160 бар 316L нержавеющая сталь 3 клапан коллектор для передатчика перепада давления

- Категория: >>>

- Поставщик: Chongqing Weiyun Technology Development Co. Ltd.

Сохранить в закладки 1601202166486:

Описание и отзывы

Характеристики

Product Description

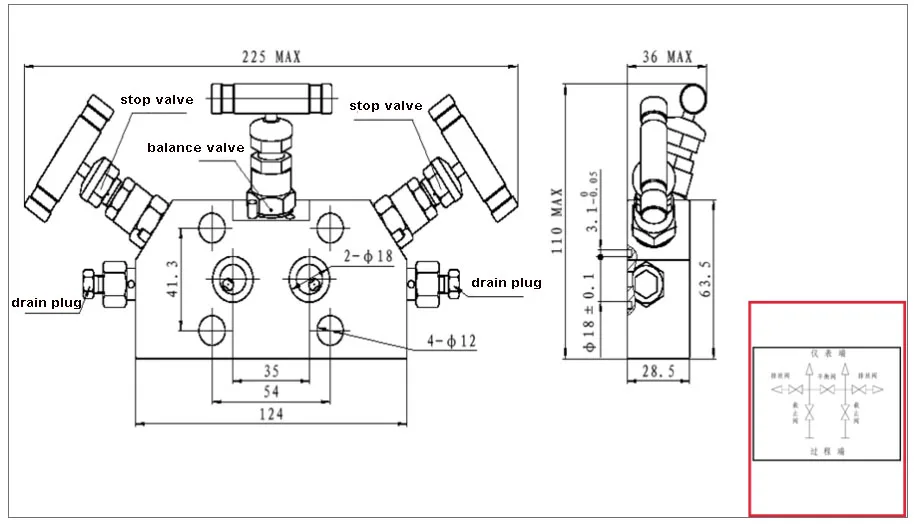

High Pressure 3 Manifold Valve

Integrated structure, safe and reliable;

Using stainless steel pins to prevent valve seats from falling off due to vibration;

Burr free threads and inner surfaces reduce leakage and ensure instrument accuracy;

Structure Feature

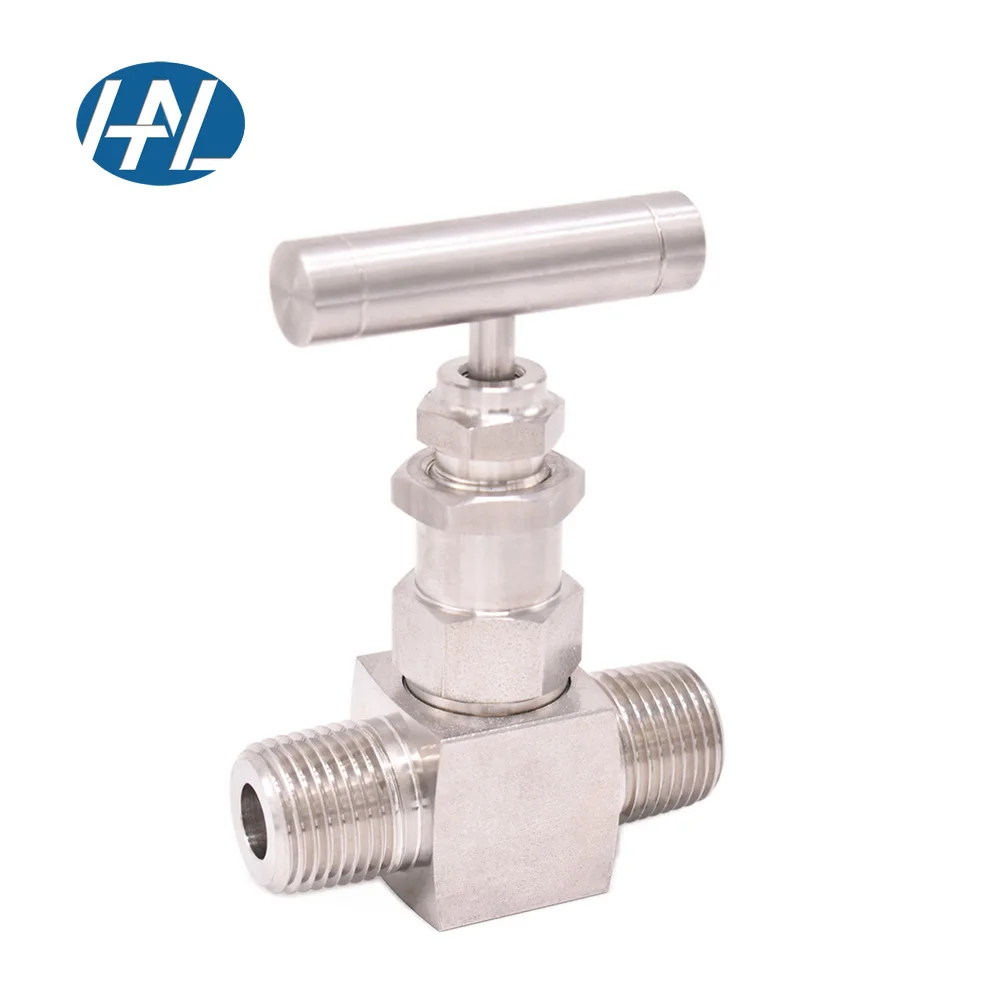

1. Handle with anti retreat screws for better torque transmission.

2.Blue, green, and red dust covers are used to distinguish globe valves, balance valves, and drain/test valves, and to prevent dust and impurities from entering the valve stem and affecting sealing.

3.Compression nut is used to push and compress the packing, causing it to deform and expand, forming a seal with the valve stem and valve seat. When there is slight leakage, it can also be used for secondary or multiple adjustments.

4.The valve stem adopts rolling thread to improve the surface hardness of the thread, making it more wear-resistant and extending the service life of the valve stem.

5.Lock the nut to provide reliable locking force and prevent the packing from losing its sealing function due to vibration loosening of the clamping nut.

6.The sealing part of the valve stem is processed by extrusion, with a surface roughness of Ra0.1, which reduces friction with the packing and improves the service life of the valve stem and packing.

7.Metal washers provide no rotational thrust and reduce packing damage caused by rotational friction.

8.Design PTFE/flexible graphite packing to prevent medium from entering and corroding valve stem threads.

9.When the valve is fully open, the back conical surface of the valve stem forms linear contact with the valve seat, providing auxiliary sealing for the valve stem.

10.Dual phase steel cone head, improving higher hardness and avoiding damage to the cone head after multiple uses; The tail ball head design provides non rotating push pressure, and the head cone design makes the valve body hole shape sealed.

Specification

item | 3 value Manifold |

Type | High Pressure |

Customized support | OEM, ODM, OBM |

chongqingPlace of Origin | chinqing |

Model Number | wingoil |

Application | High Pressure |

Temperature of Media | High Temperature, ,Medium Temperature, Normal Temperature |

Media | Water,oil ,gas |

Port Size | customized |

Structure | Needle |

Packing & Delivery

Wooden case

Company Profile

FAQ

1. who are we?

We are based in Chongqing, China, start from 2010,sell to Domestic Market(50.00%),Southeast Asia(30.00%),Mid East(11.00%),North America(4.50%),Northern Europe(4.50%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Pressure Test,Oil Exploration,Oilfield service,customized manufacturing,OEM

4. why should you buy from us not from other suppliers?

*expertise engineers and technician in the field of oilfield test and logging equipment; *professional sales & service team; *Independent intelligence property right and technical patent; *Cooperation with western known company like Maximator in Germany.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese

We are based in Chongqing, China, start from 2010,sell to Domestic Market(50.00%),Southeast Asia(30.00%),Mid East(11.00%),North America(4.50%),Northern Europe(4.50%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Pressure Test,Oil Exploration,Oilfield service,customized manufacturing,OEM

4. why should you buy from us not from other suppliers?

*expertise engineers and technician in the field of oilfield test and logging equipment; *professional sales & service team; *Independent intelligence property right and technical patent; *Cooperation with western known company like Maximator in Germany.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese

Похожие товары

3000psi6000 PSI штекерное соединение Npt регулируемые клапаны из нержавеющей стали мини-мужские прямые Игольчатые

Регулируемый высокотемпературный J24W-160P из нержавеющей стали DN6 DN10 DN15 L-Type прямоугольный сварочный игольчатый клапан газовая гидравлическая мощность

651,39 ₽ - 717,63 ₽

Игольчатый клапан из нержавеющей стали с микрорегулировкой угла расхода

Настраиваемый высокочистый Регулируемый резьбовой игольчатый клапан из нержавеющей стали

154,57 ₽ - 165,61 ₽

Регулируемый игольчатый клапан J24W-160P DN6 DN10 DN15 нержавеющая сталь высокая температура правый угол сварки l-типа

651,39 ₽ - 717,63 ₽

Модель USUN: HI60121-NO 60 K psi высокого давления нормальный открытый воздух игольчатый клапан для нефтегазовой промышленности

79 490,60 ₽ - 81 698,67 ₽

HNV 316l нержавеющая сталь 3000psi клапан регулировки потока запорный 1/2npt прямой через Двойные наконечники игольчатый

3 312,11 ₽ - 4 305,75 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $