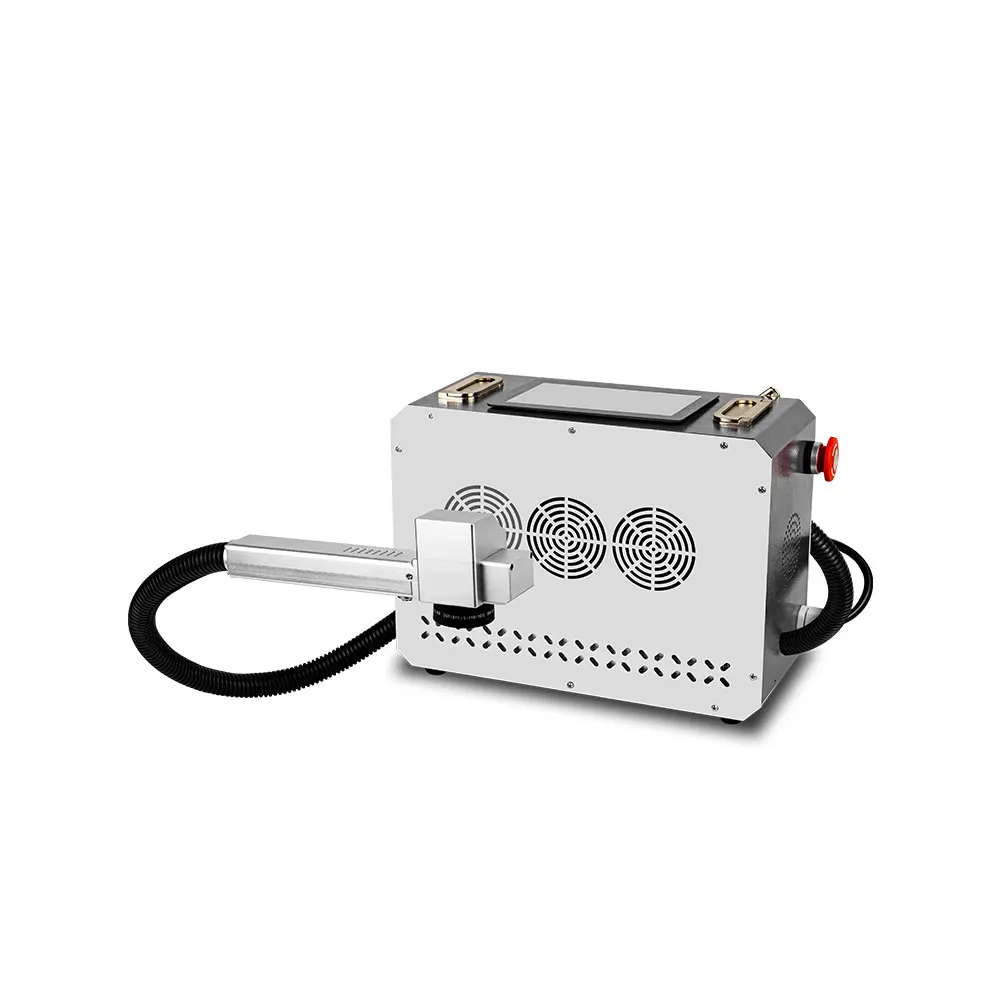

Высокоскоростная Лазерная Очистительная Машина импульсная 300 Вт для удаления ржавчины лазерный очиститель оксида металла

- Категория: >>>

- Поставщик: Jiangsu Huaxia Star Technology Co. Ltd.

Сохранить в закладки 1601191691660:

Описание и отзывы

Характеристики

Difference between pulse cleaning machine and continuous cleaning machine:

1. Cleaning efficiency comparison:

*Aluminum painted remove: The paint removal efficiency of pulse laser is much higher than that of continuous laser with 7.7 times. The cleaning efficiency of pulsed laser is 2.77m²/h, while that of continuous laser is 0.36m²/h.

*Carbon steel painted remove: The paint removal efficiency of pulsed laser is also higher than that of continuous laser. The rate is 3.5 times that of continuous light. The cleaning efficiency using pulsed laser is 1.06m²/h, while the cleaning efficiency of continuous laser. Efficiency is 0.3m²/h

2. Material surface roughness comparison

Carbon steel surface: Pulsed laser causes less damage to the surface of the sample, the surface roughness is close to or even lower than the original material. But after using continuous light cleaning, the surface of the sample is severely damaged, so the surface roughness of the cleaned sample is the roughness value of the original material 1.5 times, which is 1.7 times the surface roughness after pulse light cleaning.

3. In conclusion: the difference between pulse cleaner and continuous cleaner

*Under the same power conditions, the cleaning efficiency of pulse laser is much higher than that of continuous laser. Pulsed lasers can better control heat input, preventing the substrate from overheating or micro-melting.

*Continuous lasers price is cheaper and can be compensated for efficiency and pulse up time by using high-power lasers. But the heat input of higher power continuous light is larger, and the degree of damage to the substrate will also increase.

*Therefore, both have fundamental differences in application scenarios. High precision requires strict control of substrates motherboards that require native lossless applications, such as molds, should choose pulse lasers. For some For large steel structures, pipelines, etc., due to their large size, fast work, and low requirements on base material damage, continuous lasers can be selected.

Packing & Delivery

1.Outside package: Strong wooden case.

2.Inner package: Water-proof plastic film package with foam protection in each corner Solid Seaworthy Wood Box Package.

Jiangsu Huaxia Xingguang Technology Co., Ltd. production equipment mainly includes: industrial dust collector, handheld laser welding machine, jewelry welding machine and laser consumables .

The annual output can reach more than 9,000 units, and the products are sold in 150 countries and regions. Has served 60,000+ corporate users. The equipment processes products with high precision, smooth cutting, fast speed and higher productivity. We have a complete after-sales service system, and we have the strength to promise to provide new and old customers with high-quality and cost-effective laser welding machine equipment.

Q1: What can I get the available machine if I don't know anything about laser?

A1:We provides will provide the customized application solution for your requirement, just tell us your material, material thickness, worktable and e-mail or whatsapp ID.

Q2: When I got this machine, but I don’t know how to use it. What should I do?

A2: We provides installation,commissioning and training for users’ technicists, ensures that uses can get familiar with operation methods and put machines into use as soon as possible;

Q3: If the machine has problem in my place, how could I do?

A3: Usually there won't be any problem under "normal use" as per the user manual. But in case you have any problem, our professional after-service team will provide you any support you need any time!

Q4: This model is not suitable for me, do you have more models available?

A4: Sure, in order to meet different customers' different requirments, we reserched many other different models.

Похожие товары

Автоматическая лазерная машина для очистки нового состояния волоконный лазер металла и нержавеющей стали ключ точки продажи-автоматический

Нержавеющая 2000 Вт листовое водяное охлаждающее алюминиевое портативное сварочное оборудование для очистки импульсной металлической поверхности сварные машины

1000 Вт 1500 2000 3000 CW аппарат для непрерывного лазерного удаления ржавчины с ручным пистолетом

Лазерный сварочный аппарат 2000 Вт портативный лазерный поставщики с сертификатом Ce и Oem обслуживанием

60/100/200 маленький мини сварочный аппарат Ювелирная сварка ювелирных изделий

Низкая цена волоконно-лазерная Очистительная Машина для удаления ржавчины/краски/масла с сертификатом CE

Промышленный очиститель для пляжа

Новые поступления

Новинки товаров от производителей по оптовым ценам