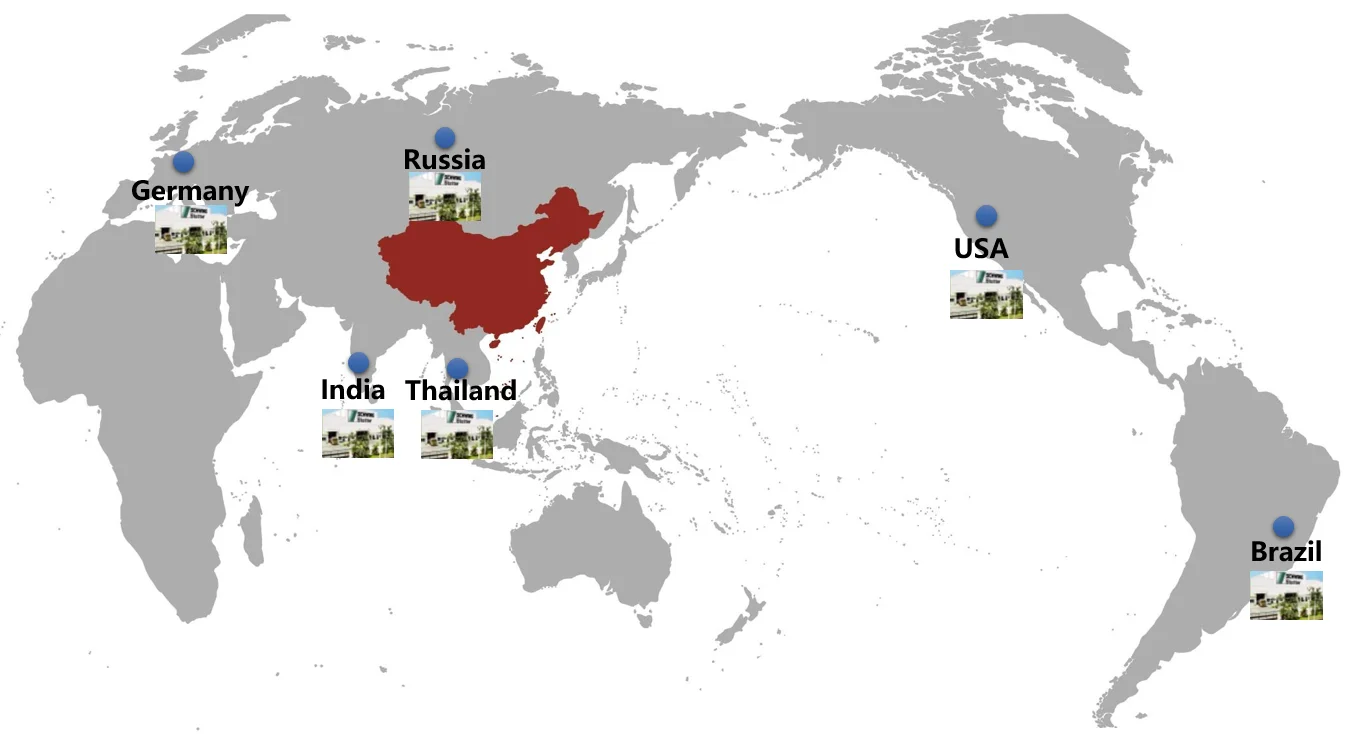

Seamless Bonding:

The machine utilizes advanced technology to achieve seamless bonding of fabrics, eliminating the need for traditional stitching. This results in a cleaner, more professional finish that enhances both the durability and aesthetic appeal of garments.

Folding Function:

The folding function is specifically engineered for precision. It ensures that hems, especially on T-shirt sleeves, are perfectly aligned and folded, maintaining consistency across all products. The folding process is automated, reducing the likelihood of human error and ensuring a uniform finish.

Heating Press:

The heating press feature is integrated to finalize the bonding process. By applying controlled heat, the machine securely bonds the fabric layers, creating strong, long-lasting seams. The heat settings are adjustable to cater to different fabric types, ensuring versatility in production.

Production Efficiency:

1 Labor for 3 Steps:

This machine is designed to be operated by a single laborer, who can simultaneously manage the bonding, folding, and pressing processes. This consolidation of tasks significantly reduces the need for multiple workers and streamlines the workflow.

Fast Production:

The machine is engineered for high-speed operation, enabling rapid production without compromising quality. Its automated features allow for continuous operation, making it ideal for large-scale manufacturing.

Straight Line Bonding:

The machine specializes in straight-line bonding, particularly for T-shirt sleeve hems. This feature ensures that the seams are perfectly straight, which is essential for maintaining the professional appearance of the final product.

Ease of Use:

No Special Technical Skills Required:

The machine is user-friendly, designed with straightforward controls that do not require specialized technical knowledge. This accessibility allows for quick training of new operators and reduces the dependency on highly skilled labor.

Applications:

This machine is particularly well-suited for T-shirt production, where sleeve hems and other straight seams are common. However, its versatility makes it applicable to a wide range of garments and fabric types, making it an invaluable asset in any garment manufacturing setting.

Conclusion:

By combining seamless bonding, precise folding, and efficient heating press functions, this garment-making machine revolutionizes the production process. It enables manufacturers to achieve high-quality results with reduced labor costs, faster production times, and minimal technical requirements, making it an essential tool for modern garment production.oduction.