Формовочные инструменты для формования стоимостных форм и штампов Формовочный пресс полостей над техническим кузовом автомобиля форсунками

- Категория: >>>

- Поставщик: Jie Mei Mould Co. Ltd.Jie Ltd.

Сохранить в закладки 1601216410001:

Описание и отзывы

Характеристики

Mould Description

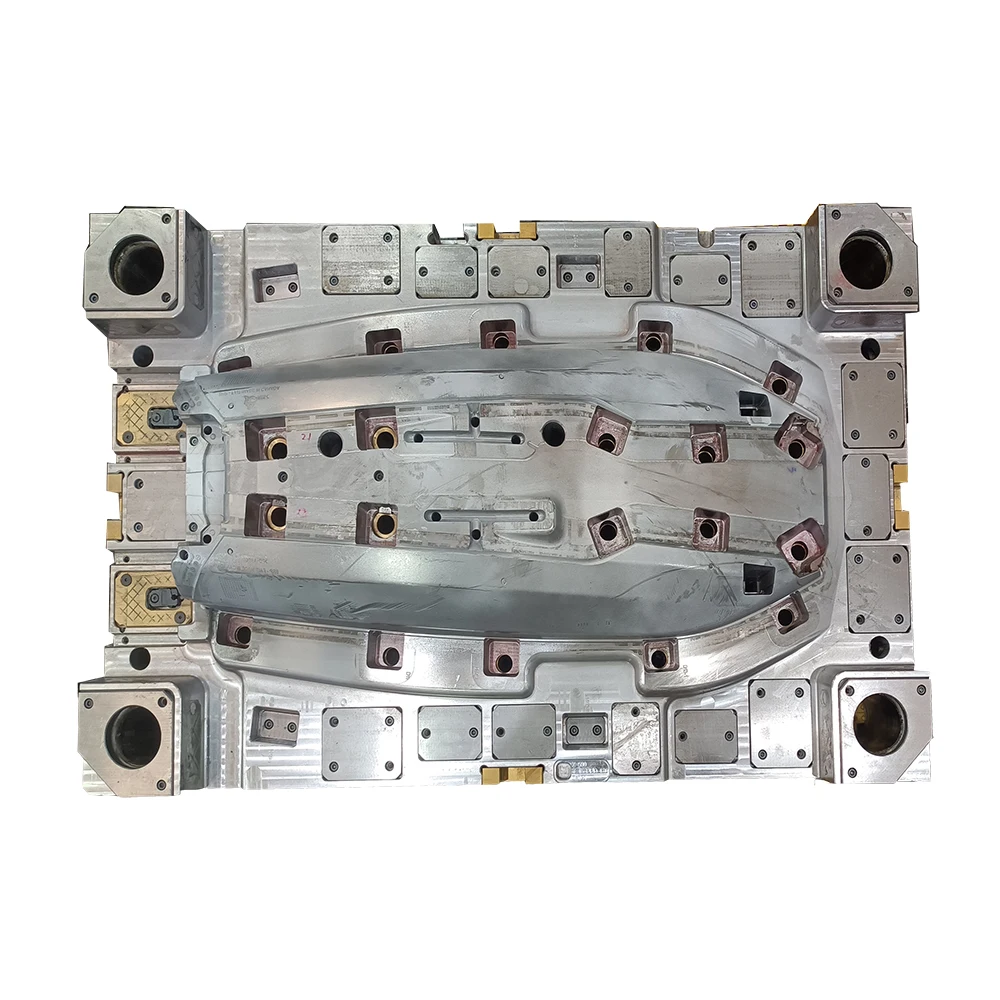

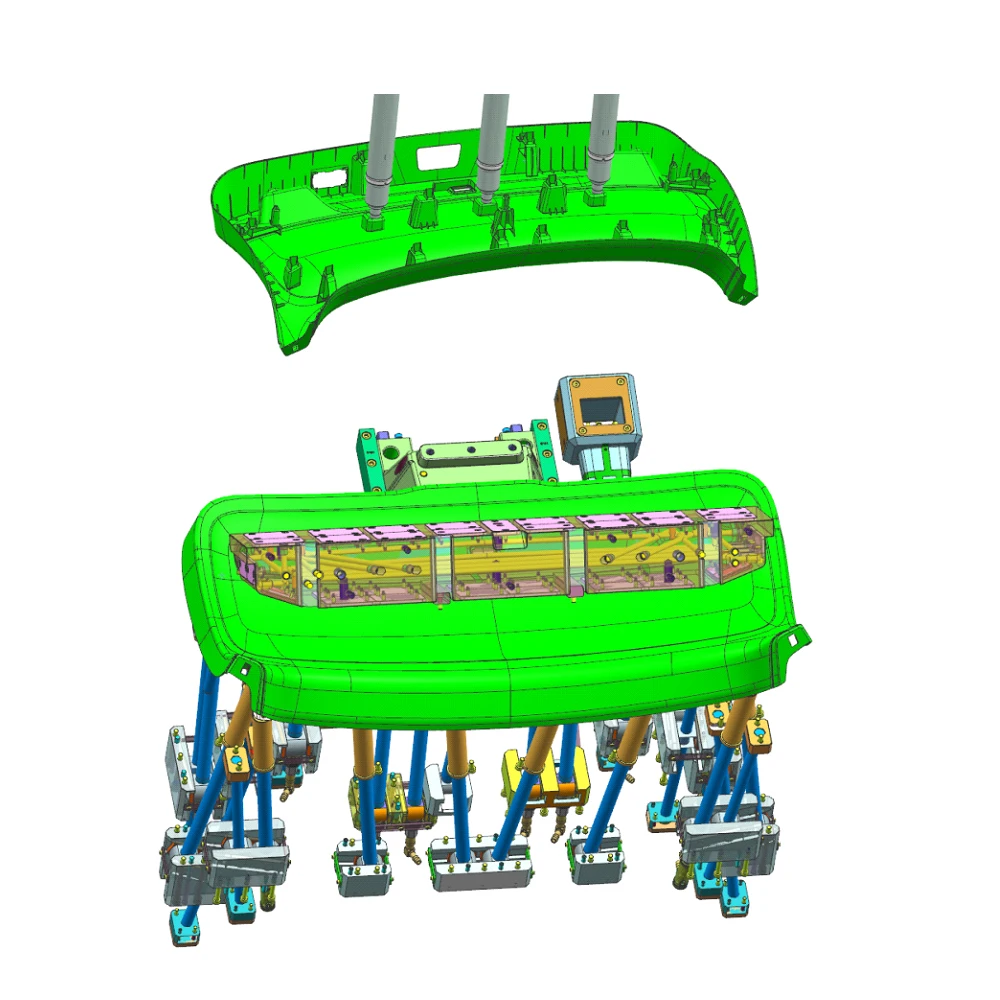

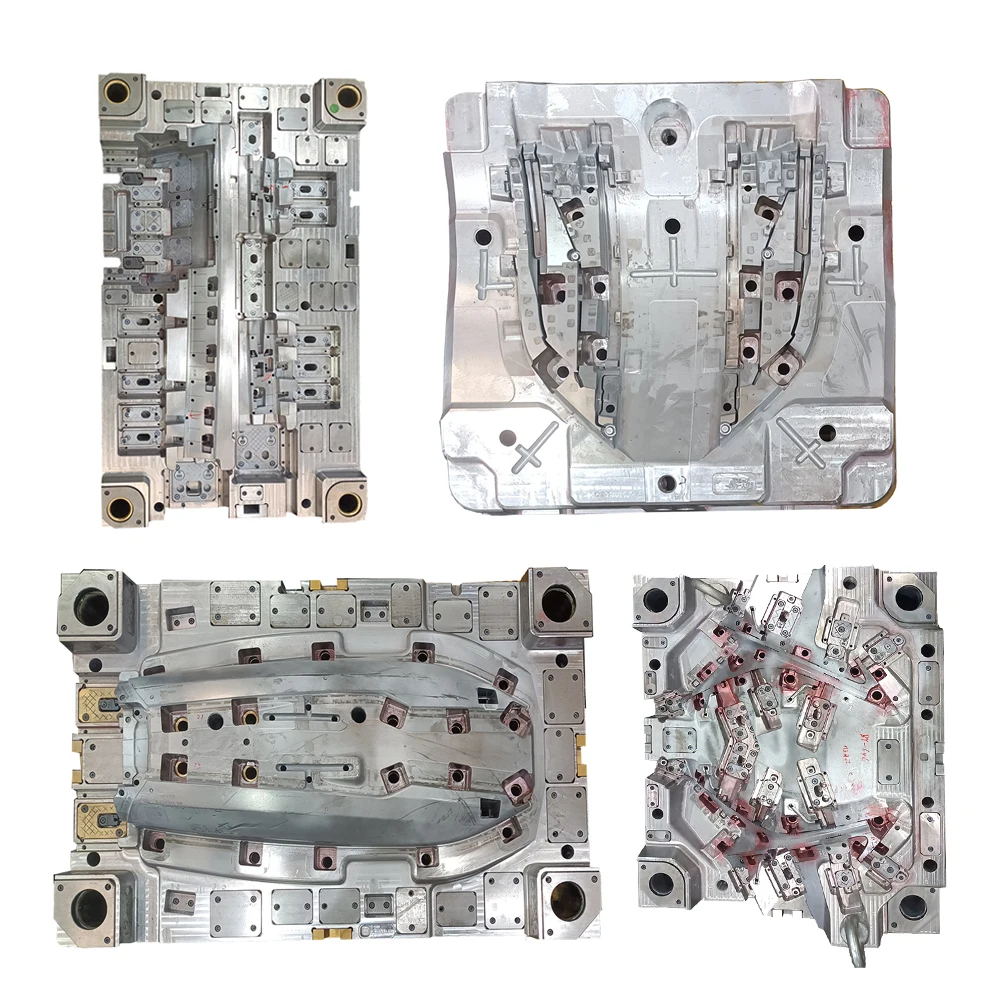

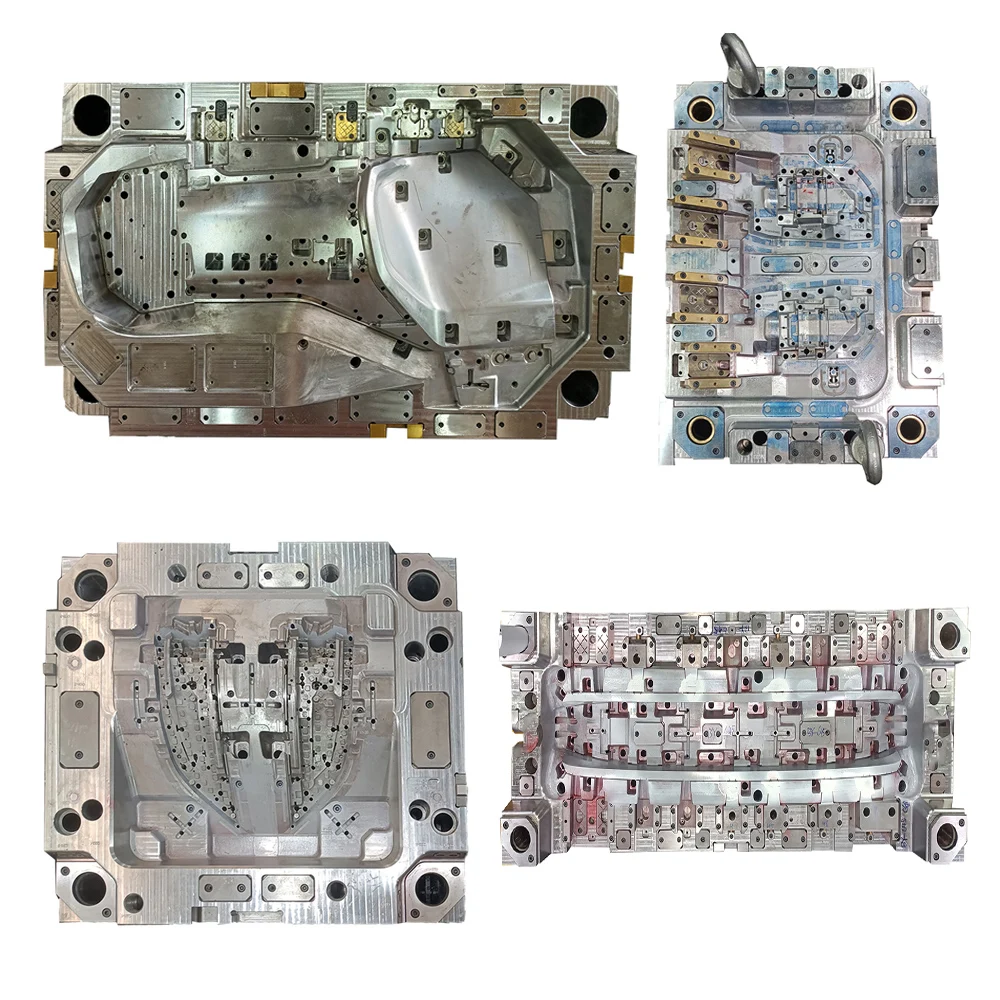

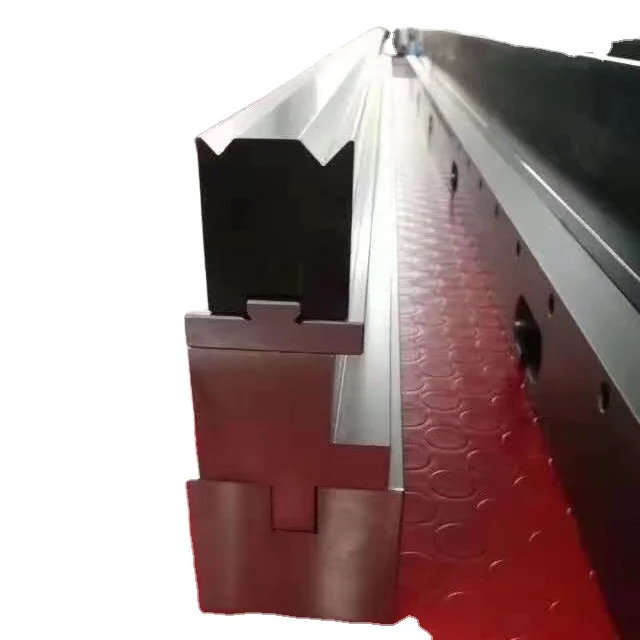

large plastic injection molds

Jiemei Mould, as a plastic mould manufacturer, focuses on customized moulds since 2006, we customize large plastic moulds for our customers, the maximum size of the moulds are 2.4m in length, 1.6m in width and 2.2m in height. Maximum mould weight is 50 tonnes and maximum injection machine is 4200 tonnes. We have made large plastic moulds for automobile dashboards, door panels, central control panels, wings, bumpers and so on for our customers.

If you need plastic moulds, please provide us with drawings and we will evaluate and quote for you!

If you need plastic moulds, please provide us with drawings and we will evaluate and quote for you!

Mould name | custom made large size big pleasetic injection mould maker |

Product size | To be confirmed |

Application Field | Auto industry |

Cavity No | 1*2 |

Trial machine | 1000-4200T |

Cycle time | To be confirmed |

Plastic material | Determine materials according to product requirements |

Surface finish | Meeting customer needs |

Core/cavity steel | Selection of materials according to product requirements |

Feeding | Single Incoe hot nozzle open gate |

Main Feature | with 4 lifters and 16 mechanical sliders |

auto parts mold maker

large plastic inject mold

big plastic mold desing and production

Company Info

Jie Mei Mould Infomation

Jie Mei Mould Co., Ltd as a plastic mould manufacturer, was established in 2006, and has been committed to auto-motive injection mould research and development, design and manufacturing, and has overseas offices in Sweden,

Britain, Poland, $lovakia, Nexico。Jie Mei Mould has provided more than 10, 000 sets of high quality moulds for domestic and foreign customers, and and is recognized by our customers as a trusted high quality supplier.

Jie Mei Mould adheres to the people-oriented, training and has a group of excellent technical personnel, including more than 100 design engineers and project engineers,more than 30% of the core technology backbone are from the

Jie Mei Mould adheres to the people-oriented, training and has a group of excellent technical personnel, including more than 100 design engineers and project engineers,more than 30% of the core technology backbone are from the

domestic automotive mould industry benchmarking enterprises, 60% of the senior management team are from dom

estic listed companies and multinational groups,to support the rapid development of the company escort.

Jie Mei Mould has Swiss Mikron high speed machining center, Japanese Sodick and Swiss Agie Charmilles wirecutting, Swiss Agie Charmilles, mirror EDM machine, Swedish Hexagon and Japanese Mitutoyo measuring instr-ument and other advanced equipment. And has obtained [S09001/ IATF16949 quality management system, to prov-

Jie Mei Mould has Swiss Mikron high speed machining center, Japanese Sodick and Swiss Agie Charmilles wirecutting, Swiss Agie Charmilles, mirror EDM machine, Swedish Hexagon and Japanese Mitutoyo measuring instr-ument and other advanced equipment. And has obtained [S09001/ IATF16949 quality management system, to prov-

ide a strong quality assurance for the moulds manufacture.

Jie Mei Mould attach importance to the research and development and innovation of automotive injection moulds, and has obtained 13invention patents and nearly 30 utility model patents, which provide technical support for the sustainable development.

"Achieve society, achieve customers, achieve emplovees" is our business philosophy.

High quality, fast delivery, low cost, good service" is our management philosophy;

Respect the people, believe in people, rely on people" is our talent concept.

We will make unremitting efforts to become a world class automotive injection mould solution provider

Jie Mei Mould attach importance to the research and development and innovation of automotive injection moulds, and has obtained 13invention patents and nearly 30 utility model patents, which provide technical support for the sustainable development.

"Achieve society, achieve customers, achieve emplovees" is our business philosophy.

High quality, fast delivery, low cost, good service" is our management philosophy;

Respect the people, believe in people, rely on people" is our talent concept.

We will make unremitting efforts to become a world class automotive injection mould solution provider

What We Can Do

Customize Made Car Plastic Parts Moulds Manufacturer

JieMei Mould as a plastic injection mold maker, we can make various kinds of auto plastic parts, from big plastic parts to small plastic parts, including below items:

1. auto door assembly: handle, armrest, handguard, front/rear door holder, cover, LGD, light guide, defrost, glove box door, door foot, shaft, filter door, door heater, lock, speaker/horn cover, seal strip.

2. auto light assembly: taillight, foglight, headlight button, light carrier, fixing bracket, frame, lamp trim, housing, lamp champer, decorative strip, light room, fixture.

3. auto dashboard assembly: panel body, cover plate, holder, hatch, glove box, storage, air conditioner outlet

4. auto console assembly: console body, frame, console side panel

5. auto seat assembly: seat base, seat guide, seat armrest.

6. auto bumper assembly: bumper grille, rear bumper decorative panel, trim, air intake grille, decorative strip, upper grille, lower grille.

7. auto tank assembly: tank lid and cover,

8. auto mirror assembly: rearview mirror housing, decorative frame, fixed bracket, mirror base cover, mirror holder, housing trim

5. auto seat assembly: seat base, seat guide, seat armrest.

6. auto bumper assembly: bumper grille, rear bumper decorative panel, trim, air intake grille, decorative strip, upper grille, lower grille.

7. auto tank assembly: tank lid and cover,

8. auto mirror assembly: rearview mirror housing, decorative frame, fixed bracket, mirror base cover, mirror holder, housing trim

9. auto mudguard assembly: fender, fender strip, fender bracket

Why Choose JieMei Mould

1. Professional technology

2. quality control

3. delivery on time

4. competitive price

5. technical support and after-sale service

Jie Mei Team

Currently we have 350 employees, They include:

1. Technical center: 48 mold design engineers,

4 DFM (Design for Manufacturability) engineers,

6 mold flow analysis engineers

2. Customer service: 45, including project engineers, marketing, merchandiser, after-sale service people

3. Machine center: 85, including programming engineer, CNC, EDM, Wire-cutting, drilling, lathing, grinding workers

4. Mold assembly: 96, including mold fitting and polishing workers

5. Injection section: 12

6. QC section: 15

7. Others: 39

Jie Mei manufacturing Capacity and annual turnover

In 2023, we have produced 1054 sets of molds for our customers, and annual turnover achieved 38 million dollars

with the increasingly management level and our strong mind of pursuing higher targets, we believe we will accomplish

more mold amounts and turnover in 2024.

CNC Rough and Medium-Fine Milling

4 sets of CNC Planer Milling Machine

5 sets of CNC Medium-Fine Milling

4 sets of CNC Rough Milling Machine

EDM machining Center

2 sets of Mirror-finish EDM Machine

5 sets of Double-head EDM Machine

3 sets of Single Head EDM Machine

Fitting mold

1 set of 500T spotting Machine

1 set of 250T spotting Machine

1 set of 150T spotting Machine

1 set of 50T spotting Machine

Injection machine

1 set of 1600T injection machine

1 set of 1000T injection machine

1 set for each of the 618T, 368T, 268T, 230T.208T.160T,148T,98T,80T,60T,20T

Quality control

We have obtained ISO9001/IATF16949 quality management system, to provide a strong quality assurance fore the molds manufacture, strict inspection include:

Incoming material, steel, standard parts, customized parts, self-made parts before mold trial and before mould shipment

Certification

State-level high-tech enterprises

Shenzhen “Specialized, proficient, special and New” Small and Medium-sized Enterprises

ISO9001 certification

Ts16949 certification

Mold Packaging

Anti-rust oil spray

vacuum packaging

wooden box

Customers Visit

European customers visited to attend mold trial

American customers visited to learn about JM team and audit our factory

European customers visited to join JM company's annual celebration

European customers visited to learn about mold progress

Middle-east customers visited to learn

about JM team and audit our factory

South American customers visited to build cooperation with JM

Похожие товары

Haco CNC Прецизионные пресс-инструменты для листового металла

Professional Magnesium Zinc Aluminum Alloy Pressure Zipper Slider Die Casting Body Mold Making for

81,00-108,00 $

Android Tv Box Iptv сильный Hdr приемник 4K 8K Ott 2 4G/5G двойной Wifi Bt умный плеер 10 12 13 Stick приставка

Китайские производители ПВХ процесс литья под давлением на заказ формование черных цветов

Conveyor Components Belt Nylon Sprocket Gear Collet Guardrail Clamps

5,00-9,00 $

Компоненты ленточного конвейера круглая направляющая зажим фиксированный кронштейн ножной разъем

Компоненты ленточного конвейера аксессуар для большой и маленький t зажим поперечный разъем

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $