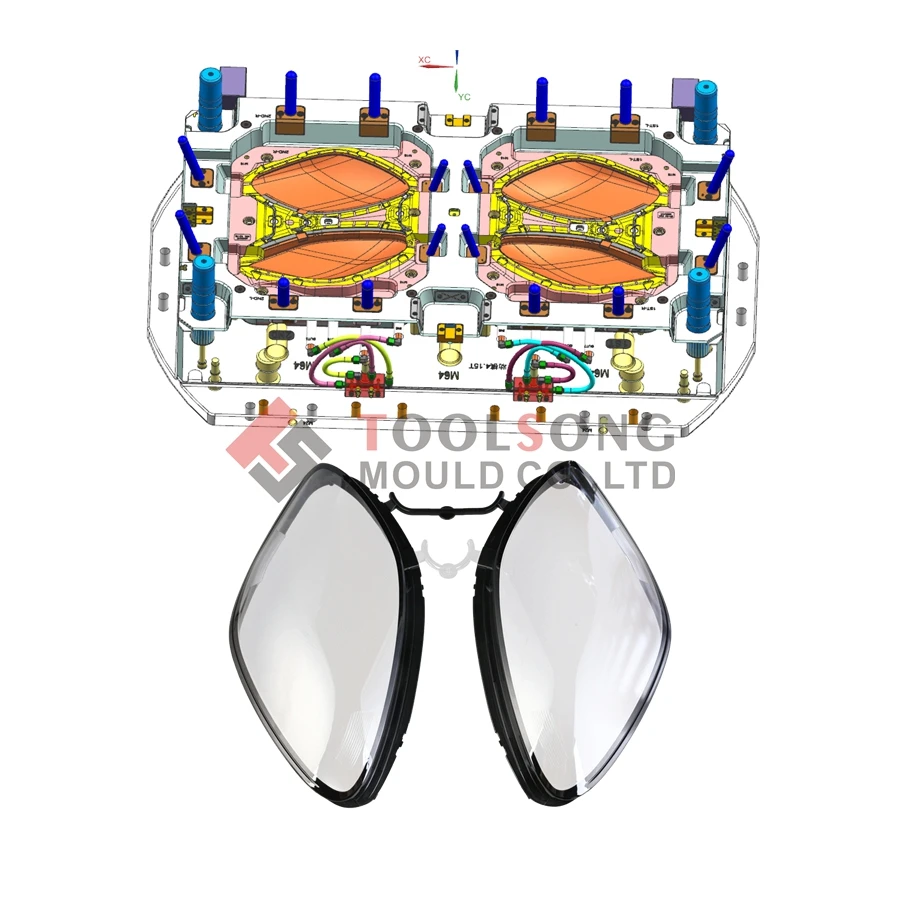

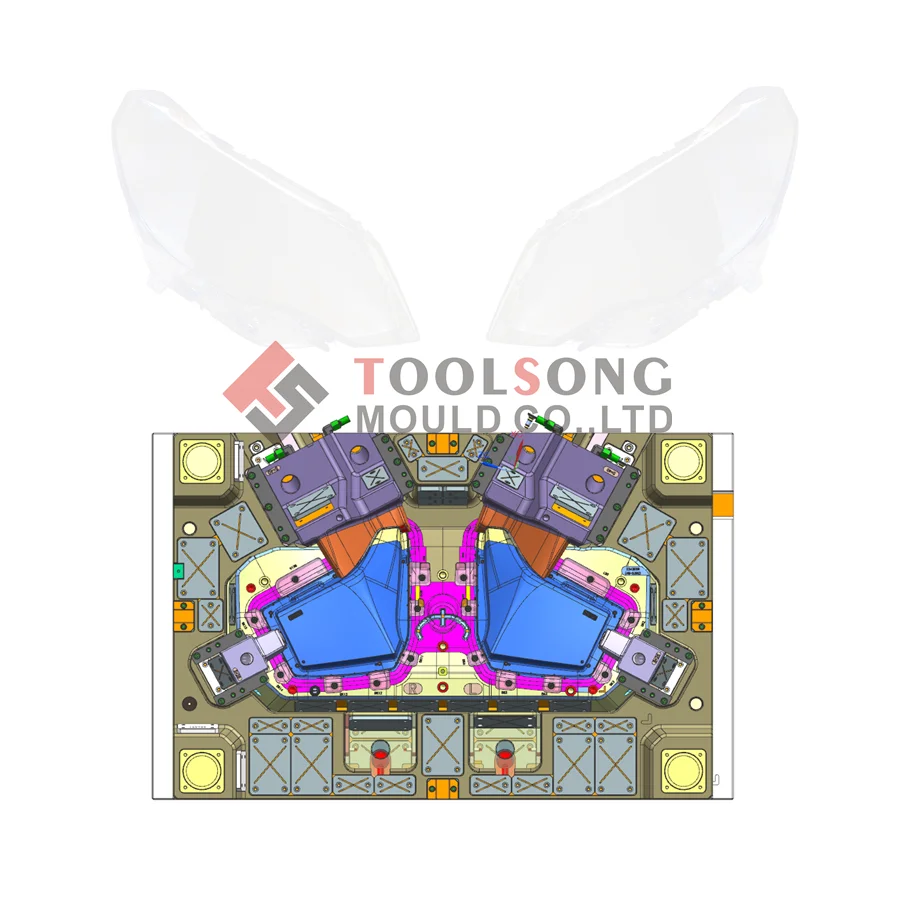

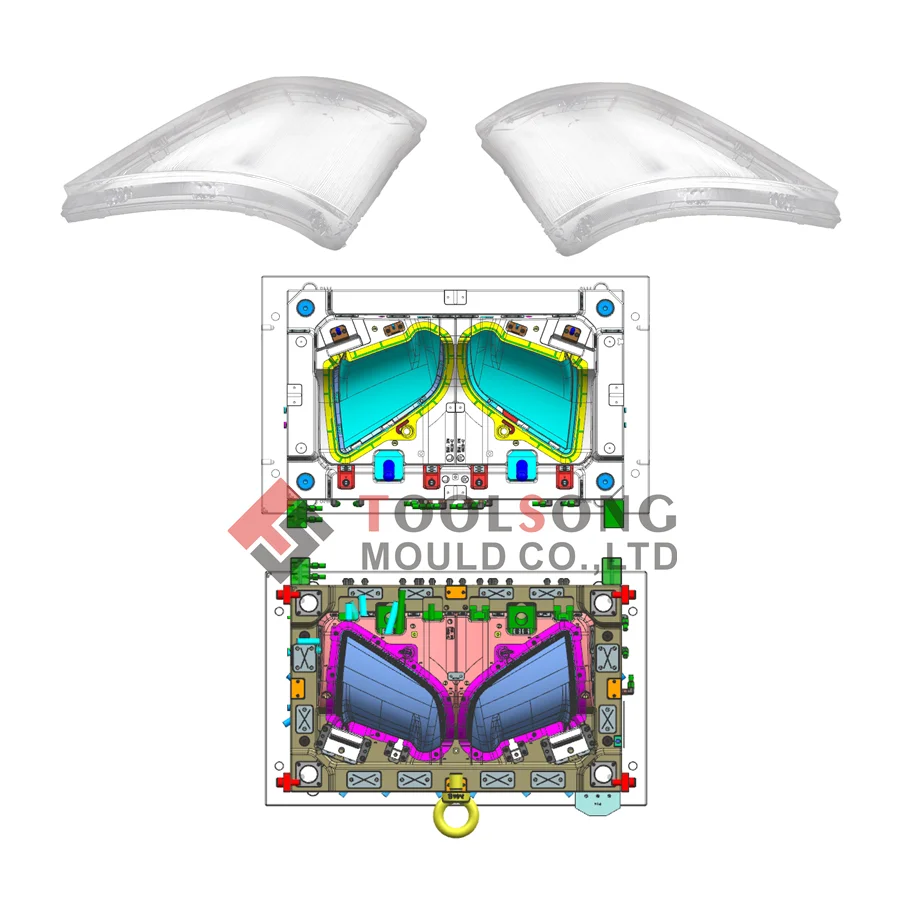

Формовочная форма для фар

- Категория: >>>

- Поставщик: Taizhou Toolsong Mould Co. Ltd.Taizhou Ltd.

Сохранить в закладки 1601240323697:

Описание и отзывы

Характеристики

Product Name | Headlamp Injection Mold Maker Tooling Automotive Front Lamp Light Inject Customized Lighting Mould |

Product Material | PC, PMMA, ABS, PC+ABS, PET, PA66, etc |

Mold Steel | P20, 1.2738, 1.2343ESR, 1.2344ESR, 718HH, etc |

Injection System | HRS, Moldmaster, Synventive hot runner |

Ejection System | pin ejection, blade ejection, hydraulic ejection, air ejection, etc |

Mold Life | 500,000 shots |

-- Project Manager Takes Full Responsibilities for Mold Quality, Cost and Delivery.

We have 2 plants for manufacturing plastic toolings.

Plant

Average Experience of Tool Makers: 16 years

Review Meeting

Project Review before Sending Tool Design to Customer.

R&D Team

Software: UG, CATIA, AUTO-CAD.

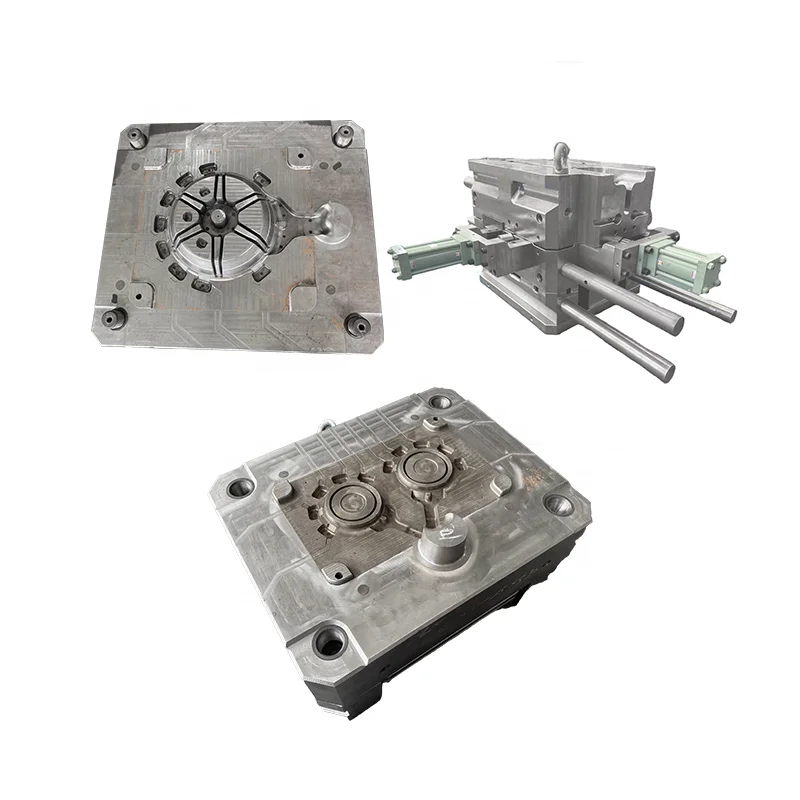

Machining Center

Equipped with 5 Axis, 3+2 Axis, CNC Milling, EDM,

Deep Hole Drilling Machine, Die Spotting Machine, etc.Machining Pictures

High Precision Machining is Regarded as the Most Crucial Process After Tool Design Closed.

1) Customer shall provide tool specification as well as part picture or drawing (In STP, X-T) for quotation.

2) Toolsong will quote within 24-48 hours.

1) Quality Control in each mold manufacturing process.

2) Mold Inspection: each mold should be disassembled and inspected before shipment.

1) Tool Makers strictly follow up schedule.

2) Project Managers make preventative plan, manage and report maufacturing status.

Похожие товары

2025 пресс-форма для литья под давлением

Изготовленная на заказ алюминиевая форма для литья под давлением автомобильных осветительных компонентов с прецизионным инжинирингом

Пресс-штамп и пресс-форма для металла с более высокой

Ротационная формовочная форма для детских игрушечных машин 2024 ротационного литья из алюминиевого сплава с ЧПУ ротационная обработка

Пластиковая форма для рисования ведра с бериллиевой медной формой

Влажные литые сборные бетонные люки для выращивания конического грунта

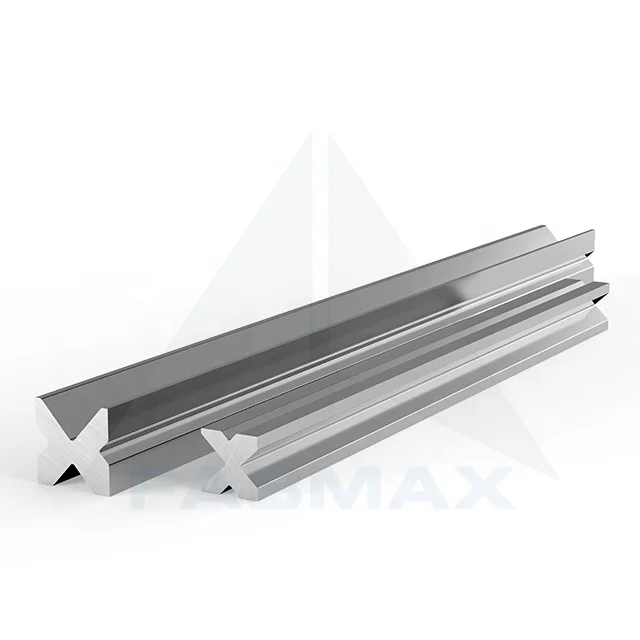

Многофункциональные штампы FABMAX прочные высококачественные инструменты для прессового тормоза и индивидуальные специальные

Новые поступления

Новинки товаров от производителей по оптовым ценам