9 дюймов одноосный качественный червячный привод поворотный для солнечного трекера круг экскаватора

- Категория: >>>

- Поставщик: Xuzhou Fenghe Slewing Bearing Co. Ltd.

Сохранить в закладки 1601201877646:

Описание и отзывы

Характеристики

slewing bearing also known as slewing ring bearing,turntable bearing.It contain outer ring,inner ring,rolling body,seals.The material of our products are generally high alloy-structural steels ,such as 42CrMo 50Mn.The slewing bearing can work normally at a temperature of -30℃ to +70℃,and we can design special type as customer need.

| Type of slewing bearing | single row ball slewing bearing double row ball slewing bearing three row roller slewing bearing single row cross roller slewing beariing double line ball slewing bearing ball and roller combined slewing bearing |

| Outer diameter | 280mm-4726mm |

| Inner diameter | 120mm-4272mm |

| Gear | External Gear,Internal Gear,No Gear |

| rolling element | Ball or Roller |

| Brand | FengHe |

| Material | 42CrMo,50Mn |

FH slewing bearing is a key mechanical transmission component, widely used in various heavy machinery and industrial machinery. Its main function is to support and rotate the mechanical structure, bearing weight and rotational force. Slewing bearing is usually composed of inner and outer rings and rolling elements, and high strength and wear resistance are ensured through precision machining and heat treatment.

FH slewing drive is a key component used in rotating mechanical structures, usually composed of a motor, a reducer, a slewing bearing and a transmission chain. Its main function is to achieve the rotation of mechanical equipment through an electric or hydraulic system. The slewing drive is widely used in various engineering machinery, construction machinery, port machinery and other fields, such as excavators, tower cranes, container cranes, etc.

Choose us, 20 years of custom processing experience at your service, strict quality control, professional team to provide technical support, tailor-made products, quick response to customer needs, to ensure high quality and excellent service.

The quality control of slewing bearings includes material inspection, processing monitoring, size and hardness testing, surface inspection, performance testing, anti-rust treatment and packaging inspection to ensure high quality.

The processing flow of slewing bearings includes: raw material preparation, forging, rough machining, heat treatment, finishing, drilling, assembly, inspection and testing, painting, and packaging.

Похожие товары

Литиевая батарея портативное радио с зарядкой ваш телефон аварийное рукоятка солнечная перезаряжаемая радиостанция для продажи

Система монтажа панели солнечных батарей алюминиевая рельсовая монтажная конструкция для Комплект рельсов по индивидуальному заказу

Pv bipv распределительная коробка настраиваемый заводской прямой PV солнечный комбайн

Кабельные зажимы из нержавеющей стали

CS01 360 градусов вращающийся черный держатель для камеры с креплением на винт солнечной панели охотничьей Универсальный

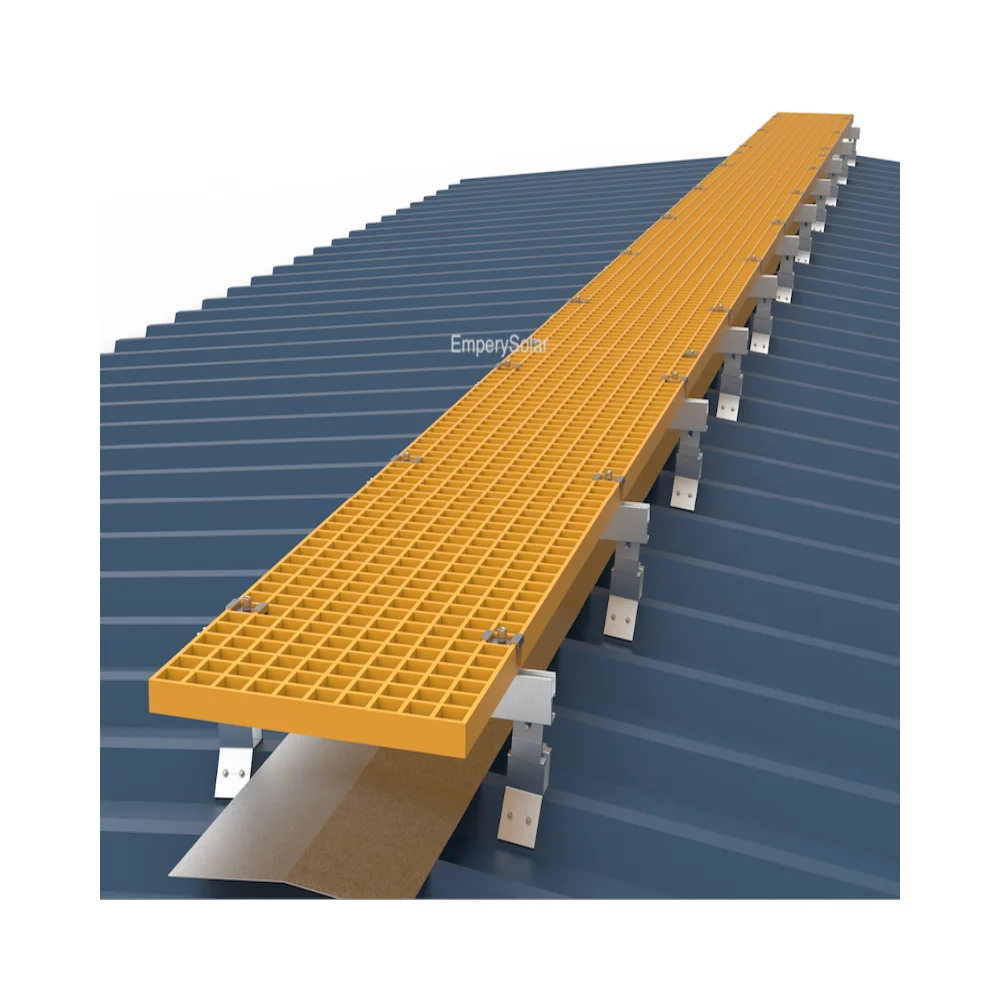

Заводская оптовая цена 25 мм * frp решетка ступней из стекловолокна для дерева дорожки горячее погружение

Индивидуальная конкурентоспособная цена высокое качество IP65 4 6 8 10 12 16 24 канала система солнечных батарей постоянного тока блок совмещения гирлянд для солнечной энергии

Новые поступления

Новинки товаров от производителей по оптовым ценам