Игольчатые подшипники с внутренней втулкой rna4919 rna4920 rna4922 axz84061 Упорный игольчатый подшипник rna49 16x20x8

- Категория: >>>

- Поставщик: Timson Power Technology (shanghai) Co. Ltd.

Сохранить в закладки 1601202781618:

Описание и отзывы

Характеристики

Product Description

needle bearings

Needle bearings, also known as needle roller bearings, are a type of roller bearings used to reduce friction between moving parts. They are designed to have a high length-to-diameter ratio and can carry heavy radial loads with relatively small cross-sections.

The needle bearings consist of cylindrical rollers, known as needle rollers, within a thin outer ring. These rollers have a small diameter in proportion to their length, which allows them to support high radial loads while occupying minimal space. This design is particularly useful in applications where space is limited or where high radial loads need to be accommodated.

One of the key advantages of needle bearings is their ability to handle high radial loads in a compact design. This makes them ideal for use in various applications, including automotive transmissions, industrial machinery, and power tools. Needle bearings are commonly used in applications where the load is primarily radial and the housing bore is limited in size.

In addition to their high load-carrying capacity and compact design, needle bearings offer other benefits as well. These bearings have low friction levels, which helps to reduce energy consumption and operating temperatures. They also have a high wear resistance and operate smoothly at high speeds.

Needle bearings come in various designs, including drawn cup needle roller bearings, solid needle roller bearings, and caged needle roller bearings. Each design has its own set of characteristics and is suitable for different applications.

Drawn cup needle roller bearings have a drawn outer shell that serves as a raceway for the rollers. These bearings are compact and have a high load-carrying capacity. Solid needle roller bearings do not have an outer ring and rely on the shaft as a raceway. They are suitable for applications with limited space.

Caged needle roller bearings have a cage that retains the rollers and separates them, allowing for smooth rotation and even distribution of load. This design helps to prevent the rollers from contacting each other, which can result in increased wear and reduced efficiency.

Needle bearings are essential components in various mechanical systems, providing high load-carrying capacity, low friction, and compact design. Their versatility and performance make them ideal for a wide range of applications across industries.

needle roller bearing | needle bearing fc69423.10 | axial needle bearing ax inner diameter 6 outer d14 | 19ym3607vh needle roller bearing | needle roller bearing 20x42x18 mm |

needle bearings | 20x26x15 needle bearing | needle bearing plastic needle bearing | linear needle roller bearing | nk14 12 needle roller bearing |

automotive needle roller bearing | steering needle bearing | needle bearing nk10/16 with inner ring needle roll | flat cage needle bearing | rna4905 needle bearing Игольчатый подшипник |

22x28x16 needle bearing 3 | toyota needle bearing | isuzu needle bearings roller bearing | 17mm needle bearing clutch | audi automatic transmission needle bearing |

needle roller linear bearings | needle bearing kt 202417 | needle roller bearing hk 812 2rs bearing | k38x43x13 needle cage bearing | 070 090 chainsaw needle bearing |

needle bearings 180x166x65 | needle roller bearing 4017 | bearing needle | k384313nsk needle cage bearing | k 35x47x20 needle bearing k354720 |

needle roller bearings cage 12x16x10 | needle bearing cage k158x166x40 | bajaj needle bearing | needle bearing sizes f | flat cage needle roller bearing |

needle bearing tvs king | thrust needle roller bearing | needle bearing bk1616 | needle bearing neck spindle | trust needle bearing ax6 14 |

needle bearing nkia 59/22a | needle bearing bk1616 22x16x16 | needle bearing 46x73x24 | needle roller bearing 32ym4020p | needle roller bearing te hv5212715 |

linear flat cage roller needle bearing | transmission gearbox needle bearing | 15x12x15 needle bearing | needle bearing 15x30x9 5 | drawn cup needle roller bearing |

dz series textile spindle neck bearing dz1 needle | ntn needle bearing k127x120x34 | needle bearing k127x120x34 | ba needle roller bearing | automatic needle bearing assembly machine |

needle bearing supplier | excavator needle roller bearings | needle bearing cage | needle bearings pillow blocks | needle roller bearing 35 mm |

needle roller bearing hn 122012 | bh 108 needle bearing | ceramic needle bearing | db 76553 needle bearing | chain saw 15x12x15 needle bearing |

needle bearing inner ring complement | needle roller bearing 13x19x14 | needle bearing f230627 | 20x26x14 needle roller bearing | needle bearing sce610-pp |

ina bearing needle bearings | needle roller bearing k | needle cage bearing | needle roller bearing ta5520z | f-226399 needle bearing |

needle bearing nk162712 | needle roller bearing for toyota | plastic needle bearing | nc 250 needle bearing | nta 1625 needle thrust bearing |

needle bearing pins | starter motor needle roller bearing | rna4905 needle bearing | pump needle roller bearing | m5 x 18mm needle bearings |

connecting rod needle bearing | needle roller bearing 30x38x18 mm | gearbox needle bearings | needle bearing aj 502515 | needle bearing for fishing reel |

needle roller bearing 1612 | cat pump needle roller bearing | motor needle bearings | heidelberg hk1210 needle bearing | linear flat needle roller bearings |

nk 32/20 needle bearing | needle roller bearing hk 4020 | hf0812 needle bearing | needle roller bearing na1020 | needle roller bearings with inner sleeve |

split cage needle roller bearing | hk202918 rs needle roller bearing | bearing needle roller | hk 455538 needle bearing | axz84061 thrust needle bearing Игольчатый подшипни |

needle roller bearing with sleeve | needle roller bearings for caster | k152012 needle bearing | flat needle roller bearing | bearing needle automatic transmission audi 46x73x |

needle bearing k24x28x13 | full complement needle roller bearing hn2520 | linear needle bearing | 320d pump needle roller bearing | flat cage needle roller bearing triple |

needle thrust bearing | bmw 320i n46e91 model 2008 needle roler bearing | toyota needle bearing puller | plastic slide needle roller bearing | cat 320d pump needle roller bearing |

needle bearing 158x166x65 | bmw 320i n46e91 model 2008 needle roler bearing plas | thrust needle bearing ax816 | nk 305117 needl roller bearing | bearing hk20 single row needle roller |

needle roller bearing with inner ring | needle bearing nk10/16 with inner ring | 16 x 20 x 8 needle bearing | steel needle roller bearings 3mm diameter x 25mm len | |

connecting rod needle bearing rodamiento de agujas | nk150 35 needle roller bearing Игольчатый подшипни | hk323924-needle-roller-bearing | trust needle bearing ax inner diameter 6 outer d14 | |

needles for bearing diameter 6mm long 24mm | drawn cup needle roller bearing open 3 | needle roller bearings with inner sleeve single ro | din 808-42-b25-156-dwcarbon steel bearing needle |

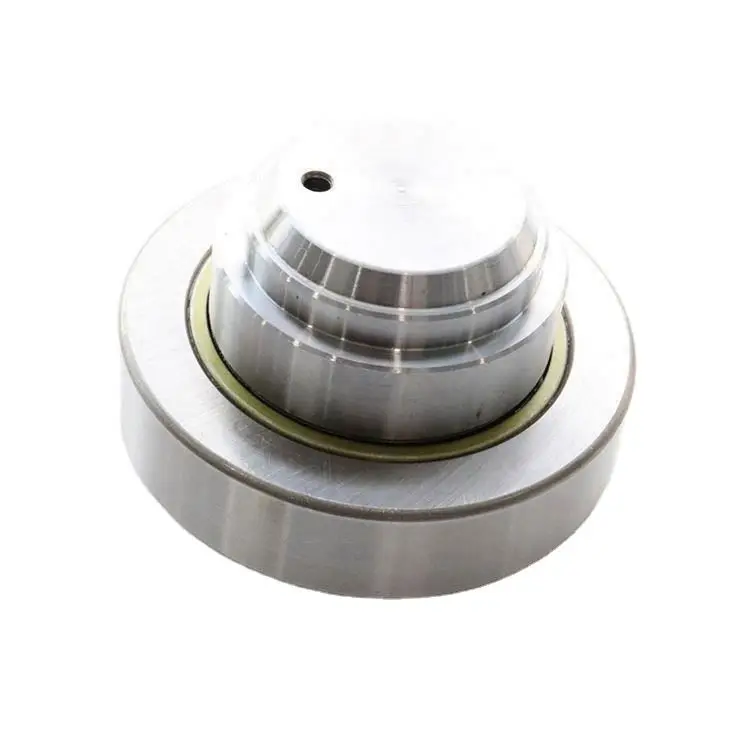

puller bearing tool

A bearing puller is a specialized tool used for removing bearings from a shaft or housing. It is designed to grip the bearing firmly and apply force in a controlled manner to pull the bearing out without causing damage to the surrounding components.

A typical bearing puller consists of a center bolt or threaded rod that passes through the center of the bearing and exerts force against the inner race of the bearing. The puller also has arms or jaws that grip the outer race of the bearing, providing stability and ensuring that the force is applied evenly.

Bearing pullers come in various sizes and designs to accommodate different types and sizes of bearings. Some pullers are designed for use with specific types of bearings, such as ball bearings, roller bearings, or tapered bearings.

A bearing puller is an essential tool for mechanics or technicians working with machinery and equipment that require regular maintenance or repairs involving bearings. It helps to facilitate the removal of bearings efficiently and safely, saving time and minimizing the risk of damage to the bearing or other components.

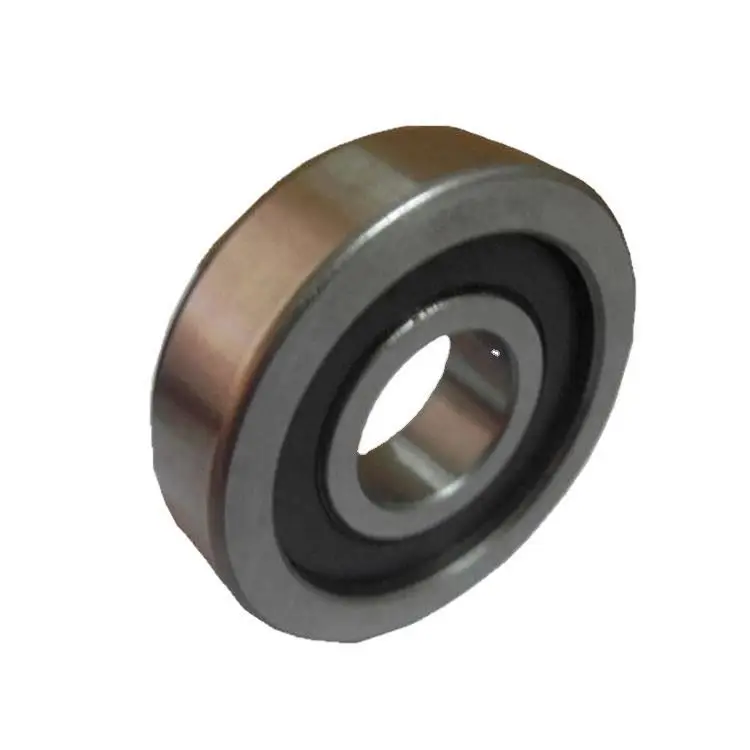

Deep groove ball bearing types

Deep groove ball bearings are mainly used to withstand radial loads, but they are also commonly used to withstand composite radial and axial loads. Especially when the speed of mechanical equipment is very high and it is not suitable to use thrust bearings, this bearing can be used to withstand bidirectional pure axial loads without maintenance during operation. It is a low-cost and widely used bearing.

The models of deep groove ball bearings include:

Deep groove ball bearing (60000 type);

Deep groove ball bearings with stop grooves on the outer ring (60000N type);

A deep groove ball bearing (60000-ZN type) with a dust cover on one side and a stop groove on the outer ring on the other side; Deep groove ball bearings with dust covers on both sides and stop grooves on the outer ring (60000-2ZN type);

Deep groove ball bearing with dust cover on one side (60000Z type);

Deep groove ball bearings with dust covers on both sides (60000-2Z type);

Deep groove ball bearings with sealing rings on one side (60000-LS type, 60000-RZ type);

Deep groove ball bearings with sealing rings on both sides (60000-2LS type, 60000-2RZ type);

Deep groove ball bearing with flange outer ring (F60000 type);

Deep groove ball bearing with flange outer ring and dust cover on one side (F60000-Z type);

There are 11 types of flange outer ring deep groove ball bearings (F60000-2Z type) with dust covers on both sides. [2]

The models of deep groove ball bearings include:

Deep groove ball bearing (60000 type);

Deep groove ball bearings with stop grooves on the outer ring (60000N type);

A deep groove ball bearing (60000-ZN type) with a dust cover on one side and a stop groove on the outer ring on the other side; Deep groove ball bearings with dust covers on both sides and stop grooves on the outer ring (60000-2ZN type);

Deep groove ball bearing with dust cover on one side (60000Z type);

Deep groove ball bearings with dust covers on both sides (60000-2Z type);

Deep groove ball bearings with sealing rings on one side (60000-LS type, 60000-RZ type);

Deep groove ball bearings with sealing rings on both sides (60000-2LS type, 60000-2RZ type);

Deep groove ball bearing with flange outer ring (F60000 type);

Deep groove ball bearing with flange outer ring and dust cover on one side (F60000-Z type);

There are 11 types of flange outer ring deep groove ball bearings (F60000-2Z type) with dust covers on both sides. [2]

According to the size of deep groove ball bearings, they can be divided into:

(1) Micro bearings - bearings with a nominal outer diameter size range of 26mm or less;

(2) Small bearings - bearings with a nominal outer diameter size range of 28-55mm;

(3) Small and medium-sized bearings - bearings with a nominal outer diameter size range of 60-115mm;

(4) Medium and large-sized bearings - bearings with a nominal outer diameter size range of 120-190mm

(5) Large bearings - bearings with a nominal outer diameter size range of 200-430mm;

(6) Extra large bearings - bearings with a nominal outer diameter size range of 440mm or more.Processing form

(1) Micro bearings - bearings with a nominal outer diameter size range of 26mm or less;

(2) Small bearings - bearings with a nominal outer diameter size range of 28-55mm;

(3) Small and medium-sized bearings - bearings with a nominal outer diameter size range of 60-115mm;

(4) Medium and large-sized bearings - bearings with a nominal outer diameter size range of 120-190mm

(5) Large bearings - bearings with a nominal outer diameter size range of 200-430mm;

(6) Extra large bearings - bearings with a nominal outer diameter size range of 440mm or more.Processing form

The processing form of deep groove ball bearing parts is as follows:

1. Multi process processing: Generally, bearing production requires 20-40 processes, with more than 70 processes.

2. Forming processing: The working surface of bearing parts is a rotary forming surface, suitable for processing using the forming method.

3. Precision machining: The vast majority of bearing parts require grinding on their surfaces, with grinding dimensions and geometric accuracy measured in micrometers

1. Multi process processing: Generally, bearing production requires 20-40 processes, with more than 70 processes.

2. Forming processing: The working surface of bearing parts is a rotary forming surface, suitable for processing using the forming method.

3. Precision machining: The vast majority of bearing parts require grinding on their surfaces, with grinding dimensions and geometric accuracy measured in micrometers

The tapered roller bearing Features and benefits

Low friction

The optimized roller end design and surface finish on the flange promote lubricant film formation, resulting in lower friction. This also reduces frictional heat and flange wear. In addition, the bearings can better maintain preload and run at reduced noise levels.

Long service life

The crowned raceway profiles of basic design bearings and the logarithmic raceway profiles of The tapered roller bearing optimize the load distribution along the contact surfaces, reduce stress peaks at the roller ends , and reduce the sensitivity to misalignment and shaft deflection compared with conventional straight raceway profiles .

Enhanced operational reliability

Optimized surface finish on the contact surfaces of the rollers and raceways supports the formation of a hydrodynamic lubricant film.

Consistency of roller profiles and sizes

The rollers incorporated in DIMSEN tapered roller bearings are manufactured to such close dimensional and geometrical tolerances that they are practically identical. This provides optimal load distribution, reduces noise and vibration, and enables preload to be set more accurately.

Rigid bearing application

A single row tapered roller bearing is typically adjusted against a second tapered roller bearing. By applying a preload, a rigid bearing application can be achieved.

Running-in period with reduced temperature peaks

Tapered roller bearings typically have a running-in period, during which a conventional design tapered roller bearing experiences a significant amount of friction, resulting in wear. This effect is noticed as a temperature spike . With tapered roller bearing designs, friction, frictional heat and wear are significantly reduced, provided the bearings are mounted and lubricated correctly.

Separable and interchangeable

The inner ring with roller and cage assembly can be mounted separately from the outer ring . Furthermore, the separable components are interchangeable. This facilitates mounting, dismounting and also maintenance inspection routines.

The optimized roller end design and surface finish on the flange promote lubricant film formation, resulting in lower friction. This also reduces frictional heat and flange wear. In addition, the bearings can better maintain preload and run at reduced noise levels.

Long service life

The crowned raceway profiles of basic design bearings and the logarithmic raceway profiles of The tapered roller bearing optimize the load distribution along the contact surfaces, reduce stress peaks at the roller ends , and reduce the sensitivity to misalignment and shaft deflection compared with conventional straight raceway profiles .

Enhanced operational reliability

Optimized surface finish on the contact surfaces of the rollers and raceways supports the formation of a hydrodynamic lubricant film.

Consistency of roller profiles and sizes

The rollers incorporated in DIMSEN tapered roller bearings are manufactured to such close dimensional and geometrical tolerances that they are practically identical. This provides optimal load distribution, reduces noise and vibration, and enables preload to be set more accurately.

Rigid bearing application

A single row tapered roller bearing is typically adjusted against a second tapered roller bearing. By applying a preload, a rigid bearing application can be achieved.

Running-in period with reduced temperature peaks

Tapered roller bearings typically have a running-in period, during which a conventional design tapered roller bearing experiences a significant amount of friction, resulting in wear. This effect is noticed as a temperature spike . With tapered roller bearing designs, friction, frictional heat and wear are significantly reduced, provided the bearings are mounted and lubricated correctly.

Separable and interchangeable

The inner ring with roller and cage assembly can be mounted separately from the outer ring . Furthermore, the separable components are interchangeable. This facilitates mounting, dismounting and also maintenance inspection routines.

industry bearing supplier

bearings buy

bearing balls

bearings buy

bearing balls

Bearing balls, also known as ball bearings or steel balls, are crucial components in many mechanical systems, particularly in industrial machinery and automotive applications. These small, spherical balls are typically made from steel, ceramic, or other materials and are designed to reduce friction and facilitate smooth rotation between two surfaces.

Bearing balls are used in various types of bearings, such as deep groove ball bearings, angular contact ball bearings, and thrust ball bearings. They are inserted between the inner and outer races of the bearing to support radial and axial loads, allowing for efficient movement of rotating parts.

The size and material of bearing balls can vary depending on the specific application requirements. Steel balls are the most common due to their durability and cost-effectiveness, while ceramic balls are preferred for high-speed and high-precision applications due to their lighter weight and resistance to corrosion.

abba linear guideway abba linear guide

A linear bearing slide is a mechanical component that facilitates linear motion between two surfaces, typically a stationary base and a moving carriage or platform. The slide consists of several components, including linear bearings that reduce friction and enable smooth and precise movement along a track or rail.

The linear bearings are usually ball bearings or roller bearings housed within a carriage that travels along a linear guide rail. The bearings allow for low friction movement in a single direction, preventing side-to-side or rotational movement. This configuration provides high precision and repeatability in applications requiring linear motion, such as in machine tools, automation systems, and robotics.

Linear bearing slides come in various designs and sizes to accommodate different load capacities, speed requirements, and environmental conditions. They are commonly used in industrial machinery, medical equipment, laboratory instruments, and other applications where precise linear motion is essential. Regular maintenance and proper lubrication are necessary to ensure the longevity and performance of linear bearing slides.

linear bearings

Linear bearings are mechanical components that allow motion in a straight line along a fixed axis. They are typically used in

various industrial applications to support and guide moving parts, such as in machinery, equipment, and automation systems. Linear

bearings help reduce friction and provide smooth and precise linear motion while supporting heavy loads. They come in different types, including ball bearings, roller bearings, and sleeve bearings, each offering specific advantages depending on the

application requirements. Overall, linear bearings play a crucial role in ensuring efficient and reliable linear motion in various

mechanical systems.

various industrial applications to support and guide moving parts, such as in machinery, equipment, and automation systems. Linear

bearings help reduce friction and provide smooth and precise linear motion while supporting heavy loads. They come in different types, including ball bearings, roller bearings, and sleeve bearings, each offering specific advantages depending on the

application requirements. Overall, linear bearings play a crucial role in ensuring efficient and reliable linear motion in various

mechanical systems.

used motorcycles ball bearing 11a

A motorcycle bearing is a crucial component in the motorcycle's system that helps reduce friction between moving parts, allowing them to move smoothly. Bearings are typically made of high-quality steel and are designed to withstand the high-speed and high-temperature conditions commonly found in motorcycle engines and wheels.

There are several types of bearings used in motorcycles, including ball bearings, roller bearings, and needle bearings. Ball bearings consist of hardened steel balls that rotate between two grooved rings, providing a smooth surface for rotational motion. Roller bearings use cylindrical or tapered rollers to facilitate motion between parts, while needle bearings use small cylindrical rollers with a high length-to-diameter ratio for reduced friction.

Proper maintenance of motorcycle bearings is essential to ensure optimal performance and longevity of the motorcycle. This includes regular lubrication to reduce friction and prevent premature wear and tear. Inspecting bearings for signs of wear, corrosion, or damage is also important to prevent potential failures that can lead to safety hazards or mechanical issues while riding.

motorcycle bearings play a crucial role in the performance and safety of a motorcycle, and proper care and maintenance are essential to ensure a smooth and enjoyable riding experience.

car bearing koyo

There are many types of Koyo bearings for automobiles, and from their usage positions, there are mainly three types:

Koyo wheel hub bearing

Hub bearings are mainly used to bear weight and precisely guide the rotation of the hub. They bear both axial and radial loads and are a very important component.

Koyo clutch release bearing

The clutch release bearing is an important component in automobiles, which is installed between the clutch and the transmission. The release bearing seat is loosely sleeved on the tubular extension of the first shaft bearing cover of the transmission. Through the return spring, the shoulder of the release bearing is always pressed against the release fork and retreated to the final position, maintaining a gap of about 3-4 mm with the end of the release lever (release finger).

Due to the synchronous operation of the clutch pressure plate, release lever, and engine crankshaft, while the release fork can only move along the axial direction of the clutch output shaft, it is obviously not feasible to directly use the release fork to shift the release lever. By using the release bearing, the release lever can rotate while moving along the axial direction of the clutch output shaft, ensuring smooth engagement, soft separation, and reducing wear, thus extending the service life of the clutch and the entire transmission system.

Bearings - driven

Koyo sliding bearing

Sliding bearings can be classified in the following ways:

Classified by bearing structure: round bearings, elliptical bearings, three oil leaf bearings, stepped surface bearings, tilting pad bearings, and foil bearings, etc

Classified by lubricant type:

Oil lubricated bearings, grease lubricated bearings, water lubricated bearings, gas bearings, solid lubricated bearings, magnetic fluid bearings, and electromagnetic bearings

According to the direction of load bearing capacity:

Radial (radial) sliding bearings and thrust (axial) sliding bearings

Classified by bearing material:

Bronze bearings, cast iron bearings, plastic bearings, gemstone bearings, powder metallurgy bearings, self-lubricating bearings, and oil containing bearings, etc

Classified by lubrication film thickness: thin film lubrication bearings and thick film lubrication bearings;

Koyo wheel hub bearing

Hub bearings are mainly used to bear weight and precisely guide the rotation of the hub. They bear both axial and radial loads and are a very important component.

Koyo clutch release bearing

The clutch release bearing is an important component in automobiles, which is installed between the clutch and the transmission. The release bearing seat is loosely sleeved on the tubular extension of the first shaft bearing cover of the transmission. Through the return spring, the shoulder of the release bearing is always pressed against the release fork and retreated to the final position, maintaining a gap of about 3-4 mm with the end of the release lever (release finger).

Due to the synchronous operation of the clutch pressure plate, release lever, and engine crankshaft, while the release fork can only move along the axial direction of the clutch output shaft, it is obviously not feasible to directly use the release fork to shift the release lever. By using the release bearing, the release lever can rotate while moving along the axial direction of the clutch output shaft, ensuring smooth engagement, soft separation, and reducing wear, thus extending the service life of the clutch and the entire transmission system.

Bearings - driven

Koyo sliding bearing

Sliding bearings can be classified in the following ways:

Classified by bearing structure: round bearings, elliptical bearings, three oil leaf bearings, stepped surface bearings, tilting pad bearings, and foil bearings, etc

Classified by lubricant type:

Oil lubricated bearings, grease lubricated bearings, water lubricated bearings, gas bearings, solid lubricated bearings, magnetic fluid bearings, and electromagnetic bearings

According to the direction of load bearing capacity:

Radial (radial) sliding bearings and thrust (axial) sliding bearings

Classified by bearing material:

Bronze bearings, cast iron bearings, plastic bearings, gemstone bearings, powder metallurgy bearings, self-lubricating bearings, and oil containing bearings, etc

Classified by lubrication film thickness: thin film lubrication bearings and thick film lubrication bearings;

Koyo sliding bearings are bearings that operate under sliding friction. It has many advantages, such as smooth operation, reliability, and no noise. Under liquid lubrication conditions, the sliding surface is separated by lubricating oil without direct contact, which reduces friction and surface wear, and the oil film has a certain ability to absorb vibration. However, there is relatively high frictional resistance during start-up.

Spherical roller bearing with relubrication features

Spherical roller bearings can accommodate heavy loads in both directions. They are self-aligning and accommodate misalignment and

shaft deflections, with virtually no increase in friction or temperature. The design includes features to facilitate

relubrication. The bearings can be used in a modular system, including housings, sleeves and nuts. * Accommodate misalignment

* High load carrying capacity

* Relubrication features

* Low friction and long service

life

* Increased wear resistance

shaft deflections, with virtually no increase in friction or temperature. The design includes features to facilitate

relubrication. The bearings can be used in a modular system, including housings, sleeves and nuts. * Accommodate misalignment

* High load carrying capacity

* Relubrication features

* Low friction and long service

life

* Increased wear resistance

Super-precision angular contact ball bearings

Matched set of two super-precision, high-capacity, D design, single row angular contact ball bearings

These matched sets of two super-precision, high-capacity, D design, single row angular contact ball bearings are available in a

variety of arrangements. They are designed for high-load capacity and relatively high speed operation and, compared to the

equivalent SKF B and E design high-speed bearings, are best suited for heavier loads. * Very high running accuracy

* Very high load carrying capacity

These matched sets of two super-precision, high-capacity, D design, single row angular contact ball bearings are available in a

variety of arrangements. They are designed for high-load capacity and relatively high speed operation and, compared to the

equivalent SKF B and E design high-speed bearings, are best suited for heavier loads. * Very high running accuracy

* Very high load carrying capacity

Super-precision, high-speed E design, single row angular contact ball bearing

These super-precision, high-speed, E design, single row angular contact ball bearings, with 15° or 18° contact angle, accommodate

radial and axial loads acting simultaneously, where the axial load acts in one direction only. They are designed to accommodate

very high speeds. Compared to the equivalent SKF B design high-speed bearings, have a slightly higher speed capability and can

accommodate heavier loads. * Very high running accuracy

* Accommodate very high speeds

* Accommodate relatively high radial loads and large unilateral axial loads

radial and axial loads acting simultaneously, where the axial load acts in one direction only. They are designed to accommodate

very high speeds. Compared to the equivalent SKF B design high-speed bearings, have a slightly higher speed capability and can

accommodate heavier loads. * Very high running accuracy

* Accommodate very high speeds

* Accommodate relatively high radial loads and large unilateral axial loads

Self-aligning ball bearing

Self-aligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted raceway

grooves in the inner ring. They are insensitive to angular misalignment of the shaft relative to the housing, which can be caused,

for example, by shaft deflection. * Accommodate static and dynamic misalignment

* Excellent high-speed performance

* Excellent light load performance

* Low friction

grooves in the inner ring. They are insensitive to angular misalignment of the shaft relative to the housing, which can be caused,

for example, by shaft deflection. * Accommodate static and dynamic misalignment

* Excellent high-speed performance

* Excellent light load performance

* Low friction

Rod ends

The rod end housings are available with the following shank designs:

* female or male thread (standard threaded shanks)

* slotted shank with clamping screws and female thread

* welding shank with cylindrical or rectangular section

The integral bearings are available with the following sliding contact surface combinations:

* steel/steel

* steel/bronze

Rod ends requiring maintenance are available in a wide variety of series and variants, and are described below.

* female or male thread (standard threaded shanks)

* slotted shank with clamping screws and female thread

* welding shank with cylindrical or rectangular section

The integral bearings are available with the following sliding contact surface combinations:

* steel/steel

* steel/bronze

Rod ends requiring maintenance are available in a wide variety of series and variants, and are described below.

Radial spherical plain bearings

Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment.

This specific design includes a steel/PTFE fabric sliding contact surface combination and the bearings are maintenance-free.

Except for those with designation suffix TXGR, they have a double-lip contact seal (-2RS) or a triple-lip, heavy duty contact seal

(-2LS) on both sides. Those with designation suffixes TXGR, TXG3E or TXG3A are made of stainless steel. * Designed for radial and

combined radial and axial loads

* Long service life and

maintenance-free

* Suitable for very heavy,

constant direction loads

* Low coefficient of

friction

This specific design includes a steel/PTFE fabric sliding contact surface combination and the bearings are maintenance-free.

Except for those with designation suffix TXGR, they have a double-lip contact seal (-2RS) or a triple-lip, heavy duty contact seal

(-2LS) on both sides. Those with designation suffixes TXGR, TXG3E or TXG3A are made of stainless steel. * Designed for radial and

combined radial and axial loads

* Long service life and

maintenance-free

* Suitable for very heavy,

constant direction loads

* Low coefficient of

friction

needle roller bearing

Single row needle roller bearings without an inner ring consist of an outer ring with a needle roller and cage assembly. They are

an excellent choice for compact bearing arrangements in applications where hardened and ground raceways can be provided on the

shaft. The outer ring includes two integral flanges to guide the bearing axially and an annular groove with one or more

lubrication holes to facilitate relubrication. * High radial load carrying capacity

* High stiffness

* Low cross-sectional height

* Accommodate axial displacement in both directions

an excellent choice for compact bearing arrangements in applications where hardened and ground raceways can be provided on the

shaft. The outer ring includes two integral flanges to guide the bearing axially and an annular groove with one or more

lubrication holes to facilitate relubrication. * High radial load carrying capacity

* High stiffness

* Low cross-sectional height

* Accommodate axial displacement in both directions

Support rollers

Support rollers (yoke-type track rollers) are designed to run on all types of tracks and to be used in cam drives, conveyor

systems, etc. They are based on a single row needle roller bearing without an inner ring, intended for applications where hardened

and ground raceways can be provided on the pin or shaft. They have a thick-walled outer ring with a crowned running surface and

are supplied sealed and ready-to-mount. * High radial load carrying capacity

* Able to withstand shock loads

* Long service life

* Ready to mount

* Integral sealing prolongs bearing service life

systems, etc. They are based on a single row needle roller bearing without an inner ring, intended for applications where hardened

and ground raceways can be provided on the pin or shaft. They have a thick-walled outer ring with a crowned running surface and

are supplied sealed and ready-to-mount. * High radial load carrying capacity

* Able to withstand shock loads

* Long service life

* Ready to mount

* Integral sealing prolongs bearing service life

Single row deep groove ball bearings are particularly versatile, have low friction and are optimized for low noise and low

vibration, which enables high rotational speeds. They accommodate radial and axial loads in both directions, are easy to mount,

and require less maintenance than many other bearing types. * Simple, versatile and robust design

* Low friction

* High-speed capability

* Accommodate radial and axial loads in both directions

* Require little maintenance.

vibration, which enables high rotational speeds. They accommodate radial and axial loads in both directions, are easy to mount,

and require less maintenance than many other bearing types. * Simple, versatile and robust design

* Low friction

* High-speed capability

* Accommodate radial and axial loads in both directions

* Require little maintenance.

Single row deep groove ball bearings with seals on one or both sides are particularly versatile, have low friction and are

optimized for low noise and low vibration, which enables high rotational speeds. They accommodate radial and axial loads in both

directions, are easy to mount, and require less maintenance than other bearing types. The integral sealing can significantly

prolong bearing service life because it keeps lubricant in the bearings and contaminants out. * Integral sealing prolongs bearing

optimized for low noise and low vibration, which enables high rotational speeds. They accommodate radial and axial loads in both

directions, are easy to mount, and require less maintenance than other bearing types. The integral sealing can significantly

prolong bearing service life because it keeps lubricant in the bearings and contaminants out. * Integral sealing prolongs bearing

Single row deep groove ball bearings with seals or shields are particularly versatile, have low friction and are optimized for low

noise and low vibration, which enables high rotational speeds. They accommodate radial and axial loads in both directions, are

easy to mount, and require less maintenance than many other bearing types. The integral sealing can significantly prolong bearing

service life because it keeps lubricant in the bearings and contaminants out.

noise and low vibration, which enables high rotational speeds. They accommodate radial and axial loads in both directions, are

easy to mount, and require less maintenance than many other bearing types. The integral sealing can significantly prolong bearing

service life because it keeps lubricant in the bearings and contaminants out.

Spherical roller thrust bearings

Spherical roller thrust bearings accommodate very heavy axial and considerable radial loads. They have the highest load rating ofall thrust bearings, enabling compact, high power density bearing arrangements. By combining two or more spherical roller thrust bearings, it is possible to create a bearing arrangement that is either self-aligning, allowing misalignment of the shaft, or very stiff.

* High load carrying capacity

* Can accommodate combined loads

* Allow misalignment or create very stiff bearing arrangements

* Long service life and low friction

* Separable design

* Can accommodate combined loads

* Allow misalignment or create very stiff bearing arrangements

* Long service life and low friction

* Separable design

Single direction thrust ball bearing

Single direction thrust ball bearings can accommodate axial loads in one direction. They must not be subjected to any radial load.

Their separable components facilitate mounting/dismounting and maintenance inspections. Many of the components are

interchangeable. The shaft washers have a ground bore that enables an interference fit. * Separable design facilitates

mounting/dismounting and maintenance inspections

* Interchangeable components

* Ground bore of shaft washers enable

interference fit

Their separable components facilitate mounting/dismounting and maintenance inspections. Many of the components are

interchangeable. The shaft washers have a ground bore that enables an interference fit. * Separable design facilitates

mounting/dismounting and maintenance inspections

* Interchangeable components

* Ground bore of shaft washers enable

interference fit

Single row cylindrical roller thrust bearing, single direction

Single row cylindrical roller thrust bearings are designed to accommodate heavy axial loads and peak loads in one direction, but not radial loads. They provide a high degree of stiffness and require little axial space. They are mainly used in applications where thrust ball bearings do not have sufficient load carrying capacity. An important feature is the separable design, which facilitates mounting and enables the bearing components to be interchanged. * High axial load carrying capacity

* High stiffness

* Long service life

* Require little axial space

* Separable design

* High stiffness

* Long service life

* Require little axial space

* Separable design

Insert bearings

Insert bearings are based on sealed deep groove ball bearings. This variant is suitable for applications with both constant andalternating directions of rotation. It has an inner ring extended on both sides and is locked onto the shaft by tightening two(set) screws on the inner ring, making it easy to mount.

* Designed for a constant andalternating rotation

* Quick and easy to mount onto the shaft

* Reduce noise and vibration levels

* Quick and easy to mount onto the shaft

* Reduce noise and vibration levels

Single row cylindrical roller bearing

Single row cylindrical roller bearings are designed to accommodate high radial loads in combination with high speeds. Having twointegral flanges on the outer ring and no flanges on the inner ring, NU design bearings can accommodate axial displacement in bothdirections. An important feature is the separable design, which facilitates mounting and enables the bearing components to be

interchanged.

interchanged.

* High radial load carrying capacity

* Low friction

* Long service life

* Accommodate axial displacement in both directions

* Separable design

* Low friction

* Long service life

* Accommodate axial displacement in both directions

* Separable design

Specification

front bearing alsvin 2024

Front Bearing Alsvin 2024 is a high-quality bearing specifically designed for use in automotive applications. This bearing is engineered to provide reliable performance and durability in the front suspension of the Alsvin 2024 model. It features precision construction and materials that ensure smooth operation and longevity, even under demanding conditions. With Front Bearing Alsvin 2024, you can trust that your vehicle's front suspension system will have the support it needs for a smooth and safe driving experience..

jetta mk3 double right bearing

The Jetta MK3 double right bearing refers to a specific automotive part used in the Jetta MK3 model. The double right bearing typically consists of two separate bearings designed to support the right side of the vehicle's suspension or wheel hub assembly. This component plays a crucial role in ensuring smooth and efficient rotation of the wheel while driving.

These bearings are essential for maintaining proper alignment and stability of the wheel, especially during turns or when encountering bumps on the road. By reducing friction and allowing the wheel to spin freely, the double right bearing helps enhance overall driving performance and safety.

It is important to regularly inspect and maintain the double right bearing to ensure optimal functionality and prevent potential issues such as noise, vibration, or wheel misalignment. If any signs of wear or damage are detected, it is recommended to replace the bearing promptly to avoid further problems.

the Jetta MK3 double right bearing is a vital component that contributes to the smooth operation and handling of the vehicle, providing reliability and performance on the road.

Designation | Principal dimensions |

Deep groove ball bearings | Inner Bore:6-1250 mm Outer Diameter 20-1700mm |

Self-aligning ball bearings | Inner Bore:20-150 mm Outer Diameter 52-240mm |

Spherical roller bearings | Inner Bore:20-900 mm Outer Diameter 52-1180mm |

Tapered roller bearings | Inner Bore:15-500 mm Outer Diameter 32-700mm |

Insert bearings | Inner Bore:20-200 mm Outer Diameter 40-700mm |

Angular contact ball bearings | Inner Bore:10-240 mm Outer Diameter 300-440mm |

Cylindrical roller bearings | Inner Bore:15-800 mm Outer Diameter 35-1150mm |

Thrust ball bearings | Inner Bore:3-150 mm Outer Diameter 8-300mm |

Cylindrical roller thrust bearings | Inner Bore:15-630 mm Outer Diameter 28-750mm |

Spherical roller thrust bearings | Inner Bore:60-1600 mm Outer Diameter 130-2280mm |

Packing & Delivery

Company Profile

Dimson supre power transmission inc. is headquartered in Delaware USA, with over 80 years of industry service history and

experience. It operates over 20 branches in 8 countries worldwide. Timson Power Technology (Shanghai) Co., Ltd.is Dimson's first

wholly-owned subsidiary in China, established in Shanghai in 2012. We specialize in bearing research, production, and

import/export operations. As a renowned manufacturer and authorized distributor of bearings for world-renowned brands, we offer

industry-leading services and prices. Our products primarily cater to industries and enterprises such as automotive, agricultural

machinery, electrical appliances, construction machinery, light industry textiles, and mining machinery. "Quality is paramount" is

our service motto, and we warmly welcome inquiries from esteemed clients.

experience. It operates over 20 branches in 8 countries worldwide. Timson Power Technology (Shanghai) Co., Ltd.is Dimson's first

wholly-owned subsidiary in China, established in Shanghai in 2012. We specialize in bearing research, production, and

import/export operations. As a renowned manufacturer and authorized distributor of bearings for world-renowned brands, we offer

industry-leading services and prices. Our products primarily cater to industries and enterprises such as automotive, agricultural

machinery, electrical appliances, construction machinery, light industry textiles, and mining machinery. "Quality is paramount" is

our service motto, and we warmly welcome inquiries from esteemed clients.

Похожие товары

Электропроводящий миниатюрный шариковый подшипник 234460M. Sp 234760M. Sp 23464M. Sp шаровой подшипник поворотный

0,01 $

22216K Сплит сферические роликовые подшипники 222SM70-TVPA 222SM70

Специальный нестандартный автомобильный подшипник ST4390 43x90x30

YNR вилочный погрузчик мачты подшипник CZ15512134-2Z 30711K 55*121*34 мм

MG308FFP YNR погрузчик мачты направляющий подшипник

Комбинированный гусеничный роликовый подшипник KRES 089 муль089 с монтажной пластиной

Обгонная муфта подшипника CSK35

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $