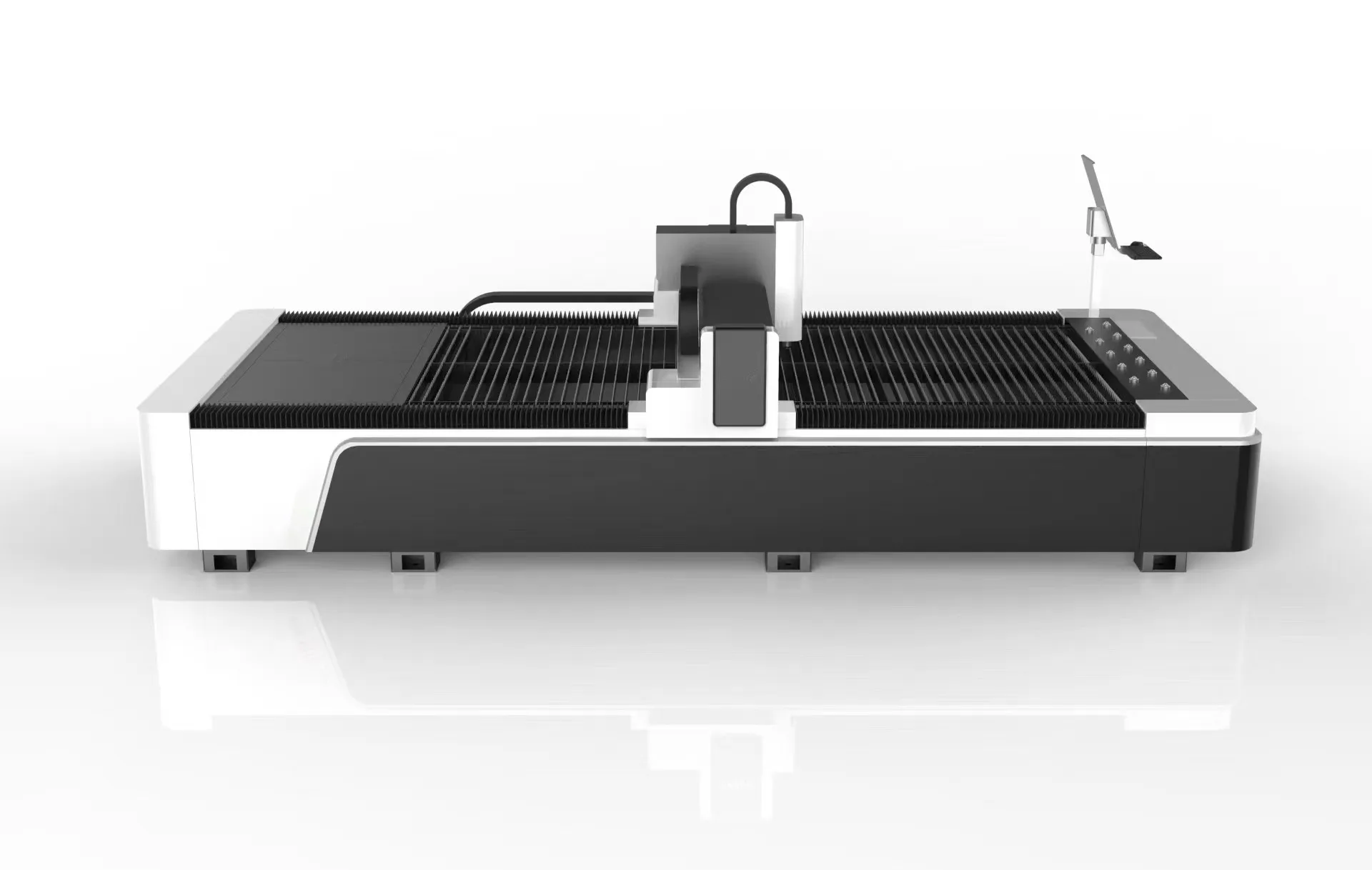

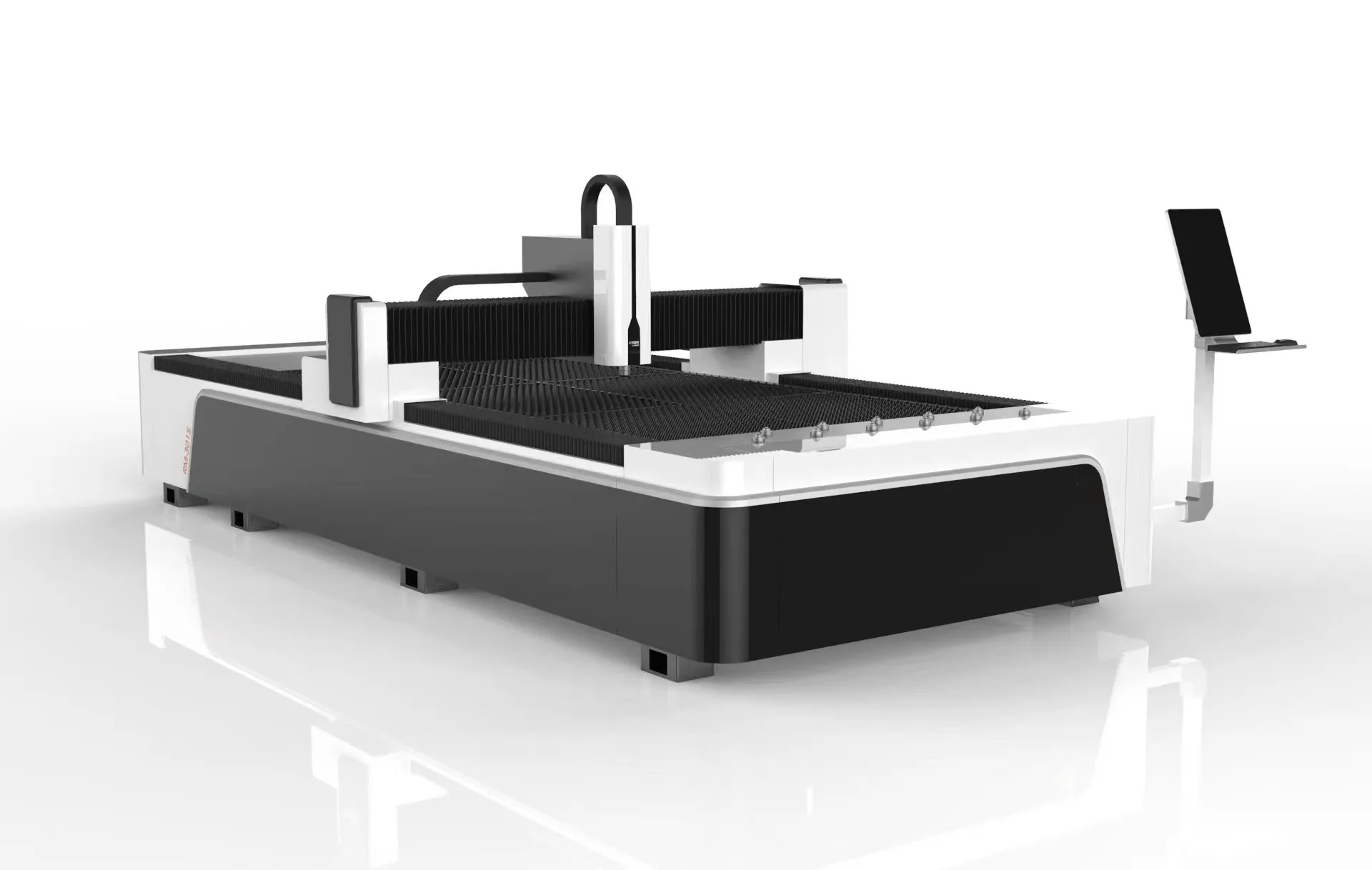

1500*3000 мм Лазерная резка металла машина для резки лазера

- Категория: >>>

- Поставщик: Xuzhou HaiBo CNC Technology Co. Ltd.

Сохранить в закладки 1601231745287:

Описание и отзывы

Характеристики

2024 Hot Sale 1500w 2000w 3000w 6000W Fiber Laser Cutting Machine for cutting metal

APPLICATIONS

The CNC Fiber cutting machine is widely used in many manufacturing and processing industries like sheet metal processing, Automobile manufacturing, kitchen appliances, electric control cabinets, advertisements, fitness medical equipment, etc.

Configurations list

Name | Quality | Brand |

Fiber Laser | 1 set | MAX |

Laser Head | 1 set | RAYTOOLS |

Precise rack for XY | 3 set | YYC |

Reducer | 3 set | Shimpo |

High speed servo motor and drive | 4 set | INVONCE |

High precision Linear guide(bed) | 3 set | HIWIN |

Precision ball screw(Z-axis) | 1 set | TBI |

Control system | 1 set | Raytools |

Electric | 1 set | Schneider |

Gas circuit system | 1 set | SMC |

Water cooler | 1 set | Hanli |

Computer | 1 set | Lenovo |

Technical Parameters

Working Area(Board processing) | 1500*3000 mm |

Laser power | 6000W |

Cutting thickness | Carbon steel 1-22mm Stainless steel 1-14mm |

X-axis travel | 1515mm |

Y-axis travel | 3030mm |

Z-axis travel | 100mm |

X-axis motor power | 750W |

Y-axis motor power | 750W |

Z-axis motor power | 400W |

Positioning accuracy of X / Y axis | ±0.05mm |

Repeated positioning precision of X / Y axis | ±0.02mm |

Maximum speed | 140M/min |

Maximum acceleration | 1.5G |

Machine details

China Max laser Source

In addition, Max is currently one of the most popular laser Source in the world. Both in terms of quality and service are in a leading position in the industry.

Compared with traditional lasers, MAX fiber laser has higher efficiency electric-optical conversion, lower power consumption and excellent beam quality. The fiber laser is compact and ready to use. It can be used as a stand-alone unit or easily inserted into user’s apparatus.

Raytoos Software

1. Raytoos is the most popular control system with simple operation.

2. Supports 13 languages such as English, Spanish, Russian and French.

3. It can import graphics through USB or Ethernet. The system can directly import graphics formats such as dxf.dwg.plt.eng.

Laser head

l Swiss Raytools BT240

lAuto focus Raytools fiber laser cutting head with Anti-crash function, good sealed,high Pressure resistant, auto- tracking system and anti-crash and stop system can protect good cutting quality and longer the life of lens.

Automatic Height Follower

l USA improved technology and adopt China patents, automatic sensor senses the capacitance from the tip of the isolated cutting nozzle to the metal being cut. This data is then fed into the Height Follower Controller .

l If the metal sheet have wavy surfaces, the focus height follower can ensure constant distance between the focal lens and the plane of the metal sheets to be cut, so that consistent cutting quality can be achieved .

l It can avoid defects caused by wavy metal surfaces and also avoid the damage of the nozzle head.

Wireless control handle

The cutting process can be controlled by the handle, which is simple and convenient, and the size is similar to a mobile phone.

The 3th generation of aviation aluminum beam

For the beams, we use high-strength aviation aluminum beams. The advantages of aviation aluminum are light weight and good dynamic performance, which is conducive to controlling the accuracy of cutting. Annealing to remove stress-Rough milling-After secondary vibration aging treatment- Fine milling.The four processes can fully guarantee the overall strength and stability of the beam.

For the beams, we use high-strength aviation aluminum beams. The advantages of aviation aluminum are light weight and good dynamic performance, which is conducive to controlling the accuracy of cutting. Annealing to remove stress-Rough milling-After secondary vibration aging treatment- Fine milling.The four processes can fully guarantee the overall strength and stability of the beam.

Cutting Capacity

Plate weld bed

Our machine bed is welded with high-strength steel pipes, after high temperature aging, 5-axis milling center rough milling, vibration aging, natural aging, and 5-axis milling center fine milling. Improve the rigidity and torsion resistance of the bed and ensure the accuracy of the machine.

Our machine bed is welded with high-strength steel pipes, after high temperature aging, 5-axis milling center rough milling, vibration aging, natural aging, and 5-axis milling center fine milling. Improve the rigidity and torsion resistance of the bed and ensure the accuracy of the machine.

Layout drawing

After sales service

(1) After check and accept by clients, the warranty period is 2 years.

(2) During 2 years warranty period, the company provides free repair service in case of failure due to defective part/ component, and replace defective part/component free of charge. Transportation costs are borne by clients ,such as express fees.

(3) During the 2 years warranty period, when we get maintenance call ,we will reply within 8 hours,and set up a 1:1 chat group on Whatsapp or QQ to follow-up,through video and computer remote control etc,guide the customer to remove the fault or replace accessories.

If clients need on-site repair,the company will arrange the overseas engineer ( usually 1 person ,can speak English) immediately,the cost of air tickets (round trip), food, accommodation, local transportation, translation, internet, communication and visa charges for our engineers at buyer’s site shall be borne by customer at actual against documentary evidence.

Travel allowance USD 150/per person per day for eight (8) hours for travel from China to customer’s local project site and return shall be considered extra at actual.

(4) After the warranty period,the replacement parts will be charged at the cost price.Transportation costs are borne by clients ,such as express fees/air costs.

(5) CNC Controller and software will lifetime upgrade free .

(6) The company will supply life-long maintenance service.

Похожие товары

Производители производят волоконно-лазерную резку мощностью 1000 Вт цена на машину для лазерной резки металла 500 и

1000 Вт 2000 3 кВт волоконно-оптическое оборудование cnc lazer резак для углеродистой стали нержавеющая сталь алюминиевый лист

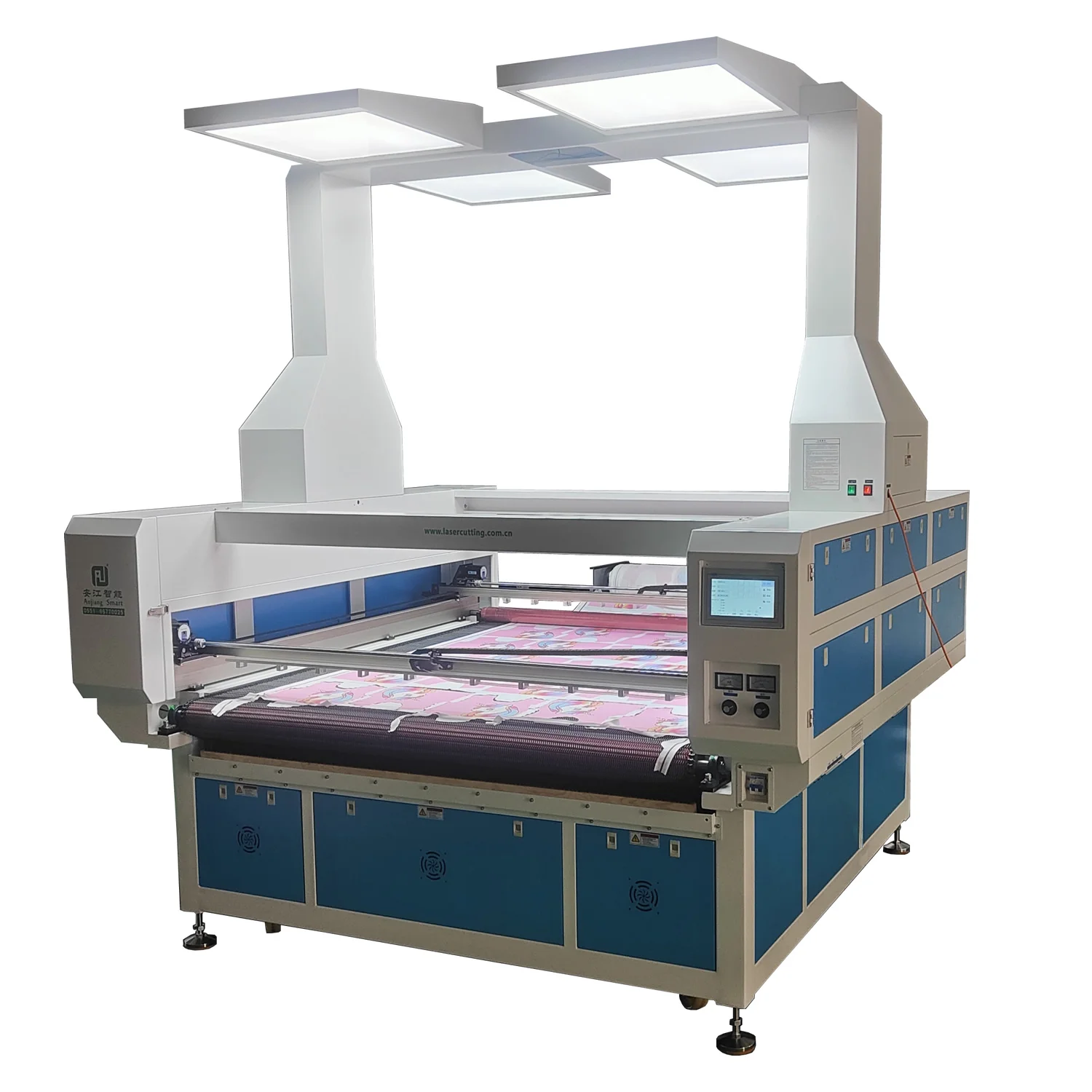

Высокоскоростная машина для лазерной резки с двумя головками одежды домашнего текстиля и других отраслей промышленности

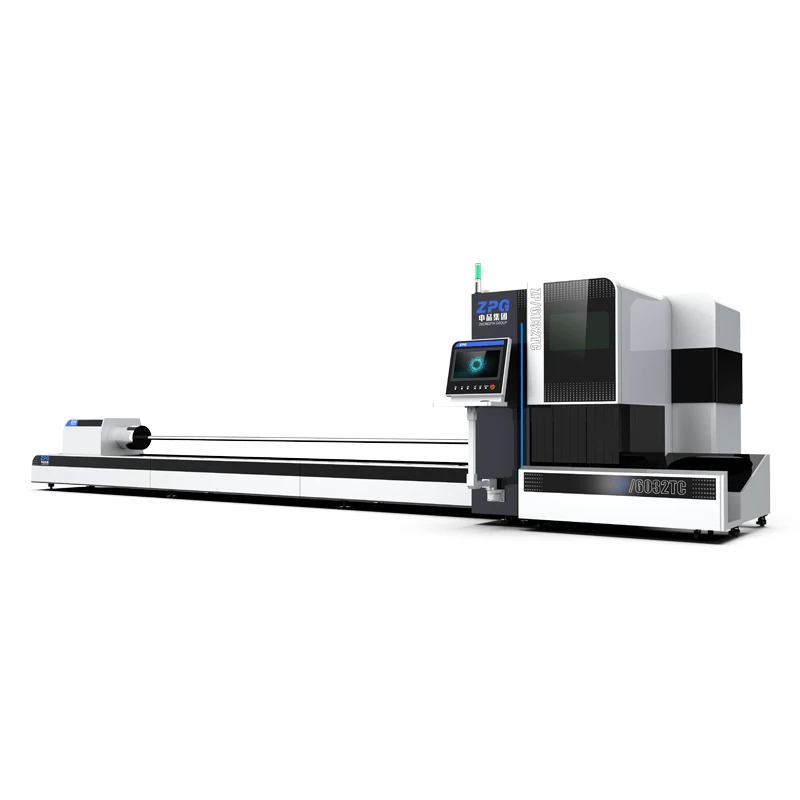

Круглая трубка волоконно-лазерный резак для гибкого металлического шланга 3 кВт Автоматическая лазерная резка машина

ZPG 1500w/2000w/3000w/6000w углеродистая алюминиевая трубка лазерная резка металла lazer машина для резки

Профессиональный 2024 для резки труб 8000 Вт углеродный волоконный лазер с металлом

ZPG-3015E волоконный лазерный станок для резки нержавеющей стали из углеродистой латуни 1000w/2000w/3000w/4000w/5000w/6000w/7000w

Новые поступления

Новинки товаров от производителей по оптовым ценам