Фрезы карбида вольфрама CNC режущий инструмент для металла HRC 45/55/65

- Категория: >>>

- Поставщик: Sichuan Mighty Machinery Co. ltd.

Сохранить в закладки 1601194207553:

Описание и отзывы

Характеристики

Products Description

Size | 2-20mm |

Material | Tungsten Carbide |

Color | Bronze/Black/Blue |

Coating | TiN/TiCN/TiAlN |

Standard | DIN6527K/DIN6528 |

Packaging | 1pc/Plastic tube |

Lead Time | 30~45 Days |

Sampling Time | 5~10 Days |

How to recognize and use the carbide tools and HSS tools?

1. The difference in weight is the most simple and direct, due to the high density of carbide cutting tools, the carbide cutting tools is more heavy than HSS cutting tools if same size.

2. Different color of material , the appearance of carbide cutting tools is bright but little black. The appearance of HSS tool is bright and more white.

3. Different coating, carbide cutting tools are generally coated with bronze, black, blue, high-speed steel cutting tools are generally plain or yellow.

4. Price difference, carbide cutting tool price is more high, high-speed steel cutting tool price is low if same size.

5. Difference in use, carbide tools cutting speed, long performance life, high-speed steel tools are easy to wear, low service life. Cemented carbide tool hardness is high but easy to break, the edge is easy to collapse if drop on the ground, high-speed steel tool toughness is not easy to collapse edge

6. Cemented carbide tools are generally processed ferrous metal materials, and the use of high-speed steel tools to process non-ferrous metal materials. Cemented carbide hardness, especially at high temperatures, can withstand higher cutting speeds, but the toughness of HSS tools is better,generally used in some complex and difficult to mold or require sharpness and high toughness and other occasions.

7. Whether choose tools for CNC machine tool or general machine tool, we have to comprehensively consider the milling material and hardness, milling specifications, such as: cutting edge length, cutter length, cutting edge diameter, shank diameter and so on. HSS tools are usually suitable for general machine tools, while CNC machine tools better use carbide tools.

1. The difference in weight is the most simple and direct, due to the high density of carbide cutting tools, the carbide cutting tools is more heavy than HSS cutting tools if same size.

2. Different color of material , the appearance of carbide cutting tools is bright but little black. The appearance of HSS tool is bright and more white.

3. Different coating, carbide cutting tools are generally coated with bronze, black, blue, high-speed steel cutting tools are generally plain or yellow.

4. Price difference, carbide cutting tool price is more high, high-speed steel cutting tool price is low if same size.

5. Difference in use, carbide tools cutting speed, long performance life, high-speed steel tools are easy to wear, low service life. Cemented carbide tool hardness is high but easy to break, the edge is easy to collapse if drop on the ground, high-speed steel tool toughness is not easy to collapse edge

6. Cemented carbide tools are generally processed ferrous metal materials, and the use of high-speed steel tools to process non-ferrous metal materials. Cemented carbide hardness, especially at high temperatures, can withstand higher cutting speeds, but the toughness of HSS tools is better,generally used in some complex and difficult to mold or require sharpness and high toughness and other occasions.

7. Whether choose tools for CNC machine tool or general machine tool, we have to comprehensively consider the milling material and hardness, milling specifications, such as: cutting edge length, cutter length, cutting edge diameter, shank diameter and so on. HSS tools are usually suitable for general machine tools, while CNC machine tools better use carbide tools.

Company Profile

Sichuan Mighty Machinery Co. Ltd. is one of the most famous mechanical parts supplier in China.Our products have been exported to

Europe, America,the Middle East market and other areas since 1999.MIGHTOOLS is the tools dept., we are specialized at cutting

tools,also providing varieties of products include:Machine tool accessories,Measure tools,Hand tools,Vehicle repair tools,Garden

tools,Wood working tools,Non-standard automation parts and other customized Machining Parts according to drawings(OEM),etc.

Europe, America,the Middle East market and other areas since 1999.MIGHTOOLS is the tools dept., we are specialized at cutting

tools,also providing varieties of products include:Machine tool accessories,Measure tools,Hand tools,Vehicle repair tools,Garden

tools,Wood working tools,Non-standard automation parts and other customized Machining Parts according to drawings(OEM),etc.

Our Advantages

Own 3 Factories

HSS Tools: twist drill bits,step drill bits,center drill,countersink,annular cutter etc.

Carbide Tools:Carbide end mill and carbide burr etc.

Tool Holder:Lathe cutter,Machine tools accessories etc.

Morden Production lines

Made-to-Order, Low Cost and Punctual Delivery.We supply not only comprehensive solutions of custom made parts, but also provide additional services like product design, process optimization, quality control and logistics,one-stop service.

Strictly Quality Control

Not only Testing equipments like,projector, tool microscope,

offset runout detection instrument,

magnetic particle flaw detector,

hardness machine and other testing instruments and gauges etc.

offset runout detection instrument,

magnetic particle flaw detector,

hardness machine and other testing instruments and gauges etc.

But also our professional engineers.

Recommend Products

Carbide 2 Flutes Square End mill

Special for milling keyways and is used to machine grooves of various shapes and sizes on the surface of workpiece.

Keyway milling cutters generally have only two teeth, its end face have no center hole, can be directly cut down into worepiece, equivalent to a drill, can be drilled out of the flat bottom holes, mainly processed in the groove and keyway.

Keyway milling cutters generally have only two teeth, its end face have no center hole, can be directly cut down into worepiece, equivalent to a drill, can be drilled out of the flat bottom holes, mainly processed in the groove and keyway.

Carbide Corner Radius Endmill

Mainly used in milling machines, CNC machine tools for machining flat surfaces, grooves and step surfaces with R angle, machining surfaces with a small range and small angle surface processing. The contact surface of the cutting edge with R angle is larger than that of the ball nose cutter, so the wear is smaller and the tool service life is longer.

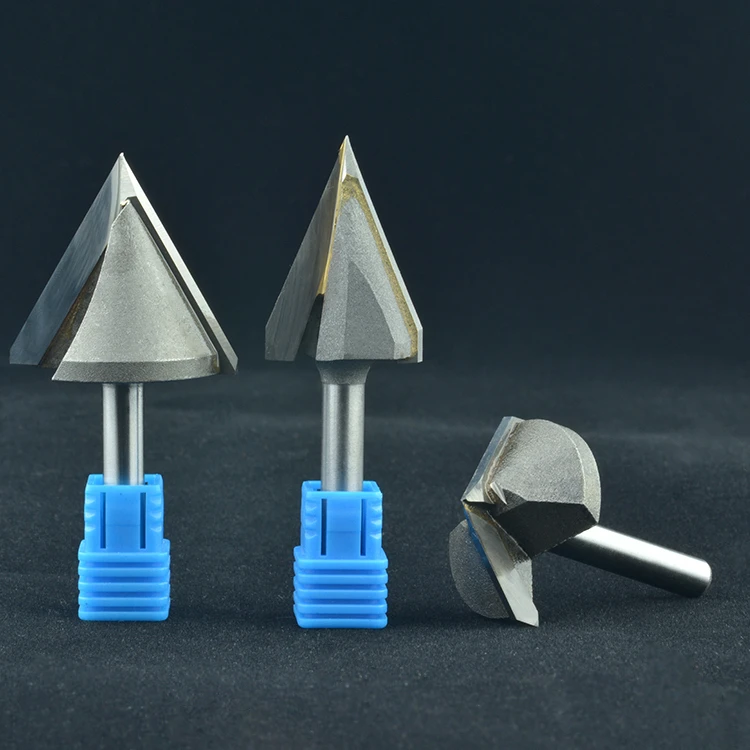

Carbide Tappered Ball Nose Endmill

Tappered Ball Nose Endmill is a special form of milling cutter. It has a shape that tapers from the shank to the cutting edge, with a tapered tip.

It can be mainly used to process workpieces with inclined surfaces,

It can be mainly used to process workpieces with inclined surfaces,

such as inclined holes, inclined slots and inclined surfaces.

Exhibition

Похожие товары

Apmt 1135 и Apmt 1604 для всех типов Pvd Cvd покрытие вставка для протирания карбида вольфрама высокая износостойкость высокая точность

70,49 ₽ - 92,18 ₽

Твердосплавный токарный инструмент с 6 флейтой, токарный инструмент с высоким твердым покрытием (HRC 70), мощный концевой Фрезер, Заводская распродажа, режущие инструменты типа

Вольфрамовый карбид, антивибрационный винт, Расточная штанга, токарный станок с ЧПУ, прочный цанговый патрон R8, высокоскоростной стальной фрезерный станок с ЧПУ

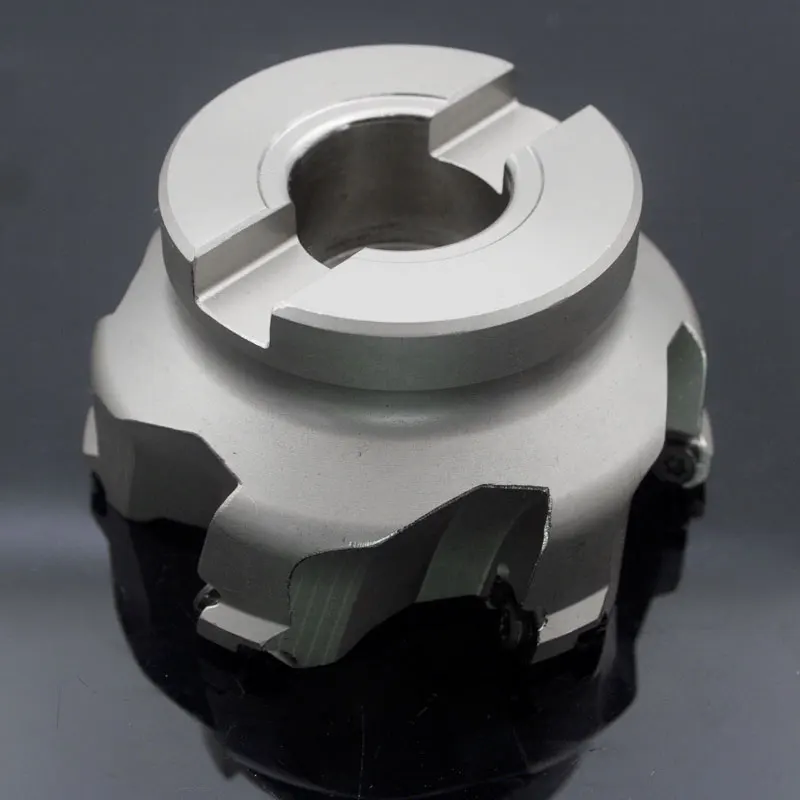

Черновая режущая оболочка торцевая фреза

3 773,57 ₽ - 4 120,57 ₽

Фреза для деревообработки, 90 градусов

Карбидный фреза для деревообработки

JR136 T-резак фрезерный станок с ЧПУ шлицевой прямой хвостовик без покрытия HSS T-type резак

487,97 ₽ - 4 294,07 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Полезные Порошковые напитки подходящие для

7,52-13,23 $

Многофункциональный портативный мини-ридер для нарезки рыбы швейная машина игольчатый ридер набор иголок

Фингель цветок лотоса плавающий свет со светодиодной подсветкой

Квадратная бумажная коробка для попкорна

0,04-0,06 $

Черный порошок хны для ухода за волосами Banjara с гибискусом натуральное окрашивание волос

Ортодонтия Prophy мотор беспроводной

69 $

Недорогие коврики с 3D-печатью

7,20-7,99 $

Уличная Водонепроницаемая светодиодная лампа IP65 E27 фитинг для фермы патрон лампы со шнуром праздничная лента с колпачком ламп на солнечной батарее

6-8 $