Промышленное оборудование генератор газа азота 99.99% чистоты для еды

- Категория: >>>

- Поставщик: Minfa Intelligent Technology(shandong) Co. Ltd.Minfa Ltd.

Сохранить в закладки 1601238664326:

Описание и отзывы

Характеристики

Industrial equipment nitrogen gas generator 99.99% purity nitrogen generator for food

working principle

The QYN-Y series liquid nitrogen equipment is based on the principle of pressure swing adsorption, using high-quality carbon molecules as adsorbents to produce nitrogen from air under a certain pressure. Purified and dried compressed air is subjected to pressurized adsorption and depressurized desorption in an adsorber. Due to the dynamic effect, the diffusion rate of oxygen in the micropores of carbon molecular sieves is much higher than that of nitrogen. When adsorption reaches equilibrium, nitrogen is enriched in the gas phase, forming finished nitrogen gas. Then the pressure is reduced to atmospheric pressure, and the adsorbent desorbs the adsorbed oxygen and other impurities to achieve regeneration. Generally, two adsorption towers are set up in the system, one tower adsorbs and produces nitrogen, and the other tower desorbs and regenerates. The two towers are automatically controlled by a PLC program to cycle alternately. The finished nitrogen is then passed through a Stirling cooler to produce liquid nitrogen.

Technical features

This machine has the characteristics of simple process flow, normal temperature production, high degree of automation, convenient start and stop, few vulnerable parts, easy maintenance, and low production cost.

Technical indicators

Liquid nitrogen production | 5L/day-100L/h | Nitrogen purity | ≥99.9% |

Nitrogen liquefaction | -180℃ | dew point | ≤-40℃(Normal pressure) |

Nitrogen pressure | ≥0.7MPa | Continuous operation of equipment | 8500Hour |

application area | Food freezing, preservation, and processing; Medical beauty, vaccine storage, etc; Cryogenic treatment, cold assembly; Biological tissue storage; Liquid nitrogen fracturing technology; Infrared cooling, etc | ||

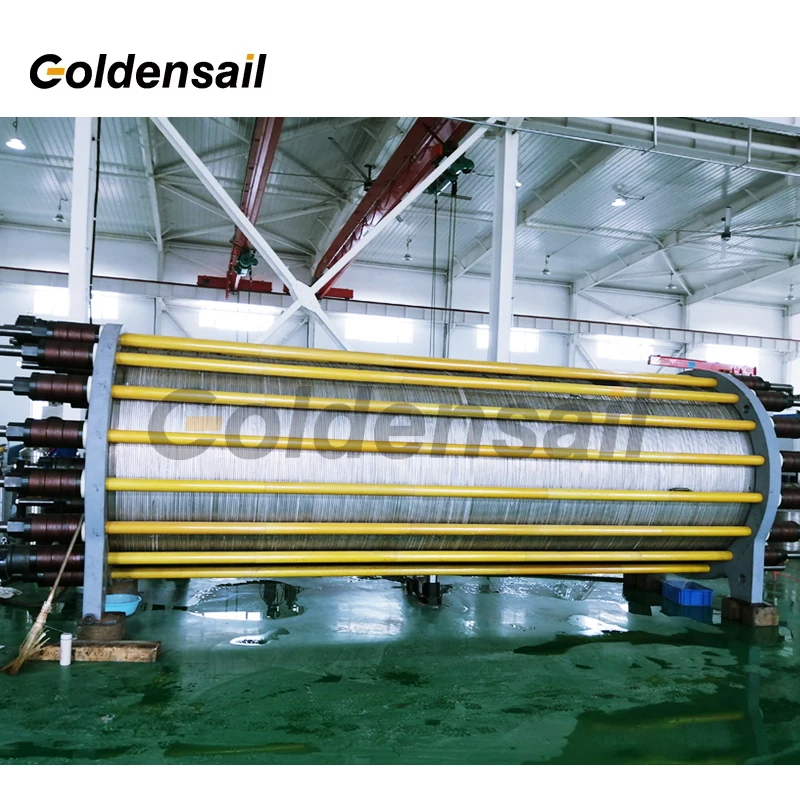

Main components | Screw air compressor, air purification system, air buffer tank, nitrogen buffer tank, nitrogen generator, control cabinet, nitrogen analyzer, chiller, liquid nitrogen machine, etc | ||

Q: What is the terms of payment?

A: T/T, L/C, Western Union etc.

Q: How long is your delivery time?

A: Generally it is 10-50 working days depending on your order.

Q: How to get a prompt quotation?

A: When you send us inquiry, please kindly tell us the below technical information.

1) O2 Flow rate: ____Nm3/h

2) O2 Purity: ____%

3) O2 Discharge pressure: ____Bar

4) Voltages and Frequency: _____V/PH/HZ

5) Application or use for which industry.

Q:Is it in stock?

A:PSA Oxygen Generator is a custom equipment, we manufacture the equipment according to customer's requirements, so there is no stock. Lead time is about 15-20 working days.

Q:What's the higest purity?

A:The highest oxygen purity that can be achieved with the PSA process is 99.5%.

Q:Do you provide equipment startup instruction video?

A:Yes, before shipment, we do machine debugging work for every set of equipment, and we will send customer all the debugging videos and startup instruction videos.

Q:Do you provide overseas machine debugging service?

A:Yes, if customer need, we can send our technician to customer's site for machine debugging and equipment operation guidance and training.

Q:Equipment warranty?

A:Warranty is one year. However we provide lifetime free technical consultation service.

Похожие товары

Производитель hangzhou высокочистый 99.999% жидкого азота производство криогенного азотного генератора ASU

Завод по производству жидкого азота небольшой генератор Z-кислород высокой чистоты китайский заказной для продажи 10 л/день

Хорошая цена генератор азота для лаборатории/генератор пищевых продуктов/генератор чистоты

Азотное оборудование для производства криогенного газа генератор жидкого O2 N2 лабораторного использования небольшой азота

Asme пульт дистанционного управления 1 кВт пленка Fcc башня газоочистки водородный разделительный модуль для нефтеперерабатывающего завода выхлопных газов

Высокое качество чистый щелочной электролизер генератор водорода электролитическая ячейка

HT-LA561 анализатор кислорода с высоким содержанием

Новые поступления

Новинки товаров от производителей по оптовым ценам