Жидкий силиконовый каучук (LSR) совместимый респиратор химический противогаз для защиты органов дыхания литье под давлением OEM завод

- Категория: >>>

- Поставщик: Sil Link Silicone Products Co. Ltd.Sil Ltd.

Сохранить в закладки 1601180743229:

Описание и отзывы

Характеристики

PRODUCT SPECIFICATIONS

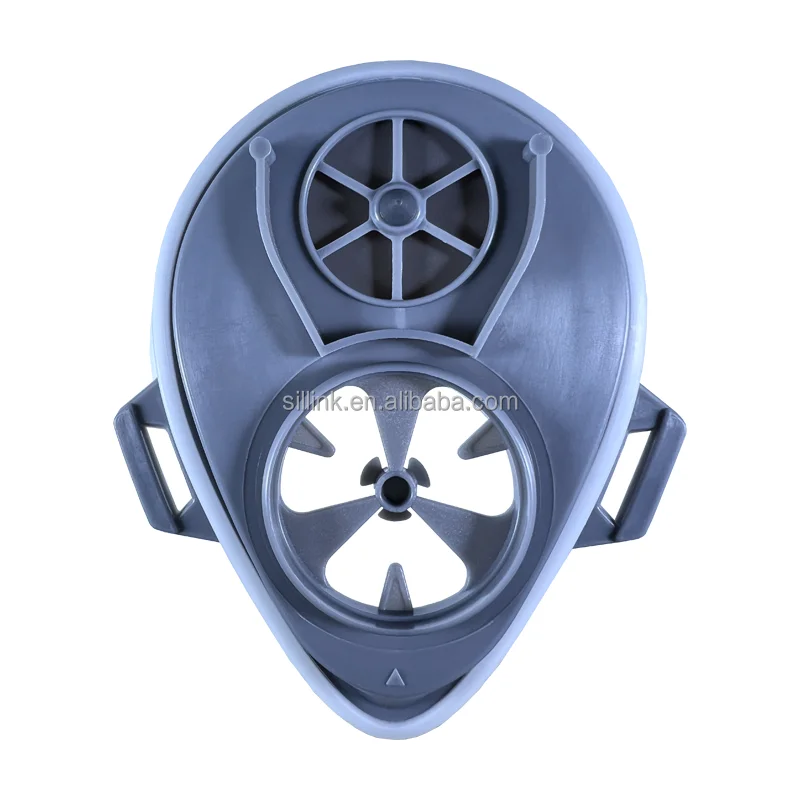

Chemical gas mask

Respirator

Chemical gas mask

For silicone injection molding machine

Product Name | Chemical gas mask |

Parts Material | Silicone rubber(LSR)/Silicone liquidity |

Molding type | LSR injection molding/ over molding |

Cooperation mode | Customization |

MOQ | 1K |

Quality control | 100% inspect before delivery |

Delivery time | 7-15 days after deposit confirm |

OUR SERVICE

LSR Injection Mold Customization

Mold accessories standard according to HASCO/DME/PUNCH/MISUMI

Cold runner silicone injection mold ,which can achieve fully automatic,high efficiency molding,and mold life can reach 1 million shots.

LSR Injection Molding OEM Service

For decades,We specialist capabilities LSR injection molding,include multi-k moulding,clean room production and more.

With rich experience,we can provide competitive and tailored solutions.

With rich experience,we can provide competitive and tailored solutions.

COMPANY PROFILE

Company Profile

Sil Link company specializes customization Liquid silicone rubber molds manufacture and LSR injection molding service.we also provide cost-Efficient Lsr rapid tooling develop.

LSR cold runner injection molding request precision processing. Our team good at accurate mold flow analysis ,make high quality cold runner valve gate injection system,with feasible vacuum technology mold,assist your products ideal a reality.

More than 10 year molding experience for liquid silicone injection molding .We can provided LSR and plastic molding solutions for many industries, It cover medical device, baby products, electronic appliances, auto parts etc...

LSR cold runner injection molding request precision processing. Our team good at accurate mold flow analysis ,make high quality cold runner valve gate injection system,with feasible vacuum technology mold,assist your products ideal a reality.

More than 10 year molding experience for liquid silicone injection molding .We can provided LSR and plastic molding solutions for many industries, It cover medical device, baby products, electronic appliances, auto parts etc...

FACTORY FACILITIES

Mold manufacturing workshop

Which can ensure mold delivery one time with high-quality.

A complete mold manufcturing center,

Which can ensure mold delivery one time with high-quality.

Our mold engineers can conduct feasibility analysis on mold making and injection molding, and also provide effective suggestions to our customers during product molding.

Makino EDM

Mold Fitting

Mold polishing

LSR Injection Workshop

2. A standard clean room that can meet medical device injection requirement.

1. Our workshop has more than 10 different tonnage LSR injection machine,include horizontal/vertical machine,can ensure your production delivery on time.

2. A standard clean room that can meet medical device injection requirement.

LSR Injection molding

Product inspection

Secondary vulcanization

PRODUCT CONFIGURATION

QUALITY CONTROL

How to ensure the quality of our products

We always a pre-production sample before mass production; and 100% final Inspection before shipment;

FAQ

Q1. Do you sale injection mold/Tooling or injection molding service?

A: We do both service ,we have our own mold manufacturing workshop and injection workshop.

A: We do both service ,we have our own mold manufacturing workshop and injection workshop.

we also provide cost-Efficient Lsr rapid tooling develop

Q2. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

A: Generally, it will take 40 days for mold building and T1,and will take other 15-30days for mold improvement to mass production.

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Похожие товары

Изготовленная на заказ металлическая Форма Для Горячего Цинкового Литья

1 500,00-2 500,00 $

Пластиковая алюминиевая литьевая форма

500,00 $

Histocore spectra st окрашенная полиуретановая оболочка мирового класса качество окрашивания и консистенция Полиуретановая для

112,00-120,00 $

Эффективная стальная литейная форма для многополостной пластиковой ложки

Высококачественный светодиодный прожектор комплект прожекторов наружное освещение литье под давлением алюминиевый корпус лампы

2,80-3,03 $

Высококачественные нейлоновые полипропиленовые пластмассовые литьевые изделия

0,75-1,50 $

BOGDA двухшнековый экструдер пластиковый лист экструзионная форма T Die

5 000,00-6 000,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $