Концентрат для добычи золотого минерального меди Золотая воздушная Флотационная установка

- Категория: >>>

- Поставщик: Jiangxi Hengchang Mining Machinery Manufacturing Co. Ltd.

Сохранить в закладки 1601177759084:

Описание и отзывы

Характеристики

Gold Mineral Copper Mining Separation Concentrate Gold Air Forth Flotation Cell Machine for Sale

Hengchang machinery Lithium Ore Beneficiation can be used for separating many minerals, such as gold, copper, tantalum, lead and zinc ore and so on. If you want to buy mining equipment, choose Hengchang, we must ensure that you are satisfied.

Products Description

Flotation machine can be used to separate non-ferrous metal, ferrous metal, noble metal, non-metallic mine, chemical material. It can be used in roughing,scavenging, selection or reverse flotation.In the flotation process, after being mixed with drug, some qualified mineral attaches on bubble, floats on the surface of slurry and is scraped out, other mineral still stays in the slurry,so the separating purpose is finished.

Application:Flotation machine can be used to separate non-ferrous metal, ferrous metal, noble metal, non-metallic mine, chemical material. It can be used in roughing,scavenging, selection or reverse flotation.In the flotation process, after being mixed with drug, some qualified mineral attaches on bubble, floats on the surface of slurry and is scraped out, other mineral still stays in the slurry,so the separating purpose is finished.

Product Working Principle

Flotation machine adopts creative forward tank,double side blades of water wheels, draft tube and the false bottom device. The slurry in tank takes upper and lower circulation according to the fixed flow mode, which is conducive to suspension of coarse particle.

Product Features

1. Large air suction volume, low power consumption.

2. Long service life of wear parts.

3. Each tank with air suction, slurry suction and flotation function does not need any accessory equipment to form flotation circle, which is convenient for process flow changing.

4. The reasonable slurry circulation minimizes coarse sand sediments, and is conducive to flotation of coarse particle.

5. Auto-control device of slurry volume, convenient adjustment.

6. Impeller with backward style upper and lower leaf, the upper blade generates upper circulation; the lower blade generates lower circulation.

7. Mechanical stirring, self- air suction, self-slurry suction.

2. Long service life of wear parts.

3. Each tank with air suction, slurry suction and flotation function does not need any accessory equipment to form flotation circle, which is convenient for process flow changing.

4. The reasonable slurry circulation minimizes coarse sand sediments, and is conducive to flotation of coarse particle.

5. Auto-control device of slurry volume, convenient adjustment.

6. Impeller with backward style upper and lower leaf, the upper blade generates upper circulation; the lower blade generates lower circulation.

7. Mechanical stirring, self- air suction, self-slurry suction.

Product Paramenters

Category | Specification model | Effective cubage (m³) | Processing capcity (m³/min) | Main shaft loam board | ||||||

Power (kw) | Rotate speed (r/min) | Rotate speed (r/min) | Power (kw) | |||||||

XJK type | XJK-0.35 | 0.35 | 0.18-0.4 | 1.5 | 483 | 25 | 1.1 | |||

XJK-0.62 | 0.62 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | ||||

XJK-1.1 | 1.1 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | ||||

XJK-2.8 | 2.8 | 1.5-3.5 | 11 | 280 | 25 | 1.1 | ||||

XJK-5.8 | 5.8 | 1.1-2.9 | 22 | 240 | 25 | 1.5 | ||||

SF type | SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 25 | 1.1 | |||

SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | ||||

SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | ||||

SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | ||||

SF-4 | 4 | 2.0-4 | 15 | 220 | 25 | 1.5 | ||||

SF-8 | 8 | 4.0-8 | 30 | 191 | 25 | 1.5 | ||||

SF-16 | 16 | 5.0-16 | 30 | 191 | 25 | 1.5 | ||||

SF-20 | 20 | 5.0-20 | 45 | 186 | 25 | 1.5 | ||||

Recommend Products

Jaw Crusher

Jaw crusher is often used as primary and secondary crusher for mining, metallurgy, construction and some other industries. It takes large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes for further processing in a

ball mill or hammer crusher.Processing Materials:

Metallic and non-metallic ores (gold, silver, copper, tantalum, barite, tungsten, quartz, coal, limestone etc.), aggregate (rocks,river stone, blast rock, lava rock), construction waste (asphalt, concrete, bricks, pavers, etc.), and some other materials.

ball mill or hammer crusher.Processing Materials:

Metallic and non-metallic ores (gold, silver, copper, tantalum, barite, tungsten, quartz, coal, limestone etc.), aggregate (rocks,river stone, blast rock, lava rock), construction waste (asphalt, concrete, bricks, pavers, etc.), and some other materials.

Spring Cone Crusher

Symons cone crusher is a modern high performance crusher integrating high swing frequency, optimized cavity type and reasonable stroke on the basis of introducing and absorbing foreign technology and according to customer demand. When used with jaw crusher,it can be used as secondary, tertiary or quaternary crushing. Generally speaking, the standard type of Symons cone crusher is applied to medium crushing. The medium type is applied to fine crushing. The short head type is applied to coarse fine crushing.

Ball Mill

Ball mill is a key mineral processing machine for milling the materials into powders after they are crushed, it has wet and dry type.

Processing Materials: Gold, silver, lead, zinc, copper, molybdenum, iron, manganese, tungsten, cement, ceramics, barite, bauxite,limestone, gypsum, calcium carbonate, coal, graphite, feldspar, potash feldspar, phosphorus ore, fluorite, clay and some other

materials.

materials.

Wet Pan Mill

Wet pan mill also called gold round mill, it is versatile ore grinding equipment not only for grinding the minerals but also for gold amalgam. It is a best replacement for medium-small capacity ball mill, owing to the excellent performance for wet crushing,

small investment and high output.

small investment and high output.

Processing Materials:Gold, silver, lead, zinc, copper, molybdenum, iron, lead, manganese, tungsten, cement, ceramics, barite, bauxite, limestone,

gypsum, calcium carbonate, coal, graphite, feldspar, potash feldspar, phosphorus ore, fluorite, clay and some other materials.

gypsum, calcium carbonate, coal, graphite, feldspar, potash feldspar, phosphorus ore, fluorite, clay and some other materials.

Spiral Classifier

Spiral classifier is one of the classifying equipment in mineral processing. It is suitable for classifying materials in the mineral processing plant as well as the desliming and dehydrating in the mineral washing operating process and widely applied to

separate the particles into a number of products graded according to size in the complete closed loop together with ball mill in the mining industry.

separate the particles into a number of products graded according to size in the complete closed loop together with ball mill in the mining industry.

Gold Centrifugal Concentrator

Gold centrifugal concentrator also called knelson concentrator is a new type of gravity concentration equipment, used in the gold mining industry. It is used for the recovery of fine particles of free gold, meaning gold that does not require gold cyanidation

for recovery.Processing Materials:Gold, silver, platinum, tin, tungsten, lead, antimony, chrome, titanium etc.

for recovery.Processing Materials:Gold, silver, platinum, tin, tungsten, lead, antimony, chrome, titanium etc.

Product packaging

Company Profile

FAQ

Q1: Are you manufacturer or trade company?

A1: We are manufacturer with CE certificate. Our factory has more than 25 years history.

Q2: Where your products have been exported before?

A2: Our products have been sold to Southeast Asia, Africa, North America, Oceania, South America, Middle East and so on.

Q3: How will you help the customer to install the equipment?

#1 Our senior engineer will supply installation and training service on-line or on-site.

#2 We have engineer in Southeast Asia and Africa, we can supply 7*24 service.

Q4: How about the wear parts supply?

A4: We will supply the wear parts with factory price. You can buy them from our factory in China.

Q5: What about after-sale service?

A5:12 months warranty for all kinds of products.

Q6: How to get the free solution and quotation?

A6: Please send inquiry to us ,leave your whatsapp and email address, our sales manager will contact you within 1 hours.

Q2: Where your products have been exported before?

A2: Our products have been sold to Southeast Asia, Africa, North America, Oceania, South America, Middle East and so on.

Q3: How will you help the customer to install the equipment?

#1 Our senior engineer will supply installation and training service on-line or on-site.

#2 We have engineer in Southeast Asia and Africa, we can supply 7*24 service.

Q4: How about the wear parts supply?

A4: We will supply the wear parts with factory price. You can buy them from our factory in China.

Q5: What about after-sale service?

A5:12 months warranty for all kinds of products.

Q6: How to get the free solution and quotation?

A6: Please send inquiry to us ,leave your whatsapp and email address, our sales manager will contact you within 1 hours.

Похожие товары

Роскошные свечи малины клубники ванили ароматизированные натуральные успокаивающие ароматические

526,91 ₽ - 582,37 ₽

2 входа 6 выходов концертный эффектор профессиональный цифровой dsp аудио

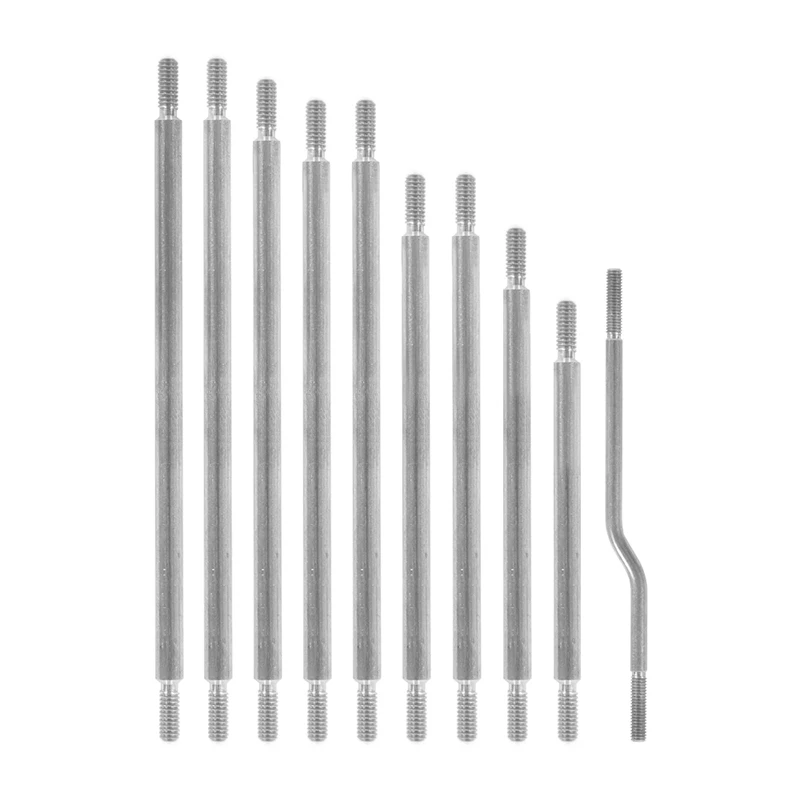

Набор тяг из титанового сплава 10 шт. для Axial SCX10 III

1 420,99 ₽ - 1 506,40 ₽

1-6x24 водонепроницаемый оптический прицел для дальнего

8 763,28 ₽ - 9 761,62 ₽

Фирменные сладости и конфеты упакованные в Пластиковые Игрушки для маленьких Мини-маракасов рекламных

24,41 ₽

Прозрачный надувной мультяшный дракон персонализированный 3d анимационный прозрачный ПВХ

Многоразовый интубационный 3-дюймовый экран для интубации видео Ларингоскопа лучшего качества с жестким многоразовым набором

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $