Индивидуальные усовершенствованные керамические циркониевые прецизионные структурные части циркониевая керамическая часть

- Категория: >>>

- Поставщик: Shenzhen Hanbao Technology Co. Ltd.

Сохранить в закладки 1601202294347:

Описание и отзывы

Характеристики

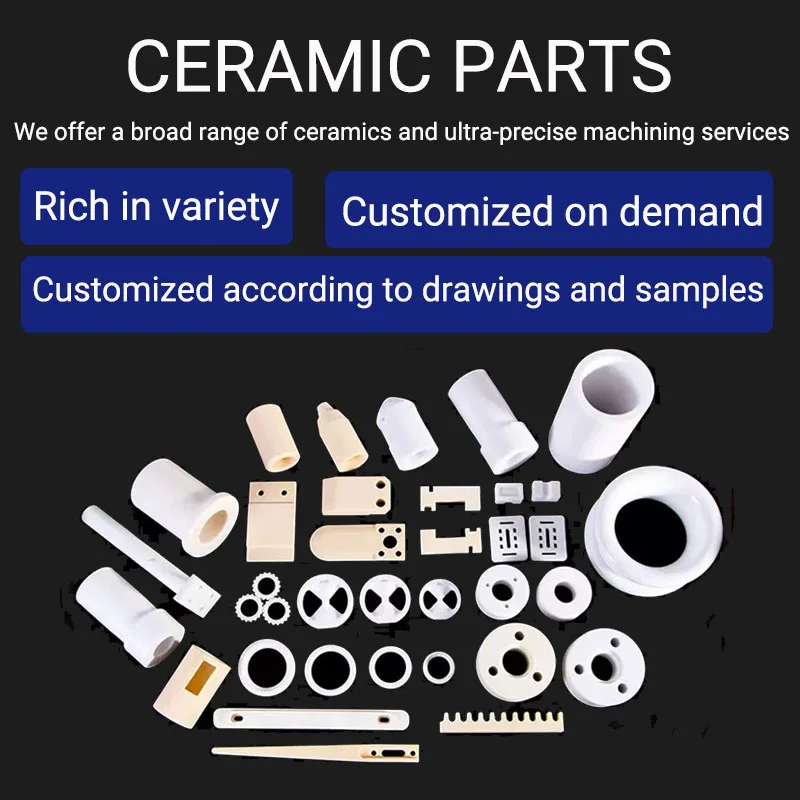

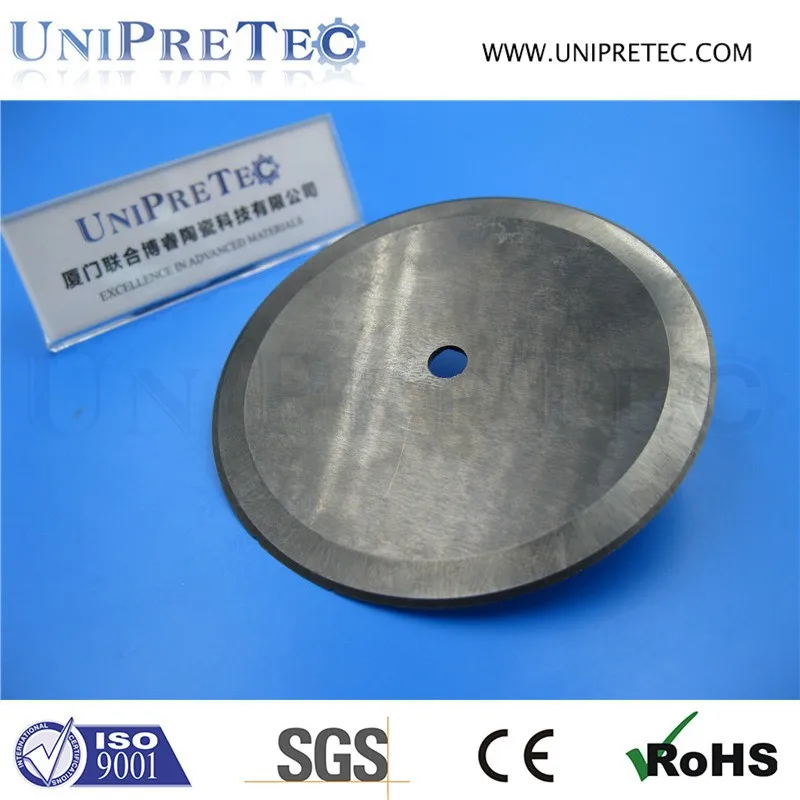

High Hardness Technical Ceramics Shop Online ZrO2 customized part ceramic Structure Zirconia Ceramic Parts

Products Description

Zirconia Material Properties | ||||

Name | Zirconia (ZrO2) Ceramic Parts | |||

Material | ZrO2 Ceramic | |||

Specification | According to customer needs | |||

Technology | Dry pressing, grouting, extrusion, cold isostatic pressing, injection, casting, hot pressing and hot isostatic pressing etc. | |||

Mechanical Properties | Density | 5.7-6.07 g/cm3 | ||

Compressive Strength | 2000-2100 MPa | |||

Fracture Toughness KIC | 8-17 MPa m1/2 | |||

Flexural Strength | 1000-1400 MPa | |||

Young’s Modulus | 200 GPa | |||

Poisson’s Ratio | 0.3 | |||

Hardness | 13-14.5 GPa | |||

Thermal Properties | Thermal Shock Resistance ΔT | 250 °C | ||

CTE2 25°C ➞ 400°C | 10 10-6/K | |||

Maximum Temperature (Inert) 1 | 1000 - 1500 °C | |||

Thermal Conductivity @ 25°C | 2-3 W/mK | |||

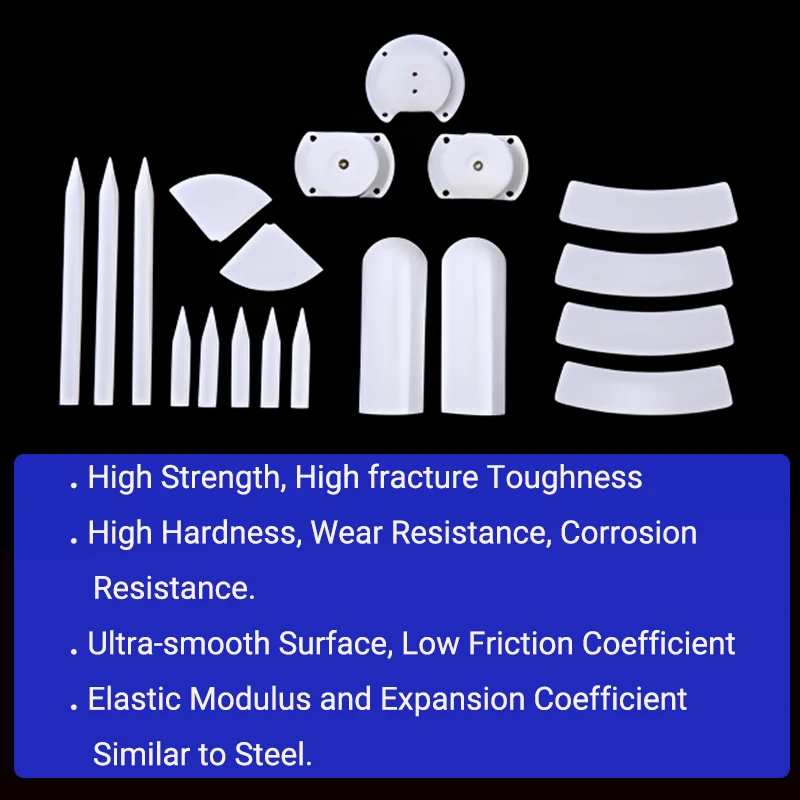

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials.

Dubbed ‘ceramic steel’, Zirconia (Zro2) ceramic offers a combination of high hardness, wear and corrosion resistance, while exhibiting one of the highest fracture toughness values among all ceramic materials.

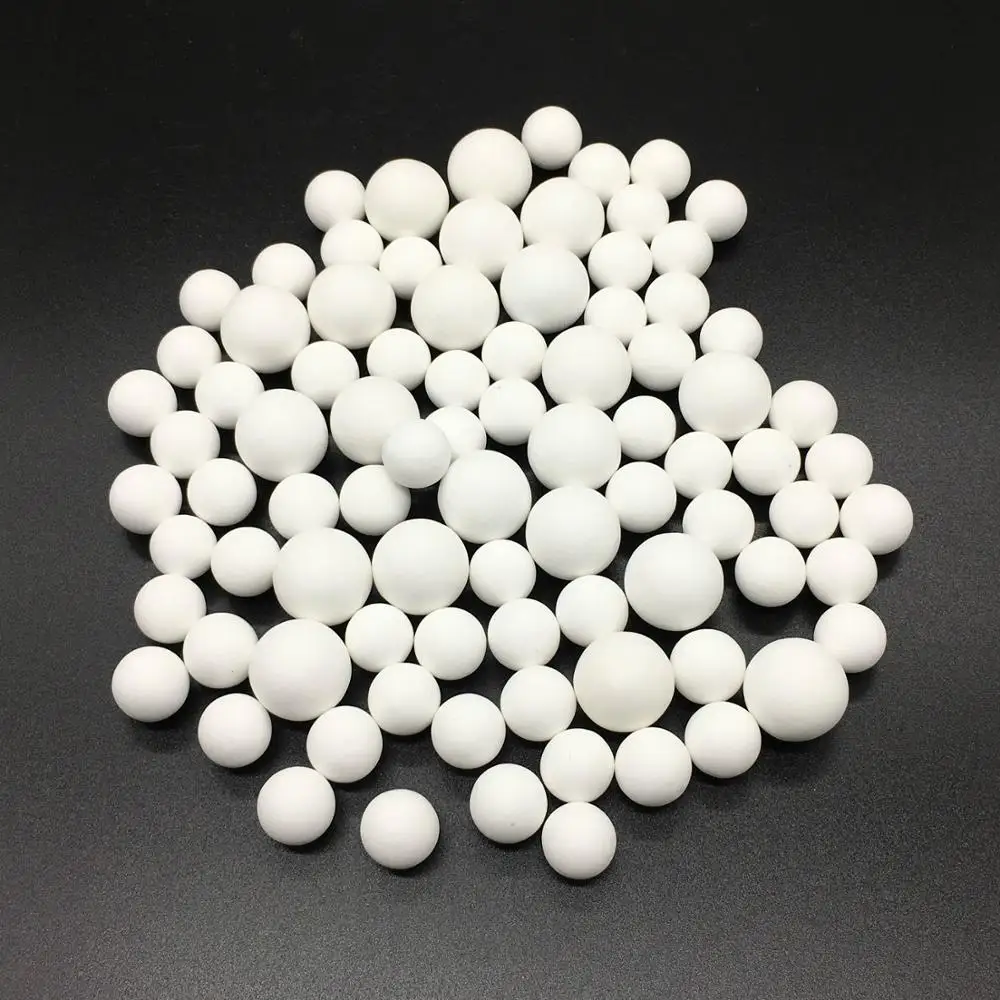

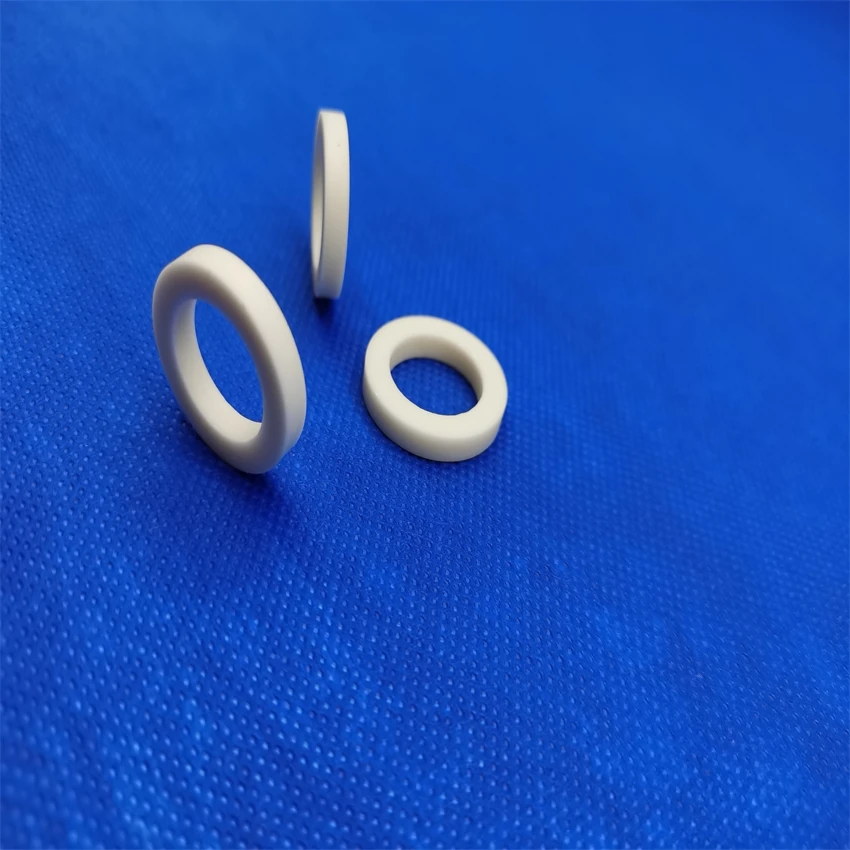

Zirconia (ZrO2) Ceramics Parts has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on.

Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on.

Contact Us

Email : dana@hanbkj.com

Whatsapp : +8615217030809

Wechat : Dana-g16

Wechat : Dana-g16

Company Profile

About Our Company

Shenzhen Hanbao Technology Co., Ltd. is a precision ceramic manufacturer.

1.We offer this expertise to all of our customers to ensure the best design and materials are chosen for their specific application and needs.2.We offer a broad range of ceramics and ultra-precise machining services to rapidly produce custom components.

3. High-quality & accurate parts are essential to our customers

3. High-quality & accurate parts are essential to our customers

FAQ

Q: Can you produce according to the samples or drawings? |

A:Surely, Our ceramic parts can be customized as your need or drawings. |

Q: Do you supply or work with other materials that are not listed on your website? |

A: Precision Ceramics is unusual as we offer the full range of technical ceramics from machinable grades like Macor and Shapal through to materials that require diamond grinding like alumina, zirconia, carbides and nitrides. We can machine and supply virtually any ceramic material – please contact us with your specific requirements for more nformation. Our goal it to optimize the material selection and design for the customer, rather than what is right for our capability. |

Q: Can you help me with material selection and design of ceramics? |

A: Yes we can. We have a competent team of technical sales staff with many years experience that can help you chose the right material. Whether it is for wear, thermal management, electrical properties or something else, we can help you by designing an appropriate component for ceramic manufacture from simple suggestions to more complex solutions. Contact us with details of your application and one of our engineers will be happy to help you. |

Q: What are technical ceramics? |

A: There are several different types of ceramics, with technical ceramics (also known as engineered ceramics or advanced ceramics) being the group with the highest performing mechanical, electrical, and/or thermal properties. Their high performance is due in part to their extremely high purities which are most commonly metal compounds combined with oxides, carbides, or nitrides. Ceramics have the ability to increase product lifespan, increase efficiency, reduce overall maintenance costs, and improve performance. |

HOME

Get a Free Quotation via Us >>> Go

Похожие товары

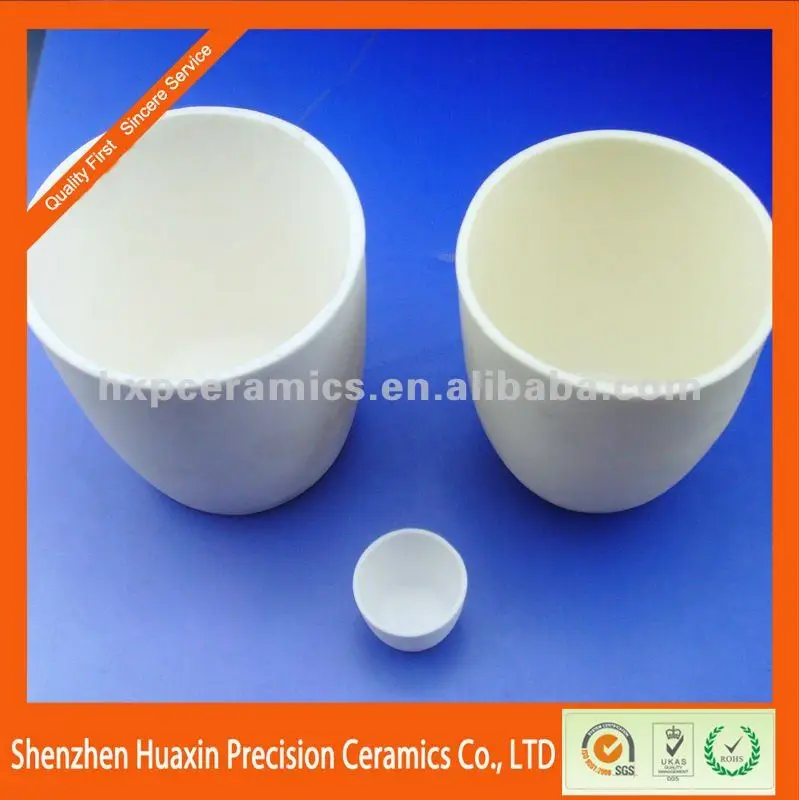

Лабораторное плавление, используемое в сплавленном кремнезе/кварце/тигель SiO2/чаша

Alsint C799 Al2o3 99.7% 99% глиноземный керамический тигель для стеклянного плавильника

Горячее прессование спеченное 99.7% Al203 алюминиевое керамическое распорное

12,00 $ - 15,00 $

Лучшая твердость высокое качество керамическая трубка стержень трубы ролики

Сигареты с фильтром режущий инструмент для табак промышленности / высокая твердость / из циркониевой керамики

Высокоэффективная инфракрасная сотовая керамическая пластина для

высокая термостойкость керамические/высокого глинозема керамический тигель

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $