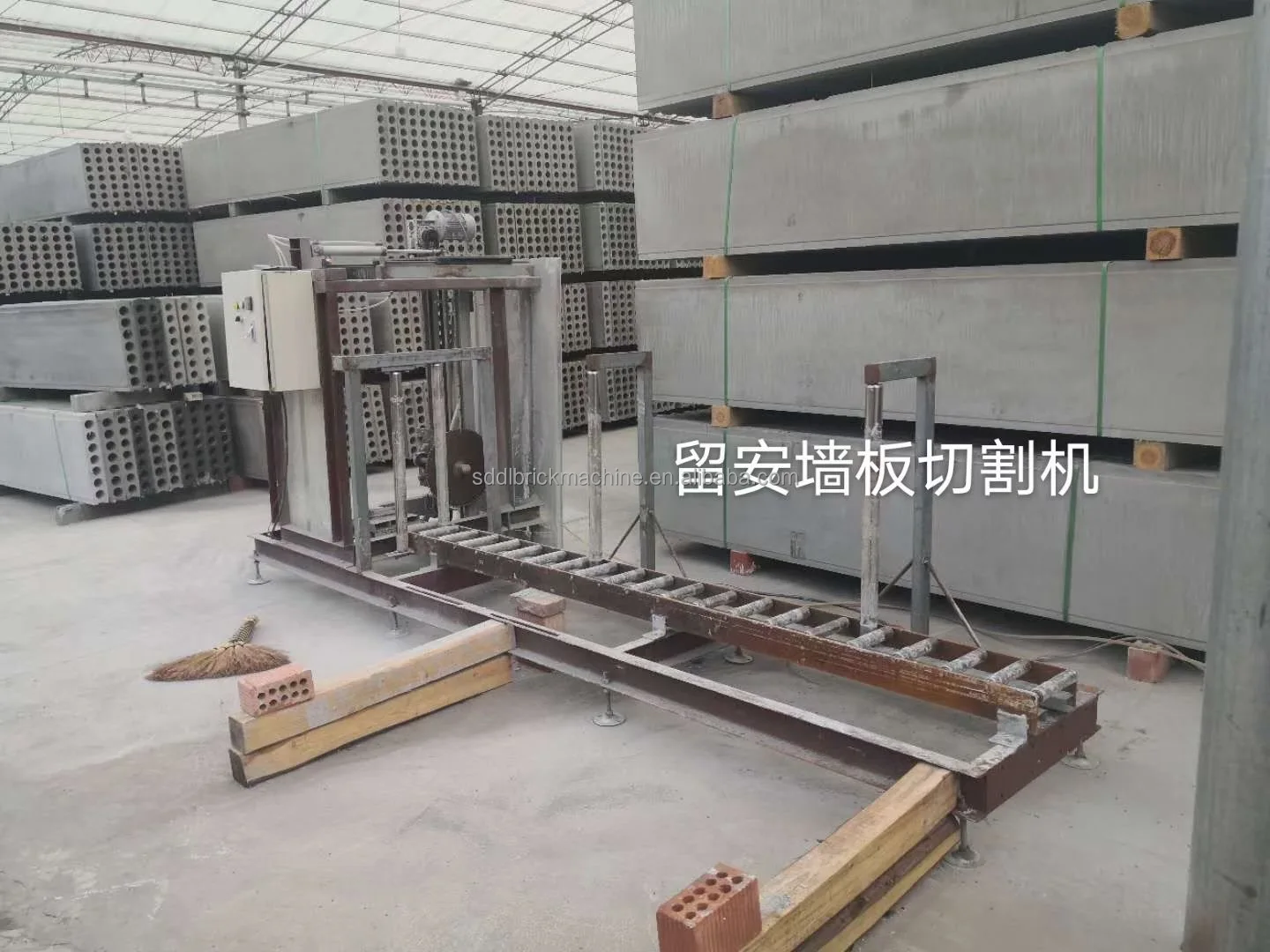

Гипсовая стеновая панель производственная линия гипсовая полая оборудование для производства стеновых панелей

- Категория: >>>

- Поставщик: Shandong Dalu New Material Environmental Protection Technology Co. Ltd.

Сохранить в закладки 1601228888694:

Описание и отзывы

Характеристики

Gypsum wall board making machine

----------- Free design drawings, technical discussion, select suitable gypsum block equipment.

------------- Since 1999 Experience in gypsum technology research.

2.Specification and model:length 3000mm(length adjustable)*width 600mm*100mm.

3.There are 11 pieces for each mold with the thickness of 100 mm.The thickness can be customized according to the customer.The 100-120 mold can be replaced, and the 150-200 mold can be replaced.Two sets of mold can be grouted alternately.A total of 4-5 people operate the equipment (one for operation,two for hanging and sorting,one for forklift to take out the plate,and one for miscellaneous work,totally five people).

4.High production capacity,including mesh distribution time to produce 100 square meters per hour (5-6 molds per hour,actual production capacity),about 1260kg of material per mold.

5.The equipment covers a small area(10m*20m, 5.8m high)

(1)Two sets of molds together have the advantage of alternating pouring.

7.Tube drawing equipment:

8.Closed open close high-speed mixer:

9.TThe cylinder clamp replaces the traditional plate machine and reverse plate machine,saves the time of puling plate,reversing and sending the bottom plate,avoids the extrusion fracture phenomenon of turnover plate,and improves the production efficiency.

10.Water metering tank:

12 .Control cabinet:manual ,automatic and continuous integration,arbitrary use,shorten unnecessary program time,increase production efficiency.

Start control cabinet → automatic water mixing machine → automatic raw material to screw conveyor → automatic metering hopper → special additive → pneumatic valve unloading material → mixing machine → start the hydraulic pouring molding box → automatic scraping groove → gypsum wallboard was pushed out → forklift lifts gypsum board into the dry site or drying room → packing → storage or production.

Raw material and production process:

Building gypsum powder as raw materials: natural gypsum powder, desulfurization gypsum powder, phosphogypsum powder, special additive, fiber reinforced material, light agent material perlite, negative material, fly ash, etc..

The raw material is stirred by water and poured into shape. After dried to make a new lightweight partition wall product - high precision gypsum wallboard.It is mainly used for frame structure and other non load-bearing walls,generally as internal partition board.

Equipment characteristics:

1, The vertical molding machine is equipped with an integral wearing (pumping) pipe machine an automatic cleaning core tube, ashock casting molding, an alarm system installed, and an automatic tube drawing after the final solidification;

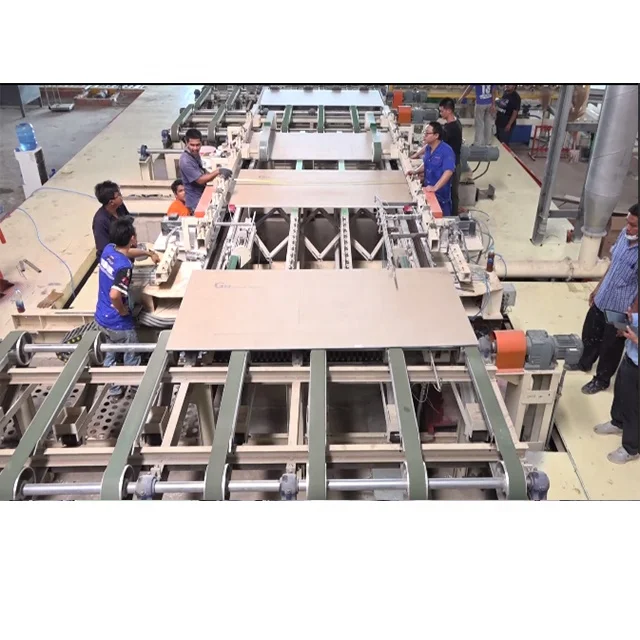

2, The production line is composed of hydraulic power control system and electrical controi system, with high mechanization;

3, Save material and improve the quality of wallboard;

4, The molding cavity has large structural rigidity, high forming precision, and the equipment is provided with a positioning

system. The utility model has the advantages of accurate thickness and good flatness; the products produced have good seismic performance, light quality and high strength;

5, Hydraulic opening and closing die, easy operation and high efficiency;

6, Overall equipment mature technology, stable and reliable, good durability;

7, The use of a machine panel, adjustable length, the group line process, with an annual capacity of 2 million square meters;

8, Plastic core pipe, surface erosion, electric pumping without time limit;

9, Automatic die closing, automatic temperature control;

10, The utility model has the advantages of low cost, simple operation and convenient maintenance;

11, The utility model has the advantages of less manpower, small occupation area, flexible and flexible operation, and can be used for field production;

12, Thickness, length can be adjusted, one machine, multi-purpose(60,90,120,150,180) can be produced.

Equipment characteristics:

The left and right walk of the block fixture is favorable for convenient transportation, convenient operation of workers and

equipment, and avoids the danger of workers operating equipment under the clamp and improves production capacity.

1. The utility model has the advantages of reasonable structure, low energy consumption, high output, small noise, convenient operation, small occupation area, and accurate product size.

2. The mould is made of hard chromium plating, which is not easy to rust and increase the service life.

3. Automatic telescopic fixture, automatically block blocks, put blocks, save manpower, reduce labor intensity.

4. The control system adopts touch screen and programmable controller PLC, equipped with data input and output device, real-time display system running state, found fault, prompt alarm. The control system has the self—locking function, avoids the misoperation to produce. The remote fault diagnosis can be realized by telephone connection, and the production of the customer can be carried out in real time.

5. The blocks are automatically metered into the mixer using a variety of additives, (equipment upgrades).

Process flow and configuration:Process flow and configuration:

Start control cabinet → automatic water mixing machine → raw material → screw conveyor → automatic metering hopper → special additive → pneumatic valve unloading materiai, mixing machine → start the hydraulic pouring molding box → automatic scraping groove → gypsum block forming ejector → automatic telescopic clamp block, electric vehicle transportation site → mechanical hand block into the dry site or drying room → packing → storage or production.

Process flow and configuration:

Building gypsum powder as raw materials: natural gypsum powder, desulfurization gypsum powder, phosphogypsum powder, special additive, fiber reinforced material, light agent material perlite, negative material, fly ash, etc..

The raw material is stirred by water and poured into shape. After drying, a new lightweight partition product - high precision gypsum block. The utility model is mainly used for frame structures and other non load bearing walls, and is generally used as an inner partition board.

Gypsum block host machine

Stainless steel and steel polished hard chrome plated die block:

1. Gypsum block host, double row die cylinder ejecting block system, with synchronization system to avoid error.

2. High precision mold stainless steel hard chrome plating, mirror polishing technology, non-stick die.

3. Automatic lifting stainless steel scraper device, can be repeated scraping, block exquisite.

4. Production block square core tube, double seal, prevent leakage of slurry.

Fully enclosed Mixer (Environment-friendly Mixer)

1. Energy saving, environmental protection, high mixing efficiency, never burn the motor.

2. Sealed dust removal system, prevent dust leakage, good collection.

3. Bottom stainless steel.Hydraulic cylinder filling.

4. Reduce pollution, energy saving, environmental protection, and effectively collecting dust.

--------- 15 years experience in overseas market projects service

---------- Experience of 2000+ projects manufacture and install abroad and domestic

We focus is customers demands, keep innovation, keep updating meet transcend custom-ers' requirements. We pursue extreme cost performance,not only price.

Our factory is a professional mechanical equipment manufacturer, production of energy conservation and environmental protection wall materials has been fully implemented lSO9001 quality standard system certification, flexible mode of operation, can be customized according to customer needs all kinds of gypsum block production line, composite insulation bricks block production line.

Before payment

1. Free contact for the most suitable machine.

2. Free professional design, including plant layout, machinery diagram, equipment list, ect for each customer especially.

After sale service

1. We supply all technical surports for raw material supplier information.

2. Our process/ installation/ electricity engineers will stay at your plant until your workers know how to produce good products.

3. After installation, we will test your production, and sign agreement with your workers after succesfully testing.

4. 24 hours technical support by phone, email or skype (email or skype).

5. One years warranty period.

6. Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

7. By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

Payment

♦ L/C, 30% deposit by T/T, 70% spare payment L/C.

♦ T/T, 30% deposit by T/T, 70% spare payment before shipment.

♦ Western Union or Paypal.

1. When can we arrange shippment?

We usually arrange shippment within 20days after getting deopsit,but customized machines should be more than 30days.

2.What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can send our engineers to repair your machines

3.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

A: Gypsum Block is a kind of light walling material, made by Gypsum Powder and adhesive material, mixing with water and being molded and dried.

5.What is the advantage of Gypsum Block?

A: Environment-protection andEnergy-saving, right now they are the most popular in China now.

6.How many types of Gypsum Block so you have?

A:Hollow Gypsum Block and Solid Gypsum Block. Hollow blocks are more popular.

7.Normally where can I use the gypsum blocks?

A: It is widely used in building as inner partition wall.

A: Light weight / Fixed shape dimension / Fire-proof / Shock-proof / Heat insulation

9.What is the regular size of gypsum blocks?

A: The regular size of blocks is 666 (600)*500cm, the thickness will be 80 / 90 /100 /120 / 150 / 200mm, Definitely we can

modify other sizes too

10.What is your Gypsum Block’s performance?

A:Air sound insulation: 40.5db;

Fire resistance:186min;

Flatness: ≤1mm/m2;

11.What is the working capacity of your machine?

A: Normally 6-8 molds / hour

12.How does your machine come to me?How many parts do you have?

A:Molding machine / Mixer / Hydraulic station / Control panel / Screw conveyor / Water metering bin / Powder metering bin /Mechanical arm clamp / Ground clamp

13.What is your machine’s working voltage and power?

Voltage: 380V(+/-10%~15%), 3 phase

Похожие товары

Машина для производства гипсовой перегородки

1-6 миллионов квадратных метров в год гипсовая настенная производственная линия

Прямые продажи с завода полностью автоматическая машина для производства гипсокартона

1-6 миллионов квадратных метров в год гипсовая настенная производственная линия

Лидер продаж автоматическая линия по производству гипсовых блоков Прямая поставка с завода

Машина для производства гипсокартона линия по производству волоконно-цементного листа

Горячая распродажа полностью автоматическая линия по производству гипсокартона

Новые поступления

Новинки товаров от производителей по оптовым ценам