Влагопоглотитель влагопоглотителя от производителя Осушитель сухого воздуха для промышленного использования

231 437,64 ₽ - 297 562,68 ₽

Сохранить в закладки 1601199883670:

Electricity Fee | Calculation Formula | Post Rotor Cooling Capacity | |

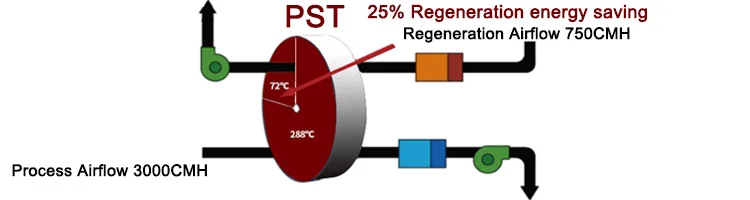

Regular Desiccant Rotor | 293.46 | (120-35)*1.005*5000*1.2/3600/0.85*24*0.073=293.46 | 70KW |

PST Desiccant Rotor | 220.095 | (120-35)*1.005*3750*1.2/3600/0.85*24*0.073=220.095 | 50KW |

ROTOR SIZE | ||||||

Diameter(mm) | Thickness(mm) | Bearing/ Inner hole | Shaft Diameter(mm) | |||

180-400 | 50,100,150,200,300,400 | 6204/20 | 53 | |||

440 | 300, 400 | 6204/20 | 53 | |||

500 | 200, 300 | 6204/20 | 53 | |||

450, 550 | 100, 200, 300, 400 | 6204/20 | 53 | |||

650-770 | 200, 300, 400 | 6204/20 | 70 | |||

850 | 200, 300, 400 | 6204/20 | 100 | |||

900 | 200, 300 | 6204/20 | 100 | |||

965-1050 | 200, 300, 400 | 6204/20 | 100 | |||

1220-1370 | 200, 300, 400 | 6206/30 | 150 | |||

1525-1800 | 200, 300, 400 | 6206/30 or 6208/40 | 150/240 | |||

1850 | 200, 300 | 6206/30 or 6208/40 | 240 | |||

1940-2190 | 200, 300, 400 | 6208/40 or 6206/30 | 240 | |||

2200-2400, 2550 | 200, 300 | 6208/40 | 240 | |||

2450-2600 | 200, 300, 400 | 6208/40 | 240 | |||

Новинки товаров от производителей по оптовым ценам