RICHI 0 6 12 мм плавучий завод по переработке кормов для рыбы

- Категория: >>>

- Поставщик: Kaifeng Richi Machinery Co. Ltd.Kaifeng Ltd.

Сохранить в закладки 1601215147712:

Описание и отзывы

Характеристики

Overview

About The Customizable Design

Multifunction Floating Fish Feed Processing Machines Plant:

Multifunction Floating Fish Feed Processing Machines Plant:

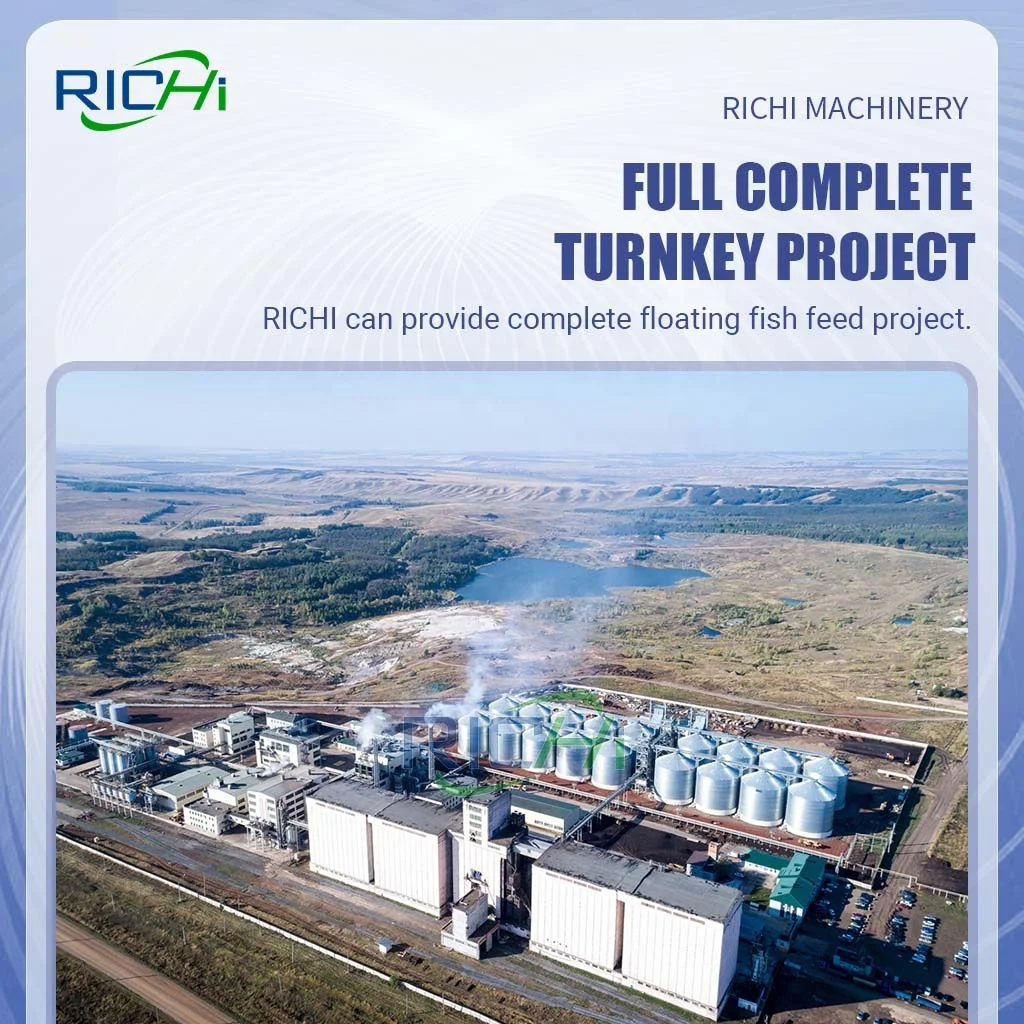

As a turnkey feed machinery manufacturer, RICHI Machinery can provide customized floating fish feed processing machinery, and other types of aquatic feed such as shrimp feed, crab feed, sinking fish feed processing machinery, etc. RICHI Machinery provides all the machinery and equipment required for this production line, and provides installation, training, technical support, two-year quality assurance, and spare parts service.

What Are The Features Of RICHI's Floating Fish Feed Processing Machines Plant?

RICHI provides a complete production line project for floating fish feed pellets. Including feed extruder, cleaning and crushing machine, dry, cooler, auxiliary equipment, PLC control equipment, steel structure, wire and cable, accessories, workshop, etc.

1. High Quality:

The core components of the machine are made of stainless steel, which is resistant to corrosion. The mold is made of special alloy steel, which is wear-resistant and has a long service life. The motor adopts Siemens motor, which runs stably.

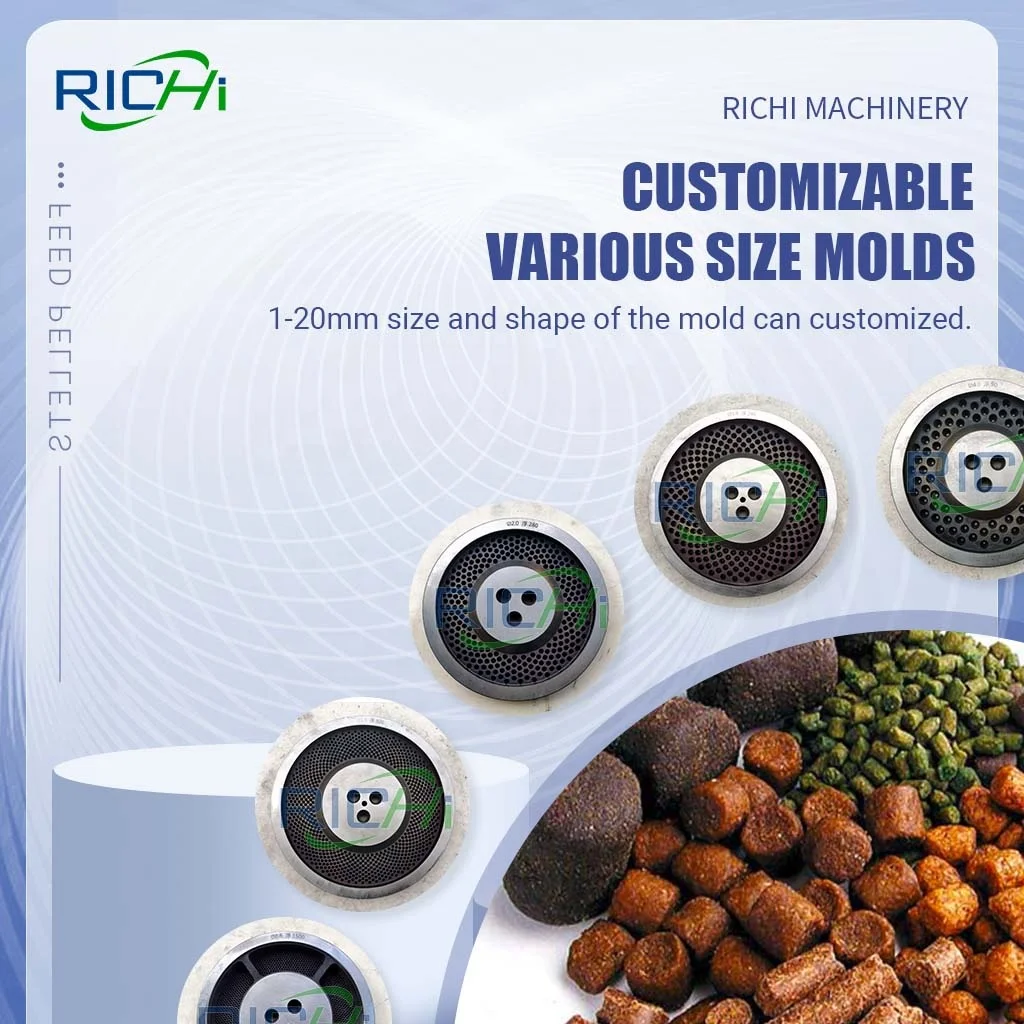

2. Customized Design:

RICHI can customize a production line for you to produce floating aquatic feed pellets suitable for different types,

habits and growth stages of aquatic products.

habits and growth stages of aquatic products.

3. Automatic Control:

According to different designs, the production line will be able to use automatic control, using PLC system. Save labor cost.

Raw Materials And Pellets

What Pellets Will Produced By This Floating Fish Feed Processing Machines Plant?

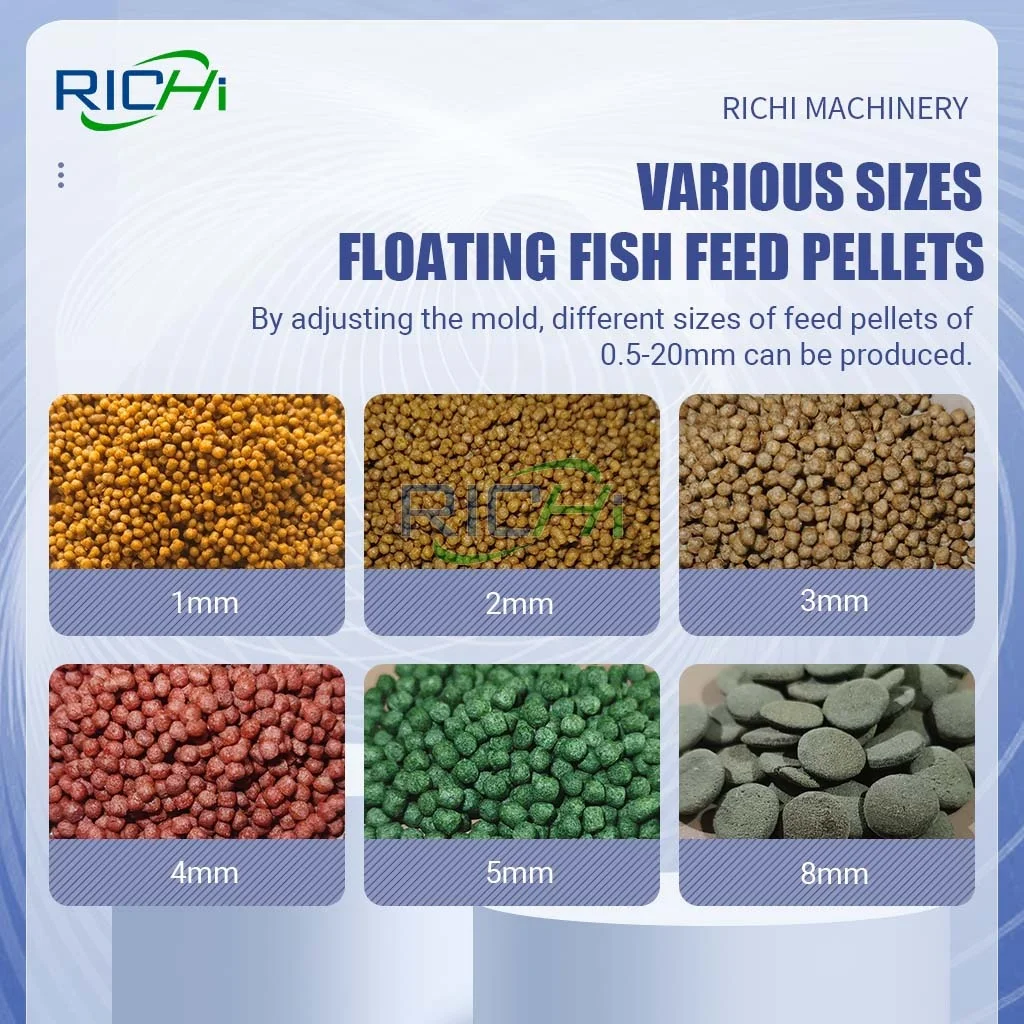

This production line can produce floating fish feed pellets of 0.6mm~12mm or other customized sizes and shapes.

Common raw materials in feed formulations include fish meal, shrimp head meal, shell meal, grain raw materials, oil, soybean meal, wheat bran, peanut meal, flour, soybean lecithin, etc. Please contact us for professional feed formulation advice.

If you need to produce shrimp feed/sink fish feed/livestock feed/poultry feed pellets etc. RICHI also provides ring die type animal feed pellet machine.

Process Flow

Flow Chart For The Floating Fish Feed Processing Machines Plant:

The production line is mainly composed of Cleaning section, Crushing Section, Mixing Section, Feed Extruding And Pelletizing Section, Drying Section, Spraying Section, Cooling Section, and Packaging Section. Each section is linked by bucket elevators, screw conveyors, or horizontal scrapers.

The entire production line can be automatically controlled by PLC, equipped with an automatic weighing and batching system, which makes the composition of feed pellets accurate and stable. The quality of floating fish feed pellets has been improved.

Parameter Of The Floating Fish Feed Processing Machines Plant: | ||

Project Name: | Floating Fish Feed Processing Machines Plant | |

Capacity: | 1-60 T/H Customized Optional | |

Height and Area Requirements: | Design According To Your Site | |

Pellets Specifications: | 0.6-12mm Customized | |

Motor Brand: | Siemens | |

Electrical Components Brand: | Schneider, Siemens, Delixi etc | |

Machine Details

Hammer Mill:

The SFSP Series Water-drop Type Hammer Mill is suitable for the crushing of various cleaned raw materials in livestock, poultry, and aquaculture feed plant. The machine adopts variable frequency impeller feeding system and negative pressure induced air system to ensure the efficient operation of the machine.

Mixer:

RICHI Machinery SLHJ Series Single-shaft Paddle Mixer can efficiently and uniformly mix various raw materials in the formulation. High mixing uniformity, short mixing time.

Fish Feed Extruder:

The RICHI Machinery Twin-screw Aqua Fish Feed Extruder is the core machinery of this production line. It uses the principle of extrusion and puffing to shape the pellets. The main body is made of special stainless steel, the motor is of Siemens brand, and it is equipped with a PLC visual touch operation screen. The machine is of high quality and easy to operate.

RICHI also provides single shaft fish feed extruder and ring type feed pellet machine to meet the different needs of customers.

Box Type Dryer:

RICHI Machinery Box-type Circulating Dryer can quickly dry fish feed pellets. The lower and uniform moisture content keeps the floating fish feed pellets better floating and also ensures the storage time.

The dryer adopts a special design to circulate the hot air and make full use of the heat energy, making its energy consumption low. The custom designed uniform material distributor allows the pellets to be dried evenly in the dryer.

Spraying Machine:

The sprayer is made of stainless steel with high corrosion resistance. It is used to spray various heat-sensitive materials on the surface of the dried feed pellets to improve the nutritional value of the feed.

Cooling Machine And Automatic Packaging System:

The Counter-flow Cooler is used to cool the pellets. The temperature of the pellets can be quickly lowered by the counter-current cold air, which can increase the hardness of the feed pellets. so that it can be packaged, transported and stored.

The automatic packaging and sewing system can quantitatively weigh and automatically bag and sew. Supports bags of various sizes.

Project Cases

About RICHI Machinery

About RICHI Machinery:

●RICHI Machinery was established in 1995 and has more than 20 years of experience in the production of fish feed pellet production lines. RICHI also provides sinking fish feed pellet production line, livestock and poultry feed pellet production line, biomass wood pellet production line, and organic fertilizer pellet production line.

●RICHI owns a sound sales system and complete sales service network, and its products are sold all over the country and overseas in more than 132+ countries and regions. At present, the international strategy is implemented stably, RICHI Machinery has 21 overseas agents, as well as 1 overseas subsidiaries in Uzbekistan.

●In the future, RICHI Machinery will always strive to enhance the core technology and international competitiveness to become a sustainable pellet machinery manufacturer.

●RICHI owns a sound sales system and complete sales service network, and its products are sold all over the country and overseas in more than 132+ countries and regions. At present, the international strategy is implemented stably, RICHI Machinery has 21 overseas agents, as well as 1 overseas subsidiaries in Uzbekistan.

●In the future, RICHI Machinery will always strive to enhance the core technology and international competitiveness to become a sustainable pellet machinery manufacturer.

●RICHI Machinery's technology R&D center and headquarters are located in Zhengzhou City, Henan Province, China. The factory is located in Kaifeng City, Henan Province, China, near Zhengzhou.

RICHI Machinery's Certifcate And Patents:

RICHI Machinery has always been technology oriented, and has many patents such as Twin Screw Feed Extruder, Ring Die Type Feed Pellet Machine, Box Dryer, Hammer Mill, Cooler, Automation Control System, etc.

With a deep commitment towards quality, we bring forth products having impeccable standards. We perform production processes with superior quality material and electrically advanced components. Tested on several parameters, our product range ensures longer service life and efficient performance. The company has passed the IS02008 quality management system certification, CE certification, etc.

FAQ

Here Are Some Questions You Might Care About:

Yes, RICHI welcomes you to visit these projects for reference. RICHI Machinery has served customers in more than 132 countries. Here are some completed projects of fish feed production project:

*8-10 T/H Automatic Floating Feed Pellet Line In America

*1 T/H Floating Fish Feed Processing Machines Plant In England

*5 T/H Animal And Shrimp Feed Pellet Line In Peru

*1 T/H Floating Fish Feed Processing Machines Plant In England

*5 T/H Animal And Shrimp Feed Pellet Line In Peru

*5-10 T/H Animal And Floating Fish Feed Line In Russia

*5 T/H Sinking Fish Feed Production Lin In Uzbekistan

*1-1.5 T/H Floating Fish Feed Production Line In Uzbekistan

*1 T/H Floating Fish Feed And 1-2 T/H Animal Feed Production Line In Uzbekistan

*1-2 T/H Floating Fish Feed Processing Machines Plant In Nigeria

*2 T/H Floating Fish Feed Processing Machines Plant In Tanzania

*1 T/H Floating Fish Feed Processing Machines Plant In Botswana

*1 T/H Floating Fish Feed Processing Machines Plant In Qatar

---------more projects, please contact us---------

▶I'm learning about the industry for the first time, how do I get started?

Good question, please don't worry, RICHI Machinery will provide you with professional advice to help you start this project. Please tell us what type of feed pellets you want to produce, what capacity you want, your site conditions and other basic information. RICHI will custom design the most suitable production line for you.

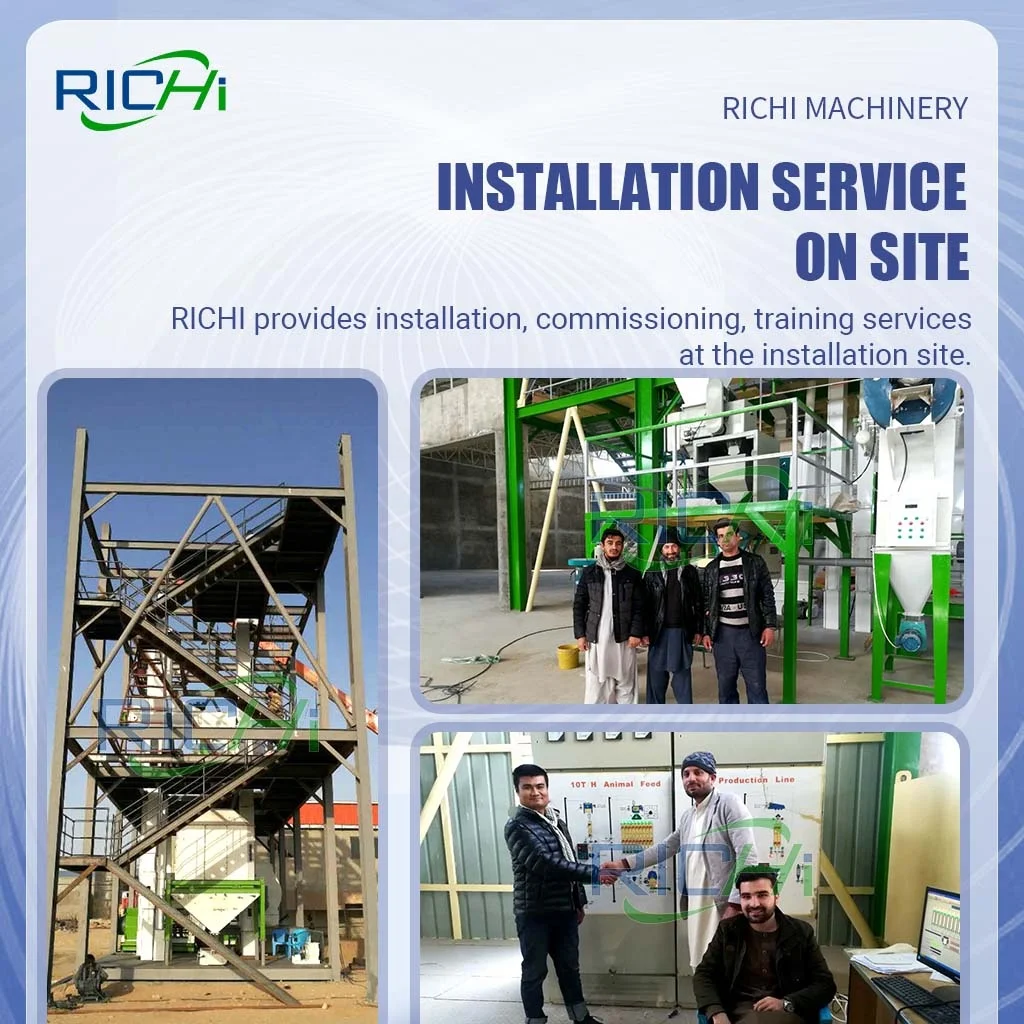

▶Does RICHI provide installation services?

Yes, We will arrange engineers to go to the site to guide how to install. And carry out technical training until the operator can fully master the skills of operating the production line.

Yes, We will arrange engineers to go to the site to guide how to install. And carry out technical training until the operator can fully master the skills of operating the production line.

▶Will it be supported if I want to extend my project again in the future?

Yes, if you want to continue to expand your line in the future, please let us know and we will provide an open line design for subsequent expansion.

Contact Us

How To Contact RICHI And Get Pictures/Videos/Quotation?

▶First Way: Click the "Send Inquiry" button below and leave your message to RICHI.

▶Second Way: Click the "Chat Now" button below to contact us online. We will be available 24/7.

Please remember to share your business card with us.

▶Second Way: Click the "Chat Now" button below to contact us online. We will be available 24/7.

Please remember to share your business card with us.

Похожие товары

Moulin a Cereales высокопроизводительный измельчитель зерна сои кукурузы гранулированных продуктов дробилка для кормов Euromill 25WL

45,00-48,00 $

Заводская цена многофункциональная самовсасывающая мельница для кукурузной пшеничной муки

350,00 $

Высокое качество 3-4 тонны в час завод по переработке кормов для цыплят куриного скота продажа

Машина для производства Рыбных хлопей пищевая машина экструдер технологический аппарат кормов Пирогов завод по производству

Оборудование для производства Рыбных хлопей

Многофункциональная машина для производства кормов животных

Кормоуборочный комбайн для кукурузы

450,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $