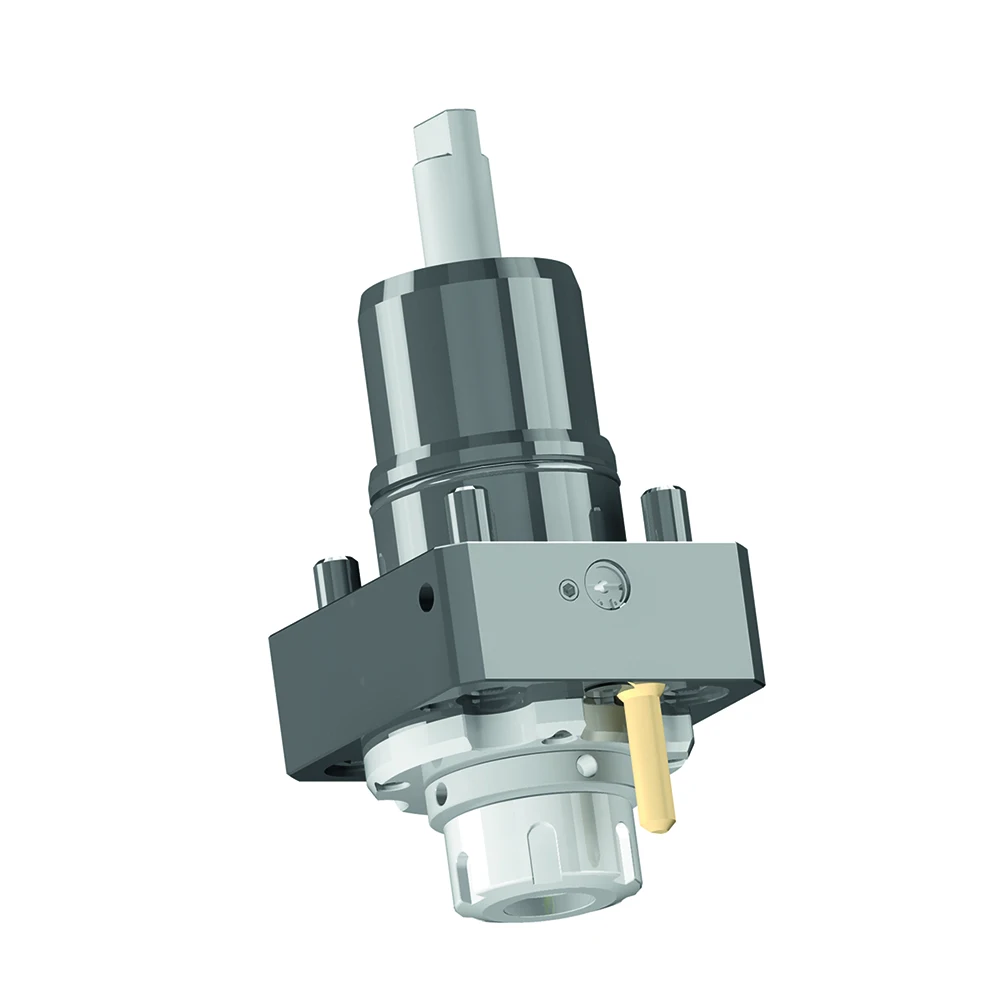

MQR Нержавеющая Сталь Сверлильный инструмент внутреннее отверстие Вольфрамовая сталь стержень формируя сплав

- Категория: >>>

- Поставщик: Changzhou Lizhiyuan Tool Co. Ltd.Changzhou Ltd.

Сохранить в закладки 1601225098065:

Описание и отзывы

Характеристики

| outside diameter | angle | blade length | Neck diameter | Neck length | Handle neck | entire length |

| 2 | 90° | 1.1 | 0.9 | 3 | 4 | 50 |

| 3 | 90° | 1.6 | 1.4 | 4 | 4 | 50 |

| 4 | 90° | 2.15 | 1.85 | 5 | 4 | 50 |

| 5 | 90° | 2.7 | 2.3 | 6 | 6 | 50 |

| 6 | 90° | 3.3 | 2.7 | 7 | 6 | 50 |

| 8 | 90° | 4.4 | 3.6 | 10 | 8 | 60 |

| 10 | 90° | 5.5 | 4.5 | 12 | 10 | 75 |

| 12 | 90° | 6.6 | 5.4 | 14 | 12 | 75 |

| 14 | 90° | 7 | 7 | 20 | 14 | 75 |

| 16 | 90° | 8 | 8 | 20 | 16 | 75 |

buyers need to know about knife selection and operation instructions

01 Before using the tool, please tilt the tool to the side. If the tool tilt exceeds 0.01mm, please correct it before cutting

02 The shorter the length of the tool extending from the chuck, the better. If the tool extends longer, the speed, feed rate, and cutting amount need to be reduced.

03 If abnormal vibration and sound occur during cutting, please reduce the speed and cutting amount until the situation improves.

04 Spray type and air jet type are preferred for steel cooling, which can provide milling cutter effect

WHY CHOOSE US

At present, we have nearly 100 imported and domestic machining centers, 10 high-end testing equipment, and a domestic standard carbide cutting tool line of scientific research, production base, process production management, material selection, production, inspection, and coating strictly according to process standards, so that our quality is stable. Strong inventory to provide customers with one-stop convenient procurement services, shorten the delivery time, ensure customer receipt time, improve efficiency.

Похожие товары

Mgmn токарные станки

Стандартный внутренний сверлильный станок с ЧПУ

Прямая поставка полные спецификации Er25-Er32 инструменты для Nakamura Tome Bmt44 - Bmt55 Bmt65

Двухбитный грубый сверлильный станок регулируемый инструмент для глубокого бурения отверстий

Держатель инструмента SK50 LBK1 LBK2 LBK3 LBK4 LBK5 LBK6 LBK держатель сверлильного

Регулируемый обоюдоострый сверлильный BT30-LBK CNC ДЕРЖАТЕЛЬ ИНСТРУМЕНТА держатели токарного станка обрабатывающий центр режущие инструменты

NBH2084 тонкая настройка набор инструментов для сверления BT40-NBH2084 держатель расточной головки BT50-NBH2084

Новые поступления

Новинки товаров от производителей по оптовым ценам