Изготовленный на заказ OEM электронный компонент высокоточный алюминиевый экструзионный светодиодный радиатор освещения

- Категория: >>>

- Поставщик: Dongguan Ruiquan Hardware Electronics Co. Ltd.

Сохранить в закладки 1601208431902:

Описание и отзывы

Характеристики

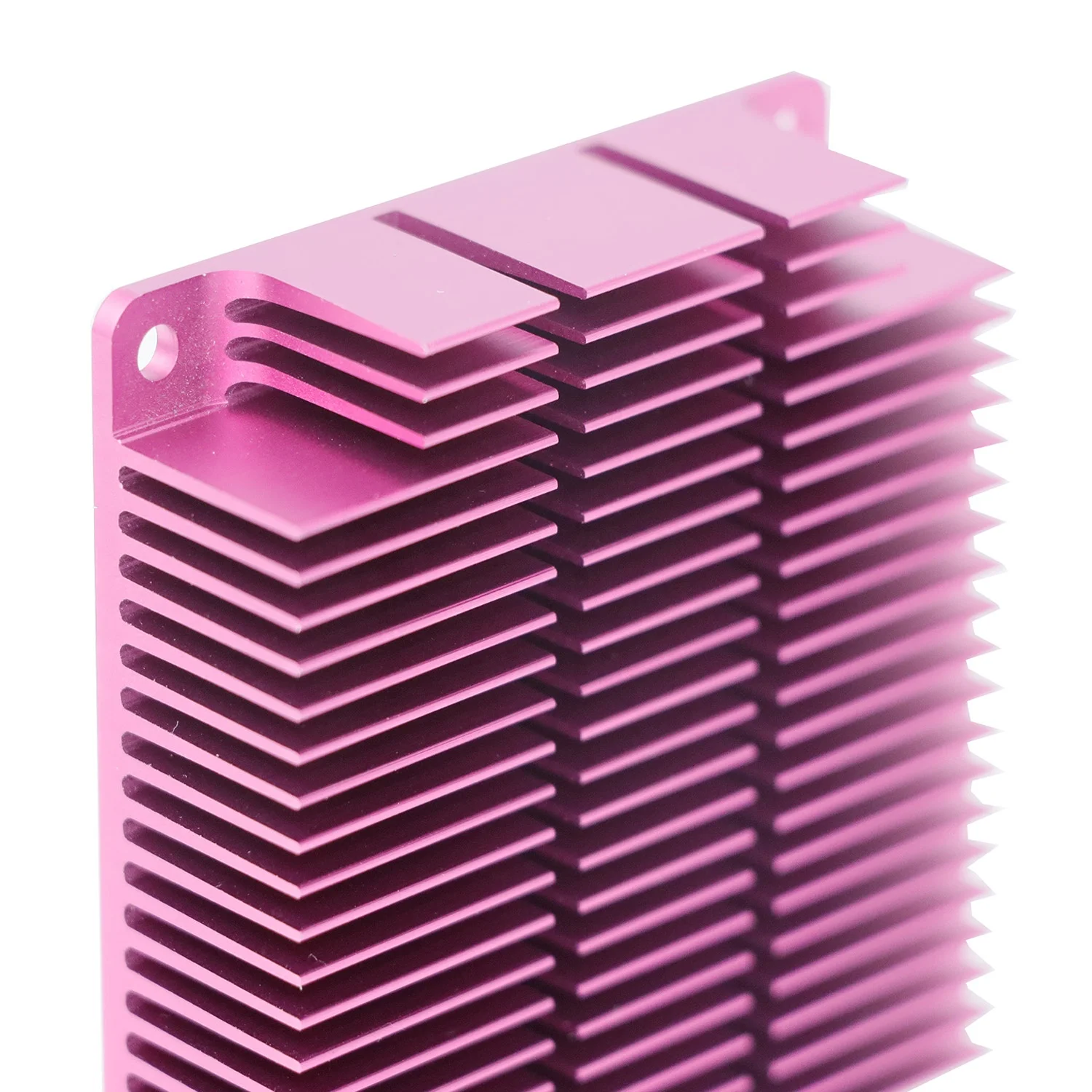

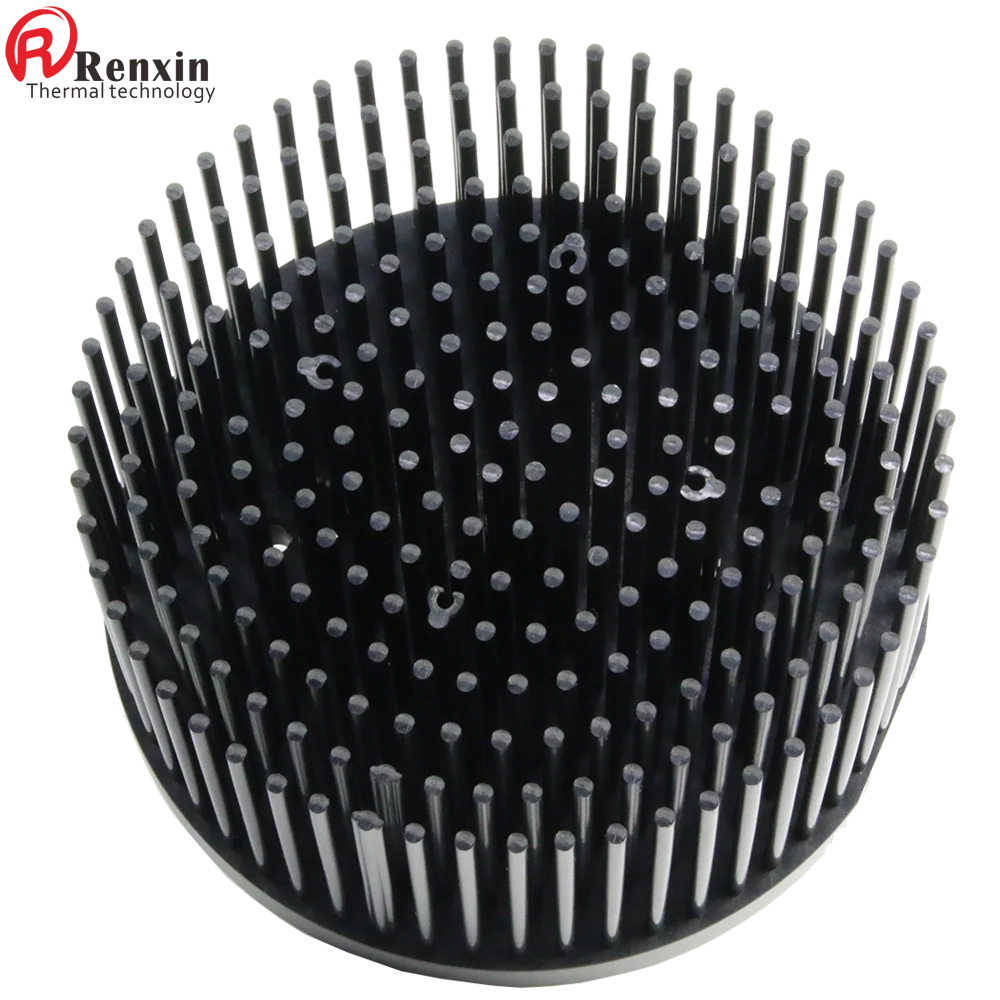

Cold forging is a manufacturing process in which the aluminum or copper heat sink is formed by using localized compressed forces. Fin arrays are formed by forcing raw material into a molding die by a punch. The process ensures that no air bubbles, porosity or any other impurities are trapped within the material and thus produces exceptionally high quality products.

Detailed Descriptions (Payment Terms/Shipment Terms/Lead time/Min. Order): | |

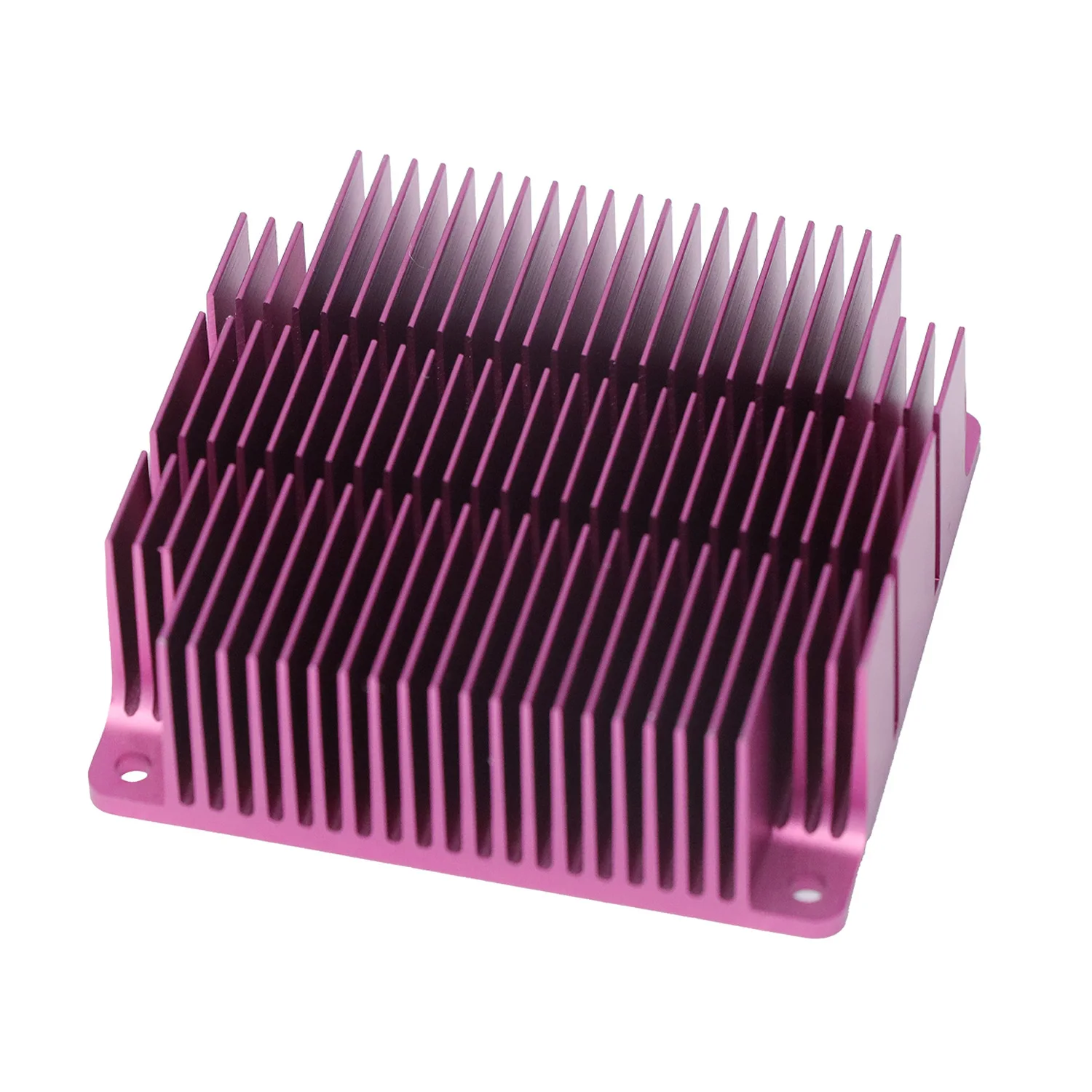

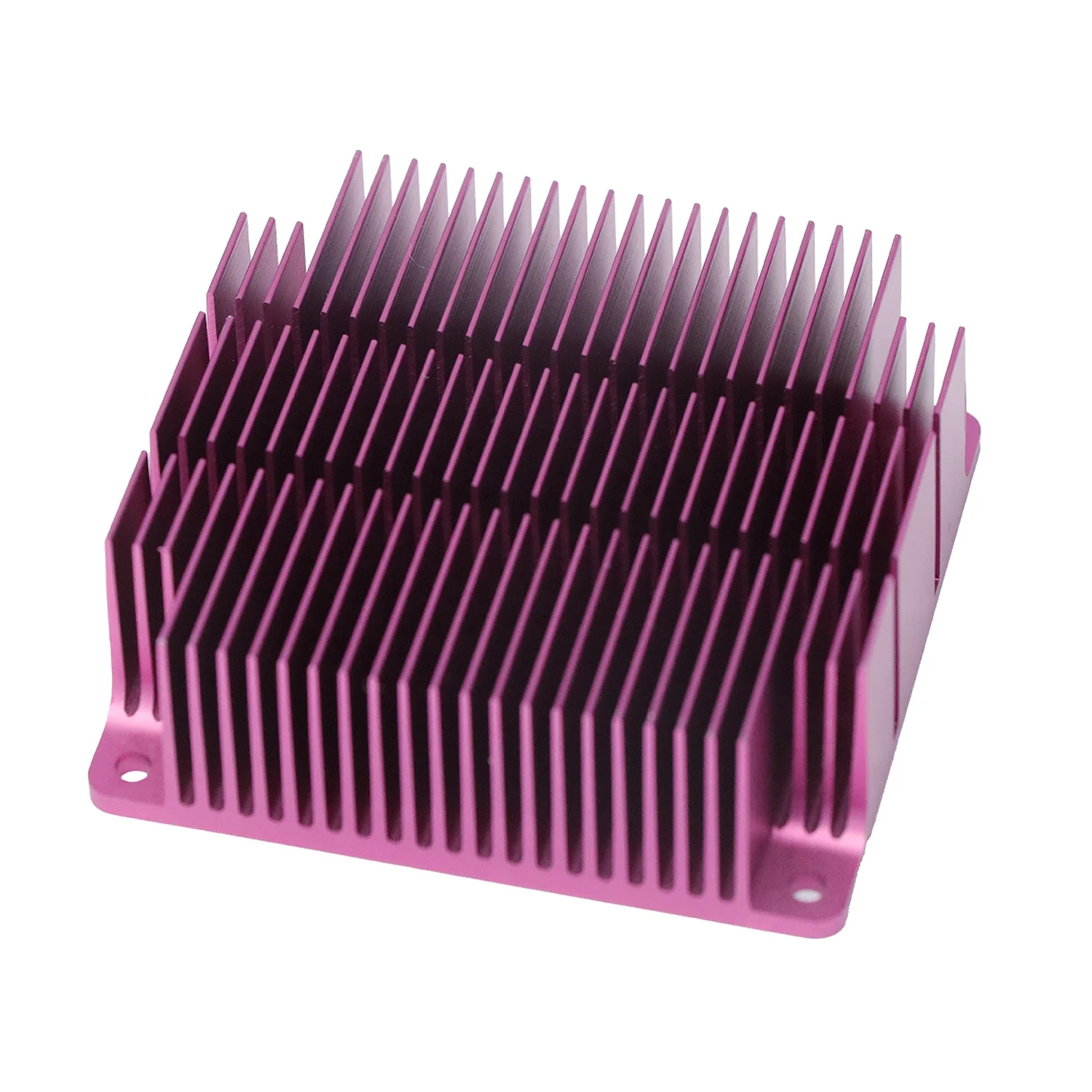

Name | aluminum heat sink enclosure from direct factory |

Size | 69.8*69.8*35 mm |

Process | CNC milling and turning, drilling, grinding, bending, stamping, tapping |

Tolerance | 0.05mm~0.1mm |

DRW format | PDF/DWG/IGS/STP/ etc |

Equipment | CNC machining center, CNC turning, General milling machines. |

Capacity: | 10,0000 pieces per month |

MOQ: | 1000 pcs |

QC System: | 100% inspection before shipment |

Payment term | T/T , West Union,FOB,L/C |

Surface treatment | Anodizing, zinc/chrome/nickel/silver/gold Plating, Polish, Imitation, , Heat treatment etc |

Q1:Do you make customized products based on our design drawings?

A1:Yes, we are a professional metal fabrication factory with an experienced engineering team to make custom products according to clients’drawings.

Q2: Will my drawing be safe after you get it?

A2:Yes, we will not release your design to third party unless with your permission. And we can sign the NDA before you send the drawing.

Q3: What is the MOQ?

A3: Usually we don’t set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Q4:Whether some samples can be provided?

A4: Yes, just need some sample cost, we will return it back when proceed into mass production.

Q5:How to deal with the parts received when they are found to be in poor quality?

A5:Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non- conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time , the resulting transportation costs borne by our company.

Q6:How can you certify capacity?

A6: 1)we have a 100 people team.

2)we have 145 machines:CNC Drill cold forging incise puch ect

3)we have ourself anode factory.

So, we can ensure the production quantity about 5000pcs/day

Похожие товары

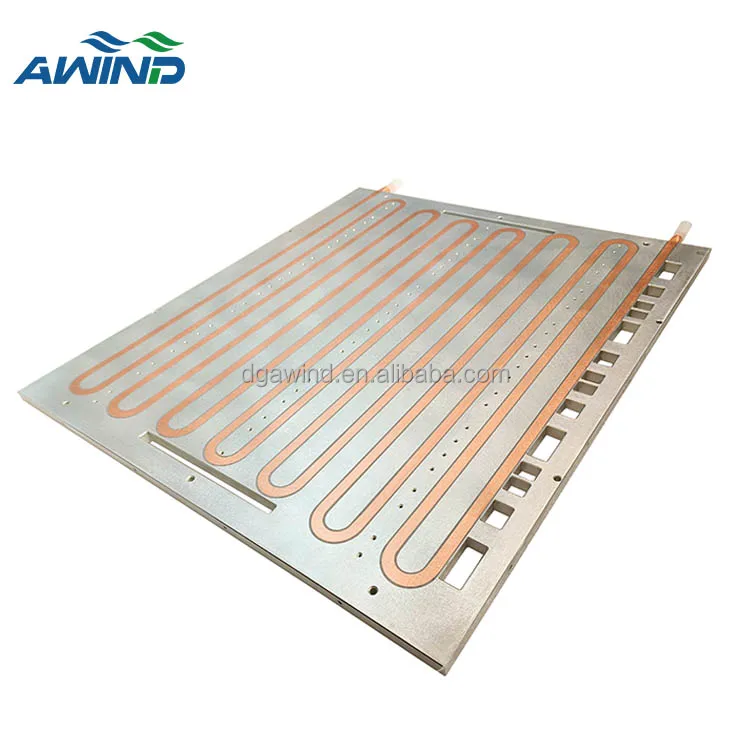

Алюминиевый, 50 мм, жидкая холодная пластина, теплоотвод, охлаждающая жидкая холодная пластина, термопарный теплоотвод

Пластина водяного охлаждения 600 мм с медной трубкой, теплообменник, алюминиевая + медная трубка, радиатор с водяным охлаждением, радиатор

Механический радиатор с ЧПУ

Модный ковкий корпус из алюминиевого профиля серии 6000 для автоматизации производства цеха

Промышленная светодиодная лента для литья под давлением, 6063, анодированный источник питания, алюминиевые детали радиатора

Радиатор с водяным охлаждением, 1000 мм, 1 кВт, 300 Вт, 400 Вт, 500 мм

Алюминиевая светодиодная труба, профиль теплоотвода на молнии, крутые инновационные гибкие графеновые радиаторы для инверторного усилителя мощности

Новые поступления

Новинки товаров от производителей по оптовым ценам