Сварочный Функциональный модуль пользовательских водяных и воздушных блоков охлаждающей воды монитор для точечной сварки охлаждающие водяные петли

- Категория: >>>

- Поставщик: XY(Nanjing) Industry Equipment Co. LTD

Сохранить в закладки 1601199193778:

Описание и отзывы

Характеристики

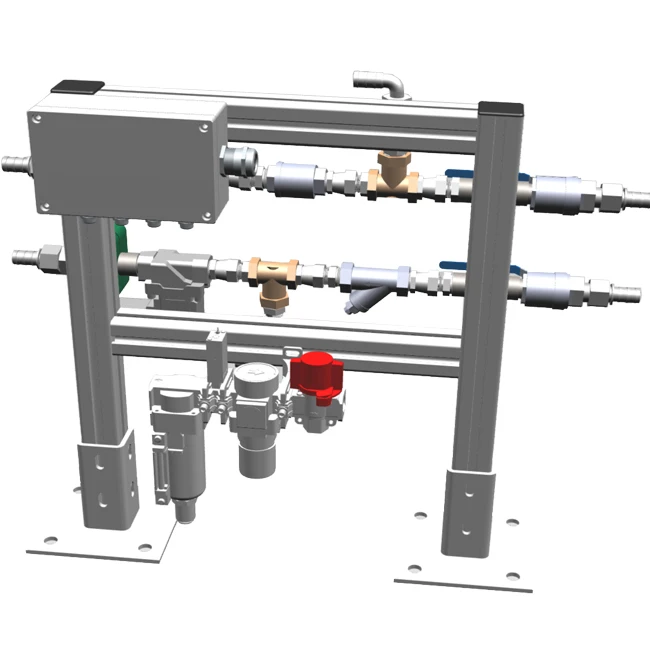

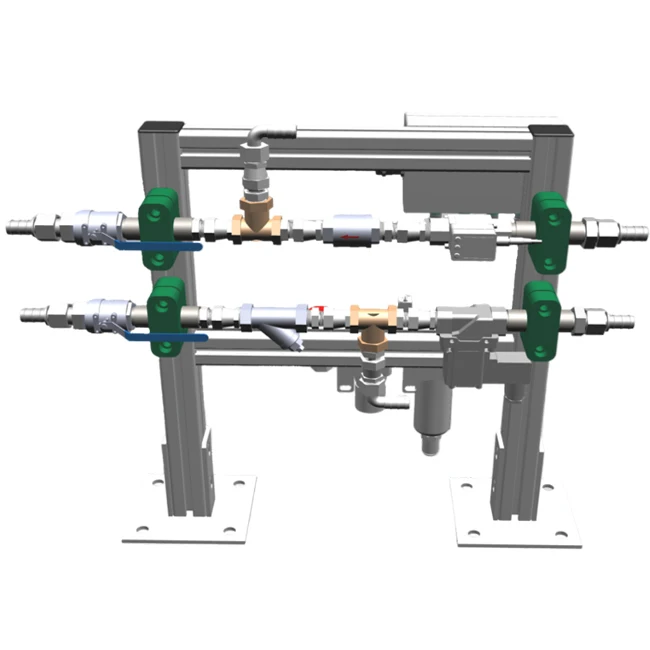

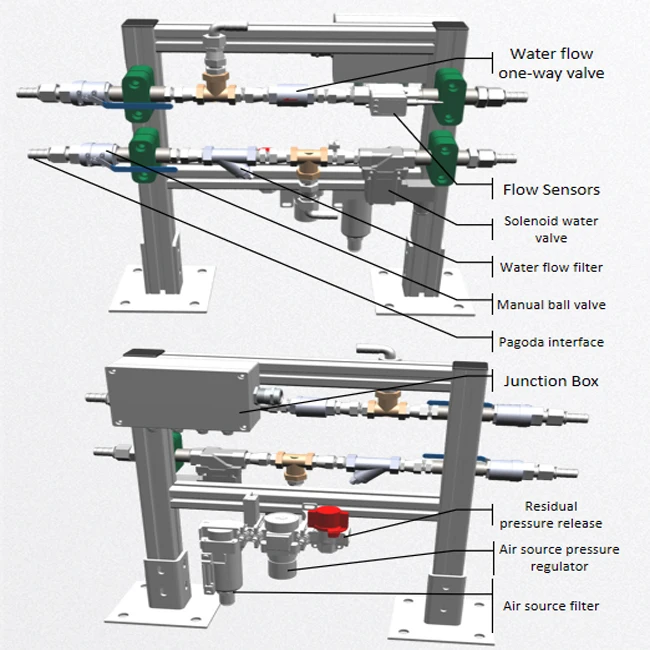

The water and air unit is fitted on the base of the robot and contains components for water and air distribution and control within the Spot Welding Functional Module. It is available for both robots carried guns as well as for stationary guns and is controlled from the robot controller via the spot welding software. The capacity and functionality depend on the choice of different options.

• Water and Air unit fitted on the base of the robot.

• Water circuit with electric shut-off valve and flow switch.

• Air circuit with filter, electrical pressure switch

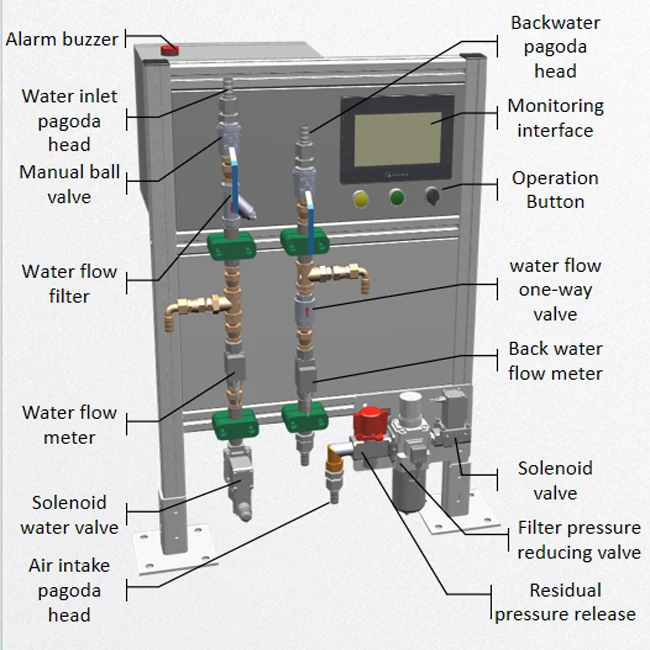

RIP- Standard type is a standard equipment used in cooling water monitoring in the welding field. It can monitor return water flow and intake pressure in real time. When the return water flow is lower than the alarm value, the flow sensor outputs an alarm signal. This signal can be connected to a PLC or robot, and then the PLC or robot controls the opening or closing of the electromagnetic water valve, ultimately realizing the monitoring of cooling water. The optional bus communication module makes the device signal network connection more convenient.

Parameter | Description |

Measurement | 570*200*510 mm |

Voltage/Power | 1PH 24V(DC) / 30W |

Communication protocols | I/O,Profinet,Ethernet/IP,EtherCAT,CC-Link etc.(Optional) |

Water pipe diameter | 1/2,3/4 (Optional) |

Water flow range | 0~16L/min,0~40L/min (Optional) |

Gas unit | Not equipped, air unit (Optional) |

Air pressure range | 0~1.0Mpa |

RIP-Split Immediately break Type is a standard equipment used in cooling water monitoring in the welding field. It can monitor inlet water flow, back water flow, back water temperature, and intake air pressure in real time. Compared with the traditional RIP, this equipment can automatically cut off the incoming water flow within 1 to 2 seconds when the electrode cap falls off, cooling water leaks, etc., and at the same time transmits an alarm signal to the PLC or robot to stop the welding process, to avoid damage to the welding gun. The built-in bus communication module makes the device signal network connection more convenient.

- For use in robot spot welding systems in the automotive industry

- Reliable detection of lost tips, burst pipes and leakage in the cooling system

- With flow meter to detect the amount of cooling water

- Pressure sensor for recognizing a sudden drop in pressure

- For controlling shut-off devices

Parameter | Description |

Measurement | 580*330*870 mm |

Voltage/Power | 1PH 24V(DC) / 60W |

Communication Protocol | I/O,Profinet,Ethernet/IP,EtherCAT,CC-Link (Optional) |

Water pipe diameter | 1/2,3/4 (Optional) |

Water flow range | 0~16L/min,0~40L/min (Optional) |

Air Unit | Not equipped, air unit, air unit + solenoid valve (optional) |

Air pressure range | 0~1.0Mpa |

We are a group company which focus on welding solution. We have three subsidiaries:

Nanjing Dianjin Welding and Cutting Equipment Co.,LTD

Nanjing FST Welding Technology Co.,LTD

XY(Nanjing) Industry Equipment Co.,LTD.

Nanjing Guoke Intelligent Technology Co.,LTD

Our company is located in the South of Nanjing City, Jiangsu Province, China which was established in 2003 with more than 20 years manufacturing experience in this field.

We have ISO900I & CE Certificate and have been sold in lots of countries all around the world and gained good reputation widely with excellent quality. In order to meet customers’ requirements and improve product quality, our company has already realized mechanical processing numerical control automatization production, and been committed to manufacturing products with best quality.

Our company adopts modern management mode and devotes itself to new high performance design and production of welding&cutting equipments, with continuous technique advantages innovation.

Q1: What does your factory produce?

A: We produce and export all kind of welding consumables, welding torch, resistance welding gun and welding working station.

Q2: How can you gurantee quality?

A: Pre-production samples can be provided before mass production and 100% inspection before shipment.

Q3:What is your terms of payment?

A:T/T or L/C at sight. We’ll show you the photos of the products and packages before the shipment.

Q4:Can you produce according to the samples?

A:Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q5: Where do your factory located?

A: Our factory located in No.16 Songyuan North Road, Chunxi Street, Gaochun, Nanjing, Jiangsu Provice, China

Q6: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

A:2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

",

Похожие товары

Оптовая продажа подгонять Электрический кабель питания средней частоты индукционной плавильной печи с водяным охлаждением кабели

Плазменная резка резак факел расходные материалы PT31 PT40 удлинить плазменное электродное сопло

Сварочные инструменты 1 0/1 5/2 0/2 5/3 0 диоптрий сварочный шлем маска Стекло Лупа линзы защитные очки для сварщика

Высокое качество 250A/305A/405A/505A держатель контактного наконечника сварочный наконечник для сварочной горелки ESAB

Запасные части для плазменной резки электродная насадка 0558001624-URC 0558002516-PRO 0558006010ATTC 0558006014ATTC расходные материалы Esab

Высокое качество 250A/305A/405A/505A держатель контактного наконечника сварочный наконечник для сварочной горелки ESAB

Сертификация качества Прямая продажа с завода сварочные аксессуары запасные части держатель контактного наконечника ESAB SPF250

Новые поступления

Новинки товаров от производителей по оптовым ценам