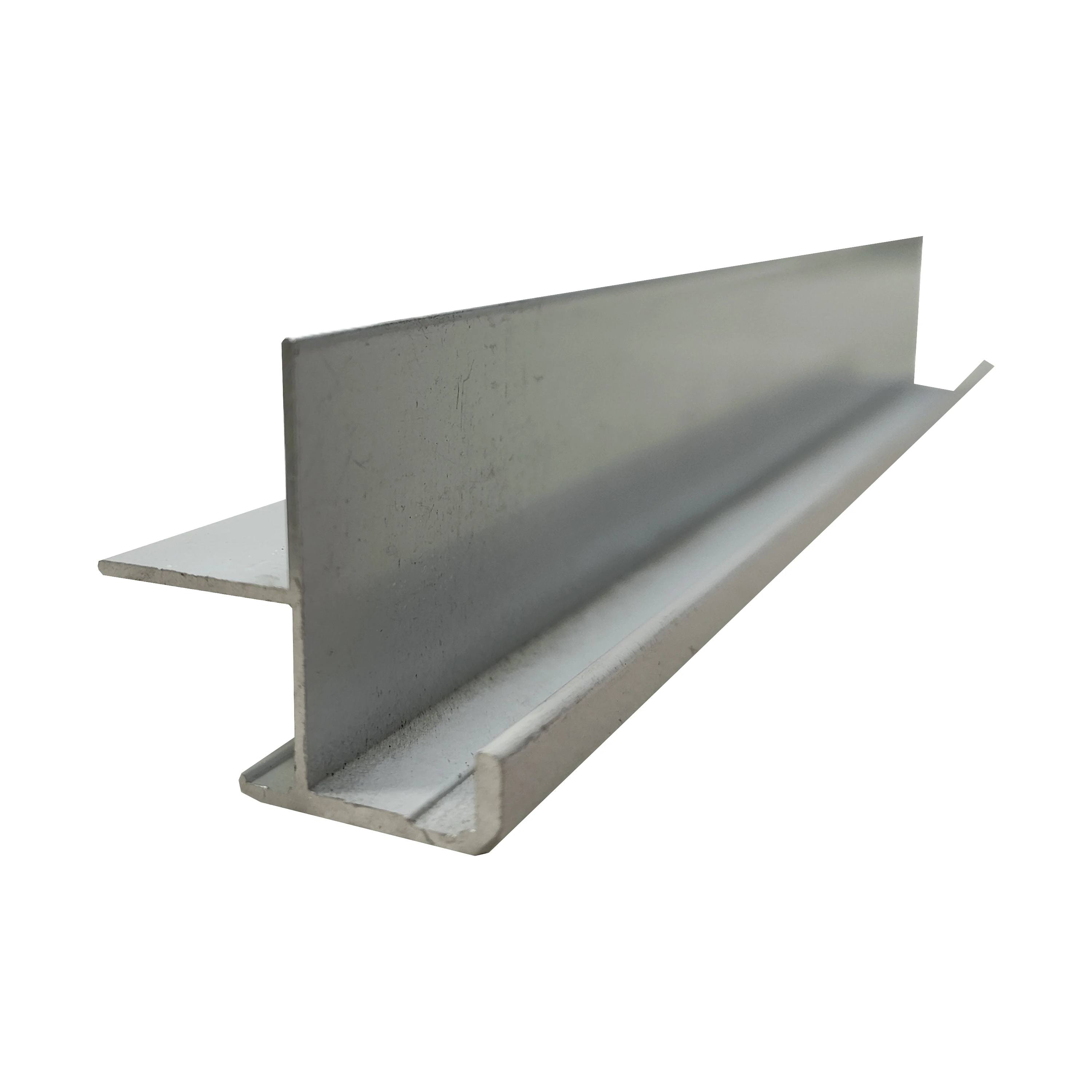

Оцинкованная стальная пластина Dx51 оцинкованная ферма ногтевая для деревянной балки из углеродистой стали

- Категория: >>>

- Поставщик: Beijing Xunengsun Technology CorporationBeijing Corporation

Сохранить в закладки 1601205271544:

Описание и отзывы

Характеристики

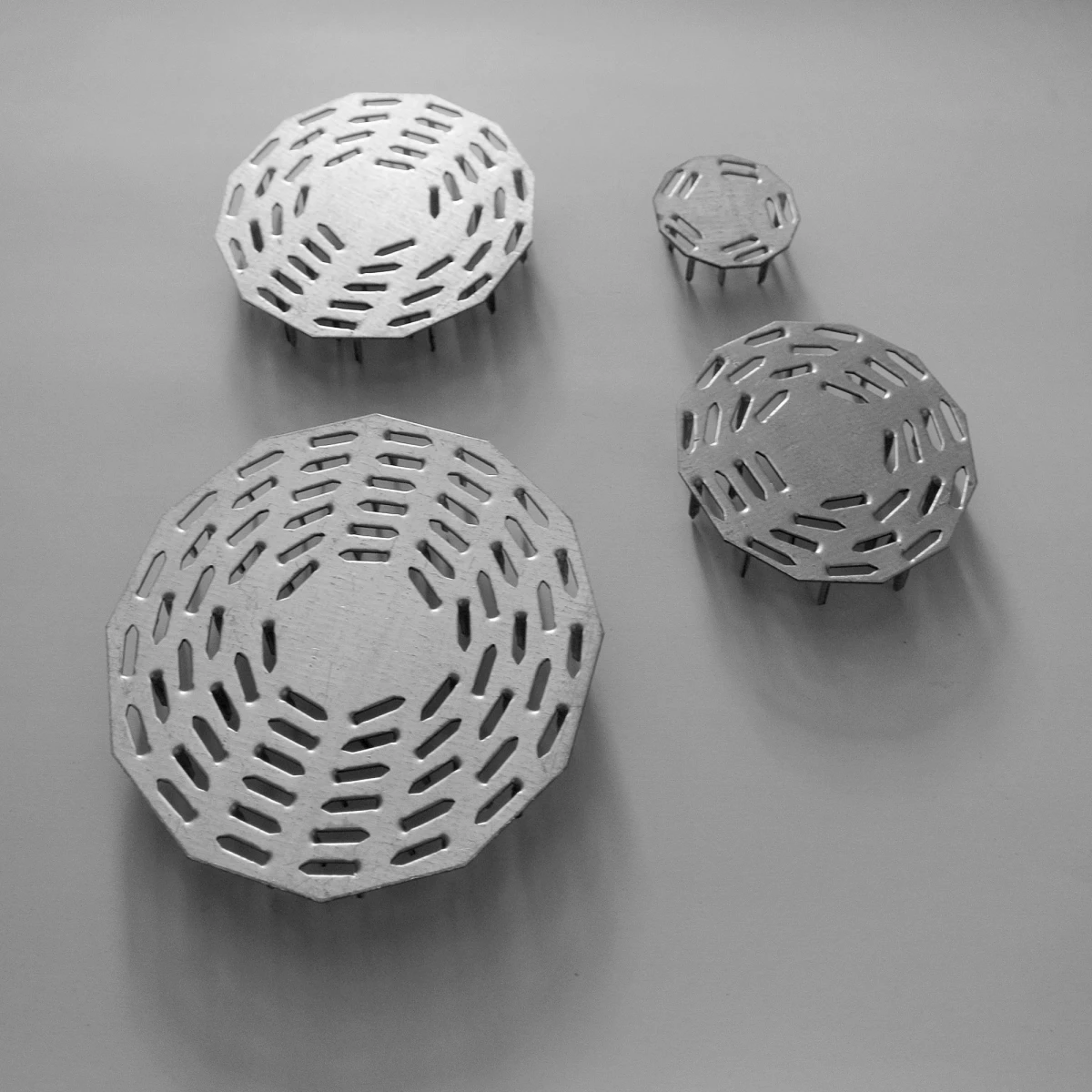

Metal connector plates

You can count on SUREALONG to keep your production line running smoothly and consistently. Our quality-controlled manufacturing facility produces a large quantity of connector plates. Our industry leading connector plates are shipped in individual boxes or skid quantities of 42 boxes (six layers with seven boxes per layer).

SUREALONG metal connector plates are well known throughout the industry for their versatility, cost effectiveness, ease of installation, and durability. Our connector plates are manufactured with high quality steel and are available in three gauges:

Prefabricated Wood Truss

Portable Building/Shed

Railroad Crossties

Pallet and Crating

Manufactured Housing

Truss Connector Plates

Truss Connector Plates are used to connect the multiple pieces of a truss at the truss joint. SUREALONG connector plates are proven to grip the timber securely and aid in the transfer of forces across the finished joint. Our plates are shipped in individual boxes or skid quantitates of 42 boxes (six layers with seven boxes per layer)..

Anti-Split Plates

Timber naturally swells and shrinks as it weathers causing it to weaken. Anti-split plates can help reduce splitting in timber, which occurs as a result of weathering, but not all plates are created equal. SUREALONG's anti-split plates are easy to press and eliminate timber splitting while reducing tooth withdrawal.

Hinge Connector Plates

Hinge plates are used on the top chord of a truss, allowing the chord to be folded down for transportation and raised on site without losing alignment and plane. SUREALONG hinge plates benefit both the manufacturer and the framer as they eliminate the need for piggyback trusses. Our hinge plates are manufactured with high quality, 18 gauge steel and are shipped in individual boxes or skid quantitates of 42 boxes (six layers with seven boxes per layer).

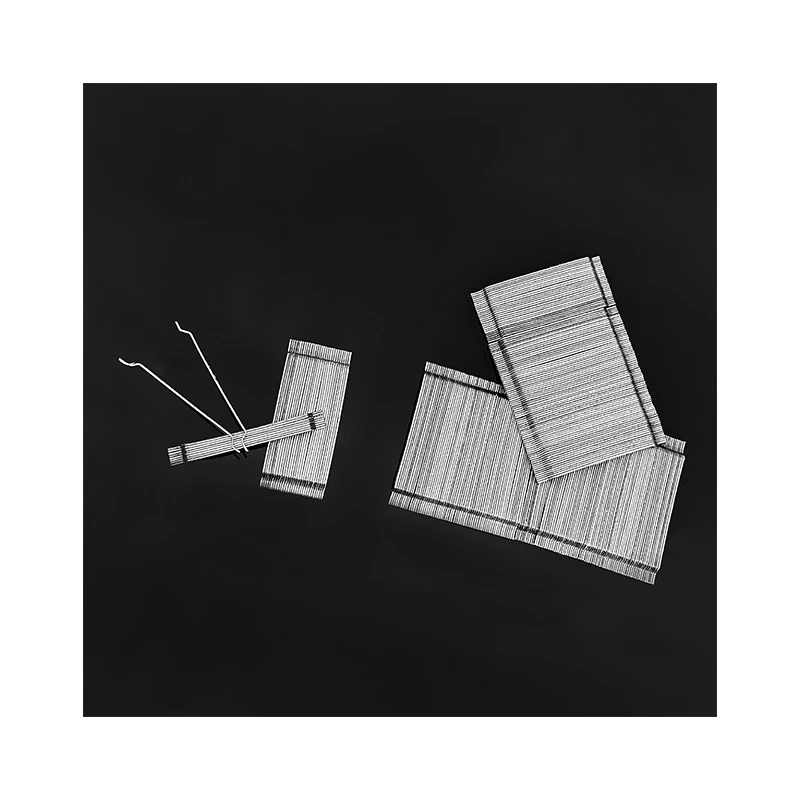

Gang nail plates for Pallet and Crating

gang nail plates

gang nail plates

knuckle nail plates /Tylok Plate for wood truss

SUREALONG Knuckle Nailplates are galvanised steel connectors with in-built, bent-up "knuckle" nails. These plates are ideal for many structural and nonstructural timber jointing and timber protection uses. Applied simply by hammering in the "knuckle nails", these plates are used by tradesmen, home owners, frame and box manufactures, electricity supply authorities and builders. Special pressing equipment is not necessary.

The steel used is 1.0 mm Zincform G300-Z275 or equivalent. G300 is the steel grade;

More info:

Among the many uses of Knuckle Nailplates, the most common are:

> jointing of wall frames together on-site

> on-site splicing of timber beams

> reinforcement of corners of boxes and bins

> reinforcement of bolted joints (eg: in Cable Truss)

> truss manufacture in areas with low labour costs.

Generally, Knuckle Nailplates:

> provide a strong, economical and easy-to-use means of jointing timber together

> protect timber from damage as they:

- resist splitting due to drying of the timber, nailing near ends or other causes eg: Bin Straps

- resist the effects of impact loads such as from fork lift tyne strikes

- dissipate electricity current surges in cross arms over a larger area (eg: Shunt plates)

- distribute concentrated loads over a wider area.

For example, they increase the strength of bolted joints, hold joints together, preventing or restricting the separation of nailed joints such as in boxes and crates, eg: Bin Straps.

Joist hanger

Angle bracket

Galvanized steel strap.

Contact us

Name:Abram Dong

SureAlong Group Corporation

Mobile Phone: 008613260091203

E-mail : autumn(at)xunengsun.com

Skype:abramdong.

About us

Surealong Group Corporation specialize in Metal stamping, metal(Steel, copper, Al, stainless steel etc.)fabrication, CNC Machinig, Laser cutting,welding and assembly. Since Surealong founded in 2010, he have been developed on low voltage component, illuminate component, automatic component, medical equipment component, communication component and precision equipment component etc. scope, and now more than 200 Surealong people commit themselves on develop this scope and new scope.

Total area of workshop is more than 6000 sqm,equipped 70 pressing machine with the tonnage ranging from 3 to 300 ton,and with supporting equipment for perform production from developing to mass production.

Professional Experience:

Committed in stamping and assembly production for years,we have obtained abundant experience on this field which can satisfy most of client's requirements. In compliance with drawing or samples from customer,to provide full service from tooling design to mass production, there are around 20 skilled engineer for tooling design and process technics, the lead-time from development counts from 3 days the shortest only and generally 2 weeks.

Packing

1) Industrial Package: Plastic Film+Carton+Wooden Pallet 2) Commercial Package: Plastic Bag/Film+Carton+Wooded Pallet

2)Customized package

Surealong Group Corporation

As a professional manufacturer of customized metal parts.we could supply metal stamping service,CNC machining service,laser cutting service and welding service.

sheet metal stamping parts

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal.Stamping is usually done on cold metal sheet.

Materials

Aluminum

Brass

Bronze

Copper

Stainless steel

Carbon steel.

Surface finished

Zinc plating

Powder coating

Hot dip galvanized

Painting

Anodic oxidation.

Process

Bending

Flanging

Embossing

Blanking

Deep drawing

Stretching

Deep drawing stamping parts,deep drawn parts

the surface area of a blank is stretched into an alternate shape via controlled material flow. See also deep drawing.

Sheet metal fabrication

Sheet metal fabrication is a classification of manufacturing processes that shape a piece of sheet metal into the desired part through material removal and/or material deformation. Sheet metal, which acts as the workpiece in these processes, is one of the most common forms of raw material stock. The material thickness that classifies a workpiece as sheet metal is not clearly defined. However, sheet metal is generally considered to be a piece of stock between 0.006 and 0.25 inches thick. A piece of metal much thinner is considered to be "foil" and any thicker is referred to as a "plate". The thickness of a piece of sheet metal is often referred to as its gauge, a number typically ranging from 3 to 38. A higher gauge indicates a thinner piece of sheet metal, with exact dimensions that depend on the material.

Machining service

Machining is a term used to describe a variety of material removal processes in which a cutting tool removes unwanted material from a workpiece to produce the desired shape. The workpiece is typically cut from a larger piece of stock, which is available in a variety of standard shapes, such as flat sheets, solid bars, hollow tubes, and shaped beams. Machining can also be performed on an existing part, such as a casting or forging.

Laser cutting

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas,[1] leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Похожие товары

Пользовательские 1-Дюймовые стальные бетонные волокна 1-фунтовые арматурные металлические строительные материалы для сдвига гофрированных стальных волокон бетона

Высокопроизводительные полипропиленовые волокна для цементного бетона и раствора

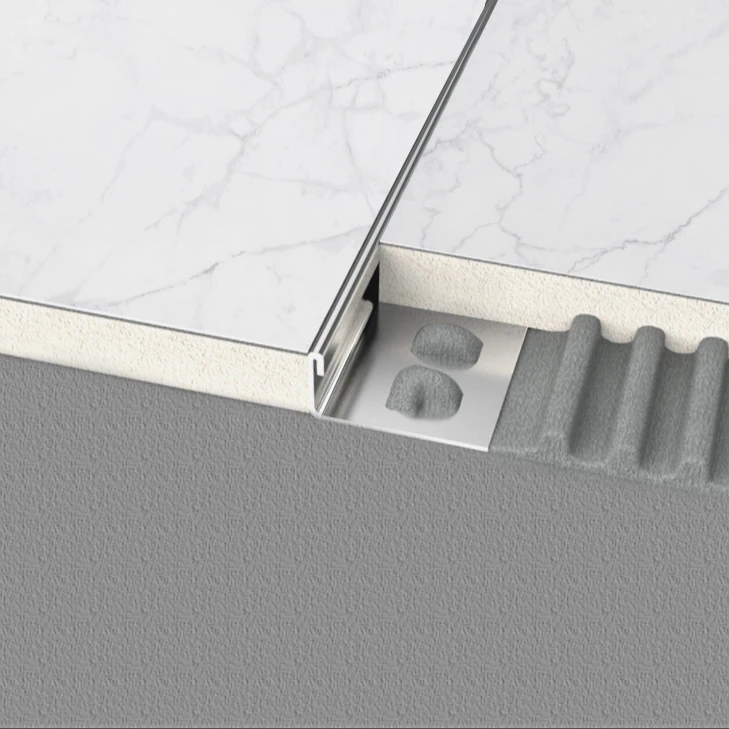

U-профиль для облицовки камня из стали оцинкованный

Прямая L-образная окантовка Ningbo Beautrim Заводская Металлическая Угловая плитка из нержавеющей стали под заказ

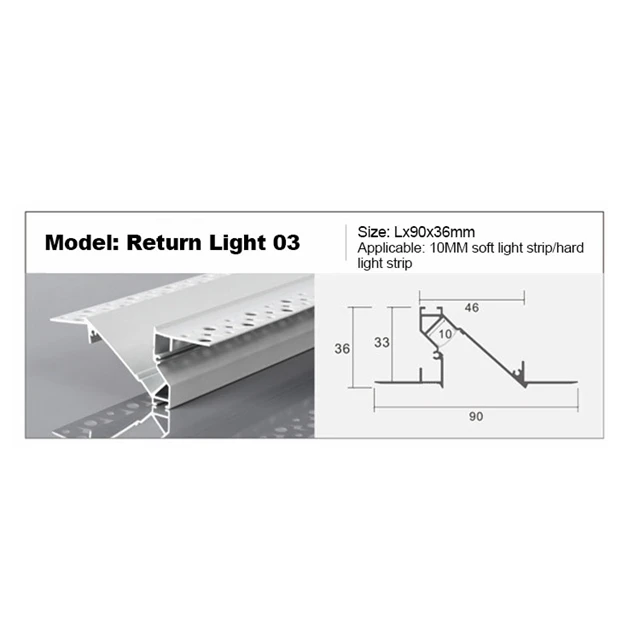

Изготовленный на заказ 6061 T6 алюминиевый профиль 80160 35x35 60x60 линейная направляющая

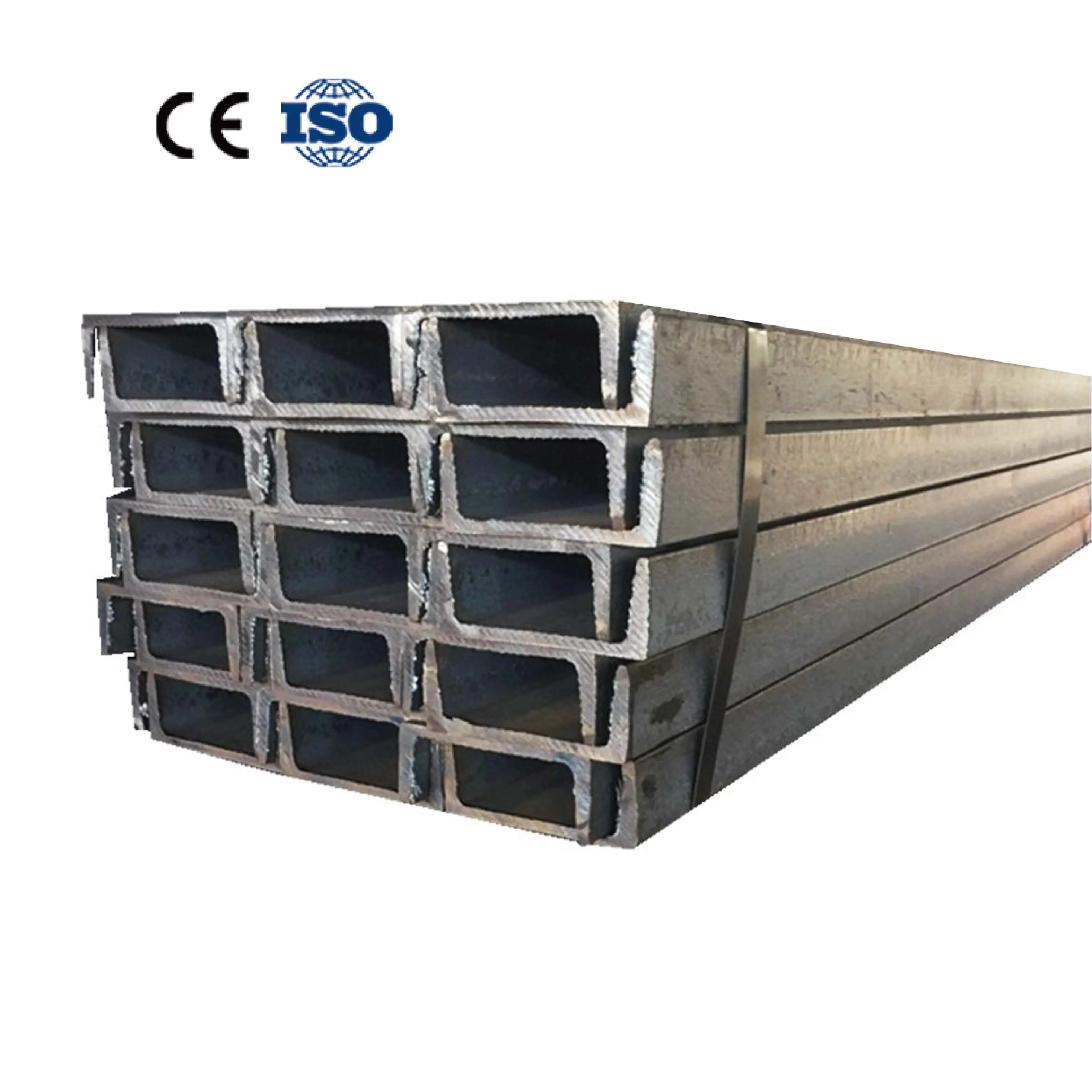

Индивидуальный размер и длина Q235B стальной канал профиль U/C образный для продажи

Угловое соединение для алюминиевых профилей прямые продажи от производителей алюминия нигерийского рынка

Новые поступления

Новинки товаров от производителей по оптовым ценам