Сборный дом сборный бетон легкая машина для изготовления стеновых панелей полый сердечник линия по производству плит

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.

Сохранить в закладки 1601200409054:

Описание и отзывы

Характеристики

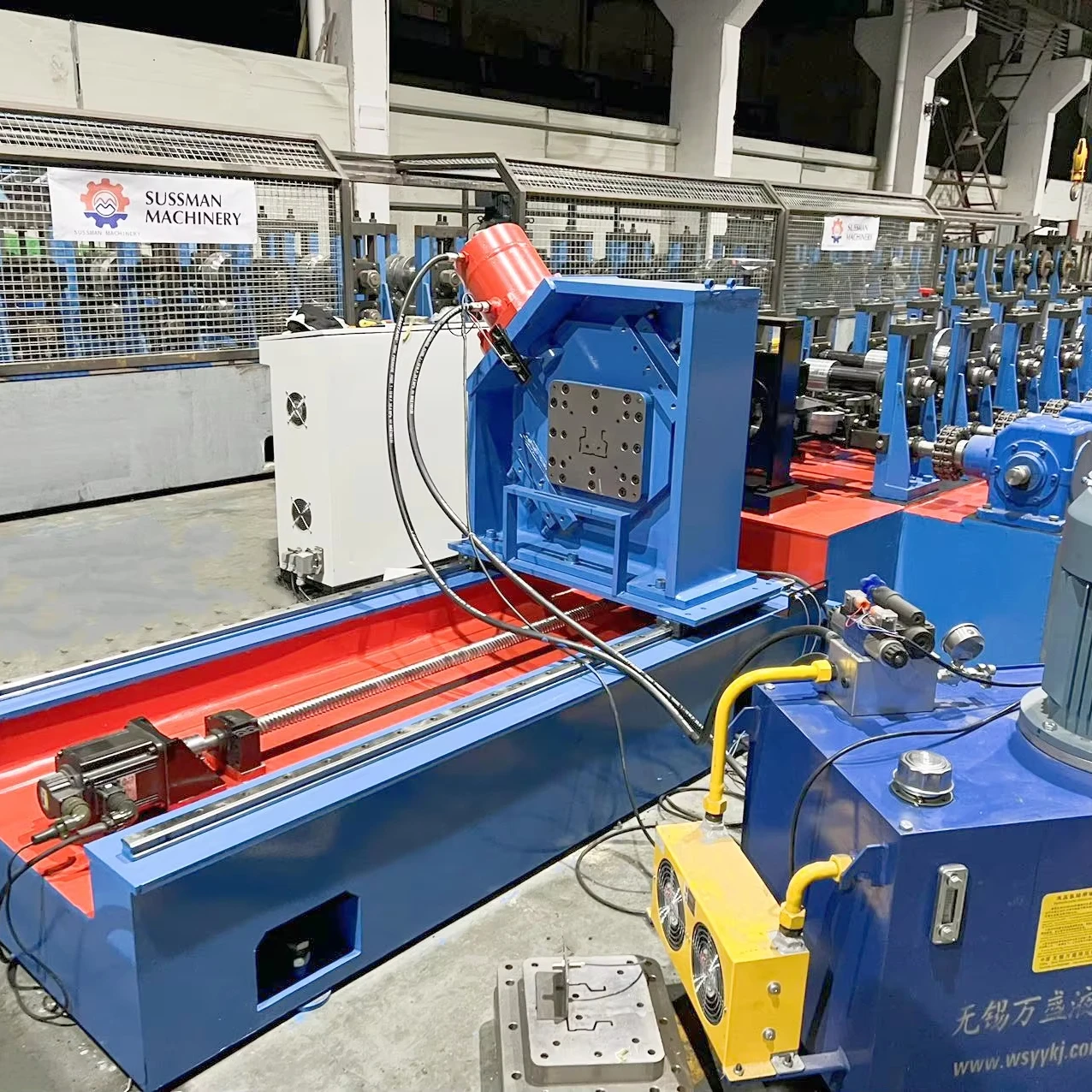

Hongfa manual precast lightweight EPS concrete sand wall panel machine, hollow core wall panel machine

Hongfa Manual Vertical Wall Panel Machine

- It is for panel length 2440mm and width 610mm, while the thickness is adjustable ( The thickness can be 60,75,90,100,120,150,200,250mm). The same machine can produce different thickness panel, just to change the Aluminium molding profile.

- This is the capacity for each panel machine: 60mm/16pcs, 75mm/14pcs, 90mm/12pcs, 100mm/12pcs, 120mm/10pcs, 150mm/9pcs, 200mm/7pcs

- The core can be cement, additive, then to add EPS or sand or ceramsite), the both side surface can be without any board, or to add calcium silicate board or fiber cement board.

- Except the panel machine, the production line will need, cement silo, screw conveyor, mixer, weighting system, pumping machine, demoulding machine.

Machine Size length*width*height(mm) | Power(kw) | Each production(m³) |

| 3500*2200*5200 | 11 | 3 |

Machine Size length*width*height(mm) | Power(kw) | Each production(m³) |

| 3000*2000*1950 | 5.2 | 3 |

| Function | Molding System | |

| Overall Dimension(mm) | 3600x1320x2800mm | |

| Number of Pallet Provided Per Time | 60mm | 58(pcs) |

| 75mm | 50(pcs) | |

| 90mm | 42(pcs) | |

| 100mm | 40(pcs) | |

| 120mm | 34(pcs) | |

| Hydraulic Unit | Motor Power | 2.2kw |

| Working Pressure | 3-4Mpa | |

| Molding Time | 6-8 hours ordinary Portland cement | |

| Installed Capacity | ≈65kw | |

| Maximum Pressure of System | ≈16mpa(vertical type overturn cart) | |

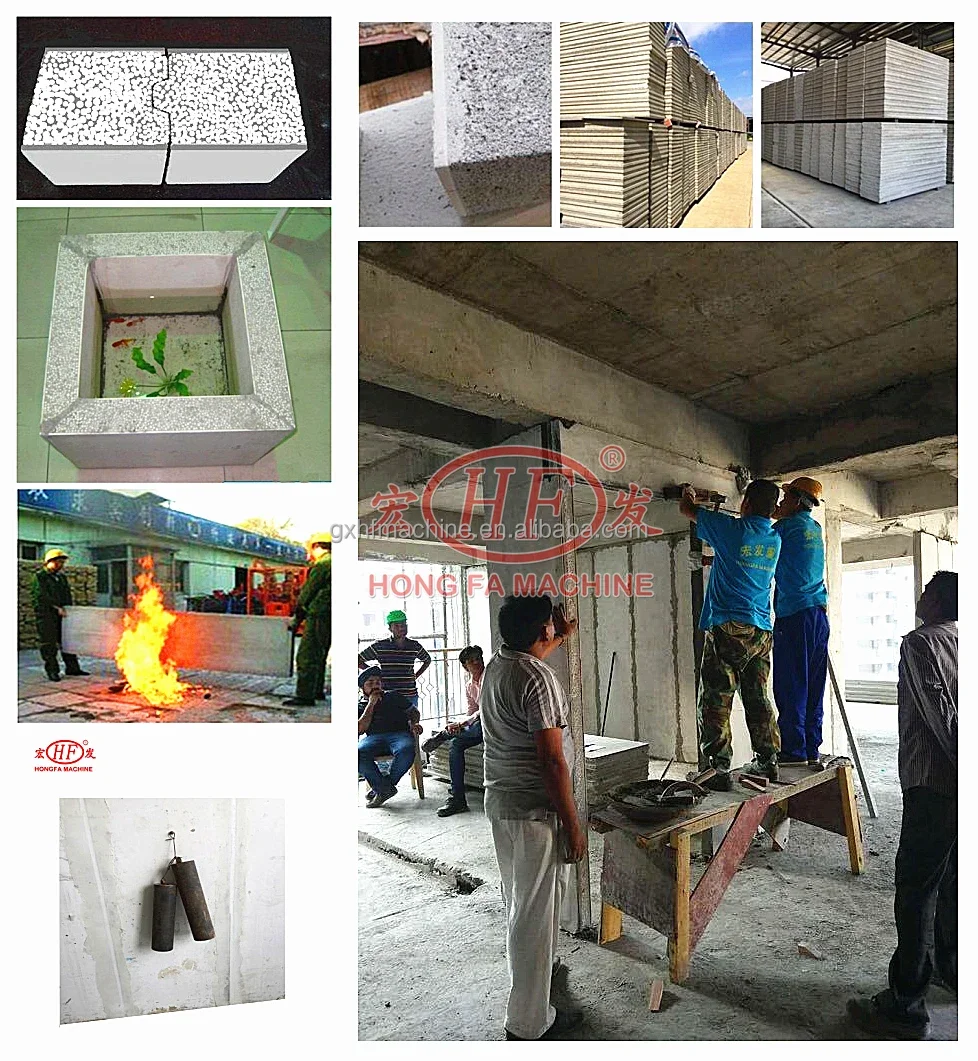

Light weight wall panel application projects for reference

Light weight wall panel characteristics

1.Light weight---60mm thickness, about 55kg/m2

2.Excellent thermal conductivity---≤1.45 W/(m2·k)

3.Reputable sound insulation

4.Easy to cut and saw for any size and shape

5.High anti-impact capacity

6.High construction speed

7.Labor saving

8.Low investment

9.High output capacity: from 100,000m3 to 300,000m3 Annual output

In Ukraine

In Ukraine

Hongfa Strengths

1)More than 30 years experience. 1500 employees (50+engineers)

2) Total 4 factories with 440,000m² and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

Packaging and shipment

Packing: Naked packing or stretch film packing or according to customers' requirements(We will send machine with plastic film package,parts with wooden case,if need, fumigation wooden carton also available.)

Delivery time: Within 25 days after receipt of deposit and moulds confirmation from buyer(Flexible Delivery Way:FCL sailing or LCL sailing,Air Transportation,parts or document with express delivery.)

1.Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

2.We will provide you with a set of spare parts for free!

3.We can supply EXW(Ex Works),FOB Qingdao(We deliver the machine to Qingdao port,China),CIF(cost+invoice+freight charge to your port)service.

T/T 30% as deposit, 70% balance payment before delivery. Or 100% L/C at sight.

20-28 days after receiving your deposit and mould comfirmation.

We strictly operate full QC process during production, and each machine will be tested before delivery.

All our machines are guaranteed for 1 year after-sales service,lifelong maintenance.

Internal Partition Wall Panel Machine Insulation wall panel Production Line cheap precast house building fast construction

Internal Partition Wall Panel Machine Insulation wall panel Production Line cheap precast house building fast construction

Похожие товары

CBS штамповочный пресс для металлических отверстий гидравлический станок алюминиевой опалубки

Двойной ленточный пресс планшетный ламинатор для машины сэндвич-панели PU

Популярный размер 80 мм 90 110

200 мм-600 мм ширина Регулируемый перфорированный кабельный лоток рулонная машина

CBS/CGMA CNC машина для прямой резки с питателем алюминиевой опалубки полностью автоматическая точность алюминиевого профиля

CBS сверхмощный Автоматический полировальный станок для алюминиевой опалубки

CBS алюминиевые опалубочные ролики лакировочная машина автоматическая для нанесения покрытия

Новые поступления

Новинки товаров от производителей по оптовым ценам