Высокоэффективная машина для сухой добычи 3 шт. 500 трехдисковый магнитный сепаратор цирконовой рутильной оловянной руды

- Категория: >>>

- Поставщик: Ganzhou Gelin Mining Machinery Co. Ltd.Ganzhou Ltd.

Сохранить в закладки 1601240772066:

Описание и отзывы

Характеристики

High Efficiency 3PC500 Dry Mining Machine Three Disc Magnetic Separator for Zircon Rutile Tin Ore

Our factory professional produce different type magnetic separator over 30 years. The products includes dry type magnetic separator, wet type magnetic separator,electrostatic separator and disc electromagnetic separator. Magnetic field intensity from 800 gauss up to 20000 gauss.

Our magnetic separator sells well in Vietnam, Philippines, Indonesia, India, Chile, Peru, Africa etc. Which are widely used for separate magnetic iron ore, ilmenite, titanium ore, hematile, manganese, cassiterite, coltan, tantalum, niobium, zircon sand, beach black sands and so on.

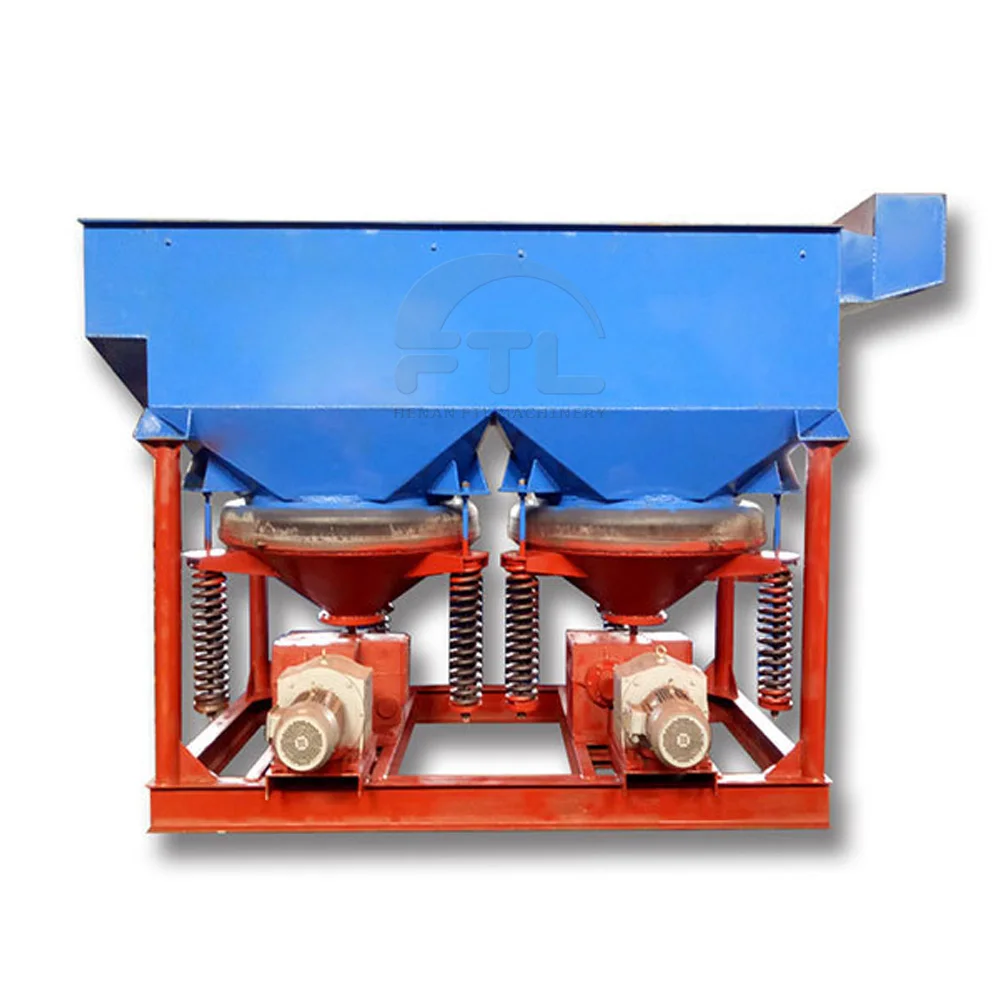

Electromagnetic Separator is divided into Three-disk electromagnetic magnetic separator and Single-disk electromagnetic magnetic separator, which is used to separate the weak magnetic raw materials of minerals. Three-disc electromagnetic separator is sorting mineral size less than 2-3mm of weakly magnetic minerals and rare metal ore selection, it is a very important mineral processing equipment. Three-disc electrmagnetic separator have 3 models.Single-disk electromagnetic separator for sorting particle size less than 6 mm.

1).Single discs electromagnetic separator( 1 PC disc magnetic separator)

885 type

Capacity:1-1.8t/h

Particle size of processing:<6mm

Complete power consumption:3kw

Overall size:2980x1830x1850mm

Magnetic field intensity: maximum18000GS

( Electromagnetic, intensity can be adjusted).

Electric control panel box included.

2).Three discs electromagnetic separator( 3 PC disc magnetic separator)

Three-disc electromagnetic separator is sorting mineral size less than 2-3mm of weakly magnetic minerals and rare metal ore selection, it is a very important mineral processing equipment. Three-disc electrmagnetic separator have 3 models.

Three-disc electromagnetic separator is for a variety of strong magnetic minerals mixed ore separation, according to the difference of magnetic minerals, can achieving efficient separation of minerals can form different intensity magnetic disk by adjusting the excitation current levels, can also be adjusted each level disk and sensing distance between dressing grain is to get different magnetic induction intensity, reaching a one-time separation of various minerals. This device is widely used in ilmenite, monazite, tungsten, tin, tantalum, iron ore and other minerals with magnetic and non-magnetic dry sorting.

Specification

| Model | Unit | 3PC-500 | 3PC-600 | 3PCX600 |

| Magnetic intensity | Hauteur | Distance to beltsurface 2mm Disk teeth 1700 | Distance to beltSurface 2mm Disk teeth 1800 | Distance to belt 2mm Disk teeth 2000 |

| Number of magnetic disk | Piece | 3 | 3 | 3 |

| Diameter of magnetic disk | mm | 500 | 600 | 600 |

| Revolution of magnetic disk | r/min | 25-40 | 22-38 | 22-32 |

| Power supply | V | 380 | 380 | 380 |

| Exciting coil | Unit | 4 | 4 | 4 |

| Matching motor | kw | 0.75 | 1.5 | 1.5 |

| Exciting power | kw | 1.5 | 1.6 | 1.6 |

| Coil temperature rise | °C | 65 | 65 | 65 |

| Rated currentof coil | A | 1.1-1.8 | 1.2-1.9 | 1.2-2.2 |

| Duty rating | Continuous | Continuous | Continuous | |

| Feed width | mm | 210 | 300 | 300 |

| Feed size | mm | ≤2 | ≤2 | ≤2 |

| Capacity | kg/h | 100-500 | 120-800 | 80-800 |

| Overall Size | mm | 2800×800×1220 | 3200×870×1160 | 3150×900×1250 |

| Weight | kg | 1900 | 2200 | 2300 |

Features

1. The materials selected for the electromagnetic machine are in accordance with the national standard copper wire.

2. High quality copper wire with long working time, it can work continuously for more than 24 hours.

3. Magnetic size of the electromagnet can be adjusted

4. Simple to operate, easy to install, easy to maintain

5. It can separate many kinds of minerals such as strong magnetism, weak magnetism and nonmagnetic at one time.

6. Multi-outputs: It's able to do the separation of up to 6 minerals of different magnetic susceptibilities in one single pass, and produce 100% clean magnetic fractions with high magnetic recovery;

Working Principle

Dry feef material (e.g.beach sands) is diacharged from a hopper onto a Vibratory Feeder tray. The material is very evenly fed onto a thin conveyor belt. An even and mon-layer of material is conveyed under the rotating high-intensity magnetic discs. Whilst underneath the magnetic discs, magnetic particles are attracted to the high-gradient magnetic zones. These captures particles are then carried by the rotating discs to the discharge chutes where they are released. Scrapers that are mounted on each of the chutes ensure the total discharge of the extracted magnetic particles. Any non-magnetic feed material will pass under each of the three discs and discharge at the end of the conveyor.

Ganzhou Gelin Mining Machinery Co., Ltd is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, separation etc. in China. Gelin have a complete service system which can provide customer full service in mining field and after sales service.By now, Gelin’s equipments and services are exported to over 60 countries,include America, Russia, India, Africa, Brazil, Chile,South Africa,Zambia etc. Sincerely welcome customers to visit our factory.

One Stop solution for beneficiation plant service

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design and equipment, we also provide the infrastructure design; Electrical and pipeline system design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands

1.Strict machine inspection before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

6. Provide technical exchanging & spare parts for life-long term

Q: How about your machine quality?

Q: If I don’t know installation and commissioning,what should I do?

Похожие товары

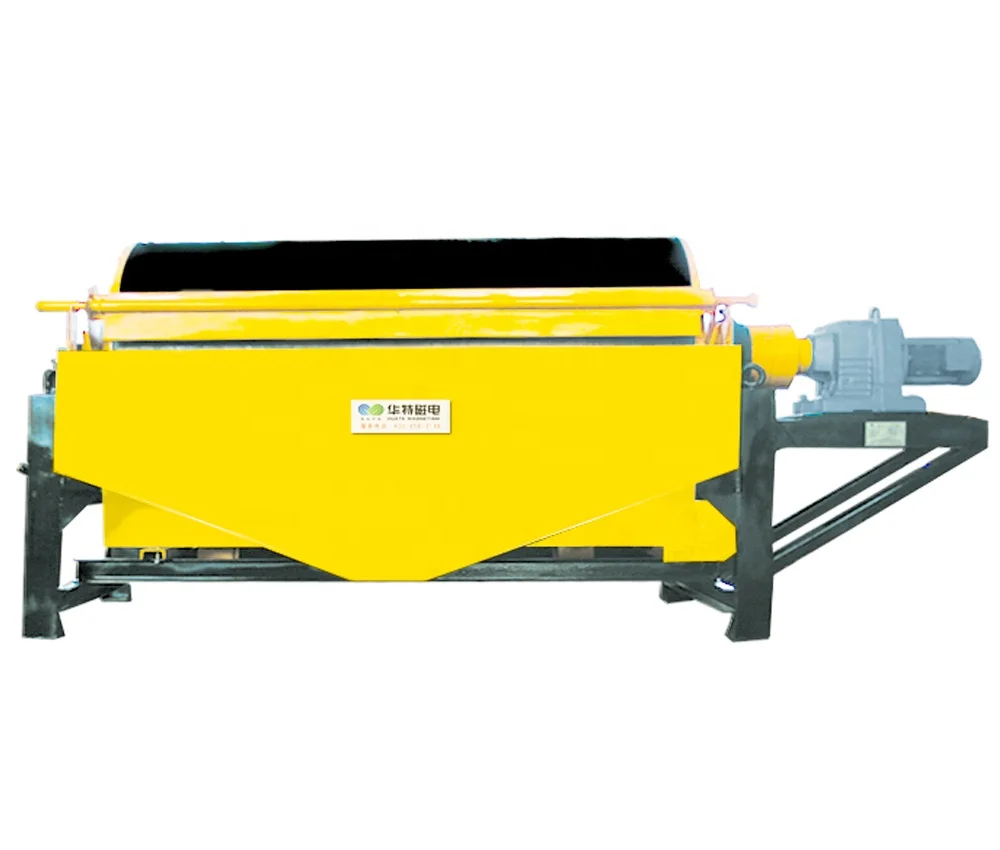

Многополюсный пульсирующий влажный барабан магнитный сепаратор для железной руды

Популярное подвижное мобильное горное оборудование для добычи Аллювиального золота

Горячий продавать мобильный двухслойный роторный экран для разделения песка и гравия

Горнодобывающее оборудование тяжелая глина гравий аллювиальный песок 40 т/ч мобильный завод по переработке золотой руды для продажи

Концентрический вихревого сепаратор тонкого металла для бутылок и пластмасс

Надежный производительный ролик/барабан/шкив вращающийся магнитный сепаратор постоянный барабанный шкив

Алмазная трапециевидная Зажимная машина для разделения марганцевой руды Индия

Новые поступления

Новинки товаров от производителей по оптовым ценам