Новый дизайн высокое качество pp pvc hdpe термоусадочная труба одностенная гофрированная производственная линия

- Категория: >>>

- Поставщик: Qingdao Fullwin Plastic Machinery Co. Ltd.

Сохранить в закладки 1601207973559:

Описание и отзывы

Характеристики

Product Overview

Single wall corrugated pipe production line

FULLWIN series of plastic single wall corrugated pipe production line meticulously developed by our company,through the gear drive module,water cooling in the water trough of the forming machine,the products are air-cooled,so that the production of the bellows molding speed,uniform corrugated shape,smooth inside and outside the wall.

FULLWIN series of plastic single wall corrugated pipe production line meticulously developed by our company,through the gear drive module,water cooling in the water trough of the forming machine,the products are air-cooled,so that the production of the bellows molding speed,uniform corrugated shape,smooth inside and outside the wall.

Production Line List | ||||

NO. | Description | QTY | ||

1 | Vacuum feeder and hopper dryer | 1 set | ||

2 | SJ65/30 Single screw extruder | 1 set | ||

3 | High quality die head and forming mould | 1 set | ||

4 | forming machine | 1 set | ||

5 | Double station winding machine | 1 set | ||

Final product&Application

Washing machine water drainage pipe.

PP PE PVC sink corrugated pipe can be washing machine drain pipes, drainage water extension pipes with connectors

Air conditioning pipe

PE corrugated pipes can be designed as air conditioning drain pipes,extension pipes with connectors, with good flexibility and

corrosion resistance

corrosion resistance

Shrinking corrugated pop tube

The telescopic bellows can be used as toy pop tube, often used as children's decompression toy tubes, finger tubes, to relieve children's depression, autism, and can also be used as party decoration tubes

Brief introduction of production line

Single screw Extruder with manual control panel

Fullwin design:single screw can use for PE,PP,PVC three materials production, it means can not only process granular raw materials, can also process powder raw materials,and it can wear iron wire too.

Inverter: ABB Delta

Contactor: Siemens

Temperature controller:Omron

Single screw Extruder with PLC control system

Customers can choose PLC control panel and manual button control panel according to individual needs

Inverter: ABB Delta

Contactor: Siemens

Contactor: Siemens

PLC control system: Siemens or Sunye

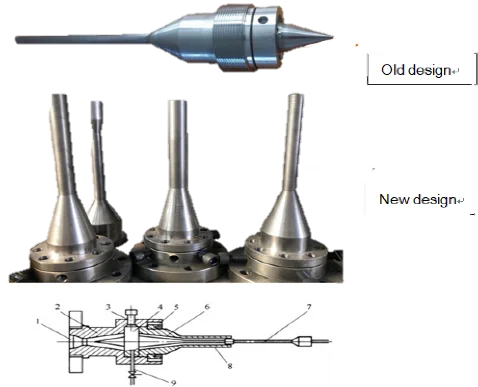

Fullwin design Die Head

Energy saving heating ringRock wool can keep warm,can help customer to save about 30% electricity cost

Mouth mold and core bar

Fullwin design :one whole part,no need to separate mouth mold and core bar,help customer to save operating time

Material:High quality material(38CrMoAIA)High hardness, strong wear resistance,has long service life.

We have double cavity and single cavity forming mould,choose double cavity forming mould can produce two size ,no need to change mould ,just adjust the forming machine is ok.It can help customer to save production time.

Production speed:20-30m/min

Plate material:38CrMoAIA ,high hardness,strong wear resistance,has long service life.

Moving method:

----up and down:electric adjustment

----left and right: manual adjustment

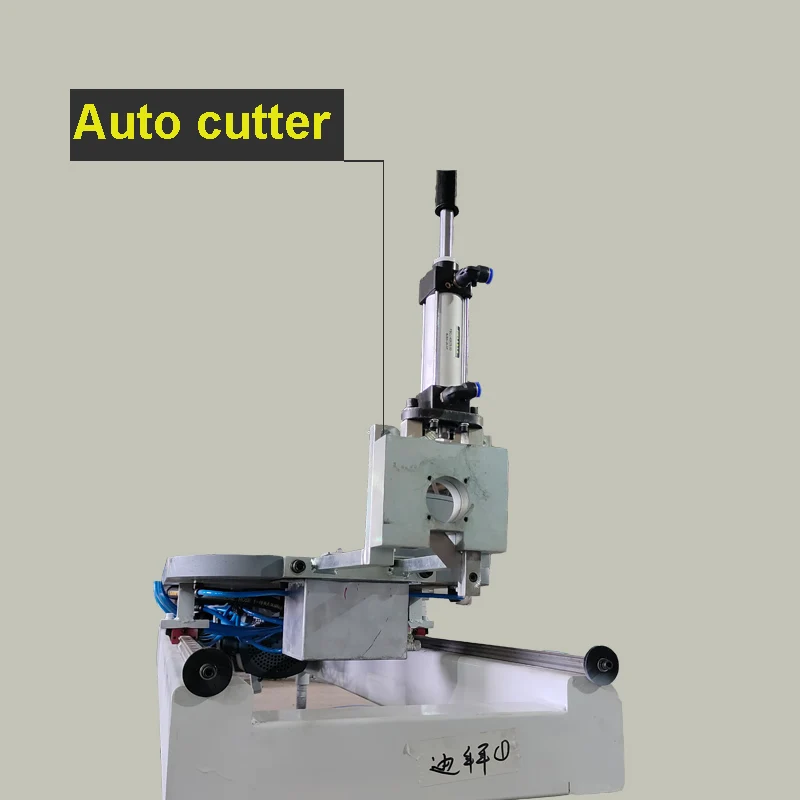

With online cutter,customer can according requirement setting length

The counter can adjust the winding speed by induction.

Customer can choose double station winder and single station winder according to their requirements.

Our team

FULLWIN PLASTIC MACHINERY CO., LTD

Our factory is located in the beautiful Qingdao city, focus on plastic extrusion manufacturers. Our company has gathered first-class scientific research talents from all over the country. At present, has successfully developed a number of plastic machinery production lines and supporting equipment, including single-wall corrugated pipe production line, double-wall corrugated pipe production line, PVC, PP water supply pipe production line, profile and sheet production line, etc. Among them, the corrugated production line has obtained a number of invention patents.

We Provide:

1.Design and manufacture suitable machine for you.

2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)

3. Delivery.(Full supervision of loading)

4. We will provide after-sales service:

(1) Field installation and commissioning;

(2) Field training your workers(will arrange our local engineer or overseas engineer to your factory;

(3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

After sale service

-After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply,

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer’s factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer’s factory.

- If buyer doesn’t request installation and commissioning by Seller’s engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer’s factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer’s factory.

- If buyer doesn’t request installation and commissioning by Seller’s engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

FAQ

1. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.what can you buy from us?

Single Wall Corrugated Pipe Machine,Double Wall Corrugated Pipe Machine,PVC/ PP Water Supply Pipe Machine,WPC/PVC Profile and Sheet Profile Machine,PVC Fiber Reinforced Pipe Machine

3. why should you buy from us not from other suppliers?

1.Advanced production technology with design capability. 2.Reasonable price with good quality and best delivey time 3.Our sales team will give prompt feedback within 24 hours . 4.Profession after sales service system

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.what can you buy from us?

Single Wall Corrugated Pipe Machine,Double Wall Corrugated Pipe Machine,PVC/ PP Water Supply Pipe Machine,WPC/PVC Profile and Sheet Profile Machine,PVC Fiber Reinforced Pipe Machine

3. why should you buy from us not from other suppliers?

1.Advanced production technology with design capability. 2.Reasonable price with good quality and best delivey time 3.Our sales team will give prompt feedback within 24 hours . 4.Profession after sales service system

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

Contact us

Похожие товары

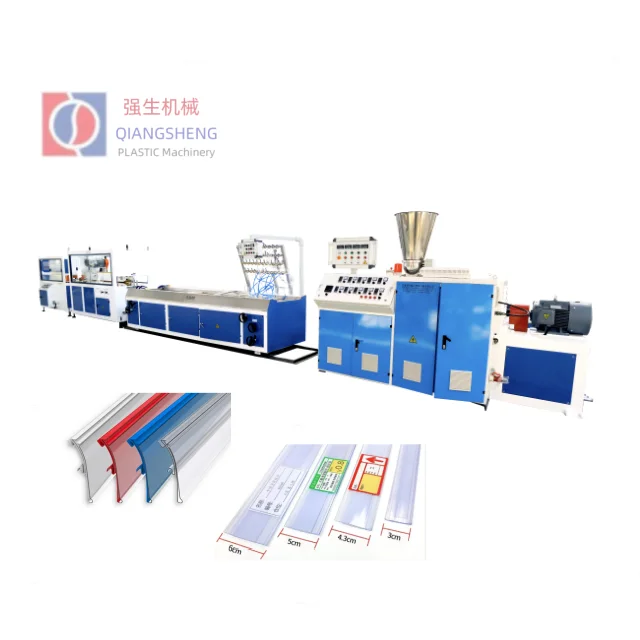

Пластиковый PP/LDPE мягкий ПВХ прозрачный профиль экструдер/подвесная лента клейкая цена полка этикетка держатель этикетки экструзионное оборудование

15 000,00 $ - 20 000,00 $

Поставка с завода, двухшнековый экструдер, пластиковый конический двухшнековый экструдер для линии по производству труб, пластиковый экструдер

6 500,00 $ - 8 600,00 $

Поставка современного Высокую прочность и небольшой плотности твердого вспененного пвх борту машины

ПВХ Кровельный Лист с эффектом пластиковой плитки машина для производства

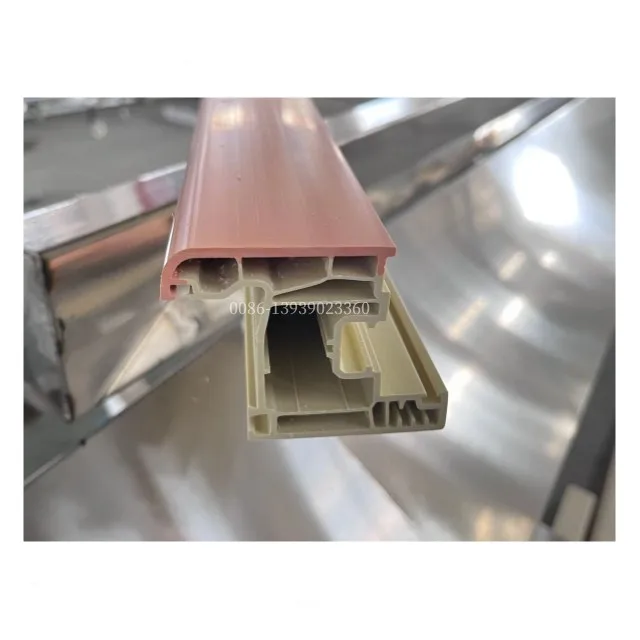

UPVC оконный и дверной профиль с прокладкой, устройство для совместной экструзии, производитель

28 000,00 $ - 30 000,00 $

ПВХ электрические Канальные трубы делая машину/высокая производительность 4 полости Экструзионная линия по производству пластикого

10 000,00 $ - 12 000,00 $

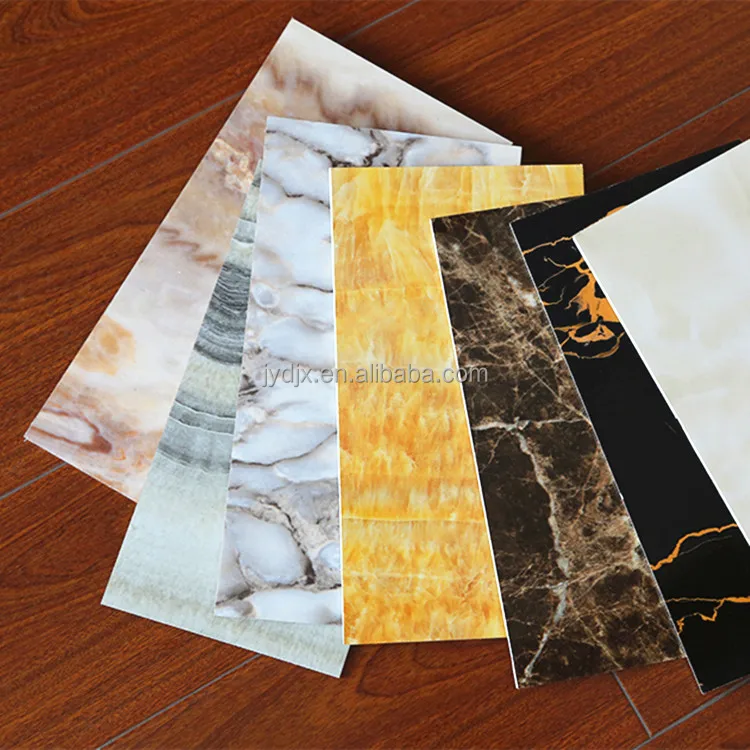

ПВХ мраморная интерьерная декоративная потолочная панель и стеновая экструдер Экструзионная

37 500,00 $ - 39 000,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $