Машина для лазерной резки металла Ipg/Raycus лидер продаж 6020 смарт куб 3 года гарантии

- Категория: >>>

- Поставщик: Accurl Cnc Machine (anhui) Manufactory Co. Ltd.

Сохранить в закладки 1601240124938:

Описание и отзывы

Характеристики

Products Description

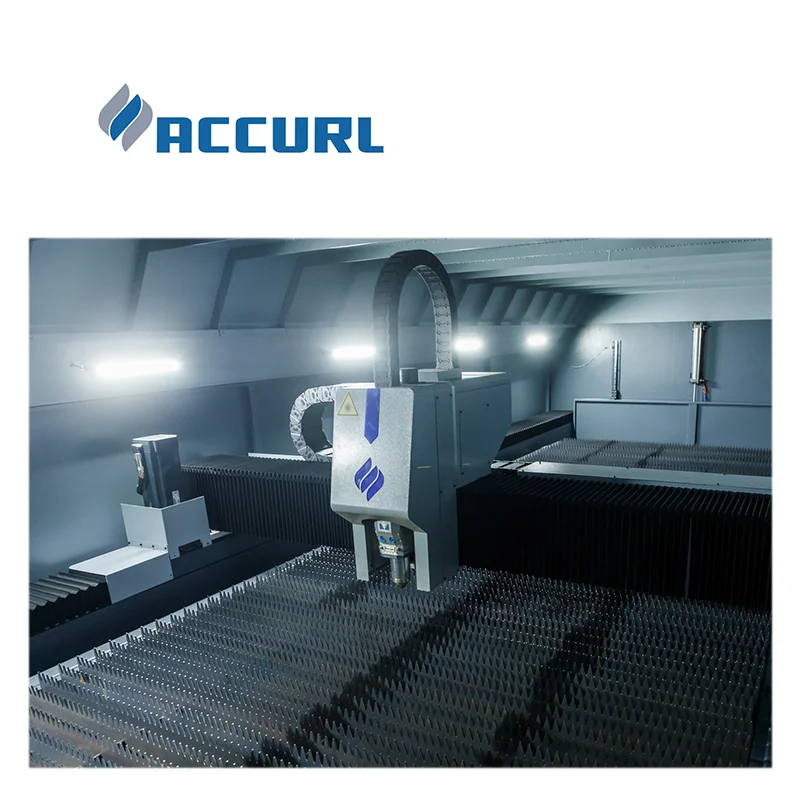

ACCURL 10KW Fiber Laser Cutting Machine for High Power 10000W Fiber Laser Cutting stainless steel

ACCURL® assemble their lasers cutting machine 2000w/3000w/4000w/6000w to the strictest quality standards with nothing but world class components to ensure lasting quality at an attractive price.

SmartLine is the general purpose 2D laser cutting machine by Accurl utilized around the globe across a multitude of applications, manufacturing demands, and budgets. Available in five sizes and with laser powers ranging from 1,000W to 6,000W fiber Laser.

The following elements are included:

• Laser Cutting Head: Raytools laser cutting head;Precitec Cutting head

• CNC Controller: CypCut Fscut 2000 CNC System; BECKHOFF TwinCAT Touch Screen Control System

• CNC Controller: CypCut Fscut 2000 CNC System; BECKHOFF TwinCAT Touch Screen Control System

HYPCUT Touch FSCUT8000 TwinCAT CNC System

• Cutting Area: 3000x1500mm, 4000×20000mm,6000x2000mm,6000x2500mm

• Cutting Speed: Max 100m/min; Positioning: 140m/min; Accelerations:1.6G

• Cutting Area: 3000x1500mm, 4000×20000mm,6000x2000mm,6000x2500mm

• Cutting Speed: Max 100m/min; Positioning: 140m/min; Accelerations:1.6G

ACCURL BRAND

SmartLine is the general purpose 2D laser cutting machine by Accurl utilized around the globe across a multitude of applications,

manufacturing demands, and budgets. Available in five sizes and with laser powers ranging from 1,000W to 6,000W fiber Laser.

manufacturing demands, and budgets. Available in five sizes and with laser powers ranging from 1,000W to 6,000W fiber Laser.

FULLY ANNEALED FRAME

ACCURL steel frames undergo annealing at over 600⁰ to relieve stress. They are built to last years of heavy use without distortion.

Auto changing pallet system allows over 1800kg loading weight.

Auto changing pallet system allows over 1800kg loading weight.

A heavier frame means less vibration and better accuracy. the machine frames are reinforced to minimize twists and deformation while the robust frame of the machine is joined to the chassis by steel bars.

LASER BEAM SECTION

The beam body adopts the overall aluminum casting method, annealing eliminates internal stress and processes, The process is casting →annealing stress → rough machining → vibration aging → semifinishing → vibration aging →finish machining, the machine is machined after tempering, the strength, rigidity and stability of the beam are guaranteed, the precision of the beam can be maintained for a long time. Mainly for the high speed cutting of high power laser cutting machine provides an effective guarantee.

GRAPHITE ANTI-BURN TECHNOLOGY

The area in the entire machine tool where the laser can shoot at isall covered and protected by 20mm thick graphite anti-bruning.

To insuring the machine bed and working table not be out of shape and burned-out.

To insuring the machine bed and working table not be out of shape and burned-out.

DRIVE SYSTEM

The beam is mounted on a pair of precision REXROTH linear guide rails & with advanced German ALPHA engineering and precision

manufacturing have created the highest quality linear systems available today.

manufacturing have created the highest quality linear systems available today.

BECKHOFF Servo Drive

BECKHOFF Servo Motor

.

DUST EXTRACTION SYSTEM

This system is used to filter dry dust from industrial leaks, in accordance with VDI guidelines 3677, paragraph. The filter elements use compact porous filters. In many countries it is forbidden to circulate filtered air during the cutting of stainless steel (CrNi). Therefore, it is recommended that the user install air ducts to the outside.

CNC CONTROL SYSTEM

The FSCUT2000 laser cutting control system of an economical laser cutting control system.

Widely used in the field of metal and nonmetal laser cutting. Because of its outstanding performance in the field of fiber laser cutting, by the vast number of high-end users.

LASER CUTTING HEAD

CUTTING HEAD PRECITEC PROCUTTER 2.0

•The new ProCutter 2.0 generation impresses with its increased performance and new automation features. Faster, easier, more efficient, more enduring – this is how laser cutting is shaping up in the new generation, due to numerous developments.

LASER SOURCE

Germany IPG Fiber Laser Resonator

IPG 12000W Ytterbium Laser Resonator

IPG 4000W Ytterbium Laser Resonator

IPG 6000W Ytterbium Laser Resonator

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

MACHINE DIMENSION AND WEIGHT | ||||||||||

MACHINE MODEL | 3015 | 4020 | 6020 | 6025 | 8025 | |||||

Lenght(mm) | 10000 | 11200 | 14000 | 14000 | 10800 | |||||

Width(mm) | 3080 | 4100 | 4100 | 4750 | 4750 | |||||

Height(mm) | 2250 | 2250 | Z axis(mm) | 100 | 100 | |||||

Weight(kg) | 12000 | 15000 | Max.sheet weight(kg) | 1100 | 1800 | |||||

OPTIONAL FOR LOADER & UNLOADER BRG SYSTEM 2.0

Accurl Loader & unloader BRG System 2.0 is the automated solution that best optimizes the flow of material, which improves both the safety at work and the safety of the process. The solutions included range from simple operation to fully automated operation.

Related Products

Company Profile

WHY CHOOSE ACCURL ?

ACCURL is a famous manufacturer of metal sheet equipments in world market. Its Brand ¡°Accurl¡± has been leading brand for many years in the field of international metal sheet equipments. Our group devote ourselves to product development, production and sales.

Our main products are: CNC Press Brake, Shears, Hydraulic press, Laser Cutter and CNC rolling machine these sheet metal processing equipments.we are using advanced technology from German, Japan, and Italy.we can produce large Hydraulic Press and Press Brake more than 16000 ton & 16m.we are with professional R&D team, and we have World-class design and manufacturing capabilities.

Our main products are: CNC Press Brake, Shears, Hydraulic press, Laser Cutter and CNC rolling machine these sheet metal processing equipments.we are using advanced technology from German, Japan, and Italy.we can produce large Hydraulic Press and Press Brake more than 16000 ton & 16m.we are with professional R&D team, and we have World-class design and manufacturing capabilities.

WE GOT 5 STARS RATING!

Exhibition

Product packaging

We are currently reviewing our product packaging from the angles of waste-reduction and resource-saving. We are also working on improving transportation efficiency from the design phase of product development.

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

Our Serives

The use of an interferometer records the machines X and Y axis movement during cutting to ensure accuracy.

Adjustments are made to ensure machine is precisely tuned before shipment.

Adjustments are made to ensure machine is precisely tuned before shipment.

A Marble test is performed to measure the X and Y axis, calculating any necessary adjustments to ensure perfect level and alignment along length of machine.

A collimator is run along the full length of the guide rail, testing for

straightness. Adjustments are made as required to ensure linear accurae linear accuracy.

Похожие товары

27% скидка 2024 лучшие продажи 1 кВт 2 кВт 3 кВт 12 кВт для лазерной резки стали и металла

27% скидка 2024 лучшие продажи китайские поставщики FORSUN 12 кВт 8 кВт 6 кВт 2030 1530 волоконно-лазерная резка для резки стального железа

13% скидка! 1325 высокоточная машина для лазерной гравировки и лазерной резки драгоценных камней Co2 80 Вт 100 Вт 130 Вт 150 Вт

13% скидка! 1325 лазерный станок для лазерной резки Co2 150 Вт

Новая 21% скидка! 1000 Вт 2000 Вт 3000 Вт волоконно-оптический лазерный гравировальный станок

2024 27% выключения 10000 Вт Лазерная резка для металла с волоконным лазерным источником

27% скидка 2024 лучшие продажи 1 кВт 2 кВт 4 кВт 6 кВт обменный Рабочий стол волоконно-лазерная резка с водяным охлаждением

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $