SS316 ss304дверной автоматический отбойный шарнир свободно открывается внутри и снаружи с закрытой страницы

- Категория: >>>

- Поставщик: Tianjin Wobeide Technology Co. Ltd.Tianjin Ltd.

Сохранить в закладки 1601204344992:

Описание и отзывы

Характеристики

Company Profile

Tianjin Wobeide Technology Co.,Ltd. is a private enterprise engaged in the export of metal products.The company is located in Tianjin, and its associated factories are located in Nanpi County, Hebei Province, which is known as the "hometown of hardware in China" .

Since its establishment, the company has continuously cultivated new employees and absorbed the sense of innovation.The factory also continuously introduces cutting-edge processing and production equipment and recruits technicians. While ensuring product quality, we will divers if your products and continue to move towards the goal of high technology. The production scope of the factory is gradually expanded.At present, the products involve dozens of industries, such as metal stamping parts, sheet metal parts, assembly welding parts, chassis and cabinet sheet metal shell, hinges, auto parts and precision electronic parts. It has not only a good reputation in China, but also exported to the United States, Europe, South America and other countries,and has a good business reputation in the international market.

Product attributes

According to customer' s requirement.

Surface Treatment:

All kinds of surface treatment is available.

Size:

According to customer' s design or sample

Size:

According to customer' s design or sample

process:

Laser Cutting /Bending/Punching/

Welding/Die casting /CNC machining

Mold can be adjusted according to customer needs

Process Methods

Precision Machining, CNC Milling, CNC Lathe Turning, Tapping, Drilling, Grinding, Die EDM, Stamping, Deep Drawing, CNC Punching,Laser Cutting, CNC Bending, Die Casting, Welding etc

We equipped with manufacturing metal stamping dies and stamping metal parts production according to customer's drawing or sample.

Our company specializes in stamping die and mould design, manufacturing and processing over 12 years experience. We can help with

your metal stamping die/mould development from ideas to a product and manufacture single stage die or progressive die according to customer's order quantity and requirements.

Except metal stamping we also offer the most cost-effective way to your project according to customer's order quantity,we can use laser cutting,CNC punching and CNC bending automatic production.We can cut all kinds of sheet metal accurately with a wide range of

thickness up to 30 mm and tube & pipe.

We are equipped with welding machine and riveting machine,which can help us assemble different parts according to customer's drawing and requirements. We provide various surface treatment according to customer's request,such as Powder Coating Plating,

Electrophoresis,

Anodized,

Brushing Polishing and so on.

The use of high power density laser beam irradiation is cut material, so that the material is quickly heated to the temperature of vaporization, evaporation formed holes, with the movement of the beam of the material, the hole continuous formation of a very narrow width (such as about 0.01mm) slit, complete the cutting of the material.

Have a variety of welding methods to meet customer needs. Such as spot welding, full welding, pressure welding, argon arc welding and so on. According to the use of the product and customer needs customized.

Process before and after production

Quotation | 1.Customer provides product drawings (Cad, PDF, dwg, stp file) 2.Provide material, quantity, surface treatment, packaging, and other product requirements 3.We provide quotation within 24-48 hours according to the drawing | ||||||

mold | 1.Produce molds according to product drawings confirmed with customers 2.Mold production sample inspection mold after mold production 3.The sample will be sent to the customer or take a video and take a photo to confirm the sample.metal manufacturer metal product metal cutting cnc parts manufacturing | ||||||

Mould payment method | 1.Before producing the mold, the customer pays 50% of the mold fee 2.After the mold is produced, confirm that there is no problem with the sample, and pay the remaining 50% of the mold fee floating shelf bracket sheet metal fabrication aviation parts | ||||||

Mold production time | According to the customer's payment time, the mold will be produced immediately after the customer pays, and the mold production time is about 20-25 days. | ||||||

Production | 1.We will provide samples to customers for confirmation 2.After confirmation, the production is arranged according to the purchase order. The production time is 35-40 days.sheet metal stamping stamping plates electrical parts 3.different according to the quantity and structure of the product, and the delivery time is different.metal manufacturer metal product metal cutting cnc parts manufacturing | ||||||

product payment | 1.While paying the remaining mold fee, pay 30%-50% product deposit (determined according to the specific situation) sheet metal stamping stamping plates electrical parts 2.After the production is completed, after the customer pays the remaining payment, we will arrange the delivery. floating shelf bracket sheet metal fabrication aviation parts 3.We accept small batch product purchases to confirm the quality of our products | ||||||

Packing | Plastic wrap, plastic bags, cartons, cartons, wooden pallets, wooden boxes, foam, etc., according to customer requirements metal fabrication services steel product | ||||||

Sample | 1.We send international express to customers to confirm samples 2.Take a video or take a photo to confirm the sample metal fabrication services steel product | ||||||

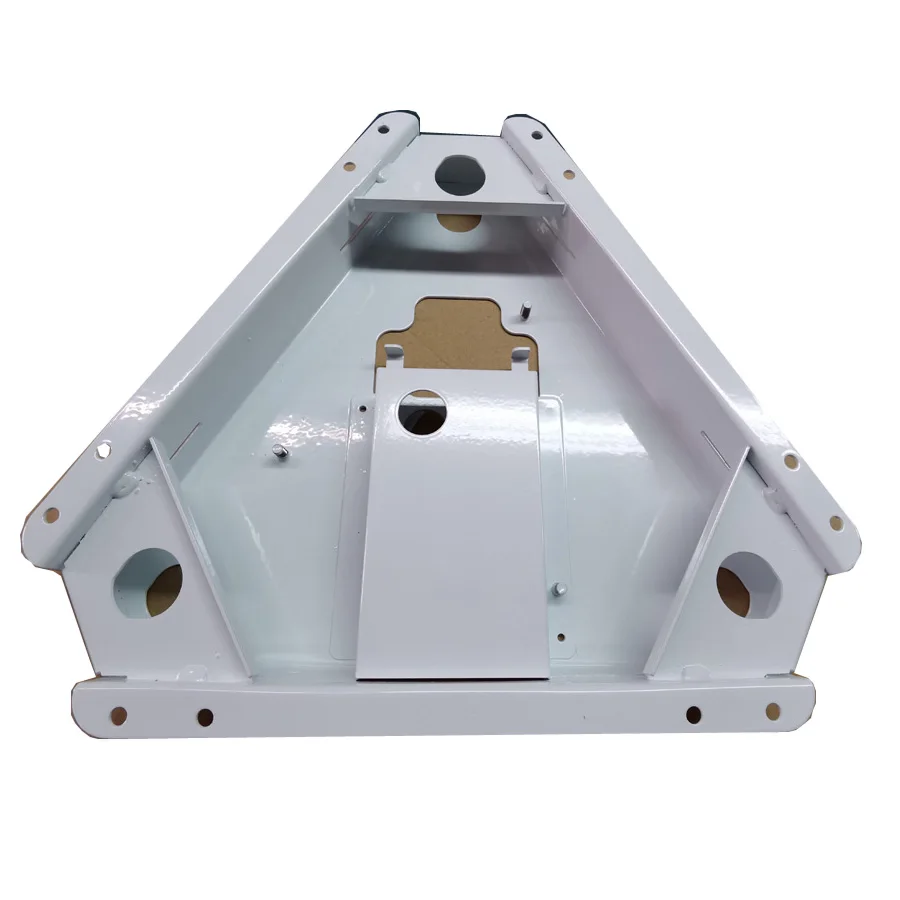

Company product display

Various chassis shells, sheet metal shells metal fabrication services steel product

All kinds of furniture accessories bracket metal fabrication services steel product

Packing & Delivery

Generally, bubble bag + carton + cling film + wooden box/wooden tray are used, and we can also pack according to customer requirements

Customer Group Photo

FAQ

Q: How can I get an offer?

Please send us the drawings, quantity, weight and materials of the products.

Q: If we don't have drawings, can you draw them for me?

A: Yes, we can draw your samples and copy them.

Q: What kind of documents can you read?

Answer: PDF, IGS, DWG, step, etc...

Q: What is your packing method?

A: We usually pack the goods according to the customer's requirements. For reference: wrapping paper, carton, wooden case, pallet.

Q: When can I get the samples and your main orders?

A:For samples: 30-35 days after the start of mold making.

Please send us the drawings, quantity, weight and materials of the products.

Q: If we don't have drawings, can you draw them for me?

A: Yes, we can draw your samples and copy them.

Q: What kind of documents can you read?

Answer: PDF, IGS, DWG, step, etc...

Q: What is your packing method?

A: We usually pack the goods according to the customer's requirements. For reference: wrapping paper, carton, wooden case, pallet.

Q: When can I get the samples and your main orders?

A:For samples: 30-35 days after the start of mold making.

For orders: 35-40 days, the exact time depends on the product.

Q: What are your terms of payment?

A: Order: 50% deposit, 50% payment before shipment.

Q: Where is your company located? Can we visit it?

We are in Tianjin, China. You are welcome to visit us at any time.

Q: What are your terms of payment?

A: Order: 50% deposit, 50% payment before shipment.

Q: Where is your company located? Can we visit it?

We are in Tianjin, China. You are welcome to visit us at any time.

Похожие товары

Китай нержавеющая сталь алюминий латунь металл табличка с именем значок бейдж позолоченный пустая металлическая гравировочная пластина

Заводские Штампованные Компоненты из нержавеющей стали оцинкованная стальная пластина металлический штампованный держатель для мобильного телефона

70,18-93,58 ₽

Оптовая продажа нержавеющая сталь алюминиевая листовая металлическая пряжка штамповка аксессуары для вытяжного вентилятора

256,15-292,41 ₽

Высококачественная лазерная обработка листового металла из нержавеющей стали выполненная по индивидуальному заказу

610,55 ₽

Изготовленные на заказ алюминиевые Анодированные корпуса из листового металла с порошковым покрытием услуги сварки и резки

1 169,64-1 403,56 ₽

Oem Индивидуальные стальные гибочные сварочные лазерные режущие детали в сборе для обработки сварочных работ по изготовлению листового металла

1,17-24,57 ₽

316 304 201 сварной профиль из нержавеющей стали для трубы inox

210,54-444,46 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $