Мини рулонный в рулон УФ струйный принтер A/B пленочный стикер с многоцветной гарантией на 1 год

- Категория: >>>

- Поставщик: Goto Tech Co LTD

Сохранить в закладки 1601240956917:

Описание и отзывы

Характеристики

Products Description

Model | GT-U300 |

Print head number | 3 pcs |

Print speed | 1.5m/h |

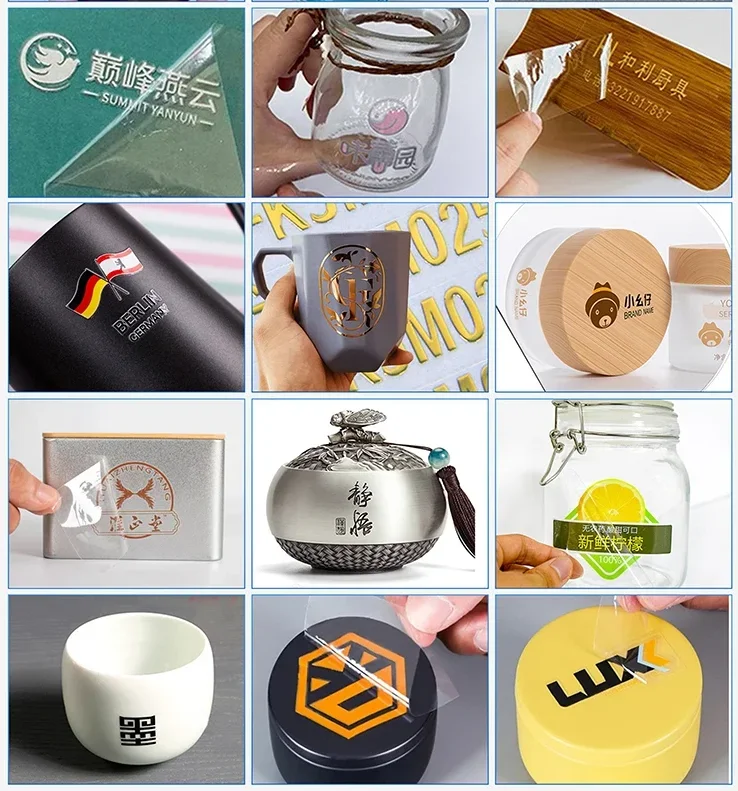

Printing medium | AB film |

Ink type | Uv ink |

Curing system | LED Curing lamp |

Ink colors | CIM/YIKIWIV |

Paper device | Pre-finished film receiver + post-protective film receiver |

Operating system | Windows718110 |

Operation language | Chinese/English |

Temperature | T&H 20-30°C'C 40%-60%RH |

RIP Software | RlN software,if Photoprint add$220/set |

Power | 450W |

Package Size | (length, width and height)1400*900*780MM |

Packing weight | Net Weight: 85kg /Gross Weight: 120kg |

UV DTF Printer

1.Pre-Sales Service:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

2.After-Sales Service:

*Within 7 days since your local customs clearance:if the machine has any problems,we will change it free.

*Exceed 7 days since your local customs clearance but within warranty period if the machine parts have any problems,we can change

the old machine parts to new ones free,but you should pay all the shipping cost.

*Exceed one year warranty period if the machine parts have any problems,we can offer new machine parts with cost price and you

also should pay all the shipping cost.

*We offer 24 hours technical support by call,email.

*Our technician can give you remote guide online(Skype/MSN/What's app/viber/Tel/Etc) if you have any question.

*Machine has been adjusted before delivery,operation disk is included in the delivery.If there is any other questions,pls kindly

tell me.

*We have manual instruction and CD (Guiding Videos) for software Installation,operation and machine's using and maintenance.

3.Dowin Tech Co.,Ltd supply free technical training for all customers all over the world until the workers from buyer can operate

the machine normally and individually. Mainly training are as follow:

*Training for Control software operation.

*Training for normatively turning on/off operation of the machine.

*Instruction of technical parameters, as well as their setting ranges.

*Basic daily cleaning and maintenance for the machine.

*Solutions for common hardware problems.

*Training for other questions and technical suggestions during daily production.

4.Training can be processed in the following ways:

*Workers of customers can come to our factory get the most professional hand-by-hand training.

*We can send engineers to customers' country and do training for workers in customers' target factory.However,tickets and daily

consumption like food and accommodation should be afforded by customers.

*Remote training through Internet tools like Team-viewer,Skype and other instant communication softwares.

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

2.After-Sales Service:

*Within 7 days since your local customs clearance:if the machine has any problems,we will change it free.

*Exceed 7 days since your local customs clearance but within warranty period if the machine parts have any problems,we can change

the old machine parts to new ones free,but you should pay all the shipping cost.

*Exceed one year warranty period if the machine parts have any problems,we can offer new machine parts with cost price and you

also should pay all the shipping cost.

*We offer 24 hours technical support by call,email.

*Our technician can give you remote guide online(Skype/MSN/What's app/viber/Tel/Etc) if you have any question.

*Machine has been adjusted before delivery,operation disk is included in the delivery.If there is any other questions,pls kindly

tell me.

*We have manual instruction and CD (Guiding Videos) for software Installation,operation and machine's using and maintenance.

3.Dowin Tech Co.,Ltd supply free technical training for all customers all over the world until the workers from buyer can operate

the machine normally and individually. Mainly training are as follow:

*Training for Control software operation.

*Training for normatively turning on/off operation of the machine.

*Instruction of technical parameters, as well as their setting ranges.

*Basic daily cleaning and maintenance for the machine.

*Solutions for common hardware problems.

*Training for other questions and technical suggestions during daily production.

4.Training can be processed in the following ways:

*Workers of customers can come to our factory get the most professional hand-by-hand training.

*We can send engineers to customers' country and do training for workers in customers' target factory.However,tickets and daily

consumption like food and accommodation should be afforded by customers.

*Remote training through Internet tools like Team-viewer,Skype and other instant communication softwares.

FAQ

Q1.How to maintain the printhead?

A1.The working environment of the machine, temperature 15-30℃, humidity 35-65%RH. Clean the printhead at the end of each day

through the auto-cleaning function, and add the moisturizing liquid in time if you don't use the machine for 3-4 days. If

possible, it is better to let the machine work every day.

Q2. Are there anti-collision devices?

A2. Anti-collision devices are installed on both sides of the printhead to prevent the printhead from being damaged.

Q3. Is the machine equipped with safety devices?

A3. (1) The machine is equipped with an emergency stop button, which will cut off the power and stop all the operations after it

is pressed. (2)The machine has limit switches at the top, bottom, left, right, front and back, and will stop automatically after

reaching the specified position, as long as you don't intentionally put your hand or other things inside the machine when it is

working, it is completely safe.

Q4. Does the machine use a Honson board?

A4.We use Better Print, which shares a same development team with Honson motherboard.

We have been using this board since 2017,and it is very stable.

Q5.Why are machines from other suppliers so much cheaper than yours?

A5.The configuration is different between the different machines. There are many accessories for UV printers, ranging from an ink

sac to the main board and body of the machine. All of them are different. Our body adopts CNC gantry milling technology, which is

more stable and precise, ensuring that the body will not deform for a long time . Cheap machine is made of sheet metal, which has

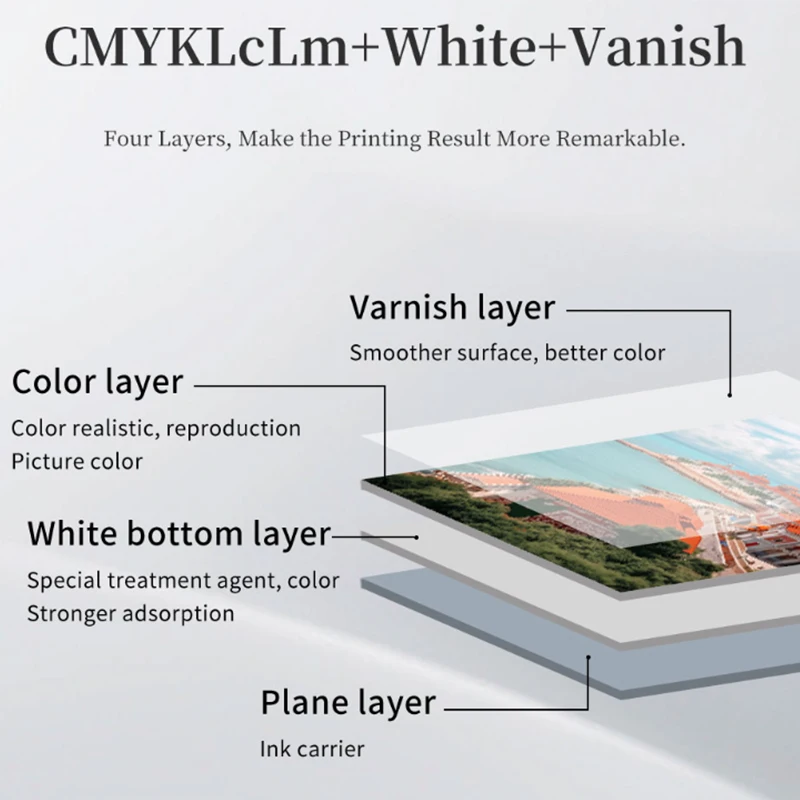

poor stability and short service life. The machine uses Hiwin guide rails, making sure the high precision. CMYKLmLc+White+Varnish

color set, higher color reproduction.

Q6.How about warranty, and is there any charge for after-sales service?

A6. (1).12 months guarantee of the whole machine(except the printhead)

(2).Main parts(excluding the consumables)shall be changed free of charge if there is any problem during the warranty period.

(3).Lifetime maintenance free of charge

(4).Machine has been adjusted and tested before delivery

A1.The working environment of the machine, temperature 15-30℃, humidity 35-65%RH. Clean the printhead at the end of each day

through the auto-cleaning function, and add the moisturizing liquid in time if you don't use the machine for 3-4 days. If

possible, it is better to let the machine work every day.

Q2. Are there anti-collision devices?

A2. Anti-collision devices are installed on both sides of the printhead to prevent the printhead from being damaged.

Q3. Is the machine equipped with safety devices?

A3. (1) The machine is equipped with an emergency stop button, which will cut off the power and stop all the operations after it

is pressed. (2)The machine has limit switches at the top, bottom, left, right, front and back, and will stop automatically after

reaching the specified position, as long as you don't intentionally put your hand or other things inside the machine when it is

working, it is completely safe.

Q4. Does the machine use a Honson board?

A4.We use Better Print, which shares a same development team with Honson motherboard.

We have been using this board since 2017,and it is very stable.

Q5.Why are machines from other suppliers so much cheaper than yours?

A5.The configuration is different between the different machines. There are many accessories for UV printers, ranging from an ink

sac to the main board and body of the machine. All of them are different. Our body adopts CNC gantry milling technology, which is

more stable and precise, ensuring that the body will not deform for a long time . Cheap machine is made of sheet metal, which has

poor stability and short service life. The machine uses Hiwin guide rails, making sure the high precision. CMYKLmLc+White+Varnish

color set, higher color reproduction.

Q6.How about warranty, and is there any charge for after-sales service?

A6. (1).12 months guarantee of the whole machine(except the printhead)

(2).Main parts(excluding the consumables)shall be changed free of charge if there is any problem during the warranty period.

(3).Lifetime maintenance free of charge

(4).Machine has been adjusted and tested before delivery

Похожие товары

3360 многофункциональная цифровая печатная машина для пластиковых ПВХ карт

Оригинальная струйная пленка Sunika Epson XP600 dtf uv принтер A3 A4 OEM & ODM стикер Принтер

Лидер продаж термальность встроенный автоматический партия кодер яйца струйный принтер цена для продажи

4-COLOR sky color Indoor eco printer inkjet for sale

330 200,70 ₽ - 396 240,84 ₽

Цифровой стабильный 2 I3200 head заводская цена большой формат 6ft 8ft 10ft Eco Solvente принтер плоттер Flex цифровая печатная машина

665 454,08 ₽ - 1 109 164,08 ₽

2023 новая технология 1.6m/1 8 m/3 2 m цифровая печатная машина для текстильного промышленного принтера вышивки крестом

776 381,58 ₽ - 1 663 801,58 ₽

3 2 м i3200 эко-растворитель 10 футов

887 309,08 ₽ - 1 608 448,75 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Профессиональная Цветочная пилка для ногтей в форме ивы специальный дизайн пластиковая стеклянная губка наждачная бумага красоты

0,09-0,12 $

Креативный металлический лоток для пепельницы жестяная коробка креативный

Новый Airtag GPS локатор защитный чехол с красочным принтом полиэстер Воротник для собак и кошек трансграничный трекер ошейник

1,50-1,70 $

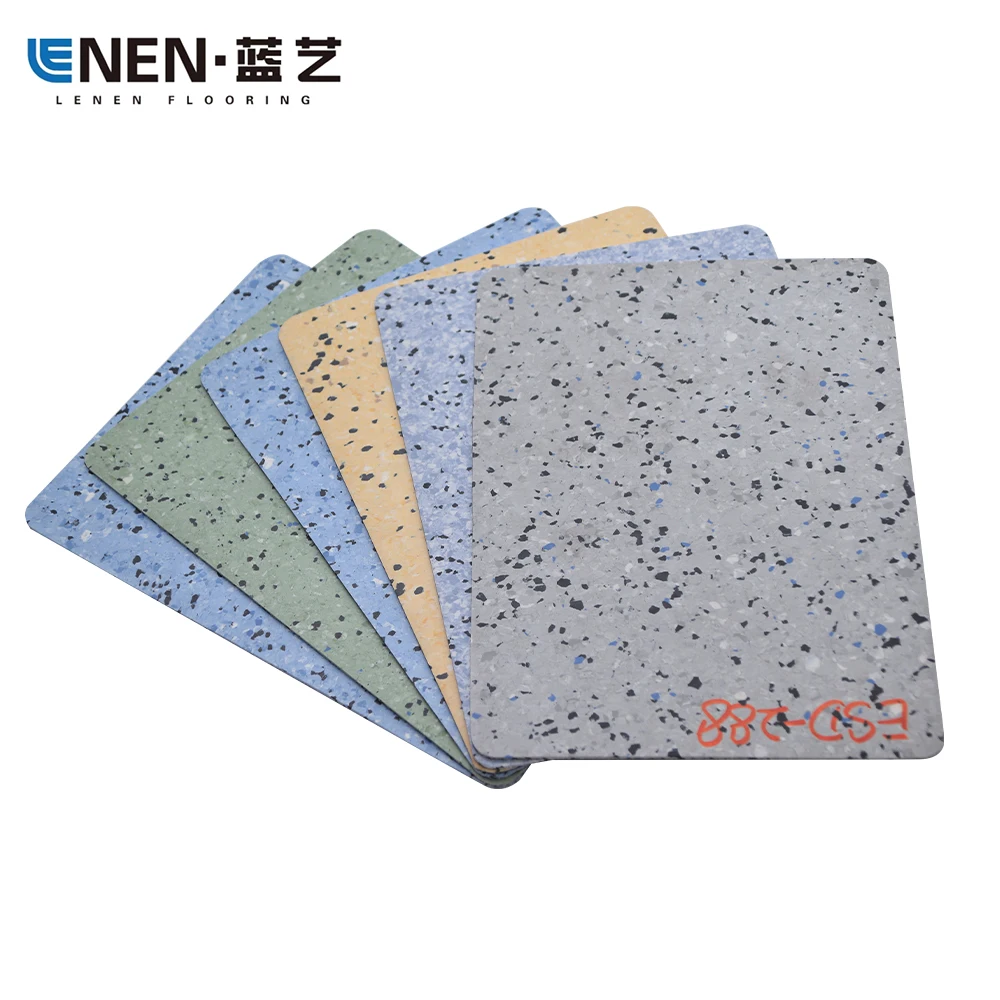

Современный дизайн коммерческий антистатический лист для напольного покрытия из ПВХ толщиной 2 мм эпоксидная проводящая виниловая плитка центров обработки данных пластиковый материал

44-футовый катер для пожаротушения с алюминиевым корпусом и 1500 галлонов водомета

208 009-209 999 $

анти- покупать насекомых полиэтилен экран

2 шт. 50 а 12 в автомобильный лодочный трек переключатель батарея двигатель старт зажигания стартер с нажимной

1,40-1,80 $