A356 T6 литые под давлением из алюминиевого сплава автомобильные детали

- Категория: >>>

- Поставщик: Tianjin HYRH Machinery Co. Limited

Сохранить в закладки 1601195777837:

Описание и отзывы

Характеристики

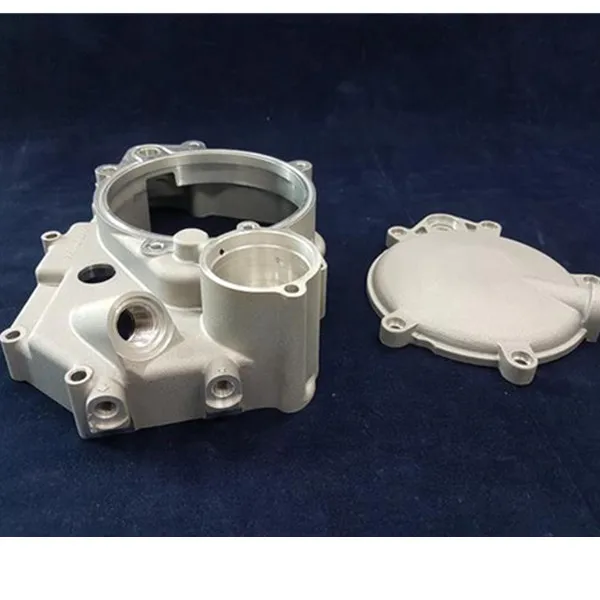

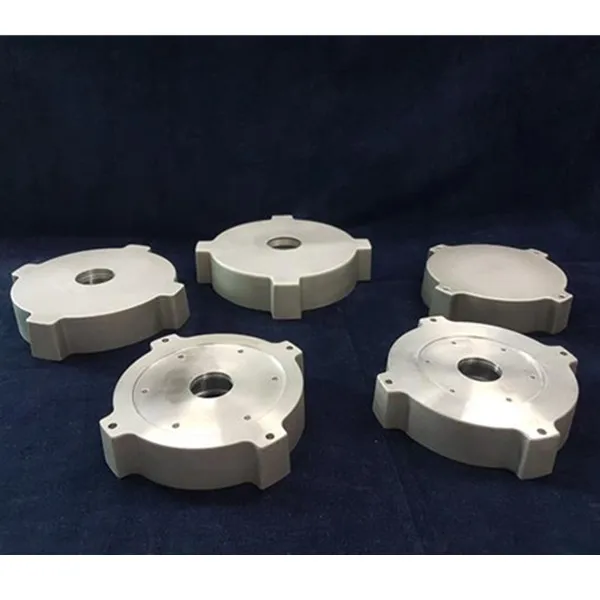

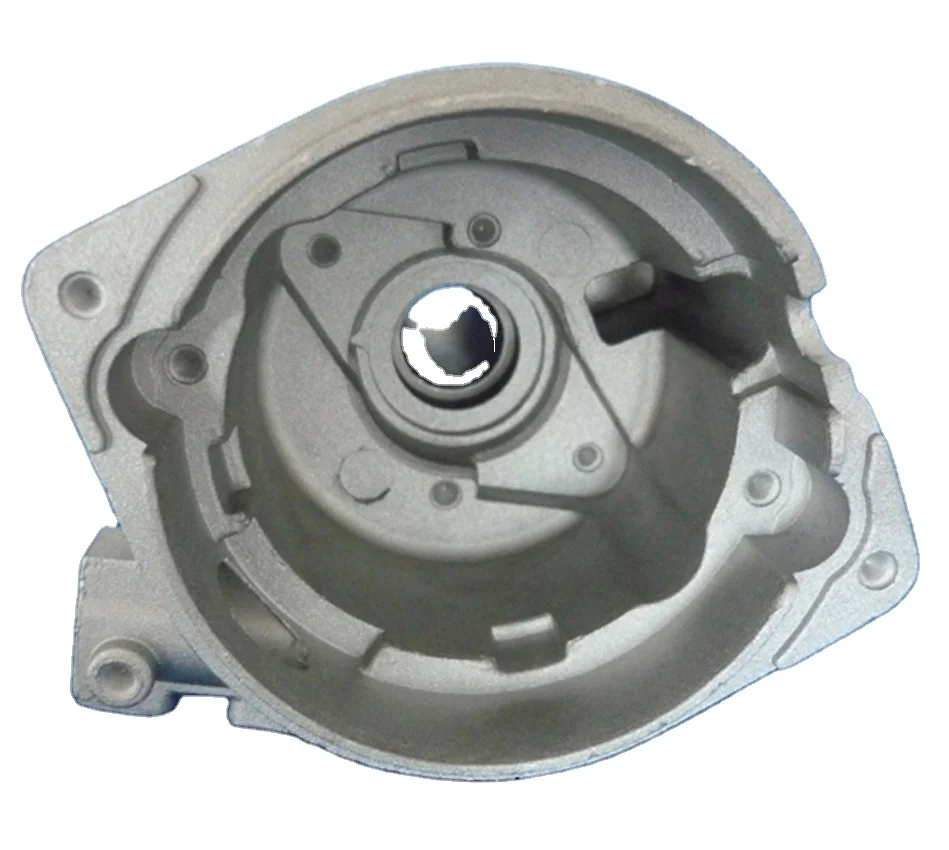

Product Name:A356-T6 Aluminum alloy gravity cast die cast sand casting automotive parts

Our aluminum alloy gravity casting process is where the molten aluminum is poured into

the metal mold, and allows molds cooled sufficiently. We have advantages of product

strength and accuracy.

(1) Products with high hardness and strength.

(2) Products can be welded onto other suppliers’ molds under same product features.

(3) By using sand core inserts, our products can be soldered in complex and hollow shape products.

(4) We welcome enquiries for both mass and a variety of small batch production products.

Gravity Casting Machine

Gravity Casting Machine List

| FACILITIES | TYPE | QTY |

| GRAVITY CASTING - VERTICAL | L700*W500*H1400mm | 2 |

| GRAVITY CASTING - VERTICAL | L1030*W530*H1400mm | 4 |

| GRAVITY CASTING - OVERTURN | L1000*W650*H1145mm | 3 |

| GRAVITY CASTING - OVERTURN | L1020*W800*H635mm | 8 |

| SHELL MOLDING | KKB-550,600*950*300mm | 6 |

| SHELL MOLDING | KKB-550,550*400*300mm | 4 |

| MELTING & HOLDING FURNACE | 360kgs | 9 |

| MELTING & HOLDING FURNACE | 600kgs | 6 |

| CNC MACHINE | MAX 1050*500*530 mm | 13 |

| NC LATHES | Max processing diameter φ450mm Max processing length500mm | 3 |

Inspection Equipments

Inspection Equipments List

| FACILITIES | TYPE | QTY |

| METALLOGRAPHIC ANALYSERS | SPECTROMAXX | 1 |

| LEAK TEST MACHINE | WATER LEAK TESTING MACHINE | 6 |

| 3D CMM | CE1006A-M, 800*1000*600mm | 1 |

| STRUCTURED-LIGHT 3D SCANNER | HDI ADVANCE | 1 |

| X-RAY | UNICOMP UNC160 | 1 |

| X-RAY | SEAMASTER ECO-L160 | 1 |

1. Shape/Material Discussion

When receiving case from customers, all the departments including business/manufacturing/engineering

technology will be gathered immediately to discuss the case, especially about design/deliver date/problems.

2. Mold design. Manufacture

In order to reduce customers' cost, reduce defective rate and optimize product, our company will actively makesuggestions about the product shape and the design.

We use the latest mold flow analysis technology before formal production. By using this technology beforehand,

we are able to simulate the issues which may be encountered in the every stage of production, such as: casting process of aluminum soup flow, solidification follow-up, analysis of strength problems. This can significantly

shorten the development time, and reduce the process problems.

3. Test / Evaluation / Mass production

To find the problems at the early stage and achieve the best quality at the mass production line, we try to evaluate

every problems in the mass production process.

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.),quantity, application or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers'

requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, paypal, western union, moneygram etc.

Q: Is it possible to know how is myproduct going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining progress.

Похожие товары

Изготовленные на заказ алюминиевые детали корпуса умного робота, алюминиевый корпус, набор для литья под давлением, услуги литья под давлением

Процесс обработки поверхности с ЧПУ для снятия заусенцев в соответствии с чертежом изделий для литья под давлением из алюминиевого сплава

Изготовленный на заказ автомобильный двигатель, алюминиевые Литые детали, Крышка корпуса двигателя A380 ADC12 A356, литые под давлением детали из алюминиевого сплава

Услуги по отливке на заказ A356, материал, новый корпус аккумулятора для автомобиля, Литые детали, услуги литья под давлением алюминия

OEM Индивидуальные алюминиевые детали для литья под давлением высокого/низкого давления ASMT A356

Прецизионные алюминиевые гравитационные Литые части строительных лесов

Поставка Shanghai для литья под давлением трансмиссии из литого алюминия

Новые поступления

Новинки товаров от производителей по оптовым ценам