Пользовательские высокое качество SA 3d Полимерная печать служба Abs Pla пластиковая Аниме Фигурка цифровые коллекционные

- Категория: >>>

- Поставщик: Ningbo Dano Intelligence Technology Co. Ltd.

Сохранить в закладки 1601200865352:

Описание и отзывы

Характеристики

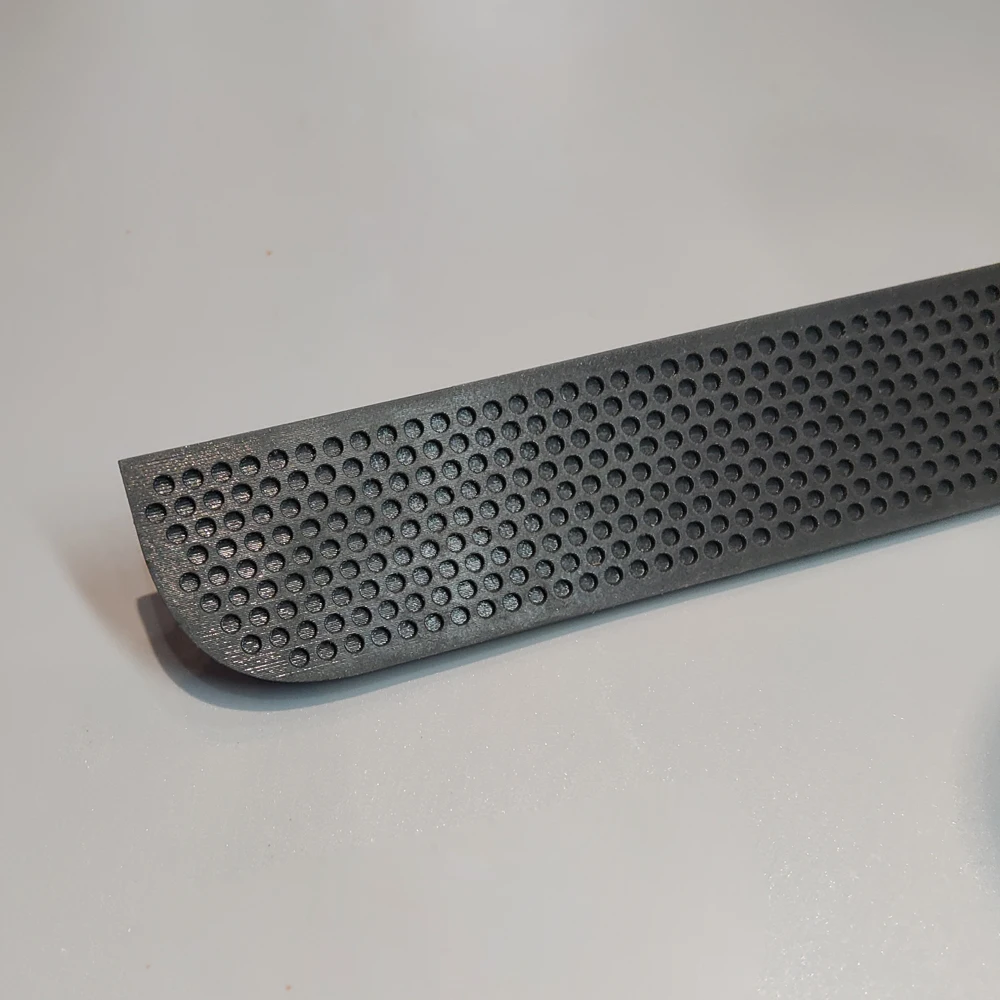

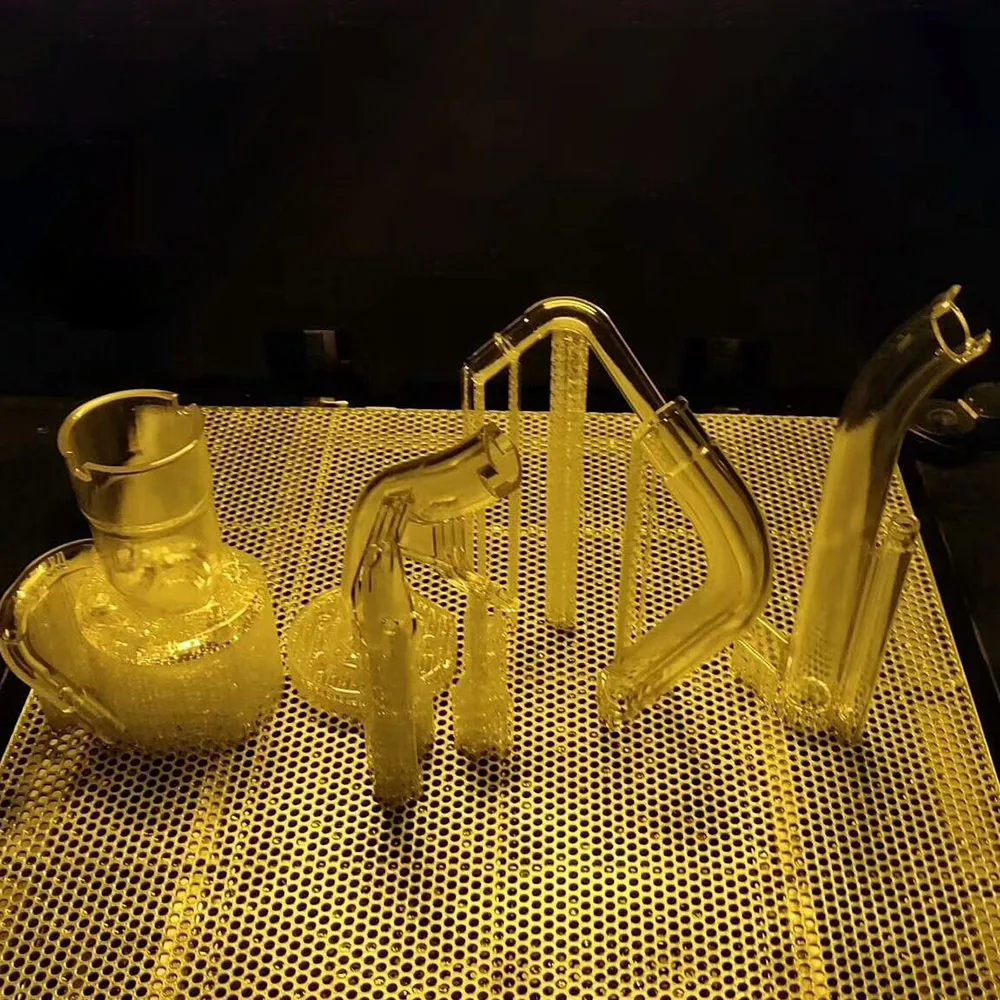

SLA 3D printing creates highly precise parts with a smooth surface texture.

Rapid Prototyping: SLA prototyping is a fully-functional prototype, with materials that can simulate polypropylene, polycarbonate, ABS, and rigid composites.

Direct Digital Manufacturing: The high accuracy and consistency of SLA makes it an ideal way to build large quantities of discrete or customized parts.

How does SLA work?

Here is how the SLA fabrication process works:

1. The build platform is first positioned in the tank of liquid photopolymer, at a distance of one layer height for the surface of the liquid.

2. Then a UV laser creates the next layer by selectively curing and solidifying the photopolymer resin. The laser beam is focused in the predetermined path using a set of mirrors, called galvo. The whole cross sectional area of the model is scanned, so the produced part is fully solid.

3. When a layer is finished, the platform moves at a safe distance and the sweeper blade re-coats the surface. The process then repeats until the part is complete.

4. After printing, the part is in a green, no-fully-cured state and requires further post processing under UV light if very high mechanical and thermal properties are required.

The liquid resin is solidified through a process called c: during solidification, the monomer carbon chains that compose the liquid resin are activated by the light of the UV laser and become solid, creating strong unbreakable bonds between each other.The photo polymerization process is irreversible and there is no way to convert the SLA parts back to their liquid form: when heated, they will burn instead of melting. This is because the materials that are produced with SLA are made of thermoset polymers, as opposed to the thermoplastics that FDM uses.

Materials

| Material Name | Description | Flexural Strength (MPa/KSI) | Elongation at Break (%) | HDT#0.46 MPa (°C) |

| Accura ClearVue | Clear/Translucent, PC-like | 67 MPa/KSI | 7% | 46°C |

| Somos Watershed Black | Black/Dark-Grey, ABS-like | 69 MPa/KSI | 15% | 50°C |

| Somos WaterShed XC 11122 | Clear/Translucent, | 69 MPa/KSI | 15% | 50°C |

| Somos EvoLVe 128 | White, | 70 MPa/KSI | 11% | 52°C |

| Accura Xtreme Grey | Grey, | 71 MPa/KSI | 22% | 62°C |

| Somos ProtoGen 18420 | White, | 71 MPa/KSI | 16% | 47°C |

| Somos Taurus | Dark Gray, | 74 MPa/KSI | 24% | 62°C |

Size and Tolerance

| Description | Standard Resolution | High Resolution |

| Build envelope | 29” x 25” x 21” | 10” x 10” x 10” |

| Tolerance, XY Plane | +/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter. | +/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

| Tolerance, Z Plane | +/- 0.010” for the first inch is typical, plus +/- 0.002” for every inch thereafter. | +/- 0.010” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

| Layer height | 0.004" | 0.002" |

| Minimum linear feature size | Under 0.030” are at risk and under 0.020” will not build. | Under 0.020” are at risk and under 0.010” will not build. |

| Minimum radial feature size | 0.035" | 0.030" |

Surface Treatment

Applications in Prototype

Applications in Life

Company Profile

DANO Intelligent Technology

DANO is a Design and Engineering company from your concept stage to prototyping and fabrication of the completed product with injection molding.

Our main focus is to help all the small and big sized companies to turn their dream projects into reality. We work very closely with our clients and strive to give them the best services at all times. Our 3D printing equipment includes SLA SLS, HP MJF machines and metal 3D printer.

With multiple years of experience and with an impressive portfolio. We are your partner in production, we process your project all the way from Zero to hero. We make all projects possible. Getting your idea valued, designed, tested, prototyped or manufactured shouldn’t be a long and dawning process.

We want to offer the future of rapid prototyping and additive manufacturing. A process that is fast, reliable, easy and supportive. We make this with a few things in mind: precision, timely delivery, low cost structure.

From Idea to Reality.

Surface Finishes Operation Site

Our Services

Question & Answer

What is the average turn around for 3D printed parts?

Can you expedite rush orders of custom parts?

--Yes, we can accomodate to rush orders and expedited delivery for your custom parts.

What 3D printing materials and technologies do you offer?

--We can produce parts in FDM, PolyJet, Stereolithography, Origin One (P3 Technologies), and SAF (Powderbed Fusion) technologies.With access to over 50+ different material options.

Is there a minimum order amount required?

--No, there is not.

What type of files do I need to prepare for print?

--Native CAD, STL, 3MF, STEP and IGES.

you can 3D print are:

* Aircraft Bracket

* Pump Impeller

* Sprocket

* End Effector

* Soft Jaws

* Welding Fixture

* CMM Fixture

* Assembly Jig

* Brake Lever

* Metal Bracket

* Stainless Steel Clevis

* Motor Housing

* Engine Block Model

* Oil Pan

* Gear Set

* Spaceship Model

* Vase

* Jewelry

* Water Bottle

Похожие товары

Высокоточная модель кровеносных сосудов, цветная прозрачная силиконовая медицинская модель из смолы, 3D-печать

Красивая 3D-печать, точная обработка, модель продукта, а не микрообработка, ЧПУ, пластик/металлический прототип обработки

OEM точный пользовательский токарный станок с ЧПУ, фрезерный станок, анодирование металла, латуни, алюминия, обработанные детали

Горячая распродажа, 3D-печать на заказ, быстрый прототип, металлическая часть, CNC, услуги по обработке смарт-цифровых запасных частей

OEM параллельные захватные пальцы зажимные приспособления пользовательские захватные Пальцы для пневматической автоматизации

Индивидуальные услуги Oem, алюминиевая сталь, латунь, прецизионная обработка ЧПУ для деталей оборудования

VDI магнитный инструмент Алюминиевый держатель полосы DIN 69880 форма E7 комбинированный токарный фрезерный станок

Новые поступления

Новинки товаров от производителей по оптовым ценам