Китайский производитель промышленные Литые алюминиевые формы с ЧПУ вращающиеся для крышки капота

- Категория: >>>

- Поставщик: Qingdao Kaway Mould Co. Ltd.

Сохранить в закладки 1601238715299:

Описание и отзывы

Характеристики

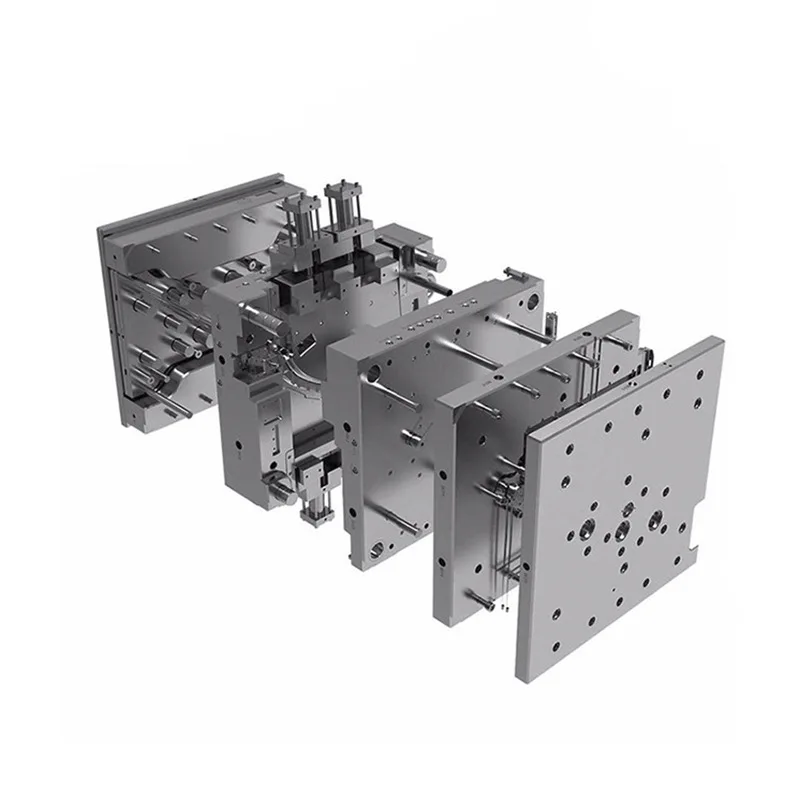

Another type of roto mould, CNC moulds, directly made from aluminum block, have better surface finish from aluminum block than cast aluminum. In contrast, the CNC moulds have higher cost than cast aluminum mould.

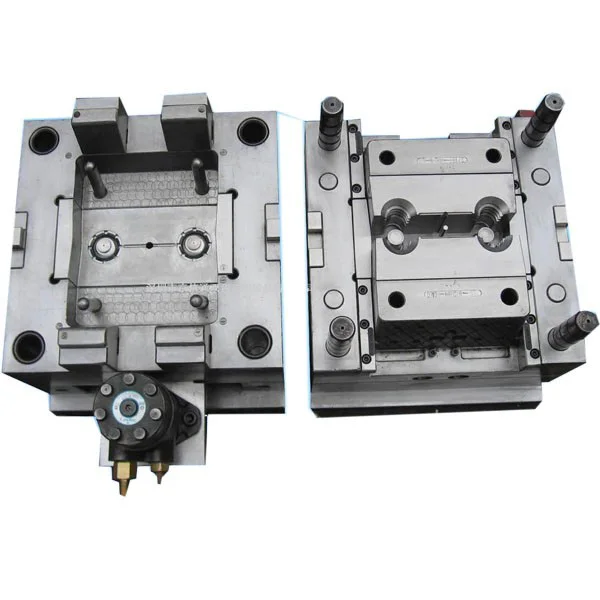

A commonly used finish is sandblasting for mould cavity surface, also called abrasive blasting, which produces a textured rustic look.

Mold making process

- Casting mold plates → CNC machining → Polishing/mating/sandblasting →

Assembling mold → Ran test → Packaging

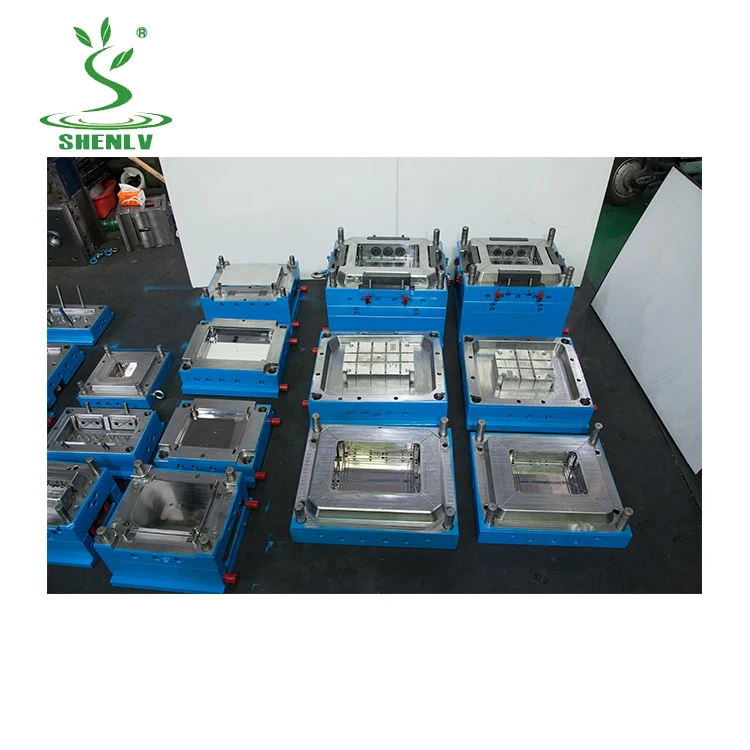

Qingdao Kaway Mould Co.,Ltd, specializes in manufacturing rotational molds, and also making products for some clients. Our advanced mold technology origins in Europe from 2012, and some engineers have ever worked in Italy for some years. So far, with many molds for kayak, water tank, fuel tank, air duct, playground equipment, and more others, we have supplied our customers domestic and in USA, Australia, Italy, Poland, Malaysia and Vietnam.

With our expertise knowledge and experience of the rotational moulding industry, we can provide a full rotational mould and moulding service, from mold design through to final production, including foam filling, especially important for some products including buoys.

We can assist customers in all aspects of product development, roto moulding process and product assembly.

Kaway can manufacturer cast aluminium molds, CNC aluminium molds or fabricated molds in metal sheet.

To value customers' needs is a must for us. We persist in continuous innovation and strict work methods such as Poka-yoke in mold development.

1) Q: What about the lead time? A: Usually, 25days~60days, upon mould size and complexity. |

2) Q: Have all molds run tests before delivery? A: Every mold has run test before delivery, Always final Inspection before shipment. |

3) Q: why should you buy from us not from other suppliers? A: We have been focusing on mould technology, and our engineers have ever experienced working in Europe for some years, have known well of the advanced technology. |

4) Q: what can you buy from us? A: Rotational mould, Rotational molding, powder material PE |

Похожие товары

Изготовитель пресс-форм из АБС-пластика по индивидуальному заказу производство литейных промышленных форм литьевых пластмасс

Промышленные пресс-формы для литья под давлением

Клеммная коробка Ftth типа 86 двухъядерный оптоволоконный блок

Промышленная упаковка для изготовления бумажной целлюлозы

Пластиковая форма для производства сложных пластиковых инъекций

Алюминиевая Экструзионная анодированная промышленная cnc алюминиевая форма от производителя 6061/6063

Оборудование для производства пресс-форм услуги по изготовлению литья под давлением производство

Новые поступления

Новинки товаров от производителей по оптовым ценам