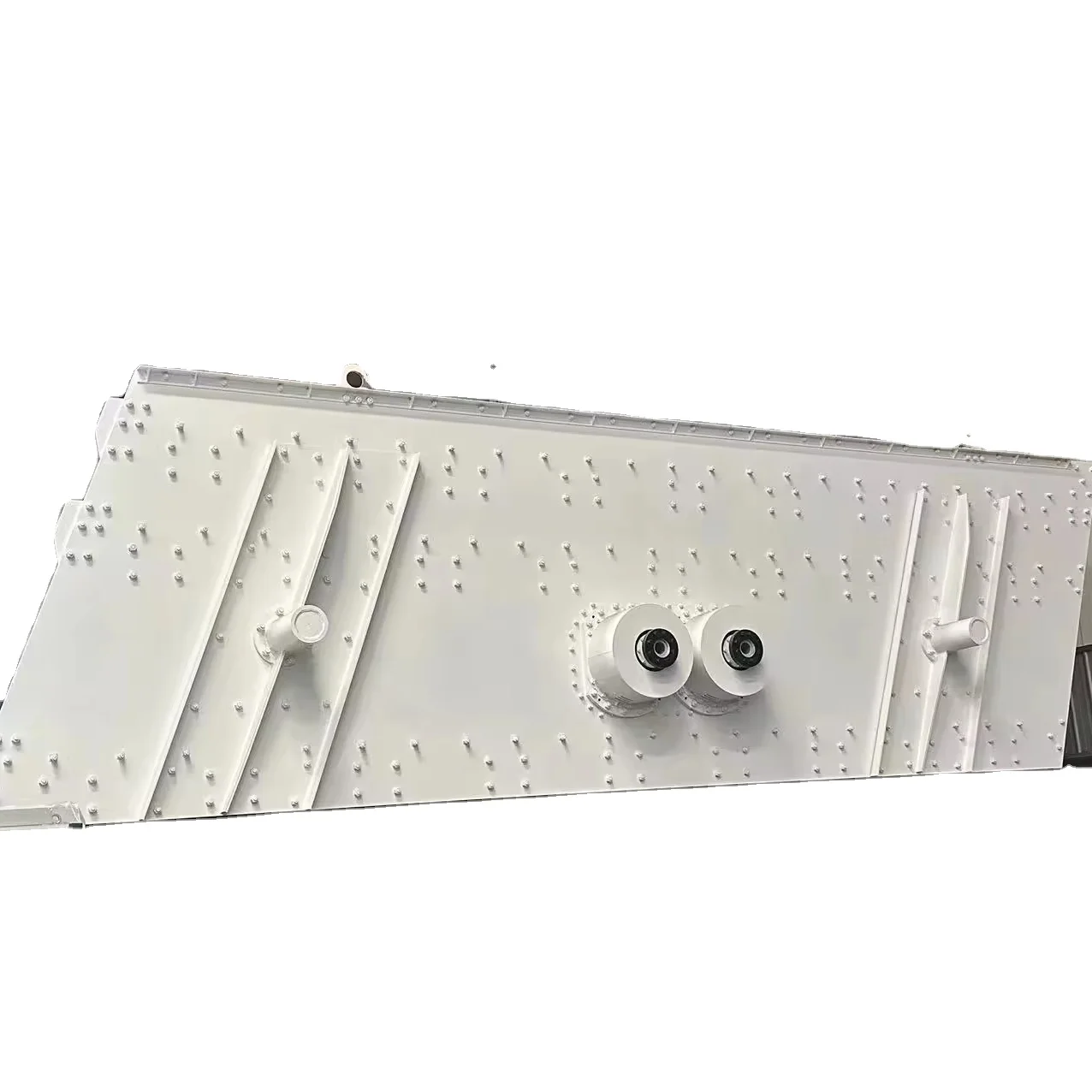

Shaolin Тяжелая машина YK3070 карьерный круговой Вибрационный экран для каменных дробилок Наклонный

- Категория: >>>

- Поставщик: Henan Shaolin Heavy Machines Co. Ltd.Henan Ltd.

Сохранить в закладки 1601166602005:

Описание и отзывы

Характеристики

Product descriptions from the supplier

Overview

Notice For Price:

1.We are factory direct sales, we will give you a more favorable price

2. The configuration and price are different according to different requirements.

3. All prices on this page are auto-generated virtual prices. Please contact us for quotation!

Circular Vibrating Screen

Product Introduction:

Circular vibrating screen is a new type of screening equipment, the vibration trajectory is circular, which is specially designed for quarry material stone, and can also be used for product classification in coal preparation, mineral processing, building materials, electric power and chemical industry. The sieve has the characteristics of advanced structure, strong excitation force, low vibration and noise, easy maintenance, and durability. The output and energy consumption of vibrating screens produced by our company have reached the national standard, ranking at the advanced level at home and abroad, and are well received by users in various industries. In terms of structure, the cylindrical eccentric shaft exciter and the partial block are used to adjust the amplitude, and the advanced rivet connection and prefabricated frame structure improve the service life of the equipment and the circular spring damping device reduces the impact on the foundation, which is a multi-layer and efficient new vibrating screen.

The material screening line of this model is long, the screening specifications are many, the specifications of each gear are clearly screened, the screening efficiency is high, and it is not easy to block. It has the advantages of reasonable structure, strong excitation force, low vibration and noise, sturdy and durable, convenient maintenance, safe use, etc., and is widely usedin product classification in mining, building materials, transportation, energy, chemical and other industries, and is an ideal equipment for crushing and screening units.

Equipment advantage

How it works:

The working principle of the circular vibrating screen mainly relies on the high-speed rotation of the eccentric block of the exciter driven by the electric motor. When the eccentric blocks rotate, they generate a centrifugal force, which acts on the screen box to produce a circular motion of a certain amplitude. On the inclined screen surface, the material is subjected to the impulse transmitted by the screen box, which produces a continuous throwing motion. In the process of meeting the material and the screen surface, the particles smaller than the screen hole pass through the screen to realize the classification and screening of the material. The structural design of the circular vibrating screen ensures its strong excitation force, high screening efficiency, and at the same time has the characteristics of low vibration noise and robustness. They are widely used in mining,building materials, transportation, energy, chemical and other industries for product grading.

Technical Parameters

Model | Screen area(m²) | Mesh size(mm) | Processing power(t/h) | Vibration frequency(r/min) | Motor power(kw) | weight(t) | DimensionsLength x width(mm) |

2YK1548 | 6 | 4-50 | 8-60 | 800-970 | 5.5 | 3.5 | 1500X4800 |

3YK1548 | 9 | 4-50 | 10-70 | 800-970 | 5.5 | 3.85 | 1500X4800 |

4YK1548 | 7.2 | 4-50 | 12-78 | 800-970 | 11 | 4.2 | 1500X4800 |

3YK1860 | 10.8 | 4-50 | 13-80 | 800-970 | 11 | 4.6 | 1800X6000 |

4YK1860 | 8.88 | 4-50 | 15-86 | 800-970 | 15 | 5.2 | 1800X6000 |

2YK2160 | 13.22 | 4-50 | 16-90 | 800-970 | 22 | 6.89 | 2100X6000 |

3YK2160 | 10.5 | 4-50 | 20-125 | 800-970 | 30 | 7.33 | 2100X6000 |

4YK2160 | 15.75 | 4-50 | 22-150 | 800-970 | 30 | 7.87 | 2100X6000 |

2YK2470 | 13.5 | 4-50 | 22.5-162 | 800-970 | 37 | 11.54 | 2400X7000 |

3YK2470 | 20.25 | 4-50 | 25-206 | 800-970 | 37 | 15.65 | 2400X7000 |

4YK2470 | 14.4 | 4-50 | 32-276 | 800-970 | 55 | 19.37 | 2400X7000 |

Customer sites

Related Products

Our Advantages

Manufacturing base1

Manufacturing base2

Henan Shaolin Heavy Machinery Co., Ltd. is an enterprise integrating scientific re-search, production, marketing and service,specializing in the production of compl-ete sets of mechanical equipment for mining, ore dressing, metallurgy and build-ing materials. Founded in August 1973, the company has been engaged in mining machinery manufacturing for 50 years, specializing in Service in China's mining a-nd building materials, mineral processing, metallurgy, powder and other industri-es, the main products are various specifications and models of crusher, ball mill, grading flotation machine, magnetic separator, dryer, rotary kiln,ultra-fine plant and other production lines, 288 kinds of products in the industry. Since 2011, the company is committed to the research and development and marketing of high-tech products, relying on scientific research units and universities, as well as do-mestic high-end industry associations of the expert team platform, and strive to build a set of equipment research and development, process research, technolo-gical transformation, project design, mechanical support, installation and commi-ssioning,production and energy saving, etc., and in 2013, it gradually became the most scientific research, design, environmental protection and one-stop compre-hensive mining industry in China. In 2013, it gradually became the most scientific research, design,environmental protection and one-stop comprehensive service enterprise in China's mining industry, and in 2015, its sales exceeded 300 million yuan. For a long time, the company adheres to the design concept of leading tech-nology and advanced equipment, and currently cooperates with 38 scientific res-earch units in China to jointly research and develop and produce roller presses, micro powder mills, suspension furnaces and other products to provide customers with new processes, technological transformation,standard excess, energy saving and protection and environmental protection services. The company's existing pr-oduct sales cover the central and western provinces and radiate across the coun-try.

Modern workshop

Numerical control machine tool

Invention patent and certification certificate

Customer visit

Exhibitions

Packing and Shipping

Why choose us

♦ We follow the standard of CE, ISO9001, Ghost, CU-TR.

♦ Our factory convers 150000 m³. Welcome to see machines!

♦ We send engineers for installation, commissioning and training.

♦ We havesufficient spare parts in stock.

♦ We have lots of production sites running aroud the world.

♦ Fast maintenance system to deal with customers's after sales issue in time.

FAQ

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to

quantity.

Q3: What is your payment method?

A: 30% of total prices should be paid by T/T as down payment; 70% balance payment should b paid by T/T before delivery.

Q4: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of crusher equipments is one year. And we will supply the spare parts for you at lowest cost.

Q5: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you set up a complete crushing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas.

Product Inquiry

Thanks for your trust! We can provide you with design scheme for complete production lines according to your demands and the site conditions. In order to recommend a suitable model for you and send you a best quotation. So please give us more information about your requirement.

1. What is the raw material to be processed?

2. What is your required capacity (t/h)?

3. What is the input size of the raw material?

4. What is the output size of the product you want?

Look forward to your inquiries! We will recommend the proper machine for you!

1. What is the raw material to be processed?

2. What is your required capacity (t/h)?

3. What is the input size of the raw material?

4. What is the output size of the product you want?

Look forward to your inquiries! We will recommend the proper machine for you!

Похожие товары

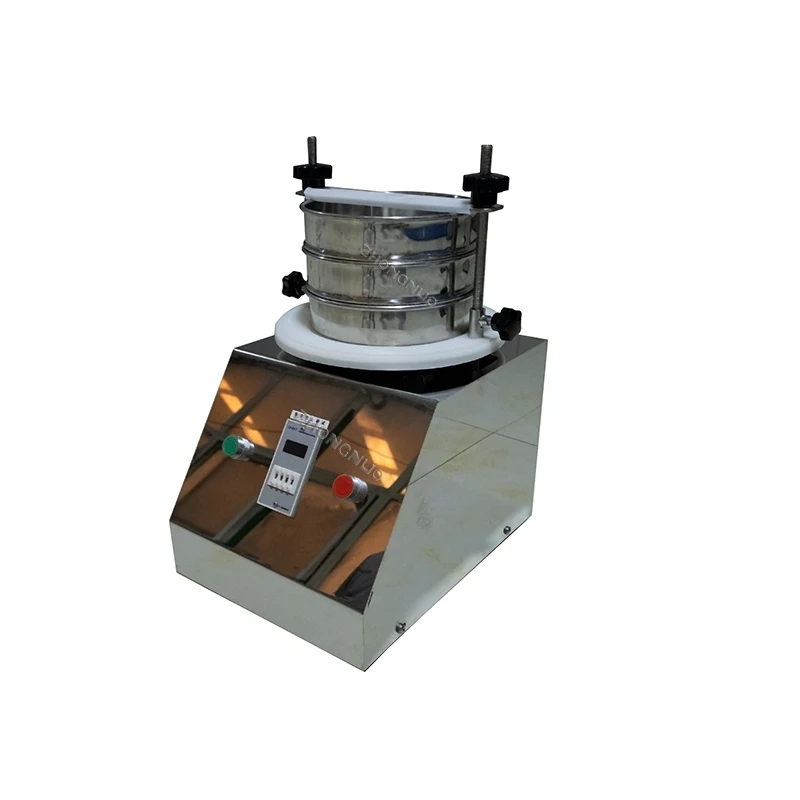

Стандартный Ситовый шейкер 200 мм лабораторный Вибрационный для машины анализа почвы

56 562,80-62 219,08 ₽

Анализ почвы тестовое сито

33 937,68-39 593,96 ₽

Лабораторные испытания песка гравия почвы Электромагнитная вибрационная машина экрана шейкера сита для анализа размера частиц

39 593,96-50 906,52 ₽

Оборудование для лабораторных испытаний вибросито из нержавеющей стали

33 937,68-39 593,96 ₽

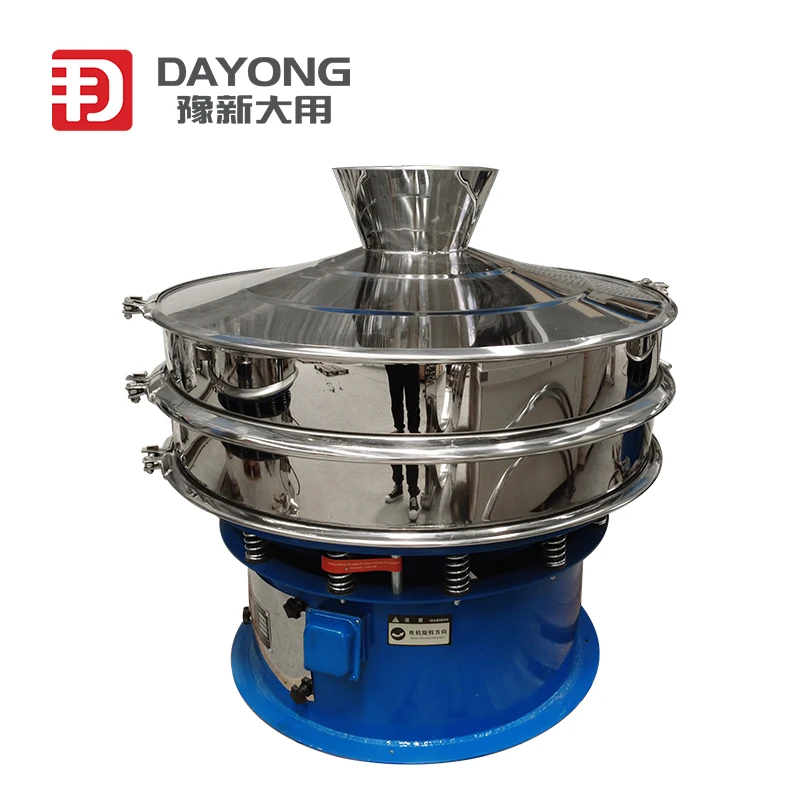

Машина сепаратора порошка сои с ультразвуковым преобразователем

113 125,60-124 438,16 ₽

Автоматическая линейная вибросортировочная сортировочная машина для кофе в зернах сушеной рыбы зерна арахиса

395 939,60-452 502,40 ₽

Тонкий масляный круговой Вибрационный экран 2HX3074 с удобством и гибкостью

6 787 536,00 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $