Изготовленная на заказ монета штампы для ноутбука корпус динамика коробка пластиковая инъекционная Ручка Форма в форме сердца

- Категория: >>>

- Поставщик: Dongguan Sanlixin Plastic Technology Co. Ltd.

Сохранить в закладки 1601231246481:

Описание и отзывы

Характеристики

DONGGUAN SANLIXIN PLASTIC TECHNOLOGY CO.,LTD.

Provide Mold Design, Mold Making, Mold Testing, Injection molded parts, Insert Molding, Over Molding, IML Injection, Double shots Molding, Surface treatment, Products assembly, Packing, Shipping, etc. services.

Products Description

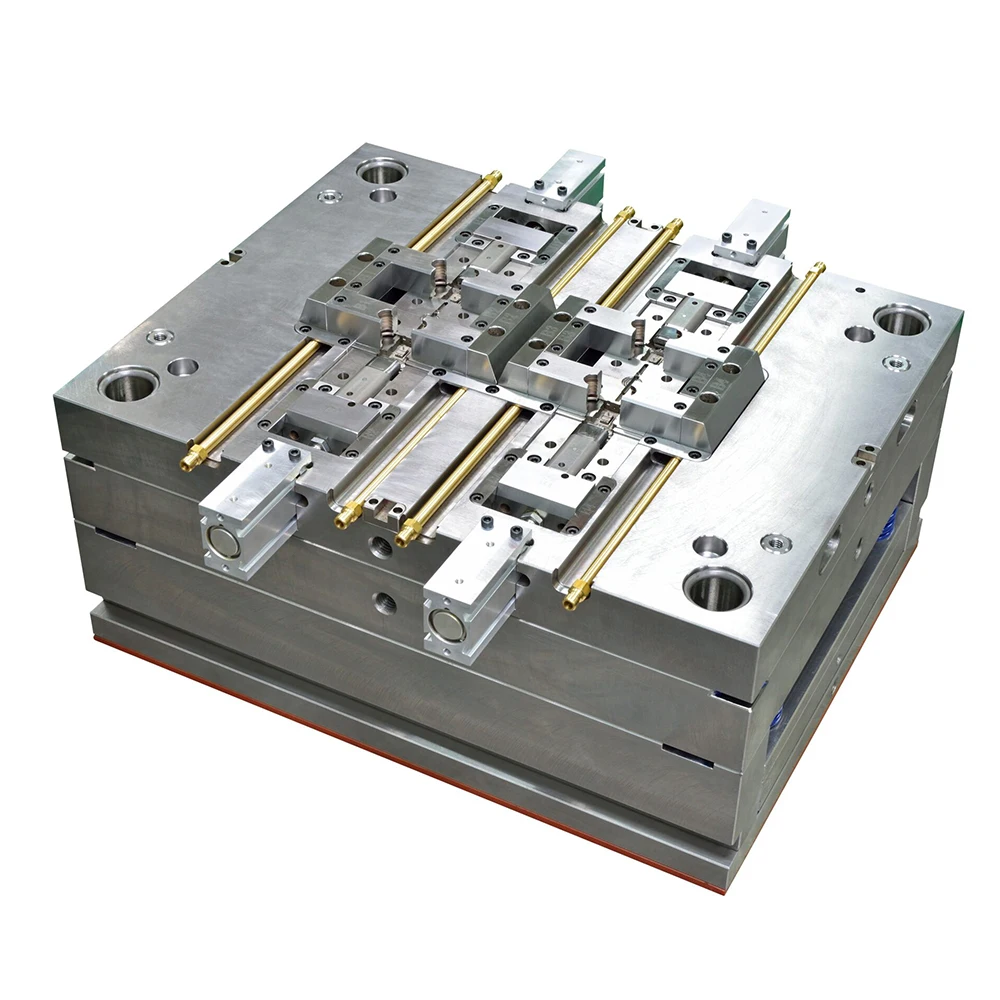

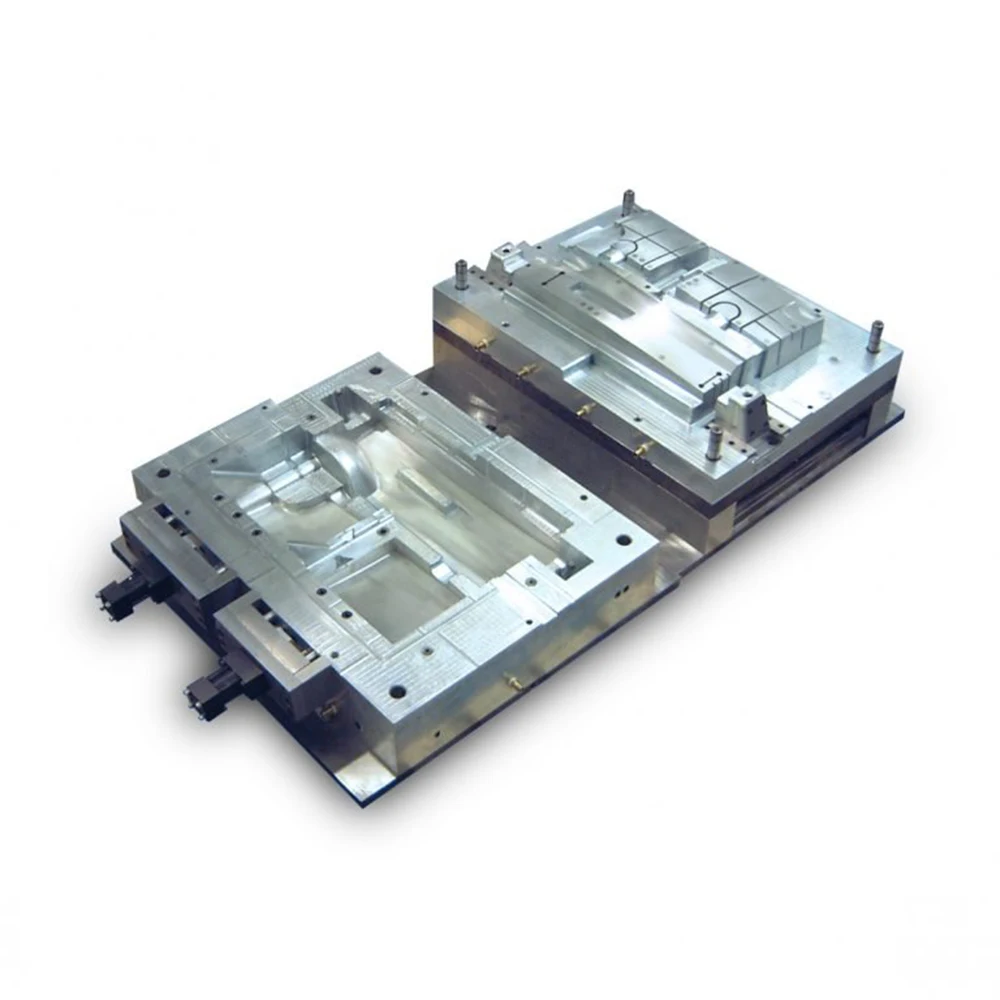

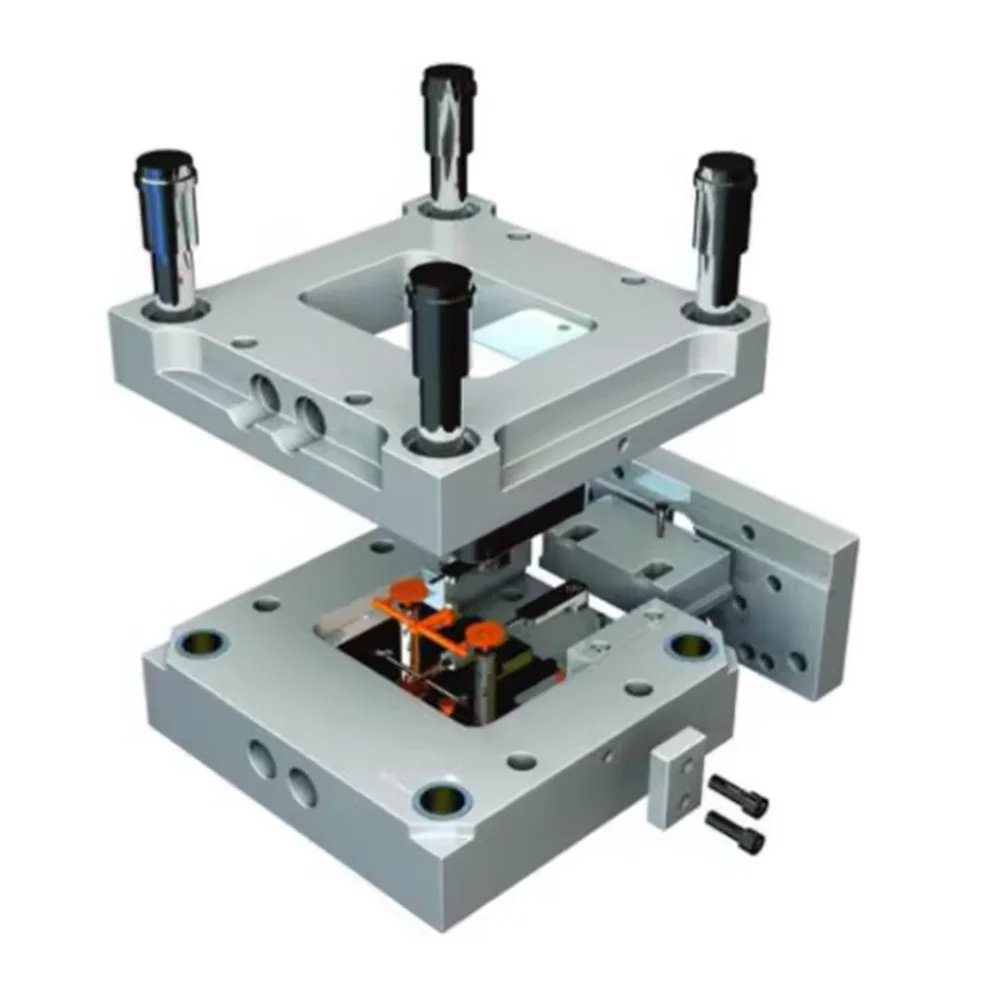

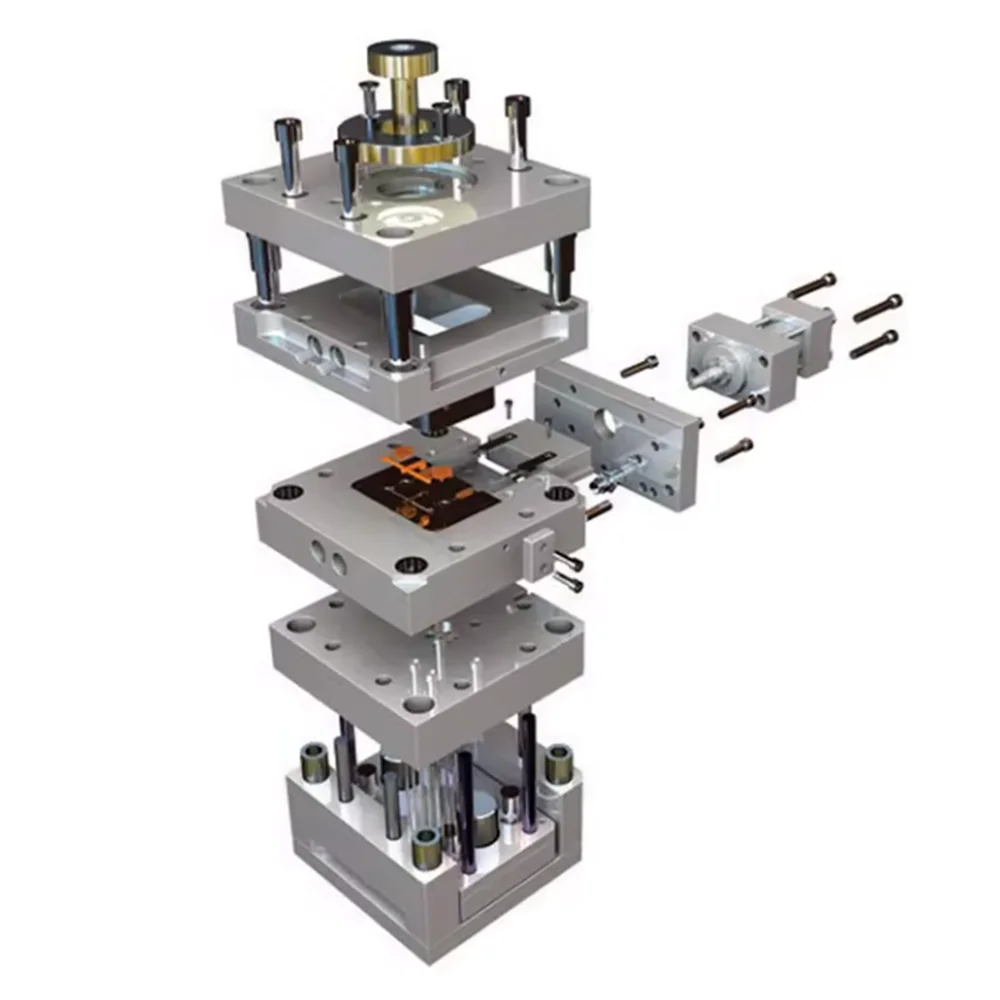

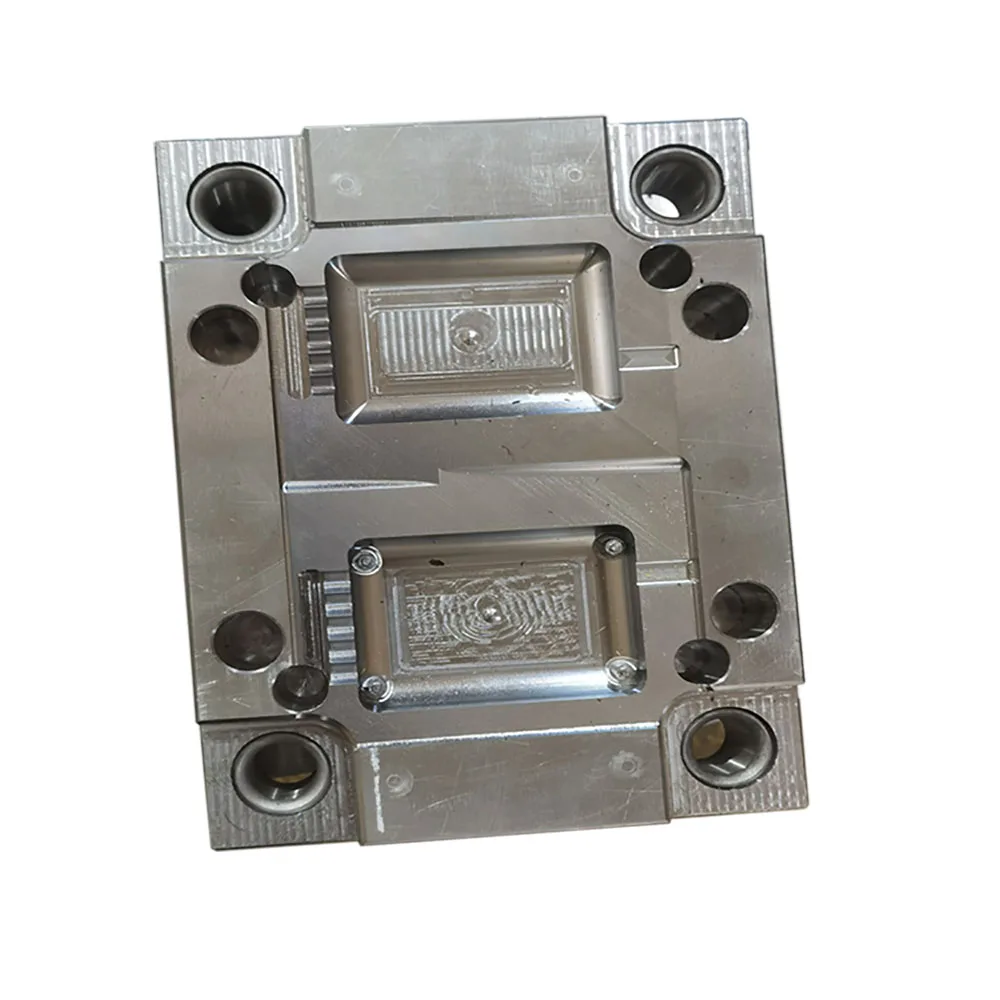

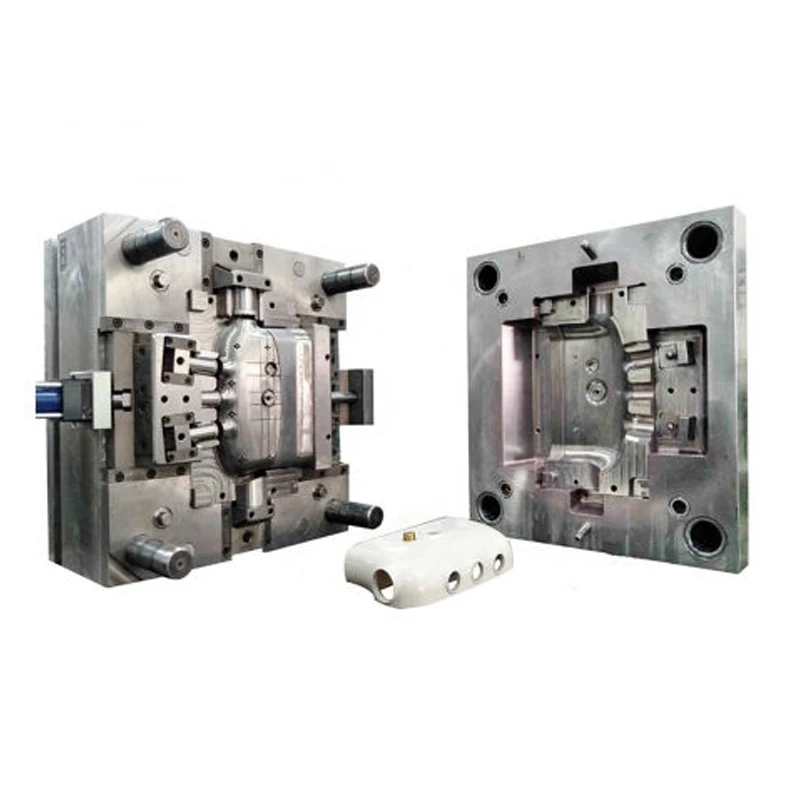

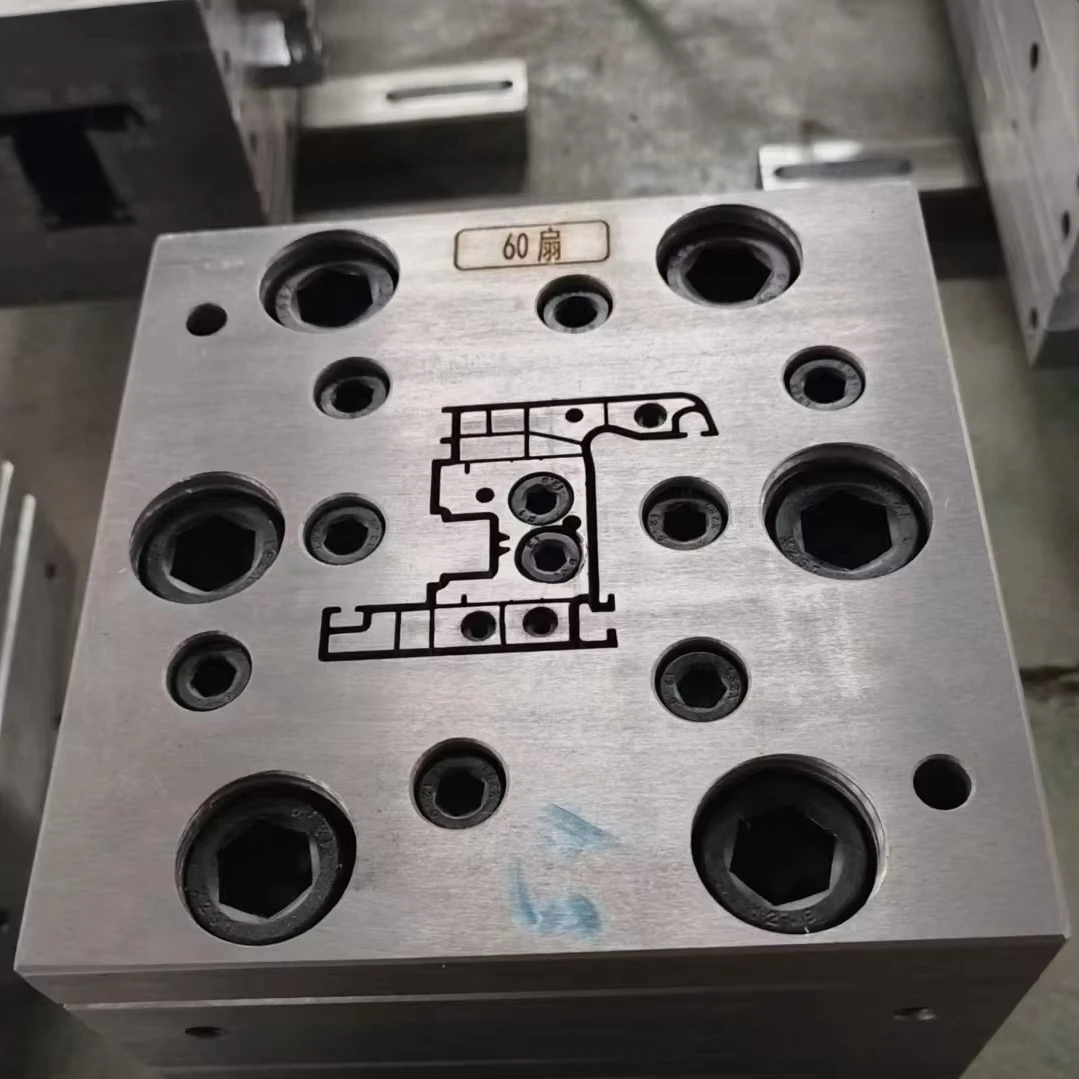

Plastic Injection Moulds

Injection Mold Experience: 16+ Years

Mould Precision: +/- 0.01mm

Molding Parts Tolerance: +/- 0.02mm

Mould Life: 50-500K shots

Maximum Mould Sizes: 1-1.5 M

Mold Building Lead Time: 15-30 Days

Annual Capacity: 500 Sets

Surface Finish: Polishing/EDM finish/Texture/Sand Blasting/MT/YS/SPI

Mold Steel: 718, 718H, 738, SKD-61, S136, S136H, NAK-80 Heat Treatment

Mould Precision: +/- 0.01mm

Molding Parts Tolerance: +/- 0.02mm

Mould Life: 50-500K shots

Maximum Mould Sizes: 1-1.5 M

Mold Building Lead Time: 15-30 Days

Annual Capacity: 500 Sets

Surface Finish: Polishing/EDM finish/Texture/Sand Blasting/MT/YS/SPI

Mold Steel: 718, 718H, 738, SKD-61, S136, S136H, NAK-80 Heat Treatment

Injection Molding Plastic Parts

Injection Molding Tonnage: 35-650 Ton

One-Station: Mold/Injection/Painting/Plating/Assembly

Material: Hard Plastic: ABS, PC, PPS, POM, PMMA, PA6, PA66, PVC, PET, PP or Fireproof/Fibered, Soft Plastic: TPU/TPE/TPR

Molding Tolerance: 0.02mm -0.05mm

Surface Finish: Texture, Sand Blasting, MT/YS, Smooth, Glossy, Spraying, Plating

Parts Types: IML Injection/Insert Injection/OverMolding/Bi-color Molding

Color: Black/White/Colourful/Transparent/Semi-transparent

One-Station: Mold/Injection/Painting/Plating/Assembly

Material: Hard Plastic: ABS, PC, PPS, POM, PMMA, PA6, PA66, PVC, PET, PP or Fireproof/Fibered, Soft Plastic: TPU/TPE/TPR

Molding Tolerance: 0.02mm -0.05mm

Surface Finish: Texture, Sand Blasting, MT/YS, Smooth, Glossy, Spraying, Plating

Parts Types: IML Injection/Insert Injection/OverMolding/Bi-color Molding

Color: Black/White/Colourful/Transparent/Semi-transparent

Technique | Injection Mould & Injection Molding Plastic Parts: Insert, Bi-color, IML |

Service | Mold, Injection, Printing, Painting, Plating, Assembly One-Station |

Mould Materials | P20, H13, 718, 718H, NAK80, S136, SKD61,SKD11 etc.18~56 HRC |

Plastic Raw Materials | ABS, PP, PC, PS, PPS, PE, PU, PVC, PA6, PA66, TPU, POM, PBT, HIPS, PMMA ect. |

Mold Hot Treatment | Quencher, Nitridation, Tempering,etc. |

Mould Base | Standard mould base,LKM, HASCO, S50C ect. |

Mould Precision | ±0.01mm/0.1mm |

Molding Parts Tolerance | ±0.02mm -0.05mm |

Cavity Number of Mold | Single cavity, Multiple cavity or one mold with different products |

Runner System | Hot runner, Cold runner with full automaticity(YUDO/HASCO) |

Gate Type | Pin point gate, side gate, slim gate, tunnel gate, banana gate |

Sliding Block | design according to your parts stucture |

Clamp Forces | from 80 Ton to 560 Ton |

Maximum Mould Size | 2,000*1,500*1,000mm |

Maximum Mould Weight | 5800g/13 Pound |

Ejection System | Motor/hydraulic cylinder/stripping plate/angle pin/ejecting block,etc |

Cooling System | water cooling or Beryllium bronze cooling |

Mould Standard | HASCO,DME, MasterFlow standard.or according to custom's request |

Design Software | UG, PROE, CAD, CAXA, SOLIDWORK, PRESSCAD, ect. |

Drawing Format | we accept DXF,DWG,IGS,STP,SIDPRT,X_T and so on |

Injection Mould Life | 50,000-5,000,000 times shots |

Surface treatment of Mould | Mirror Polishing, Texture/Graining,Sand Blasting,MT/YS/SPI,Words Corrosion |

Surface Treatment of Products | Texture, Silk Printing, Spraying/Coating, Frosted surface, Polishing, Plating |

Color | Black/White/Colourful/Transparent/Semi-transparent, PANTONE or RAL |

Design Time | Within 3 days(Generally) |

Mould Production Cycles | 15-60days, on basis of the difficulty level |

Plastic Products Production Cycles | 7-15days |

Parts Application | Exterior, Structural, Functional for Household applicance, Vehicle, Medical |

Technological Process

Company Profile

Our Advantages

Background of Mold Engineer, own 20 years Mold Experience

Our Design Team, Engineer Team, QC Team and Salesman Team

FAQ

Q1: I need a quote. What should we do? What information should I give to you for inquiry?

A: Firstly, if you have 2D/3D drawings or real samples with your special requirements such as material, tolerance, durability and surface treatments, please send to us. Also advise your demand quantity. we can make an ordinary sketch with the critical dimensions of the product and send 3D data files for your confirming. Secondly, our senior engineering team will start to study and make evaluation. our sales team will keep discussing with you to make sure every details are clear. Finally, you should advise you would like to ship your moulds away or produce at our factory. Then we will give you the quotation and reports with feasibility and our suggestions.

Q2: Does your company provide design service? I have an idea for a new product, but don't know whether it can be manufactured. Can you help me?

A: Absolutely yes, we can. We own design team and are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and enjoy discussion with each other for the advice on materials, tooling and likely set-up costs.

Q3: What kind of molds do you make? In addition to molding service, do you offer mass quantity production or OEM service as well?

A: We are mainly making plastic injection mold and all kinds of injection molding parts, we can not only offer mould making but also mass production and OEM service for your final products. We have mold workshop, and own 30 injection machines and many post processing production lines and assembly lines to control the quality and delivery by ourselves. Our service covers mold design & making, material purchase, injection molding service and post processing technology. Low MOQ and large order quantity are both acceptable.

Q4: I've decided to go ahead with my project. How long will it take to get my parts or samples?

A: It can take 3-6 weeks to have the mould tool manufactured depending on the part's complexity and the number of cavities(single or multi). After we have received final approval by you of the new tool, you can expect delivery of the first shooting parts samples within 3-5 days for your approval. Sample is available and free;

Q5: What’s the quality assurance you provided and how do you control quality ?

A: Established a procedure to check products at all stages of the manufacturing process -raw materials, in process materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

A: Firstly, if you have 2D/3D drawings or real samples with your special requirements such as material, tolerance, durability and surface treatments, please send to us. Also advise your demand quantity. we can make an ordinary sketch with the critical dimensions of the product and send 3D data files for your confirming. Secondly, our senior engineering team will start to study and make evaluation. our sales team will keep discussing with you to make sure every details are clear. Finally, you should advise you would like to ship your moulds away or produce at our factory. Then we will give you the quotation and reports with feasibility and our suggestions.

Q2: Does your company provide design service? I have an idea for a new product, but don't know whether it can be manufactured. Can you help me?

A: Absolutely yes, we can. We own design team and are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and enjoy discussion with each other for the advice on materials, tooling and likely set-up costs.

Q3: What kind of molds do you make? In addition to molding service, do you offer mass quantity production or OEM service as well?

A: We are mainly making plastic injection mold and all kinds of injection molding parts, we can not only offer mould making but also mass production and OEM service for your final products. We have mold workshop, and own 30 injection machines and many post processing production lines and assembly lines to control the quality and delivery by ourselves. Our service covers mold design & making, material purchase, injection molding service and post processing technology. Low MOQ and large order quantity are both acceptable.

Q4: I've decided to go ahead with my project. How long will it take to get my parts or samples?

A: It can take 3-6 weeks to have the mould tool manufactured depending on the part's complexity and the number of cavities(single or multi). After we have received final approval by you of the new tool, you can expect delivery of the first shooting parts samples within 3-5 days for your approval. Sample is available and free;

Q5: What’s the quality assurance you provided and how do you control quality ?

A: Established a procedure to check products at all stages of the manufacturing process -raw materials, in process materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

Contact Us

Похожие товары

Модная пластиковая литьевая форма для очков

Изготовленная на заказ форма для литья под давлением пластиковая очков от китайского производителя

54 824,20 ₽ - 219 296,80 ₽

Изготовленные на заказ солнцезащитные очки силиконовая форма пластиковая литьевая косметика для электроники

Пластиковая литьевая форма для очков

Рекламная продукция высокопроизводительные формы для экструзии ПВХ

Рекламная продукция высокопроизводительные формы для экструзии ПВХ

Производитель пластиковых форм для литья под давлением Высококачественная пресс-форма очков форма защитных

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $