Plastic Toy 3D Printing Custom Blind Box Vacuum Casting Vinyl Bobble head Figure DIY Face Sculpture SLA SLS Tide Toys Injection

- Категория: >>>

- Поставщик: Dongguan Dafeng Model Co. Ltd.Dongguan Ltd.

Сохранить в закладки 1601200098283:

Описание и отзывы

Характеристики

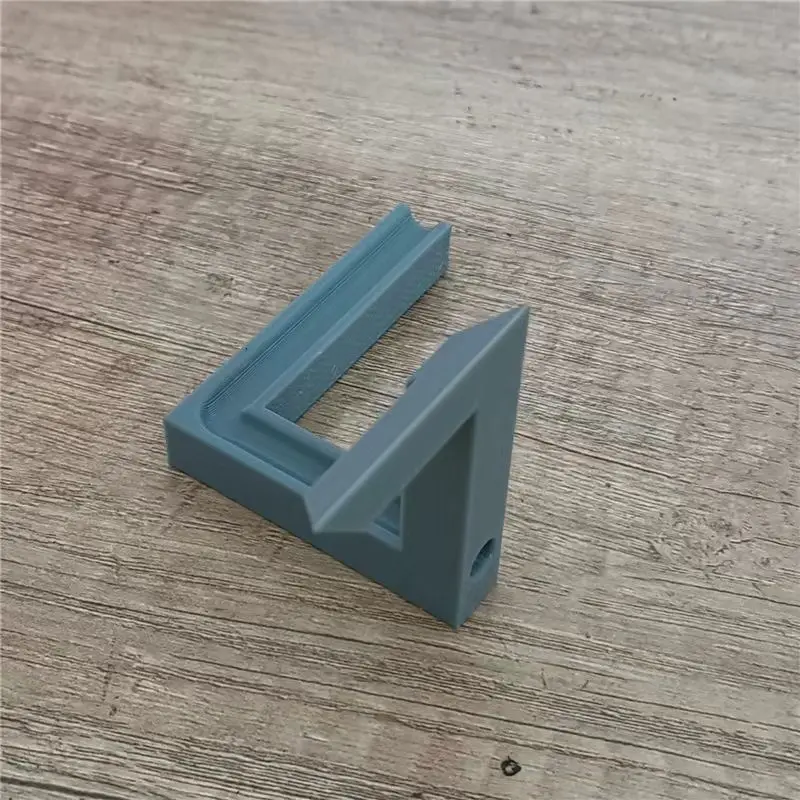

3d printing service 3d printing service plastic 3d printing service sla 3d stl acrylic fabrication design product fdm jewelry 3d printing plastic housing rapid prototype product design and development rubber 3d printing sla 3d printing service sls 3d

\t | |

\t | \t |

\t | \t |

\t | \t |

\t | \t |

\t | \t |

\t | \t |

\t | \t |

\t | \t |

SLA prints can be a lot faster, and many newer models have significantly better resolution than FDM printers, resulting in more detailed objects, but resin currently costs a little more than filament and the printers themselves are generally more expensive as well. There are many different applications for SLA 3D printing technology because of the high quality results – design, engineering, and prototyping to name a few!

Selective Laser Sintering (SLS)

Wax printing( DLP)

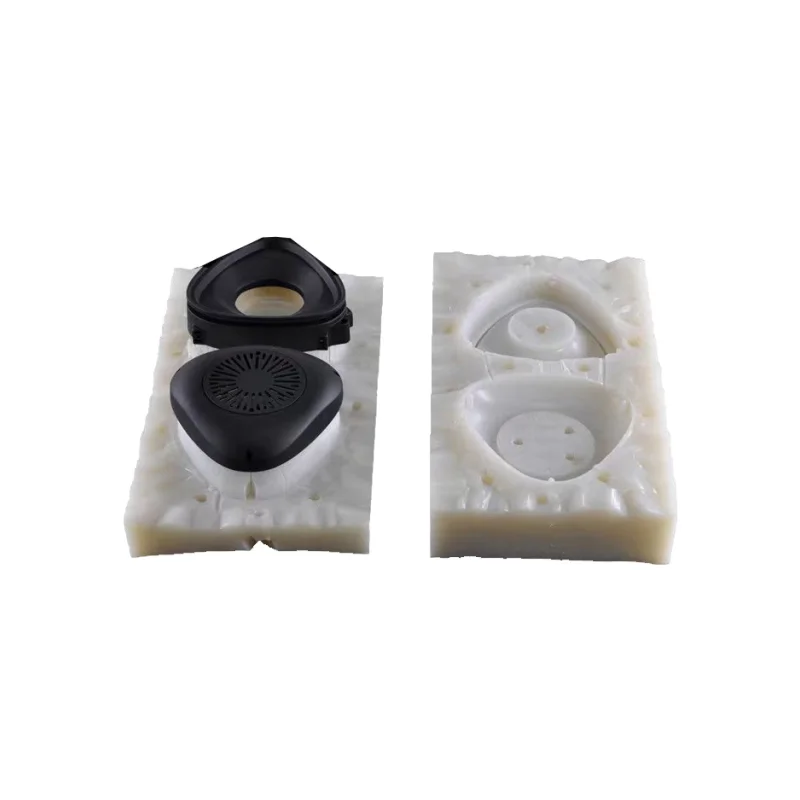

DLP (DigitalLightProcessing) is used to shape the photosensitive resin. The CAD data is stratified and supported by PerfactorysoftwareSuite+EnvisiontecMagics, and then the black and white Bitmap file is output.Each layer of Bitmap file will be projected by the DLP projector onto the work table of photosensitive resin, so that layer by layer solidification molding.High precision and quality suitable for small size products.

Похожие товары

Rapid Silicone Molding 3D Model CNC Plastic Silicon Mold for Vacuum Casting Epoxy Resin Services

Customized Coil Shaft Chemical Fiber Mechanical Equipment Winding Head Steel Parts CNC Machining

CNC Turning Shaft Motor Spare Parts Milling Custom Machining Services

Высокоточная обработка с ЧПУ индивидуальный логотип шестигранная полая внешняя Резьбовая алюминиевая часть крепежные детали штифт вала крепежный металлический сталь

Высокоточная алюминиевая застежка для камеры пряжка уличной одежды крепежные детали

OEM/ODM High Precision CNC Brass Fastener Parts Screwed Joint Machinery

Большой резервуар для металлических деталей распределительного электрооборудования с тяжелой сваркой и ЧПУ

Новые поступления

Новинки товаров от производителей по оптовым ценам