Сверхмощный диск из полиуретановой пластины для тяжелых тележек и промышленного устройства

- Категория: >>>

- Поставщик: Jixing Xinzhu Metal Products Co. Ltd.

Сохранить в закладки 1601208079019:

Описание и отзывы

Характеристики

Product Description

| Wheel Material: |

| |||||||||

| Wheel Bearing Type |

| |||||||||

| Brake Type |

| |||||||||

| Mounting Type |

|

Our Equipment

| Stamping/Punching Machines | 315T |

|

| 160T | ||

| 125T | ||

| 80T | ||

| 40T | ||

| Auto Pipe Cutting Machine | LPC80-A5 | |

| Welding Machine |

1. Welding Robots 2. MIG Welding Device 3. TIG Welding Device 4. Spot Welding Device

| |

| Drilling machines | 10 sets | |

| Shearing machine | 1 set | |

| Milling Machine | 1 set | |

| Shot Blasting Machines | 2 sets | |

| Bending Machine | 1 set |

Production Processes

|  |  | ||

| Company | Mold Design & Mold Shop | Material | ||

|  |  | ||

Shearing | Stamping/Punching | Bending | ||

|  |  | ||

| Drilling | Welding | Final Products |

Why Choose Us

CWB Certified Welders

In the past five years, the percentage of our welding parts has increased annually, reaching 30% last year.

To ensure the quality of our welding parts, we subject our welding operations, welding procedures, and welders to rigorous testing and training by CWB. This guarantees that we meet the higher welding requirements of our customers.

In-house mold shop

At our company, we believe in maintaining control over our tool-making process, which is why we have never turned to outsourcing.

We are committed to continuously improving our mold design technology and mold-making skills.

In fact, most of our new samples can be completed in just twenty days, giving us a competitive edge in terms of speed. While other companies are still in the process of making their samples, ours are already in your hands.

17 years of experience in metal stampings

Since 2007, we’ve accumulated extensive hardware manufacturing experience and identified areas for improvement.

Our company specializes in producing a wide range of products, from simple stamping parts to complex welding parts, assembly parts, deep drawing parts, and auto parts. We take pride in our ability to meet our customers' precise requirements.

FAQ

1. Sample?

Samples are free and freight to collect

2. Sample lead time?

3-7 days

3. Are you a factory?

Yes, we are a metal products factory located in Jiaxing, Zhejiang. Our nearest export port is Shanghai.

4. How can I visit you?

We can arrange to pick you up from the Jiaxing Railway station, Shanghai Hongqiao Airport.

Похожие товары

Подгонянный эксцентриковый колесный воздушный насос поршневой шатун порошковой металлургии

Индивидуальные автомобильные запчасти 3D большая модель автомобиля запасные части модели быстрое обслуживание прототипа

TEC1-06305 охлаждающий элемент холодильника медицинское устройство

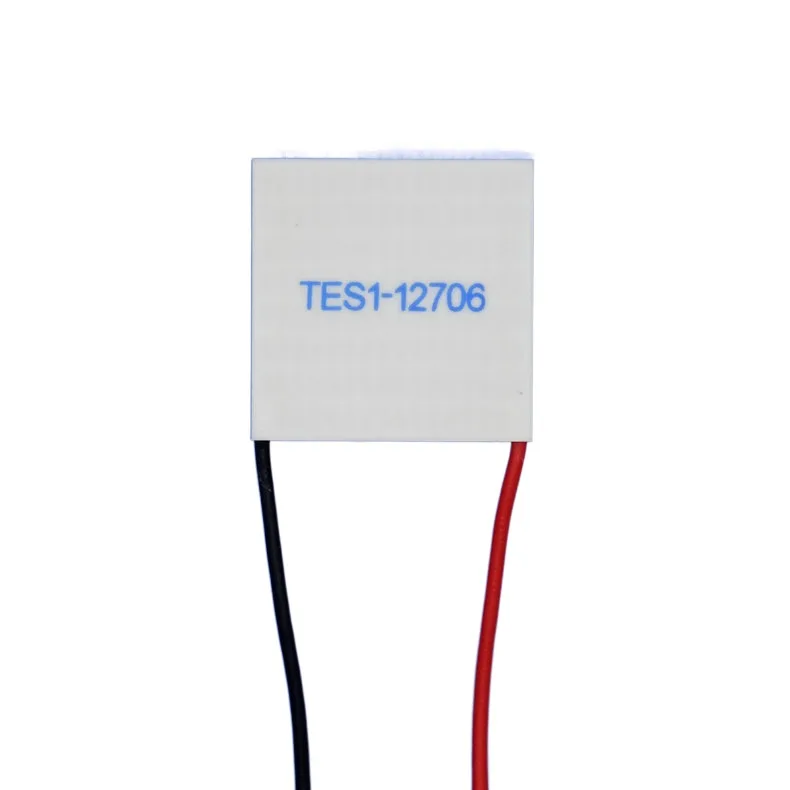

TES1-12706-30-30 промышленная холодильная деталь медицинское устройство охлаждающая пластина дозатор воды охлаждающий элемент

TEC12 * 60 10*60 15*60 высокотемпературный полупроводниковый Пельтье эффект промышленного Парр пост-охлаждения

TES1-031015 8 3 Осушитель охлаждающая пластина диспенсер для воды деталь миниатюрная

Опт на заказ аксессуары для обогрева горшков диаметр основания 195 мм коммерческий пряный горячий горшок электрический нагревательный элемент

Новые поступления

Новинки товаров от производителей по оптовым ценам