OEM производитель листы из чистого титана класса 2 0 6 мм 7 титановая пластина Gr1 титанового сплава Gr5

- Категория: >>>

- Поставщик: Baoji Youding Titanium Industry Co. Ltd.

Сохранить в закладки 1601206527099:

Описание и отзывы

Характеристики

We are manufacturer with 17 years experience in the titanium industry.

Please don't hesitate to contact us,

if you need sample or other titanium products or OEM &ODM products.

Most of samples are free.

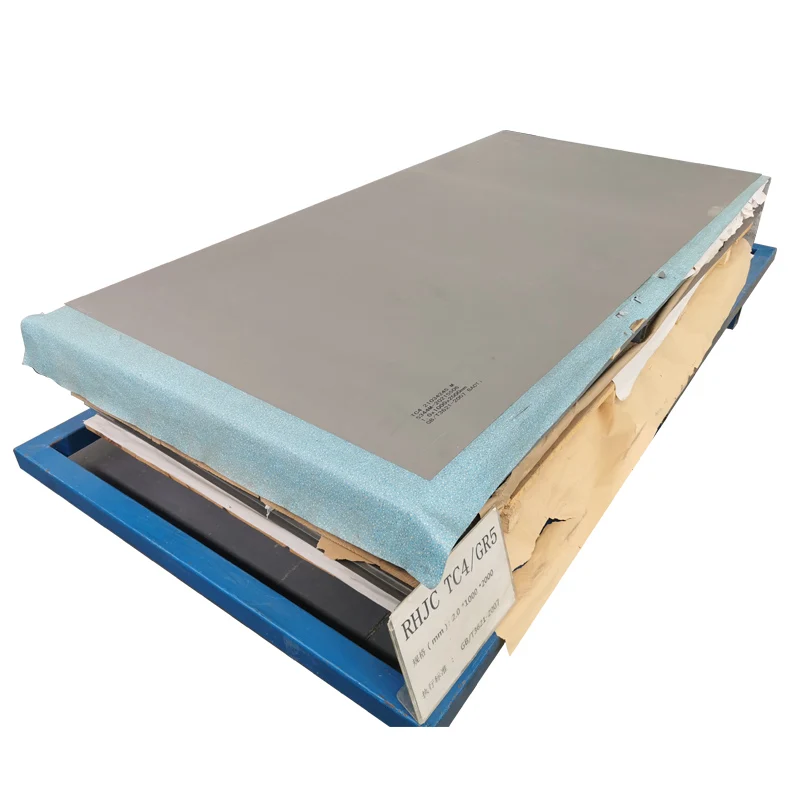

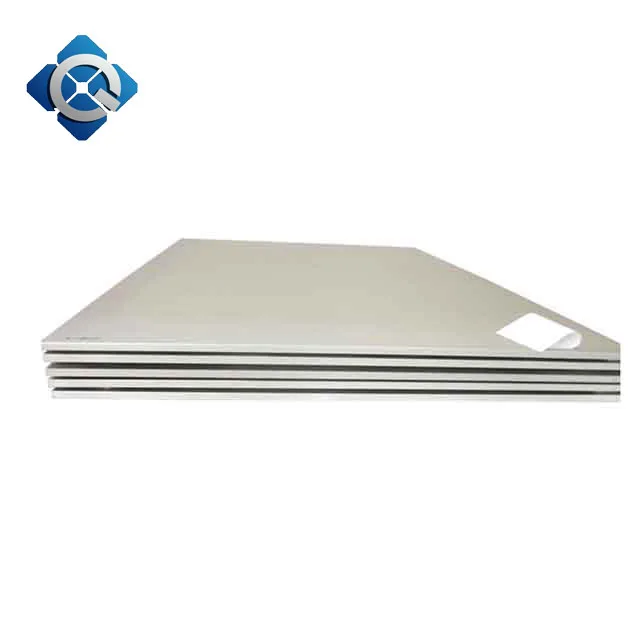

| Product Name | 0.2mm 0.5mm 1mm 2mm 4mm Thickness GR1 GR2 GR5 High Quality Titanium Price Per Kg Titanium Sheet Stock for Sale |

| Material | Pure titanium and Titanium alloy |

| Titanium Grade | Gr1,Gr2,Gr3,Gr4,Gr5(Ti-6Al-4V),Gr7,Gr9,Gr11,Gr12,Gr23(Ti-6Al-4V Eli) |

| Standard | ASTM B265/ASME SB265, ASTMF67, ASTM F67,ASTM F136 ISO-5832-2(3), AMS 4911 etc. |

| Shape | Titanium foil strip/Titanium sheets plate/Titanium coil |

| Thickness | T 0.1mm~100mm |

| Width | 10-3000mm,customizable |

| Length | Customizable |

| Surface | Pickled/Sandblasting/Polishing |

| Main Technique | Hot Rolled /Cold Rolled |

| Heat Treatment | Usually are Annealled,but Solid Solution & Aging can be also OK |

| Material Milling Certificate | According to. EN 10204.3.1 Including Chemical composition and Mechanical property |

| Application | Metallurgy, Electronics, Medical, Chemical, Petroleum, Pharmaceutical, aerospace, etc. |

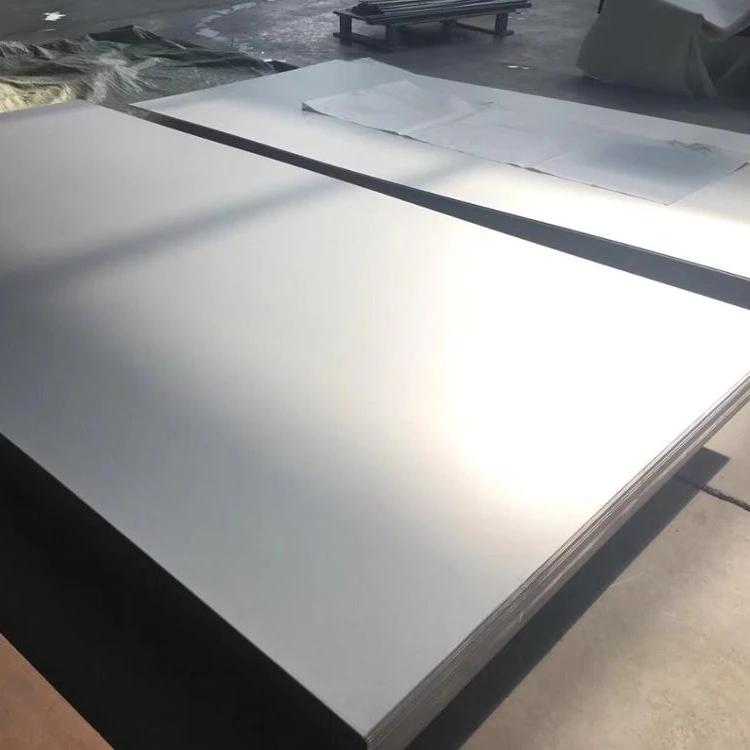

Titanium plate is the surface of the oxidized film equivalent to a good wear resistant hair separation agent, the use of titanium plate saves the separation agent, so that the plate stripping is easy, eliminating the process of pre-treatment of the plate, titanium plate is half lighter than the copper plate.

ASTM B265 high level Pure Titanium plates 99% Gr1 Grade 2

Titanium plates can be customized and processed to meet specific requirements, and they offer several unique benefits. One of the most notable features of titanium is its high strength-to-weight ratio, making it an excellent choice for a wide range of applications that require both durability and lightweight properties.

Furthermore, titanium has excellent corrosion resistance, making it ideal for use in harsh environments such as seawater or acidic conditions. This property also makes it a popular choice in marine, chemical, and aerospace industries, where equipment must withstand harsh conditions.

The cold-rolled process used in the production of titanium plates ensures that they have a superior surface finish while maintaining their strength and durability. Additionally, titanium's high purity level, which meets the strict ASTM B265 standard, makes it an excellent option for the medical and dental industries as it is bio compatible and non-toxic.

In conclusion, titanium plate's unparalleled strength, low density, corrosion resistance, and high purity make it a top choice for an array of applications across numerous industries. Its customization capabilities ensure clients can meet their specific needs, and with its superior properties, titanium plates are sure to remain a valuable material for years to come.

Feature

1.Low Density and High Strength

2.Excellent Corrosion Resistance

3.Good resistance to effect of heat

4.Excellent Bearing to cryogenic property

5.Nonmagnetic and Non-toxic

6.Good thermal properties

7.Low Modulus of Elasticity

ASTM B265 − 13

Standard Specification for

Titanium and Titanium Alloy Strip, Sheet, and Plate1

Chemical Requirements Composition, Weight Percent A.B,C,D,E

A At minimum, the analysis of samples from the top and bottom of the ingot shall be completed and reported for all elements listed for the respective grade in this table.

B Final product hydrogen shall be reported. Ingot hydrogen need not be reported. Lower hydrogen may be obtained by negotiation with the manufacturer.

C Single values are maximum. The percentage of titanium is determined by difference.

D Other elements need not be reported unless the concentration level is greater than 0.1 % each, or 0.4 % total. Other elements may not be added intentionally. Other elements may be present in titanium or titanium

alloys in small quantities and are inherent to the manufacturing process. In titanium these elements typically include aluminum, vanadium, tin, chromium, molybdenum, niobium, zirconium, hafnium, bismuth, ruthenium,

palladium, yttrium, copper, silicon, cobalt, tantalum, nickel, boron, manganese, and tungsten.

E The purchaser may, in the written purchase order, request analysis for specific elements not listed in this specification.

A Minimum and maximum limits apply to tests taken both longitudinal and transverse to the direction of rolling. Mechanical properties for conditions other than annealed

or plate thickness over 1 in. (25 mm) may be established by agreement between the manufacturer and the purchaser.

B Bend to Radius of Mandrel, T equals the thickness of the bend test specimen. Bend tests are not applicable to material over 0.187 in. (4.75 mm) in thickness.

C Material is identical to the corresponding numeric grade (that is, Grade 2H = Grade 2) except for the higher guaranteed minimum UTS, and may always be certified as

meeting the requirements of its corresponding numeric grade. Grade 2H, 7H, 16H, and 26H are intended primarily for pressure vessel use.

D The H grades were added in response to a user association request based on its study of over 5200 commercial Grade 2, 7, 16, and 26 test reports, where over 99 %

met the 58 ksi minimum UTS.

E For Grades 5, 6 and 32 the elongation on materials under 0.025 in. (0.635 mm) in thickness may be obtained only by negotiation.

F Elongation for continuous rolled and annealed (strip product from coil) for Grade 9 and Grade 18 shall be 12 % minimum in the longitudinal direction and 8 % minimum

in the transverse direction.

G Properties for material in the solution treated condition. H Material is normally purchased in the solution treated condition. Therefore, properties for aged material shall be negotiated between manufacturer and purchaser.

Manufacturing process

Hot forging A forging process performed above the recrystallization temperature of the metal. Hot rolling A rolling process carried out at temperatures higher than recrystallization. Cold rolling process in which the plastic deformation temperature is lower than the recovery temperature. Annealing: A metal heat treatment process in which the metal is slowly heated to a certain temperature, held for a sufficient time, and then cooled (usually slowly cooled, sometimes controlled cooled) at a suitable rate. Pickling: The part is immersed in an aqueous solution such as sulfuric acid to remove the oxide film on the metal surface. It is the pre-treatment or intermediate treatment of electroplating, enamel, rolling and other processes

Baoji Youding Titanium Industry Co., Ltd established in 2007, which is located in Gao Xin District, Baoji, Shaanxi, China, with modernized standard workshop more than 7,000 square meters.

We are a professional manufacturer engaged in the research, development, production, sell and service of titanium, nickel and zirconium, pure tungsten, tungsten heavy alloy, molybdenum, tantalum, niobium, nitinol as well as alloy products. Our products are widely used in chemical, lighting, glasses, medical, sports, outdoor, 3C Electronics, welding, aerospace, aviation, machinery, and furnace etc. We welcome OEM and ODM order.

The production process include melting, drawing, heat treatment, finishing and testing. Youding has obtained the ISO9001 International Quality Management System Certificate.

We are sincerely looking for long-term partners to seek for common development and realize a win-win situation with mutual benefits.

Q1: Are you a trading company or manufacturer ?

A1: We have our factory and production line, and we are rich experience on titanium and titanium alloy production.

Q2: Will you deliver the goods on time?

A2: Yes, we promise to provide the best quality products and deliver on time .Honesty is our company's tenet.

Q3: Do you provide samples? Is it free?

A3:Yes, the sample is free, but you need to pay the freight ,pleas kindly contact us directly.

Q4: Do you accept the third party inspection?

A4: Yes .

Q5: What kind of test you could make?

A5: 1. Nondestructive Test

2. UT Testing Detector

3. Tensile Tester

4. Digital Ultrasonic Detector

5. Infrared Tester

6. HV Hardness Tester

Q6: How do we trust your company?

A6: We have been specializing in titanium production for 17 years and you are welcome to investigate in any way.

Q7:What are the advantages of your company?

A7:

(1): Prime quality and reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Usually, trial order can be done in one week.

(6): Samples can be provided as your requirements.

Q8:How long is your delivery time?

A8:The products will be delivered ASAP on the basis of the quality assurance. Generally,samples order's delivery time is 6-10 days.Container orders around 25 days.

Q9:What information do you need if we order?

A9: Such as the grade, specification(such as width, thickness,diameter,etc.) coating,quantity and other special requirements,etc. According to the different products .

Q10: How to ensure product quality?

A10: Our production strictly follows the ISO9001 quality control system.

Quality is our culture. We have strict quality control department to supervise each link from assembling to shipping.

What we looking for are long-term partners instead of one-time business, so we will provide you high quality goods and do our best to provide you the best service

Q11: What your trade terms?

A11: EXW, FOB, DAP, CIF and etc can be accepted. You can choose the one which is the most convenient or cost effective for you.

Q12. How about your payment and shipment?

A12: Payment: Alipay T/T, Western Union, Paypal, Cash etc.

Похожие товары

Титановый лист ASTM B265 Gr1 Gr2 Gr5 титановый цена за грамму титановая

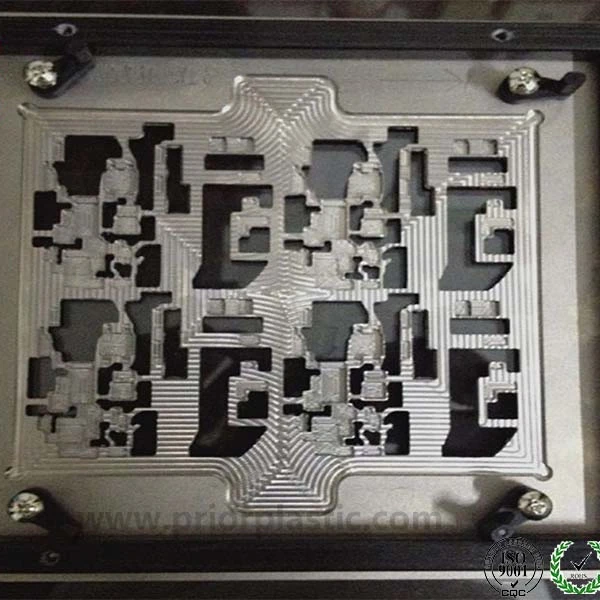

Титановый лист для паяльного поддона PCB

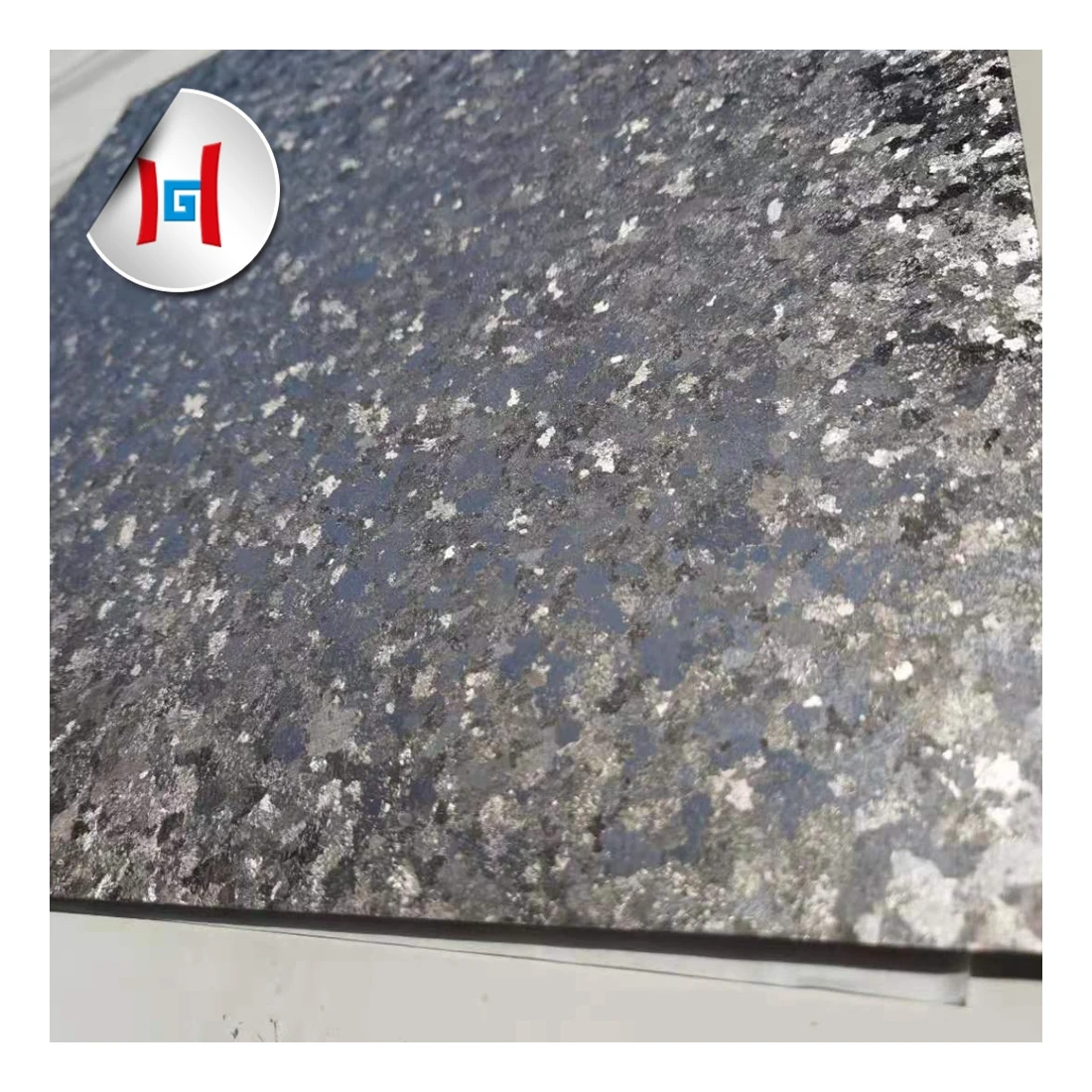

Импортный высококачественный кристаллический высокотемпературный цветной титановый лист

Титановый лист/пластина высокой чистоты хорошее качество цена за

Лидер продаж шлифовальный стержень из титанового сплава

Высококачественная взрывоопасная плакированная пластина титановая из нержавеющей

ASTM B265 класс 1 2 5 титановая пластина титановый

Новые поступления

Новинки товаров от производителей по оптовым ценам