Большая емкость шаровая мельница для извести черного порошка керамическая машина горячая распродажа

- Категория: >>>

- Поставщик: Shicheng Wanshuntong Mining Equipment Co. Ltd.Shicheng Ltd.

Сохранить в закладки 1601208303598:

Описание и отзывы

Характеристики

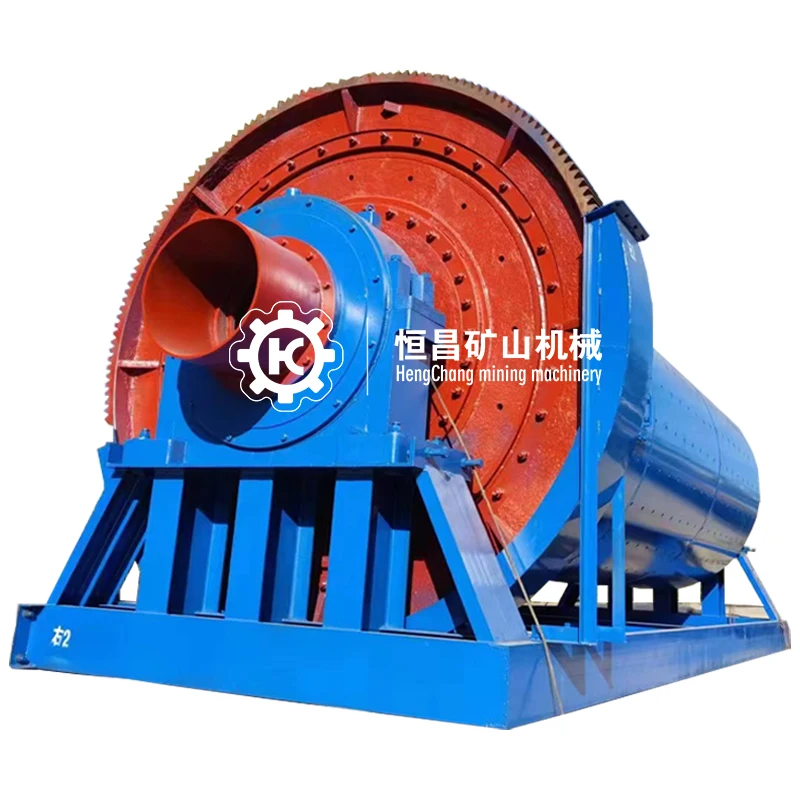

Ball Mill

Ball mill machine is the key equipment for recrushing the materials after the primary crushing. Widely used for the dry type or wet type grinding of all kinds of ores and other grinding materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals and glass ceramic industry. The ore grinding methods of ball mill include dry type and wet type.

Grinding material are brought out by air current when using dry ball mill.

Grinding material are brought out by water when using wet ball mill.

Wet ball mill is turning slowly by the driving device. The material are feed from the feed port and grinding by the steel ball and ore. As the material are feed continuously and the material inside of cylinder are moved to the discharge port by the pressure. And the finished material are discharged from the cylinder when it reaches the required size. Grinding material are brought out by water when using wet ball mill. Grinding material are brought out by air current when using dry ball mill. Tubular energy saving grid ball mill has discharge grid at the end of discharge port, so the material are discharged by force with grid plate. And the ore pulp is lower in cylinder, so the grid plate could prevent the ore being over grinding and the ball being discharged.

Model | Cylinder dia. (mm) | Cylinder length (mm) | Motor power (kw) | Length (mm) | Width (mm) | Height (mm) | Capacity (t/h) | Volume (m3) | Max.ball charge |

1200×1200 | 1200 | 1200 | 22 | 3512 | 2076 | 1620 | 0.17 ~4.1 | 1.14 | 2.4 |

1200×2400 | 1200 | 2400 | 45 | 5745 | 2352 | 1778 | 0.26~6.15 | 2.4 | 4.6 |

1200×4000 | 1200 | 4000 | 80 | 7990 | 2210 | 2262 | 0.34 ~8.3 | 3.8 | 7.8 |

1500×1500 | 1500 | 1500 | 45 | 5740 | 3075 | 2280 | 1.4 ~4.5 | 2.2 | 5 |

1500×3000 | 1500 | 3000 | 80 | 7253 | 3070 | 2280 | 2.8 ~9 | 5 | 10 |

1500×3600 | 1500 | 3600 | 110 | 8595 | 3185 | 2280 | 3~11 | 5.4 | 11.4 |

1500×4500 | 1500 | 4500 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 |

Похожие товары

Шаровая мельница большой емкости большая шаровая лучшего качества

High Guality Ball Grinding Mill Factory Small Price Machine

Горячий продукт шаровая мельница шлифовальный станок подшипник эффективная Шахта

Высокоэффективный цементный клинкер шлифовальный шаровой мельница станок

Гипсовый известняковый порошок карбонат кальция кварцевый доломит Ультратонкий шлифовальный станок Raymond

Высокоэффективная шлифовальная мельница Известняковая гипсовая тальковая каменная от производителя

2145 шаровая мельница оборудование для обработки минералов сухое мокрое измельчение хвостов угольная

Новые поступления

Новинки товаров от производителей по оптовым ценам