Лучшая цена все виды модной пластиковой экструзионной формы

- Категория: >>>

- Поставщик: Huangshi Jinrui Mould Corp. Ltd.

Сохранить в закладки 1601194891212:

Описание и отзывы

Характеристики

Product Description

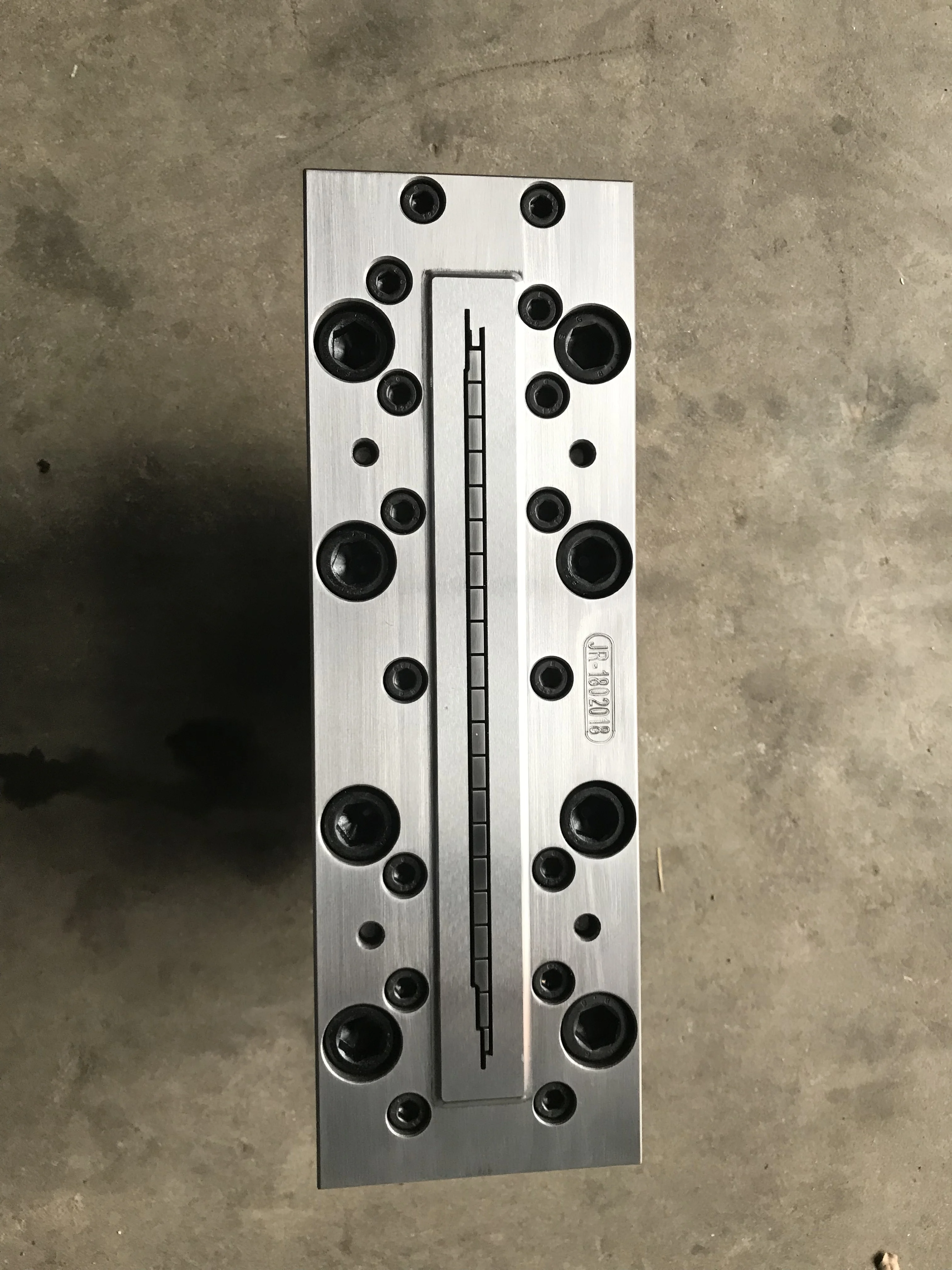

Product Name | Pvc Mould |

Mould material | 3Cr13,3Cr17,din1.2317 stainless steel |

Mould cavity | 1 or multi-cavity |

Features | various foaming types: free foaming, foamed skinning, co-extrusion foaming Wood-like process & formula development and supply |

Test | Mould will be tested to get the satisfied sample before delivery |

Lead time | Less than 45 days, 30-40 days Usually |

ODM&OEM | Accept |

Company Profile

HUANGSHI JINRUI MOULD CORP.,LTD

Established in 2006, Huangshi Jinrui Mould Corp., Ltd is located in Huangshi City, Hubei Province . We are a national high-tech enterprise specializing in the research, development and manufacture of plastic extrusion moulds, mainly producing and manufacturing moulds of plastic profile, wood plastic foam, imitation marble high calcium and foam moulds, wide panel moulds, hot laying moulds, engineering plastic moulds and hundreds of varieties of products in six categories.

Jinrui currently covers an area of 18,000m², including mould and extrusion production workshop and technology R&D base of 9,000m².There are more than 70 employees contain of more than 10 excellent technical backbone personnel who have been engaged in this industry for more than 20 years.

Our professional attitude has created the excellent quality of Jinrui moulds, which has won the trust and support of all circles and opened up a wide and stable market. Our products are sold all over the country and exported to Southeast Asia, the Middle East, Europe and America. We are dedicated to providing our global customers with high quality extrusion dies and comprehensive technical services.

Sample Room

Exhibition

Mold testing and customer factory inspection

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Extruded Products Flaws Solution | ||||

Product Flaws | Reasons | Solution | ||

Distortion | Too short cooling time, not enough cooling for finished one | delay the cooling time | ||

Too rapid speed for extrusion, forced pull to lead the distortion | Slow down the speed of extrusion die | |||

Finished product structure with defects | Modify the dies | |||

Too high temperature for die, poor cooling for finished products | reduce the mould temperature | |||

Knit line | Insufficient injection pressure, too slow injection speed, too small gate and flowing pipe | Increase the injection pressure and speed, modify the gate and flowing pipe. | ||

Too low forming temperature and mould temperature | Increase temperature and back pressure or accelerate the rotating speed . | |||

Insufficient exhaust in interflow zone and no run-off pit | Fix exhausting holes in inter flow zone and increase the number of run-off pits. | |||

Use too much release agent | Reduce to use release agent | |||

Poor luster | Too slow injection speed, insufficient pressure and low mould temperature | Increase the injection speed, injection pressure and mould temperature | ||

Hydrosphere or grease pollution in the mould cavity | Clean it up | |||

Poor grinding of mould surface or too small gate and flowing pipe | Modify mould | |||

Insufficient injection quantity or water contained in the raw material | Increase the injection pressure and injection speed, delay the jet | |||

Cracks of finished products | Too low temperature of material or mould | Increase the temperature | ||

Insufficient stripping lean or improper extrusion way | Modify the mould | |||

Too small gate | Modify the mould | |||

Insufficient stripping angle | Modify the mould | |||

Coarse surface finished products | Too low forming temperature | Increase the temperature, accelerate the rotating speed of screw | ||

Too low mould temperature | Increase the mould temperature | |||

Surface blocks of extruded one | Not clean material pipes, contain wastes | Clean up material pipe | ||

The additive articles such as color master batch are not done according to the requirements | need the corresponding color master batch | |||

Expansion of extruded one | Too low temperature of mould head or too fast rotating speed of screw | Increase the mould head temperature and reduce the rotating speed of screw | ||

Pits of extruded one | Too fast limited material | Adjust the limited material device | ||

Water contained in the raw material | Dry the material | |||

Too high meting temperature, too fast rotating speed of screw | Reduce the meting temperature, and the rotating speed of screw | |||

FAQ

Q1. Are you a trading company or a manufacturer?

A: We are a manufacturer and have more than 20 years experience in mould, and our professional team will help you make a most suitable solution to save your cost.

Q2. How about quality control in our company and delivery time?

A: Every piece of goods is tested strictly before packing and delivery. Generally, it take 45 days. It depends on the mold’s size and complexity.

Q3. How to receive an quotation in the shortest time?

A: When you send us inquiry, please kindly make sure all details with us, such as quantity, cavity, sample etc. You can provide us a sample, we will help finish the 3D drawing design.

Q4. How to ensure the products' quality before shipment?

A: We will supply picture report or send you videos to show the production process.

Q2. How about quality control in our company and delivery time?

A: Every piece of goods is tested strictly before packing and delivery. Generally, it take 45 days. It depends on the mold’s size and complexity.

Q3. How to receive an quotation in the shortest time?

A: When you send us inquiry, please kindly make sure all details with us, such as quantity, cavity, sample etc. You can provide us a sample, we will help finish the 3D drawing design.

Q4. How to ensure the products' quality before shipment?

A: We will supply picture report or send you videos to show the production process.

Похожие товары

Профессиональные Индивидуальные различные виды плесень мотоциклетный шлем плесень защитный шлем плесень

Все виды бетонных форм для скульптур животных для садовых украшений на продажу

Лучший поставщик форм, профессиональные виды форм для горшков, форма для цветочных Горшков

Производители пресс-форм для изготовления всех видов пластиковых игрушек и пластиковых деталей, формы для литья под давлением

54 696,70 ₽ - 1 093 934,00 ₽

Пластиковые формы для литья под давлением

8,76 ₽ - 109,40 ₽

Mr.mo EVO электрическая форма для одежды, паровые пластиковые детали

109 393,40 ₽

Изготовленные на заказ обрабатывающие детали прессформы типа продукта

10,94 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $