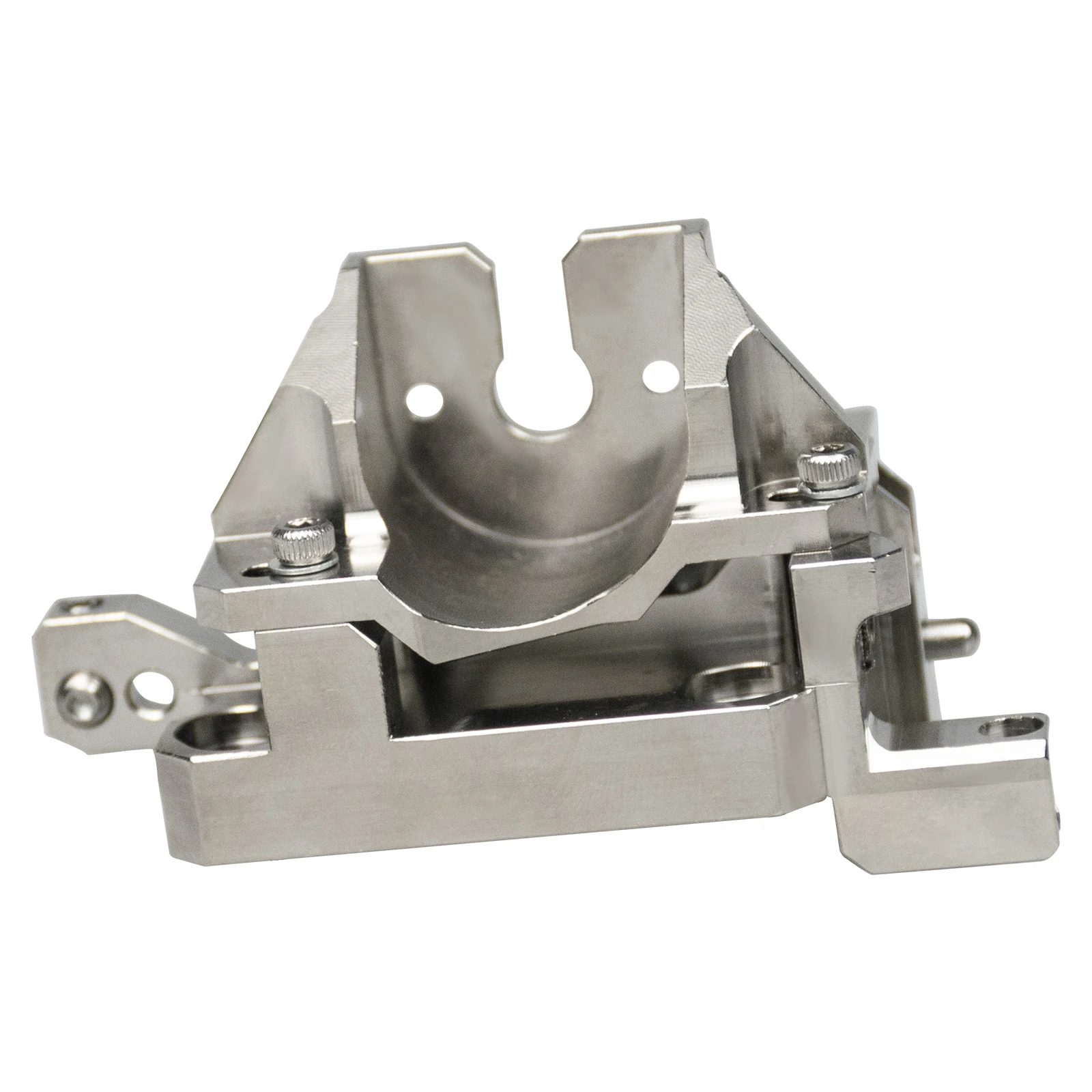

Индивидуальное фрезерование по индивидуальному заказу прецизионное изготовление металла с ЧПУ для сборки механических деталей

- Категория: >>>

- Поставщик: Dongguan Ronghang Hardware Mould Co. Ltd.Dongguan Ltd.

Сохранить в закладки 1601170977246:

Описание и отзывы

Характеристики

CNC Turning Processing

Our CNC turning and milling services can produce highly accurate and complex parts from a variety of materials, including metals,

plastics,and composites.

plastics,and composites.

Samples: 1-3 Day

Lead time:7-14Day

Machinery Axis: 3,4,5,6 Tolerance:+/- 0.01mm

Special Areas : +/-0.002mm Surface Roughness: Ra 0.1~3.2 Supply Ability:300000 Piece/Month

CNC Milling Processing

Instant Quote

Certificate:Medical,Aviation,Automobile

ISO13485, IS09001, AS9100, IATF16949

Composites: carbon fiber, fiberglass, Kevlar.

ISO13485, IS09001, AS9100, IATF16949

Composites: carbon fiber, fiberglass, Kevlar.

Plastics:ABS, acetal, acrylic, nylon, polycarbonate, and PVC.

Metals: aluminum,brass, copper, steel,stainless steel, and titanium.

Quality control:Inspection equipment includes CMMs, height gauges, and

micrometers.

Quality control:Inspection equipment includes CMMs, height gauges, and

micrometers.

Our Service

Processing | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding | ||||||

Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. | ||||||

Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |||||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |||||||

Titanium: Grade F1-F5 | |||||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |||||||

Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. | ||||||

Tolerance | ±0.002 ~ ±0.005mm | ||||||

Surface Roughness | Min Ra 0.1~3.2 | ||||||

More information, Contact Us.

Factory & Workshop

Cnc Machining Center

Workshop

.

24-H Online Service

Testing equipment

Mold workshop

Packaging workshop

Customer Feedback

Product Display

Aluminum

Material: 2024, 5052,5083, 6061,6061-T6, 6063,6082, 7075, etc.

Material: 2024, 5052,5083, 6061,6061-T6, 6063,6082, 7075, etc.

Tolerance: +/- 0.01~0.002mm

Surface treatment: oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc.

Surface treatment: oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc.

Stainless Steel / Steel

Material: SUS303,SUS304,SS316,SS316L,420,430,17-4PH,1214L/1215/4140/SCM440/40CrMo, etc.

Material: SUS303,SUS304,SS316,SS316L,420,430,17-4PH,1214L/1215/4140/SCM440/40CrMo, etc.

Tolerance: +/- 0.01~0.002mm

Surface treatment: electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment,pickling,shot peening,etc.

Surface treatment: electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment,pickling,shot peening,etc.

Brass / Copper / Bronze

Material: HPb63, HPb62, HPb61, HPb59, H59,H62,H63,H65,H68, H70,H80, H90, C110, C120, C220, C260, C280, C360 etc.

Material: HPb63, HPb62, HPb61, HPb59, H59,H62,H63,H65,H68, H70,H80, H90, C110, C120, C220, C260, C280, C360 etc.

Tolerance: +/- 0.01~0.002mm

Surface treatment: electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment,pickling, shot peening,etc.

Surface treatment: electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment,pickling, shot peening,etc.

Titanium Alloy

Material: TA1,TA2/GR2, TA4/GR5, TC4, TC16,TC18,TC21,TC22,TC26,TC118B etc.

Material: TA1,TA2/GR2, TA4/GR5, TC4, TC16,TC18,TC21,TC22,TC26,TC118B etc.

Tolerance: +/- 0.01~0.002mm

Surface treatment: electroplating, oxidation, polishing, spraying, sandblasting, wire drawing, etc.

Surface treatment: electroplating, oxidation, polishing, spraying, sandblasting, wire drawing, etc.

Plastic / Injection Molding

Material: Acetal/POM/PA/Nylon/PC/PMMA/PP/PVC/PU/HDPE/PVDF/Acrylic/ABS/PTFE/PEEK etc.

Material: Acetal/POM/PA/Nylon/PC/PMMA/PP/PVC/PU/HDPE/PVDF/Acrylic/ABS/PTFE/PEEK etc.

Tolerance: +/- 0.01~0.002mm

Surface treatment: spraying,sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing, engraving, etc.

Surface treatment: spraying,sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing, engraving, etc.

Processing Material Selection:

Metals:

Plastics:

CNC machining can work with many types of plastics, including ABS, acrylic, nylon, PEEK, polycarbonate, and PVC. These materials are lightweight,cost-effective, and have good chemical and impact resistance.

Metals:

Metals like aluminum, brass, copper, stainless steel, and titanium are popular choices for CNC machining. They are durable, have high tensile strength, and can be easily machined to produce complex parts.

Plastics:

CNC machining can work with many types of plastics, including ABS, acrylic, nylon, PEEK, polycarbonate, and PVC. These materials are lightweight,cost-effective, and have good chemical and impact resistance.

Composites:

Composite materials such as carbon fiber, fiberglass,and Kevlar are used in many industries, including aerospace, automotive, and sports equipment. CNC machining can create complex shapes and patterns with these materials.

Composite materials such as carbon fiber, fiberglass,and Kevlar are used in many industries, including aerospace, automotive, and sports equipment. CNC machining can create complex shapes and patterns with these materials.

Foam:

CNC machining can also work with foam materials, such as polystyrene and polyurethane. These materials are commonly used in packaging, insulation, and model-making.

CNC machining can also work with foam materials, such as polystyrene and polyurethane. These materials are commonly used in packaging, insulation, and model-making.

Ceramics:

CNC machining can produce intricate ceramic parts for medical, aerospace, and electronic applications. Ceramic mate

CNC machining can produce intricate ceramic parts for medical, aerospace, and electronic applications. Ceramic mate

Surface Treatment

Application field

Aerospace: The aerospace industry requires precision parts with high accuracy and tight tolerances. CNC machining services are used to produce parts such as turbine blades, engine components, and structural parts.

Automotive: The automotive industry relies on CNC machining services to produce high-precision parts for engines, transmissions, and other critical components.

Medical: The medical industry requires precision parts for various medical devices and equipment. CNC machining services are used to produce components for surgical instruments, implants, and prosthetics.

Electronics: The electronics industry requires precise components for various electronic devices. CNC machining services are used to produce components for circuit boards, connectors, and other electronic devices.

Industrial machinery: CNC machining is used to produce parts for a wide range of industrial machinery, including pumps, valves, and bearings.

Construction: The construction industry uses CNC machined parts for components such as structural steel, cladding systems, and architectural features.

Agriculture: The agriculture industry uses CNC machined parts for components such as irrigation systems, seed drills, and harvesting equipment.

Marine: The marine industry uses CNC machined parts for components such as propellers, rudders, and hull structures.

Packaging: The packaging industry uses CNC machined parts for components such as molds, dies, and cutting tools.

Food processing: The food processing industry uses CNC machined parts for components such as cutting tools, conveyor systems, and mixing equipment.

Furniture: The furniture industry uses CNC machined parts for components such as chair frames, table legs, and decorative features.

Automotive: The automotive industry relies on CNC machining services to produce high-precision parts for engines, transmissions, and other critical components.

Motorcycles:Engine components,Suspension components,Wheels,Brakes,Frame and chassis components,Exhaust systems.

Bicycle:Bike frames,Forks,Handlebars,Pedals,Brake components,Cranksets,Hubs.

Medical: The medical industry requires precision parts for various medical devices and equipment. CNC machining services are used to produce components for surgical instruments, implants, and prosthetics.

Electronics: The electronics industry requires precise components for various electronic devices. CNC machining services are used to produce components for circuit boards, connectors, and other electronic devices.

Oil and gas: The oil and gas industry relies on CNC machining services to produce components for drilling equipment, pumps, valves, and other critical components.

Robotics: The robotics industry requires precision components for robots and automation systems. CNC machining services are used to produce components such as gears, actuators, and other robotic parts.

Industrial machinery: CNC machining is used to produce parts for a wide range of industrial machinery, including pumps, valves, and bearings.

Construction: The construction industry uses CNC machined parts for components such as structural steel, cladding systems, and architectural features.

Agriculture: The agriculture industry uses CNC machined parts for components such as irrigation systems, seed drills, and harvesting equipment.

Marine: The marine industry uses CNC machined parts for components such as propellers, rudders, and hull structures.

Packaging: The packaging industry uses CNC machined parts for components such as molds, dies, and cutting tools.

Food processing: The food processing industry uses CNC machined parts for components such as cutting tools, conveyor systems, and mixing equipment.

Furniture: The furniture industry uses CNC machined parts for components such as chair frames, table legs, and decorative features.

FAQ

Q1:Where can I get product&price information?

A1:Send us inquiry e-mail , we will contact you as we receive your mail.

Q2:How long can i get the sample?

A2:Depends on your specific items,within 3-7 days is required generally.

Q3:What's kinds of information you need for quote?

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS

Q4: what's the payment terms?

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance.For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q5:How to delivery the goods?

A5:We deliver the products by courier company

Q6.Are you a trading company or factory?

A6:We are direct factory with 10 experienced engineers and more than 50 employees as well approximate 3,000 square meters workshop area.

Q7. What shall we do if we do not have drawings?

A7:Please send your sample to our factory,then we can copy or provide you better

solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q8.Can we get some samples before mass production?

A8:Absolutely

Похожие товары

Услуги CNC индивидуальная прецизионная обработка фрезерных и токарных металлических деталей из нержавеющей стали

Производитель прямые продажи высокое качество OEM/ODM cnc обработка металлических прототипов деталей

Индивидуальные 5-осевые фрезерные станки с ЧПУ для алюминиевых деталей из титана и нержавеющей стали прецизионные токарные

CNC токарные и фрезерные металлические детали алюминиевые

Китай высокоточный токарный станок с ЧПУ по индивидуальному заказу производители токарные фрезерные детали металлические компоненты

Высокоточные обрабатывающие станки с ЧПУ от производителя деталей из нержавеющей стали

ПВХ нейлоновый пластик литьевая пластмасса 3D-печать с ЧПУ обрабатывающие детали сервисный магазин

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $