Индивидуальные услуги вакуумного литья быстрый прототип фары фара автомобиля анодированная алюминиевая краска автозапчасти прозрачная часть

- Категория: >>>

- Поставщик: Dongguan Ddprototype Manufacturing Co. Ltd.

Сохранить в закладки 1601167087725:

Описание и отзывы

Характеристики

Specifiction

Vacuum Casting For Low Volume Manufacturing | ||||||||

Material | HeiCast Japan-Hei Cast 8751 (PC Like), Hei Casti-8150(ABS Like), Hei Cast 8400(Rubber Like), Hei Cast8550(PP like). Pelnox Japan-MU-52/55/56 (ABS Like), MU-858(Fire-frame ABS Like) MU-70(PPl Like), MU-89(Rubberl Like). Axson France-PX 527(PC Like), PX5210(PMMA Like), PX 223HT/118PA(ABS Like), PX245 (PA Like), UP 5690(PP/HDPE Like). Synthene France-PR 700(ABS Like), PR 740(PP/HDPE Like)PR 751(Thermal Resistance), PR2900(PA/PC Like), PRC1708(PMMA Like). | |||||||

Drawing Format | STP, IGES, Pro/E, AutoCAD, SOLIDWORK, CAXA, UG, CAD, CAM, CAE,etc | |||||||

Application | Automotive, Test systems, Sensors, Medical, Sports, Consumer, Home appliance,Electronic, Pumps, Computers, Power and energy,Architecture, Printing, Food, Textile machinery, Optical, Lighting, Security and safety, AOI, SMT equipment, etc. | |||||||

MOQ | 1 PCS | |||||||

Finishing Services | Painting , Electrical Plating , Silkscreen , We can do any color according your requirement. | |||||||

Color | Depends on Your Requirement. | |||||||

1.Materail:Strickly control of material selection , meet clients request. 2.In-prosess inspection:detect product after each process finished. 3.Final inspection :stricly quality test before items are packed. | ||||||||

Packaging Shipping | Carton, Box, wooden or as required; DHL or FEDEX. | |||||||

Qualified Certification | ISO 9001:2015 & ISO1345:2016 | |||||||

Technical Guide for Vacuum Casting | ||||||||

Standard Accuracy | Standard tolerance on ±0.15mm/100mm, with precision able to reach ±0.05 mm. | |||||||

Maximum Size | The vacuum equipment can hold 2.0 M*1.2 M*1.0 M mold specifications. | |||||||

Minimum Wall | The minimum wall thickness is 0.5mm, the best is 1.5mm~2.5mm to ensure the mold is filled properly. | |||||||

Lifetime of Mold | Typical quantities up to 20-25 copies per mold. | |||||||

Leading Time | Up to 200 copies can be produced in 5 to 7 days | |||||||

Finishing Services | Sanding, Blasting, Smooth Polish, Optical Clear Polish, Vapor Polish, Color Painting, Aluminum/Silver/Gold/Chrome Plating, PVD Coating, Silk Screen, Pad Printing. | |||||||

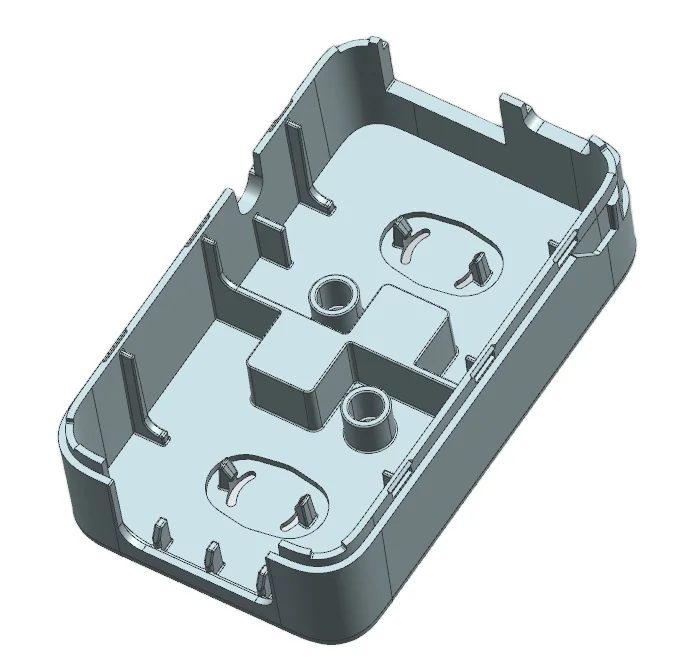

Vacuum Casting Precess

Vacuum casting (also known as urethane casting) is an economical alternative to low-volume injection molding of plastic parts and can be used to closely simulate final molded parts or finished products. Generally, molds are made from silicone rubber and use CNC machining or SLA part as a master pattern. These molds duplicate intricate details and textures and give consistent finishes from one part to the next. You can get production-like results including mechanical traits, wall thickness, colors, and surface finishes.

Company Profile

About DDPROTOTYPE

At DDPROTOTYPE, our focus is on providing you with the finest services in rapid prototyping, rapid tooling and low-volume manufacturing. Our international team of engineers and technicians are dedicated to making your custom parts using the most advanced equipment and techniques including multi-axis CNC machining , vacuum casting, sheet metal fabrication, plastic injection molding. We’re here to turn your ideas into reality quickly, accurately and at a great price.

Vacuum Casting Materials

Urethane resins are polymers with a wide range of properties and use. DDPROTOTYPE offers various urethane materials to meet your applications, including Hei-Cast from Japan and Axson from France. Materials with certain properties are similar to engineering production plastics, such as ABS, PMMA, PC, PP, PA, and so on. Casting parts can be varied from transparent, translucent to colored, and from soft rubber to hard plastic. Various materials contain those impact-resistant, high-temperature resistant (120℃) or fire-resistant (UL94-V0), glass-filled resins, and different hardness silicone.

Vacuum Casting Parts

Vacuum Casting - Urethane Casting

DDPROTOTYPE is fully capable of handling your vacuum casting and silicone molding needs. With years of expertise in the field, we can fabricate your plastic parts to the highest standard, as well as cost-efficient and with fast turnarounds.Vacuum casting is a great method to make rigid or flexible parts, and is ideal for high quality prototypes, function testing, concept proofing and display demos. Urethane casting parts can be made from a few to hundreds as required.

Vacuum Casting Case

Finishing Services

Quality Inspection

Quality Inspection Equipment

* Hexagon Coordinate Measuring Machine (CMM) 800×1200×600 (mm), MPE 3.0μm.

* ScanTech PRINCE775 Handheld 3D Scanner Laser: 7+1 red laser crosses,Accuracy Up to 0.03mm.

* Granite Inspection Table, 1200×1000 (mm) / 1000×750 (mm).

* Digimatic Heitht Gages, 0-600 (mm).

* Full Range of Vernier Caliper, 0-100-150-200-300-600-1000 (mm).

* Outside Micrometers / Digimatic Holtest, 0-25-75-100-125-150 (mm) / 12-20-50-100 (mm).

* Full Range of Pin Gage / Gage Block, 0.5-12 (mm) / 1.0-100 (mm), Step 0.01mm.

* Surface Roughness Tester, Hardness Tester, etc.

* ScanTech PRINCE775 Handheld 3D Scanner Laser: 7+1 red laser crosses,Accuracy Up to 0.03mm.

* Granite Inspection Table, 1200×1000 (mm) / 1000×750 (mm).

* Digimatic Heitht Gages, 0-600 (mm).

* Full Range of Vernier Caliper, 0-100-150-200-300-600-1000 (mm).

* Outside Micrometers / Digimatic Holtest, 0-25-75-100-125-150 (mm) / 12-20-50-100 (mm).

* Full Range of Pin Gage / Gage Block, 0.5-12 (mm) / 1.0-100 (mm), Step 0.01mm.

* Surface Roughness Tester, Hardness Tester, etc.

Quality Inspection

DDPROTOTYPE is committed to the continuous improvement and optimization of all custom manufacturing capabilities from prototype to production, and the corresponding quality control process, including CNC machining, rapid prototyping and rapid tooling.

We strictly follow the ISO 9001 certified quality management system, based on a series of standardized production procedures and work instructions, and use advanced testing equipment to measure and inspect each production step to ensure that your project meets stringent quality specifications.

Why Choose Us

With one-on-one support service from a professional technical sales team that responds quickly within hours and always attends to every detail of your needs, you will have a great customer experience from start to finish.

ISO9001:2015 certified factory ensures that your project meets strict quality specifications and reflects our commitment to continuous quality improvement and customer satisfaction.

Our confidence comes from the recognition of our customers around the world. We are the best supplier of “Made in China” you are looking for, providing more cost-effective solutions and more competitive prices.

Comprehensive production capacity, including in-house machining and post-processing, and integration of manufacturing resources across China. This allows us to fully meet your needs for any project from prototype to production.

We are a trusted partner that will not only help you meet your most difficult manufacturing challenges, but will also work with you to develop and follow production schedule that meets your needs and understand the importance of on-time delivery.

FAQ

What makes DDPROTOTYPE ’s vacuum casting service unique?

Our vacuum casting service is noted for its exceptional quality and speed. Our skilled technicians combine decades of experience with the latest technologies to produce exceptional prototypes and engineering models quickly. We can also further enhance your parts with a suite of finishing services including machining, media blasting, printing, painting and more.

Can DDPROTOTYPE provide design services, industrial design support or product development support as an extension of its vacuum casting services?

Yes. To supplement our vacuum casting services, we offer an expanded service geared for design-for-manufacturing support. While we once reserved this service only for approved orders, we now provide it to all incoming RFQs. We also offer light assembly services to meet your needs.

What are DDPROTOTYPE ’s quality standards for its vacuum casting services?

To ensure the highest standard of quality for all of your finished parts, our team adheres to a strict quality control process. This starts with the verification and testing of all materials. During production, we meticulously control temperature, humidity and other processing conditions to maintain the highest degree of consistency in your parts.

How do I get a quote for DDPROTOTYPE ’s vacuum casting services?

We make it easy to get a fast quotation. Simply upload your CAD files and product details and we’ll send you a free quotation within 24 hrs. or less.

What are the limitations of vacuum casting?

There are some limitations to the vacuum casting process. Developers need to use good design practices to ensure enough draft so the part can be released. For the same reason, avoid undercuts, deep ribs, bosses and other features that will destroy the relatively soft silicone mold when it opens.

What keeps the mold together in vacuum casting?

When our technicians cut the mold open to remove the master pattern, they make a sawtooth pattern on the cutline that acts like a key. This helps the mold to be resealed in the correct orientation for pouring resin. The mold merely needs to be taped and stapled shut to avoid any leakage during the pour.

Why would I choose vacuum casting over injection molding?

Vacuum casting is a more affordable alternative to IM, especially in low volumes. It also offers unique advantages like an excellent surface finish.

Can I make production-quality parts using vacuum casting?

Vacuum casting is best for making visually impressive prototypes, but it can also be used for non-mechanical end-use parts like cases and covers.

What happens to the silicone mold(s)? Can I keep them?

The silicone molds used in vacuum casting have a short lifespan, typically around 20 moldings, so we dispose of them after use.

If you wish to keep the 3D printed or CNC machined master model, talk to us directly.

Our vacuum casting service is noted for its exceptional quality and speed. Our skilled technicians combine decades of experience with the latest technologies to produce exceptional prototypes and engineering models quickly. We can also further enhance your parts with a suite of finishing services including machining, media blasting, printing, painting and more.

Can DDPROTOTYPE provide design services, industrial design support or product development support as an extension of its vacuum casting services?

Yes. To supplement our vacuum casting services, we offer an expanded service geared for design-for-manufacturing support. While we once reserved this service only for approved orders, we now provide it to all incoming RFQs. We also offer light assembly services to meet your needs.

What are DDPROTOTYPE ’s quality standards for its vacuum casting services?

To ensure the highest standard of quality for all of your finished parts, our team adheres to a strict quality control process. This starts with the verification and testing of all materials. During production, we meticulously control temperature, humidity and other processing conditions to maintain the highest degree of consistency in your parts.

How do I get a quote for DDPROTOTYPE ’s vacuum casting services?

We make it easy to get a fast quotation. Simply upload your CAD files and product details and we’ll send you a free quotation within 24 hrs. or less.

What are the limitations of vacuum casting?

There are some limitations to the vacuum casting process. Developers need to use good design practices to ensure enough draft so the part can be released. For the same reason, avoid undercuts, deep ribs, bosses and other features that will destroy the relatively soft silicone mold when it opens.

What keeps the mold together in vacuum casting?

When our technicians cut the mold open to remove the master pattern, they make a sawtooth pattern on the cutline that acts like a key. This helps the mold to be resealed in the correct orientation for pouring resin. The mold merely needs to be taped and stapled shut to avoid any leakage during the pour.

Why would I choose vacuum casting over injection molding?

Vacuum casting is a more affordable alternative to IM, especially in low volumes. It also offers unique advantages like an excellent surface finish.

Can I make production-quality parts using vacuum casting?

Vacuum casting is best for making visually impressive prototypes, but it can also be used for non-mechanical end-use parts like cases and covers.

What happens to the silicone mold(s)? Can I keep them?

The silicone molds used in vacuum casting have a short lifespan, typically around 20 moldings, so we dispose of them after use.

If you wish to keep the 3D printed or CNC machined master model, talk to us directly.

Похожие товары

Литье под давлением литье заказ алюминиевые Литые детали пластиковые для автомобилей

Формы для автомобильных фар

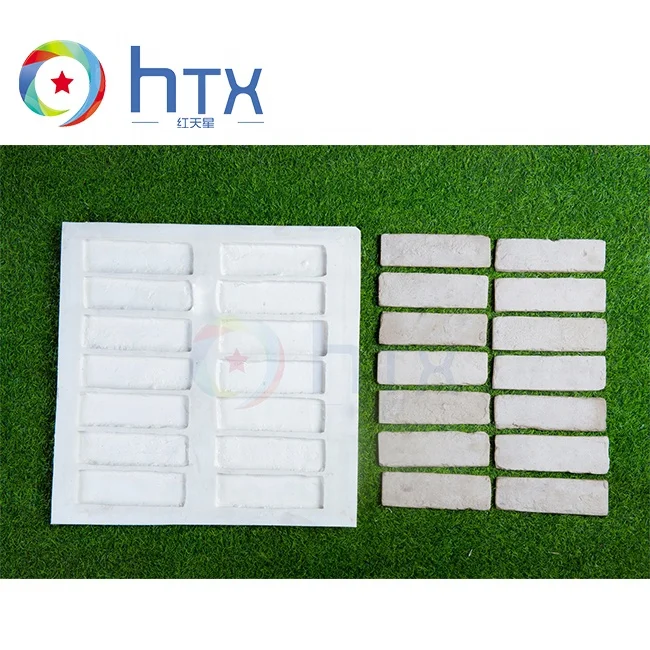

Декоративные формы из Искусственного Шпона для искусственного камня и кирпича

443,71 ₽ - 576,83 ₽

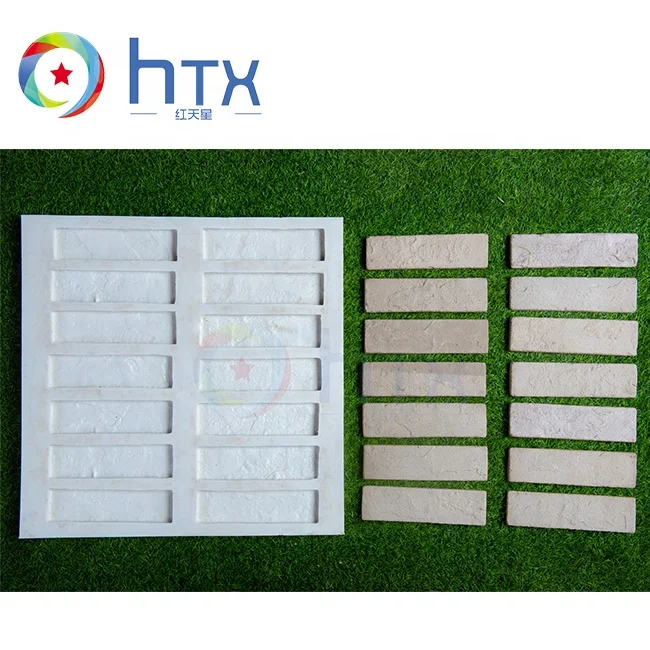

Поставка из Китая красного цвета для украшения стен искусственная культура антикварная форма искусственного камня кирпичная фанера панели 3D внешние

310,60 ₽ - 432,62 ₽

Индивидуальное медицинское оборудование Пластиковая форма для литья под давлением устройство

27,74 ₽ - 38,83 ₽

Инжиниринг и производство автоматическая медицинская электронная форма для литья под давлением нового пластикового материала резины

На открытом воздухе украшение стены цемент культивированный камень силиконовые формы

443,71 ₽ - 576,83 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $