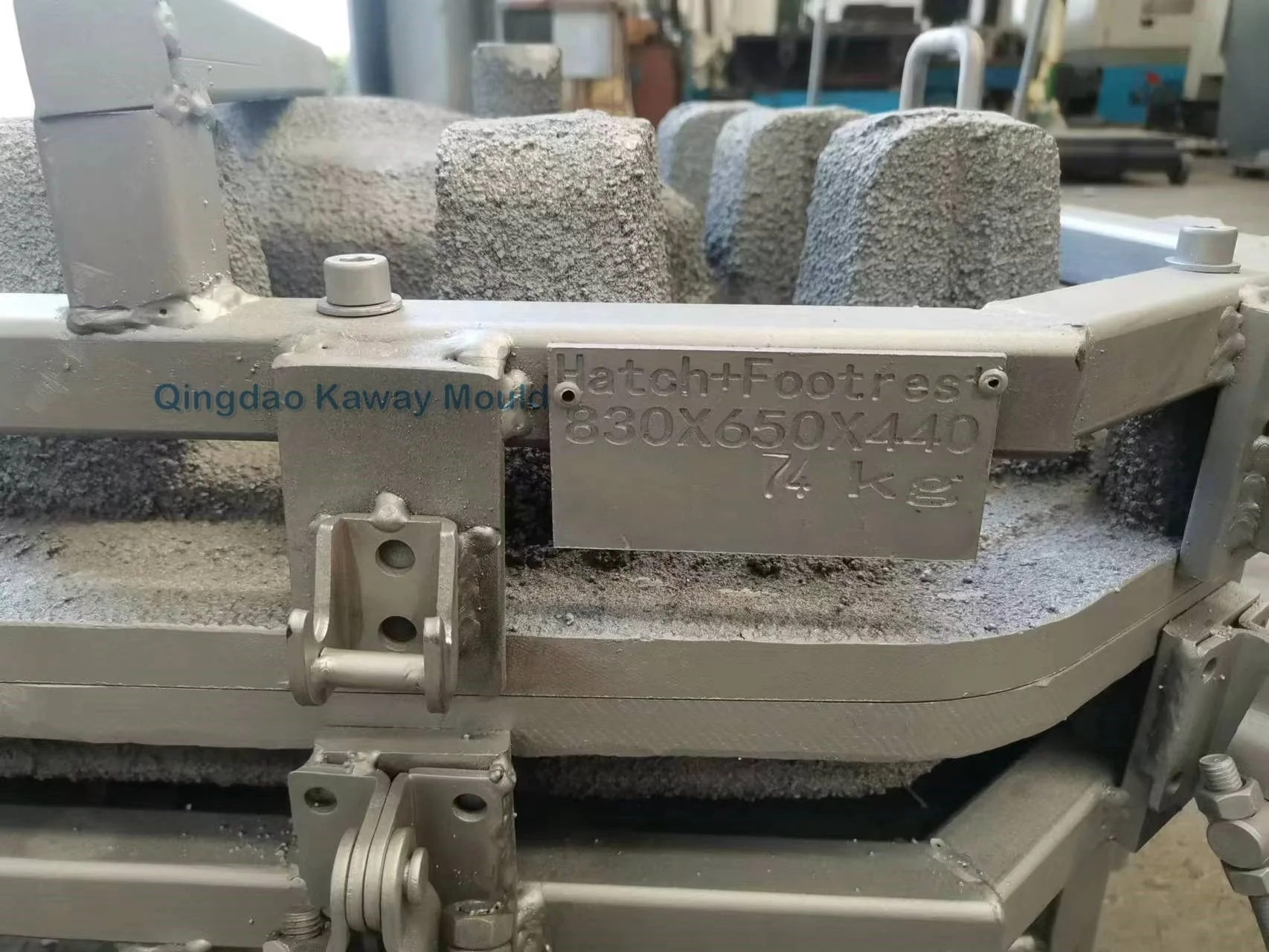

Высококачественная прочная профессиональная литая алюминиевая форма с ЧПУ вращающаяся для Каяка подставки ног

- Категория: >>>

- Поставщик: Qingdao Kaway Mould Co. Ltd.

Сохранить в закладки 1601197707001:

Описание и отзывы

Характеристики

Another type of mould, CNC moulds, directly made from aluminum block, have better surface finish from aluminum block than cast aluminum. In contrast, the CNC moulds have higher cost than cast aluminum mould.

A commonly used finish is sandblasting for mould cavity surface, also called abrasive blasting, which produces a textured rustic look. Also, we offer a smooth gloss finish and a smooth matte finish.

- Below show glossy finish

Qingdao Kaway Mould Co.,Ltd, specializes in manufacturing rotational molds, and also making products for some clients. Our advanced mold technology origins in Europe from 2012, and some engineers have ever worked in Italy for some years. So far, with many molds for kayak, water tank, fuel tank, air duct, playground equipment, and more others, we have supplied our customers domestic and in USA, Australia, Italy, Poland, Malaysia and Vietnam.

With our expertise knowledge and experience of the rotational moulding industry, we can provide a full rotational mould and moulding service, from mold design through to final production, including foam filling, especially important for some products including buoys.

We can assist customers in all aspects of product development, roto moulding process and product assembly.

Kaway can manufacture cast aluminium molds, CNC aluminium molds or fabricated molds in metal sheet.

To value customers' needs is a must for us. We persist in continuous innovation and strict work methods such as Poka-yoke in mold development.

1) Q: What about the lead time? A: Usually, 25days~60days, upon mould size and complexity. |

2) Q: Min Quantity per order? A: one set. |

3) Q: OEM&ODM available? A: Yes. |

4) Q: Have all molds run test before delivery? A: Yes, every mold has run test before delivery. |

Похожие товары

Алюминиевая ротационная формовочная форма для Каяка

Высококачественная пластиковая ротационная формовочная форма для ротационного формования, индивидуальная корзина для мусора

Алюминиевая ротационная формовочная форма по индивидуальному заказу

Вращающаяся алюминиевая форма пластиковая пассажирская лодка

Пластиковая ротационная формовочная форма под заказ

Пластик по индивидуальному заказу, ротационное формование, ротационное формование, детская горка

Пластиковая ротационная формовочная мебель/стул

Новые поступления

Новинки товаров от производителей по оптовым ценам