Панели ограждения EPS стеновые панели бетонные пресс формы оборудование изоляционные внутренняя производственная машина

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.

Сохранить в закладки 1601206089504:

Описание и отзывы

Характеристики

- WELCOME TO HONGFA MACHINERY -

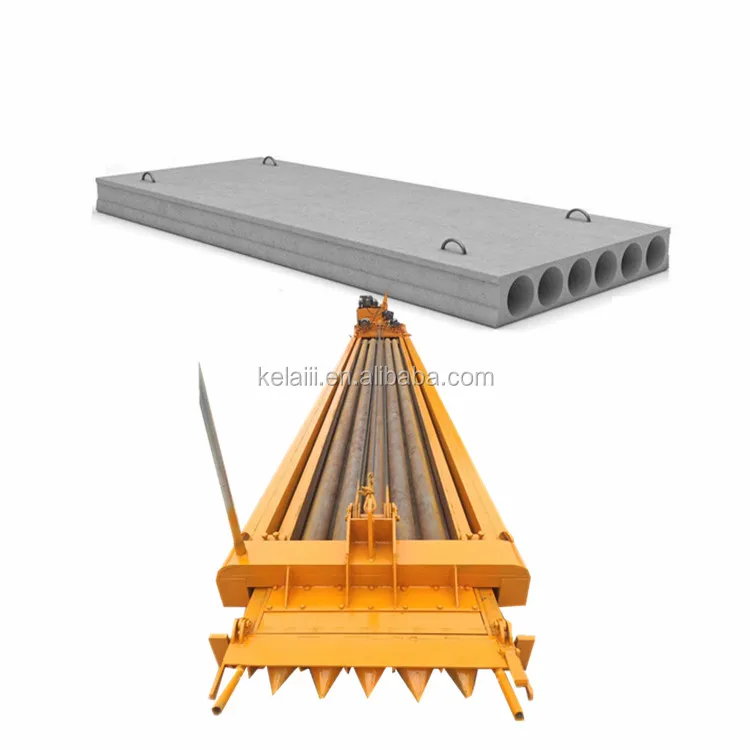

Concrete EPS Panel Molding Machinery

| Raw Materials |

|

| |

The 2 surface cover boards(calcium silicate board/ fiber cement board) , are composed of high strength water resistant, with good waterproof properties.

Common Sandwich precast EPS cement wall panel sizes

Length*Width: 2440/ 2270/ 3000mm * 610mm.

Thickness: 50mm/60mm/75mm/90mm/100mm/120mm/150mm/200mm.

Cement Board Production Line Layout

| Production Equipment |

|

| |

Sandwich Panels Size & Type (Flexible)

EPS Concrete Panels, Type: Hollow / Solid

Gypsum Board

Cement EPS Panel Advantages

| Lightweight | The raw materials used are Lightweight aggregates, fly ash,etc, non-reinforced concrete, gravel and other heavy feedstock. So it has the characteristics of lightweight, which is only 1/16 weight of the brick and concrete structure.It can significantly reduce the vertical load of the building structure and reduces building weight and project cost. |

Insulation Resistance | As this new wall panel is core of EPS insulation materials, which insulation performance is extremely advantageous and meet the building energy efficiency design standards, and rank first among similar products. |

Permeability Resistance | The bibulous rate of this new wall panel is only 3.3%,which has reached the international advanced level in the same industry. |

| Fireproof | This kind of wall panel is non-burning, and according to the testing, it is reasonable fireproof materials, for the 90mm thickness wall panel, the fireproof performance can be more 3 hours. |

| Soundproof | As new wall panel is using EPS as core, it has good sound insulation and air aspiration, which is more than 40 db sound insulation. |

EPS Sandwich Panel Application

1 The size and thickness of lightweight cement EPS wall panel can be adjustable.

2 For interior and exterior wall partition on steel or concrete structure building, new construction or renovations. It can be widely applied to wall materials of various high and low buildings such as bank, office building, hospital, school, hotel, shopping mall, amusement, old house reconstruction, residence and workshop.

Sandwich Panel Production Flow

Production Conditions

- Water: to produce 60m2 panel(9 cm thickness as example) required one ton of water. No special requirements for water quality, clean water can be used for production.

- Electricity : installed power 100 kw (depending on the capacity).

- Air and steam: Air compressor and boiler.

- Land: 1200-2000m2 workshop and 9 meters high (depending on the capacity).

- Labor: Take capacity 100,000/yearly as example, total 6 workers.

[ NEED MORE INFORMATION ? ]

Please send inquiry to Ms.Sabrina online to get answers now.

Or scar the QR code for faster talking.

We have 3 types of lightweight concrete solid/hollow core wall panel making machine, for different investment:

Automatic HFP512A

Manual HFP540M

Automatic HFP530A

SUCCESSFUL CASES

Free Inquiry and Consultation

- Free inquiry and consulting support on analyzing customers' needs and market prospect.

- Free Solution to Set up a Factory

- Provide perfect solution to set up a factory to perform EPS sandwich cement wall panel machine operation.

From the day our products sold, we will promise to do as follows:

- Provide corresponding technical solutions and site layout;

- Provide guidance equipment installation and operation for users.

- For each equipment ,we will train mainly operating personnel 5-10.

- 12 months guarantee, and provide lifelong technical support.

- Feedback within 24 hours after consulting.

- Build customers using and maintaining files as soon as dispatch machines;

- After finish debugging of equipment, users inspect and sign the acceptance certificate according to the situation of site service.

- After each service of technology,maintain,users confirm maintenance-return receipt according to the situation of site service.

1.Can this machine make my panel or other size panel?

We would design and do the mould according to customer's Drawing or as ours.

2.When do you delivery the goods?

Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

3.What about the payment?

30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

4.Does the price include the mould?

Yes,the above price includes one set mould with one host machine.

5. Would you mind provide the video?

The video is available to send to you, please contact me.

6. How about the commissioning of the machine and training to workers?

Yes, after finish the installation of the panel production line, our engineer will do the testing and commissioning, and make the most suitable ratio of the materials to make the panels, and train the workers how to operate and maintain the machines.

Are you manufacturer or trading company?

We are Direct factory, not agent or trading company, and the quality and after-sale services is Guaranteed.

How can I trust the machines quality?

Our products passed ISO9001-2000 and CE identifications, and we making machines for 34 years, with full experience, updating technical idea and application.Furthermore our machines have been exported to more than 100 countries and always have a good reputaion from our oversea customers.We will do fully test our products before shipment, make sure every equipment work well when they come to your hand.

Похожие товары

Легкий вес панели машины EPS

1200*220*7100 мм цементная плита для сборного бетона полый сердечник цена

EPS 3D панель производственная линия с проволочной сеткой обе стороны Tridi Строительная

Быстрая конструкция EPS 3D сэндвич стеновая панель производственная линия сборочная делая машину

Конструкция из пенополистирола EPS 3D сэндвич панели делая машину Сварные Панели

Форма для бетонных батарей

Запчасти для бетонных труб лидер продаж лучшее качество горизонтальная вертикальная труба центробежная технология водопропускная

Новые поступления

Новинки товаров от производителей по оптовым ценам