6 ячеек Sf1.2 флотационная машина wanshuntong флотационные ячейки цена

- Категория: >>>

- Поставщик: Shicheng Wanshuntong Mining Equipment Co. Ltd.Shicheng Ltd.

Сохранить в закладки 1601210326474:

Описание и отзывы

Характеристики

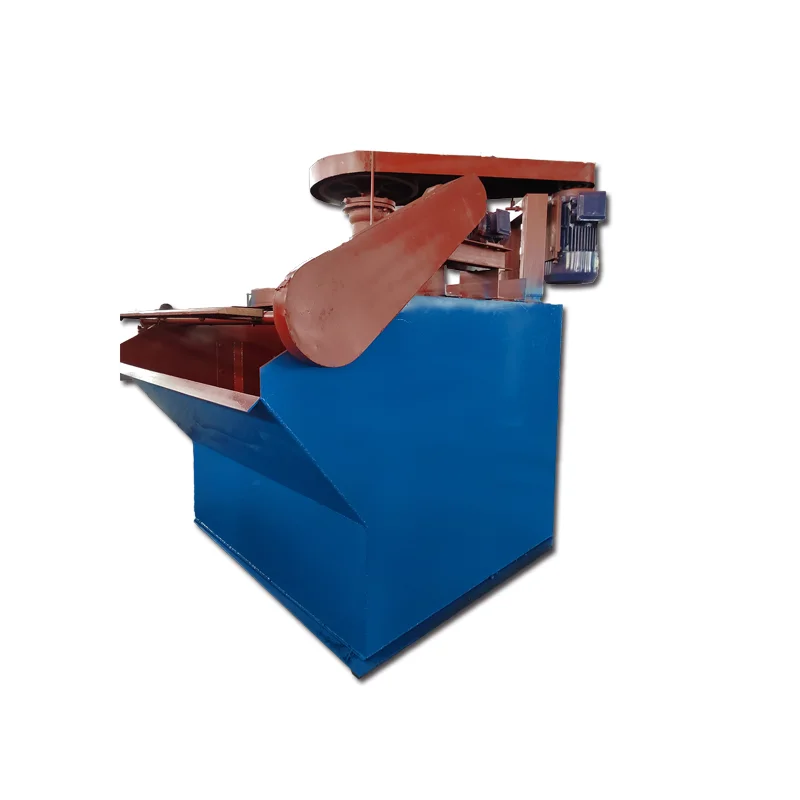

SF Flotation Machine

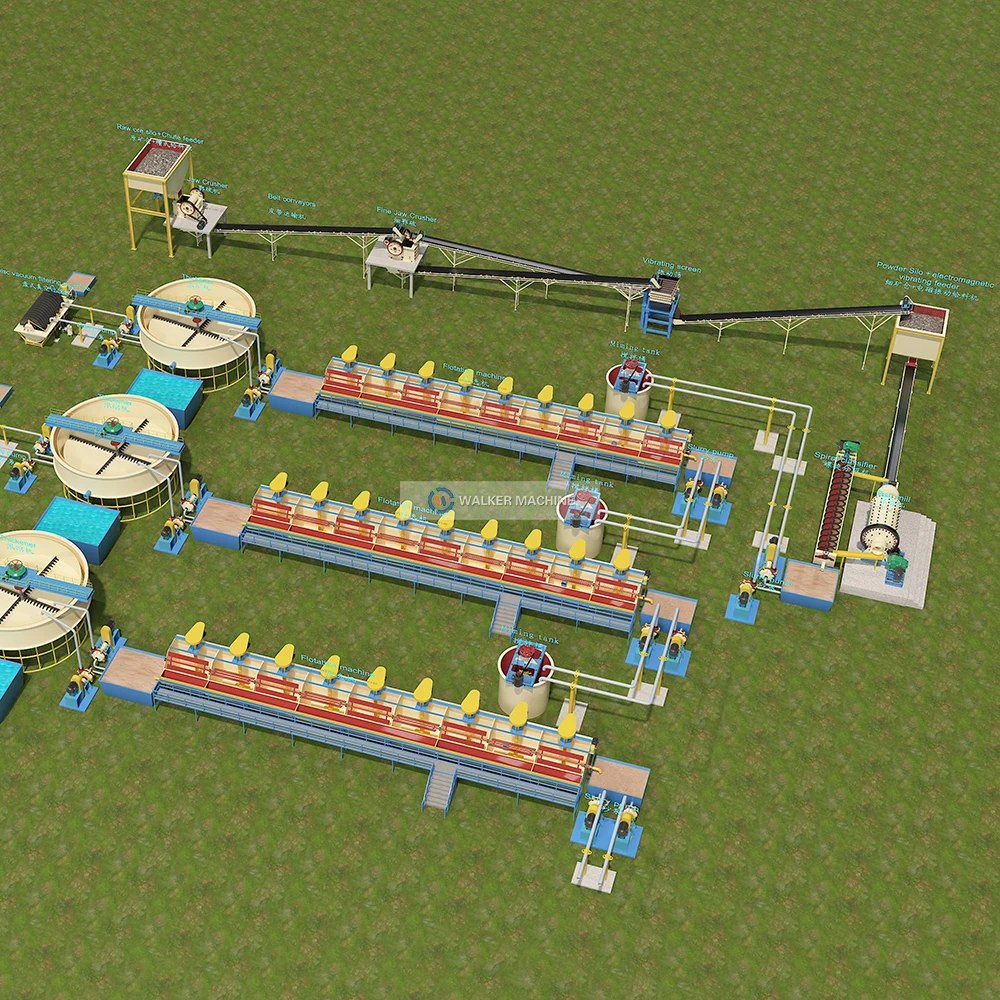

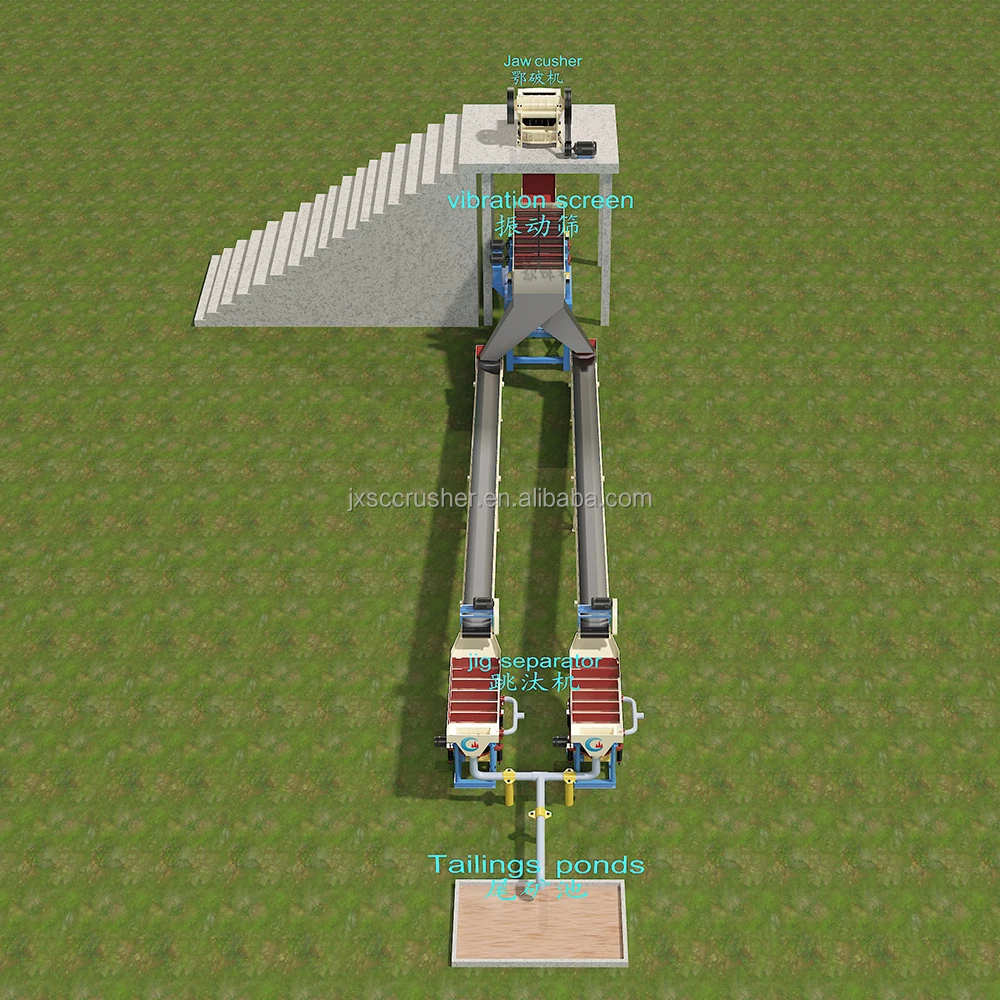

Widely used in classification non-ferrous metals and non-metal. When flotation machine works, slurry is inhaled from the bottom of the cell to the space between impellers. Meanwhile, the low-pressure air send by fan is sent to this area through the air distributor in the hollow shaft. After sufficient mixing, the slurry is pushed out by the impeller, and then goes to the whole cell. When the froth rises to the stable level, after the enrichment processing, froth overflows to the froth cell from the overflow weir. Another part of ore slurry flows to lower part of impeller for the re-mix with air. The remained slurry flows to the next cell until becomes residue.

Model | Cell capacity m3 | Impeller Dia. (mm) | Impeller R.P.M | Capacity | Impeller motor model | Power (kw) | Scraper motor model | Power (kw) | Cell dimension (mm) | Weight per cell (t) | Inspiratory capacity |

SF-0.15 | 0.15 | 200 | 536 | 0.06~0.18 | Y90L-4 | 1.5 | Y80L-4 | 0.55 | 500×500×600 | 0.27 | 0.9-1.0 |

SF-0.37 | 0.37 | 296 | 386 | 0.2~0.4 | Y90L-4 | 1.5 | Y80L-4 | 0.55 | 700×700×750 | 0.47 | 0.9-1.0 |

SF-0.65 | 0.65 | 350 | 400 | 0.3~0.9 | Y132S-6 | 3 | Y90L-6 | 1.1 | 900×900×900 | 0.93 | 0.9-1.0 |

SF-1.2 | 1.2 | 450 | 312 | 0.6~1.2 | Y132M-6 | 5.5 | Y90L-6 | 1.1 | 1100×1100×1100 | 1.37 | 0.9-1.0 |

SF-2.8 | 2.8 | 550 | 270 | 1.5~3.5 | Y160L-6 | 11 | Y90L-6 | 1.1 | 1750×1600×1100 | 2.13 | 0.9-1.0 |

SF-4 | 4 | 650 | 220 | 2~4 | Y200L-8 | 15 | Y100L-6 | 1.5 | 1850×2050×1200 | 2.58 | 0.9-1.0 |

SF-8 | 8 | 760 | 191 | 4~8 | Y250M-8 | 30 | Y100L-6 | 1.5 | 2200×2900×1400 | 4.13 | 0.9-1.0 |

Похожие товары

Высокопроизводительное горно-шахтное оборудование для разделения флотации завод по переработке серебряной руды

Сухой Тип постоянный магнитный барабанный сепаратор

Мелкомасштабное оборудование для добычи золота мини-Майнер оловянной руды концентрирующий гравитационный сепаратор вибрирующий стол Gemini на продажу

Сухой или влажный магнитный сепаратор частиц для отделения сверхтонкой железной руды от ganue

Экспериментальный магнитный сепаратор для минералов

500tpd Подгонянное оборудование для разделения добычи угля завод

Горнодобывающая техника малое золото центробежный концентратор аллювиальный Золотой

Новые поступления

Новинки товаров от производителей по оптовым ценам