Oem сталь большая шестерня 20 шт. нержавеющая 18Nicr5 4/Din1.5810 Круглый стержневой дюйм оригинальный обод кованые колеса

- Категория: >>>

- Поставщик: Shandong Meide Import And Export Co. Ltd.

Сохранить в закладки 1601208077335:

Описание и отзывы

Характеристики

Product specification

Available Material | Brass,Copper,Carbon Steel,StainlessSteel,Steel Alloy,Aluminum Alloy,etc. |

Heat Treatment | Annealing,Quenching,Nitriding,Hardening,Tempering,Normalizing,etc. |

Tolerance: | As per drawing.(+/-0.05mm,+/-0.01mm) |

Surface Treatment | Zinc-Plated,Nickel-Plated,Chrome-Plated,Anodize,Phosphating,Chemical Blackening,Salt Bath Nitriding,etc. |

Lead Time: | 20-45Days Depends On Quantities and complexity |

Application: | Forklift,Crane,Train,Truck,Lawnmower,Rail Road Euipment,medical device,industrialmachine, automobile,electric appliance,Automationmachine,other industries,etc, |

Payment Term: | L/Cat sightT/T30%deposit and balanced 70%to pay before shipment |

Port Of Loading | Shanghai or Ningbo,etc. |

Production Equipment: | CNC Machining center,CNC Lathe,Grinding Machine,Milling Machine,SawingMachine,Welding Machine,Hydraulic Press Machine,Drilling and Tapping Machine,Gear Shaping Machine,etc. |

Inspection Equipment | Electronic Penumatic Measuring Instrument,Three Coodinate Detection Equipment,Rockwell Hardness Tester,Digital Uitrasonic Flaw Detector,Surface Roughness Measuring Instrument,Leeb HardnessTester,Cladding Measuring Instrument,Salt Spraying Tester,Gear Measurement Center,etc. |

QC | 1.Incoming material will bechecked before production.2.Strict processing quality control 3.100%inspection before shipment. 4.We are responsible for product quality to the enduser. |

Package: | Method 1:Carton box or corrugated carton Method 2.Wooden case or wooden crate Method 3:Iron basket or plastic basket Method 4:Pallet |

After-sales Service: | Wewill follow up goods for customers and help to solve problems after sales. |

Product procees and feature

1.the selection of raw materials is crucial. High-quality steel is usually selected to ensure that the steel ring has good initial

performance and purity. In the heating process, the temperature and heating time need to be precisely controlled. Too high a

temperature may cause the steel to overheat or even burn, while too low a temperature will affect the subsequent forging effect.

2.During the forging process, the metal fibers are distributed along the contour of the steel ring through multiple forgings,

which greatly improves the strength and toughness of the steel ring. This process requires experienced craftsmen or advanced

automation equipment to accurately control the forging force and direction.

performance and purity. In the heating process, the temperature and heating time need to be precisely controlled. Too high a

temperature may cause the steel to overheat or even burn, while too low a temperature will affect the subsequent forging effect.

2.During the forging process, the metal fibers are distributed along the contour of the steel ring through multiple forgings,

which greatly improves the strength and toughness of the steel ring. This process requires experienced craftsmen or advanced

automation equipment to accurately control the forging force and direction.

Product procees and feature

3.In addition, Subsequent heat treatment processes can further optimize the organizational structure and performance of the steel

ring.modern production processes also focus on energy conservation and environmental protection, using advanced

equipment and technology to reduce energy consumption and reduce environmental pollution. 4.In short, the production process of

forged steel rings is a complex process that integrates multidisciplinary knowledge such as material science, mechanical

engineering and precision machining. Each link needs to be carefully controlled to produce high-quality forged steel rings.

ring.modern production processes also focus on energy conservation and environmental protection, using advanced

equipment and technology to reduce energy consumption and reduce environmental pollution. 4.In short, the production process of

forged steel rings is a complex process that integrates multidisciplinary knowledge such as material science, mechanical

engineering and precision machining. Each link needs to be carefully controlled to produce high-quality forged steel rings.

Product application

1. The automotive industry

- Application parts: engine, frame, wheel hub, drive shaft, suspension system and other key parts.

- Importance: The application of forgings in these parts ensures the high strength, high wear resistance, high precision and high reliability of the car. For example, key components of automotive engines require high-quality forgings to ensure the stability and durability of their operation.

2. Aerospace industry

- Application parts: engine, shell, flight control and other key parts.

- Importance: The aerospace sector requires very high quality parts, and forgings are widely used in this field because of their high precision, high strength and excellent mechanical properties. For example, key components such as the landing gear and engine hanger of the aircraft are forged.

3. Rail transit industry

- Application parts: wheel hub, frame and other key parts.

- Importance: Due to the high-speed, high-load, high-density operation characteristics of rail transit, the quality of parts is extremely high. The high strength and toughness of forgings can meet these requirements and improve the safety and reliability of rail transit.

4. Shipbuilding industry

- Application parts: rudder, shaft, anchor chain, main engine and drive shaft and other key parts.

- Importance: Forging can improve propeller performance and long-term operational reliability, thereby increasing the speed and load capacity of the ship. In the field of shipbuilding, the application of forgings is of great significance to ensure the safety and stability of ships.

5. Power and energy sectors

- Application parts: hydrogenerator forgings (such as spindle and intermediate shaft), thermal power plant forgings (such as rotor, impeller, ring spindle, etc.).

- Importance: The application of these forgings guarantees the stable operation of power equipment and efficient power generation. The high strength and durability of forgings enable power equipment to withstand complex working environments and high-intensity operating requirements.

6. Metallurgical machinery and pressure vessel industry

- Application: metallurgical machinery (such as cold rolls, hot rolls and herringbone shaft) and pressure vessels (such as cylinders, tank flanges and heads) and other key parts.

- Application parts: engine, frame, wheel hub, drive shaft, suspension system and other key parts.

- Importance: The application of forgings in these parts ensures the high strength, high wear resistance, high precision and high reliability of the car. For example, key components of automotive engines require high-quality forgings to ensure the stability and durability of their operation.

2. Aerospace industry

- Application parts: engine, shell, flight control and other key parts.

- Importance: The aerospace sector requires very high quality parts, and forgings are widely used in this field because of their high precision, high strength and excellent mechanical properties. For example, key components such as the landing gear and engine hanger of the aircraft are forged.

3. Rail transit industry

- Application parts: wheel hub, frame and other key parts.

- Importance: Due to the high-speed, high-load, high-density operation characteristics of rail transit, the quality of parts is extremely high. The high strength and toughness of forgings can meet these requirements and improve the safety and reliability of rail transit.

4. Shipbuilding industry

- Application parts: rudder, shaft, anchor chain, main engine and drive shaft and other key parts.

- Importance: Forging can improve propeller performance and long-term operational reliability, thereby increasing the speed and load capacity of the ship. In the field of shipbuilding, the application of forgings is of great significance to ensure the safety and stability of ships.

5. Power and energy sectors

- Application parts: hydrogenerator forgings (such as spindle and intermediate shaft), thermal power plant forgings (such as rotor, impeller, ring spindle, etc.).

- Importance: The application of these forgings guarantees the stable operation of power equipment and efficient power generation. The high strength and durability of forgings enable power equipment to withstand complex working environments and high-intensity operating requirements.

6. Metallurgical machinery and pressure vessel industry

- Application: metallurgical machinery (such as cold rolls, hot rolls and herringbone shaft) and pressure vessels (such as cylinders, tank flanges and heads) and other key parts.

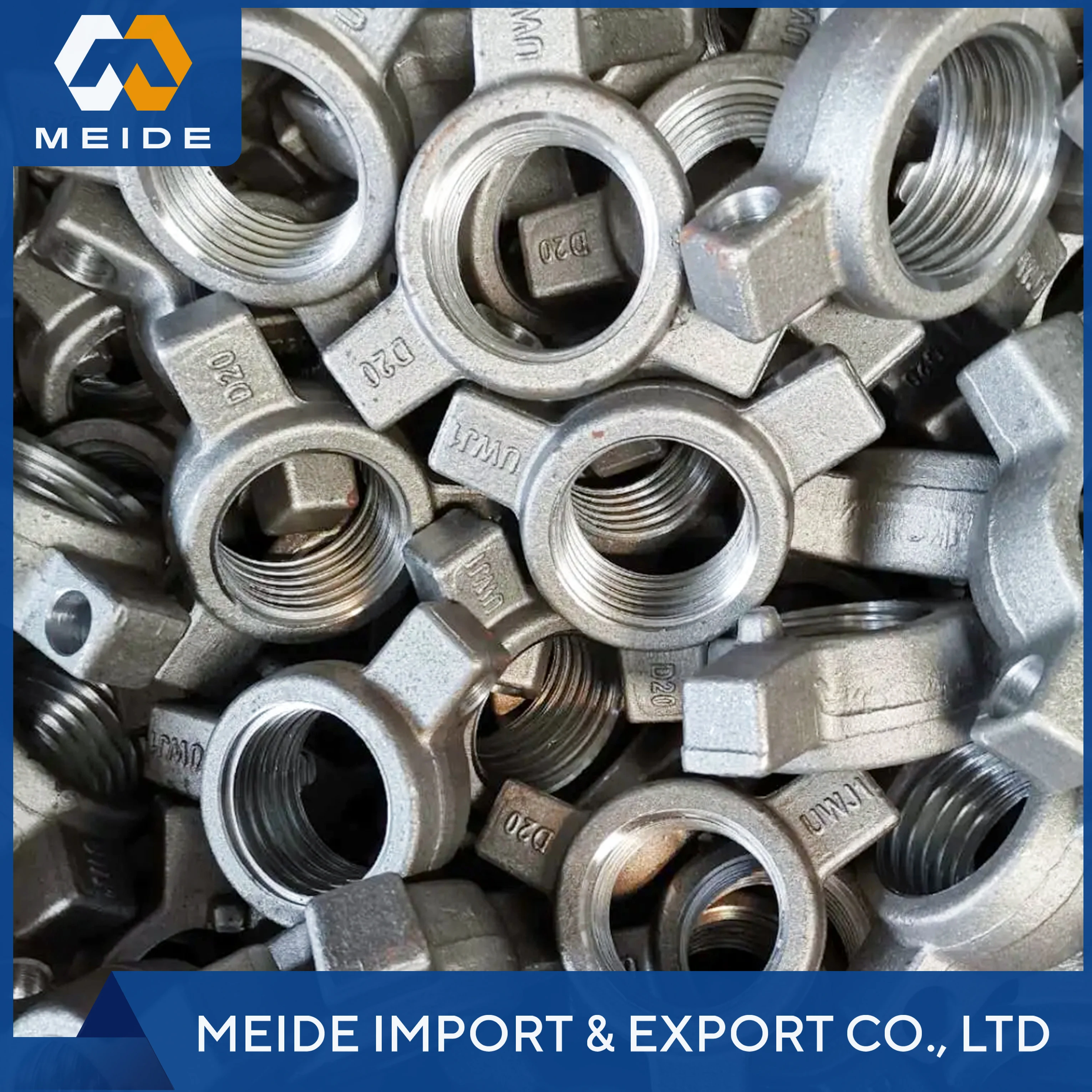

Product Display

Company Profile

Shandong Meide Import and Export Co., LTD was established in 1997. Located in Liaocheng City, Shandong Province, the largest steel logistics center in North China, focusing on the production and sales of copper, aluminum, stainless steel, special steel, mould steel, alloy steel, steel processing machinery and equipment. Our products are mainly extended to five series of plate, strip, tube, bar and profile. We have passed ISO9001:2000 quality system certification, SGS, ROSH, TUV and REACH certification. Has cold rolling, hot rolling and other production lines. Such as heat treatment chemical analysis, metal halide testing, physical testing, nondestructive testing and other testing equipment and testing technology, imported physical and chemical testing equipment full spectrum direct reading spectrometer, can quickly and accurately chemical analysis of all kinds of metal materials. According to American ASTM standard, Japanese JIS standard, German DIN standard, British BS standard and other standards production. At the same time, we can customize and develop new products according to the actual application of customers, and provide products for different cost and performance requirements. The company cooperates with more than 20 well-known steel mills in China, and has established modern large outdoor warehouse and indoor warehouse, with 20,000 tons of goods in stock. The customer base covers all provinces and cities in China, and has more than 100 long-term stable cooperative customers. We warmly welcome and look forward to cooperating with you!

Production Process

1. Material preparation:

- The production of forged parts requires the use of metal materials, usually used materials are steel, aluminum, copper, titanium and so on.

- Before forging, it is necessary to inspect and prepare the material, including the quality, chemical composition, mechanical properties, etc.

- Material preparation involves cutting metal materials to the appropriate size and shape for subsequent processing.

2. Heat:

- Heating is one of the most important steps in the forging production process.

- The material needs to be heated to the right temperature so that it becomes soft and easy to work with. The heating temperature and time depend on the type and size of the material.

Generally, the heating temperature is below the melting point of the material to avoid melting of the material.

3. Forging:

- Forging is a key step in the forging production process.

- During forging, metal materials are stressed and deformed to change their shape and physical properties.

- Forging can be divided into manual forging and mechanical forging two ways. Manual forging requires highly skilled workers to operate, while mechanical forging is usually carried out using equipment such as forging presses.

4. Heat treatment:

- Heat treatment is one of the important steps in the production of forged parts.

- During the forging process, the grain structure of the metal material will change, and the heat treatment can restore the grain structure and mechanical properties of the material.

- The methods of heat treatment include annealing, normalizing, quenching and tempering.

5. Processing:

- Machining is the last step in the forging process.

- In the process of processing, forging parts need to be trimmed, polished and surface treatment.

- Machining methods commonly used include turning, milling, grinding, drawing, stamping, etc.

6. Check:

- During the forging process, the finished product needs to be inspected to ensure that its quality and performance meet the requirements.

- The contents of inspection include size, appearance, mechanical properties, etc.

- The production of forged parts requires the use of metal materials, usually used materials are steel, aluminum, copper, titanium and so on.

- Before forging, it is necessary to inspect and prepare the material, including the quality, chemical composition, mechanical properties, etc.

- Material preparation involves cutting metal materials to the appropriate size and shape for subsequent processing.

2. Heat:

- Heating is one of the most important steps in the forging production process.

- The material needs to be heated to the right temperature so that it becomes soft and easy to work with. The heating temperature and time depend on the type and size of the material.

Generally, the heating temperature is below the melting point of the material to avoid melting of the material.

3. Forging:

- Forging is a key step in the forging production process.

- During forging, metal materials are stressed and deformed to change their shape and physical properties.

- Forging can be divided into manual forging and mechanical forging two ways. Manual forging requires highly skilled workers to operate, while mechanical forging is usually carried out using equipment such as forging presses.

4. Heat treatment:

- Heat treatment is one of the important steps in the production of forged parts.

- During the forging process, the grain structure of the metal material will change, and the heat treatment can restore the grain structure and mechanical properties of the material.

- The methods of heat treatment include annealing, normalizing, quenching and tempering.

5. Processing:

- Machining is the last step in the forging process.

- In the process of processing, forging parts need to be trimmed, polished and surface treatment.

- Machining methods commonly used include turning, milling, grinding, drawing, stamping, etc.

6. Check:

- During the forging process, the finished product needs to be inspected to ensure that its quality and performance meet the requirements.

- The contents of inspection include size, appearance, mechanical properties, etc.

Certification

Packaging and Transportation

FAQ

1. Q:Are you a genuine manufacturer?

A:Yes,all the products are produced in our ISO9001:2015 certified factory

2. Q:What should I offerto get your quotation?

A: Please offer us your detailed information for the product,such as drawings with 2D/3D by software Pro/E,Auto CAD,Solid Works,UG etc;as well as materials,surface treatment,quantity,package. Any special requirements should be highlighted especially for tolerance.

3. Q:Can we get a complete productbesides CNC parts?

A:To some extent,yes,we can. But firstly we need assess feasibility

4. Q:What'syour top process tolerance?

A:Nowour top process tolerance is ±0.005mm.

A:Yes,all the products are produced in our ISO9001:2015 certified factory

2. Q:What should I offerto get your quotation?

A: Please offer us your detailed information for the product,such as drawings with 2D/3D by software Pro/E,Auto CAD,Solid Works,UG etc;as well as materials,surface treatment,quantity,package. Any special requirements should be highlighted especially for tolerance.

3. Q:Can we get a complete productbesides CNC parts?

A:To some extent,yes,we can. But firstly we need assess feasibility

4. Q:What'syour top process tolerance?

A:Nowour top process tolerance is ±0.005mm.

5. Q:I want to keep our design in confidence;can wesign NDA?

A:Sure,to protect customers'profit is our obligatory responsibility,signed NDA would be valid to both of us.

A:Sure,to protect customers'profit is our obligatory responsibility,signed NDA would be valid to both of us.

Похожие товары

Ковка из нержавеющей стали

Опытный производитель OEM, большие закрытые Стальные Поковки на заказ

1 066,04 ₽ - 3 236,94 ₽

OEM и ODM латунная ковка

372,25 ₽ - 458,57 ₽

Высокоточные высококачественные металлические детали для ковки автомобилей и мотоциклов

214,72 ₽ - 322,62 ₽

Кованые алюминиевые автозапчасти алюминиевые аксессуары холодной ковки и детали горячей ковки

107,90 ₽ - 140,27 ₽

Заводская ковка и сварочный аппарат, кованые стальные алюминиевые детали для холодной ковки

156,46 ₽ - 178,04 ₽

Коннекторы для горнодобывающей цепи, специально разработанные услуги ковки, детали для горячей ковки

5 934,38 ₽ - 7 552,85 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $