Мост крепеж инвертор сварочный аппарат

- Категория: >>>

- Поставщик: Shanghai Yifa Stud Welder Engineering Co. Ltd.

Сохранить в закладки 1601242759168:

Описание и отзывы

Характеристики

Product Description

bridge fastener inverter welding machine

1. Technical Parameters

| Item | RSN7-1600 | RSN7-2000 | RSN7-2500 | RSN7-3150 |

| welding range | Φ4mm—Φ20mm | Φ4mm—Φ24mm | Φ4mm—Φ28mm | Φ4mm-Φ36mm |

| welding current | 200A—1600A | 200A—2000A | 200A—2500A | 300A—3150A |

| welding time | 0.1S—3S | 0.1S—3S | 0.1S—3S | 0.1S—3S |

| welding speed | Φ20 10pcs/minute | Φ24 10pcs/minute | Φ28 10pcs/minute | Φ36 8pcs/minute |

| input power | AC 3˜280V—440V | AC 3˜280V—440V | AC 3˜280V—440V | AC 3˜280V—440V |

| rated input power | 50KW | 60KW | 80KW | 100KW |

| power switch | 100A | 125A | 160A | 225A |

| protect grade | Ip23 | Ip23 | Ip23 | IP23 |

| cooling way | F | F | F | F |

| dimension(L/W/H) | 890x368x560mm | 890x398x680mm | 890x398x680mm | 890x398x800mm |

| weight | 98KG | 126KG | 135KG | 168 |

* All above parameters are subject to technical modifications. * Upon your requests, the welding machine for special use shall be designed and welcome to contact us. |

2. Welding machine for m6 welding pin features

(1) IGBT Inverter technology.

(2) Low price, less weight, power efficient, safe and reliable.

(3) Easy control and digital display of welding voltage, current and time.

(4) Special torch with extending cables, large lfiting force, low heat and durable.

(5) Inner circuit board is under waterproof, anticorrosion, dampproof and dustproof treatment.

(6) Compensatory capabilities of power voltage. When the voltage decreases, this machine can automatically stabilize welding parameters, when the voltage is extremely low, the machine still can work normally(only the max welding current is a little lower), the welding strength is much higher than ordinary welding machine. This feature applies to: electricity shortage and multiple equipments operating simutaneously in construction sites such as projects powered by generators, shipbuilding, steel construction etc.

3. Welding machine for m6 welding pin standard accessories and their connecting illustration

| Standard Accessories | |||

| No. | Accessories | Spec. | Qty. |

| (1) | torch with 5m cable | YF-DH-25 | 1pc |

| (2) | torch lengthening cable | 120mm² | 25m |

| (3) | earth cable | 120mm² | 5m |

| (4) | chucks | Φ13,Φ16,Φ19,Φ22,Φ24 | 15 sets each |

| (5) | ferrules and pressing plates | ||

| (6) | earth clamp | N/A | 1pc |

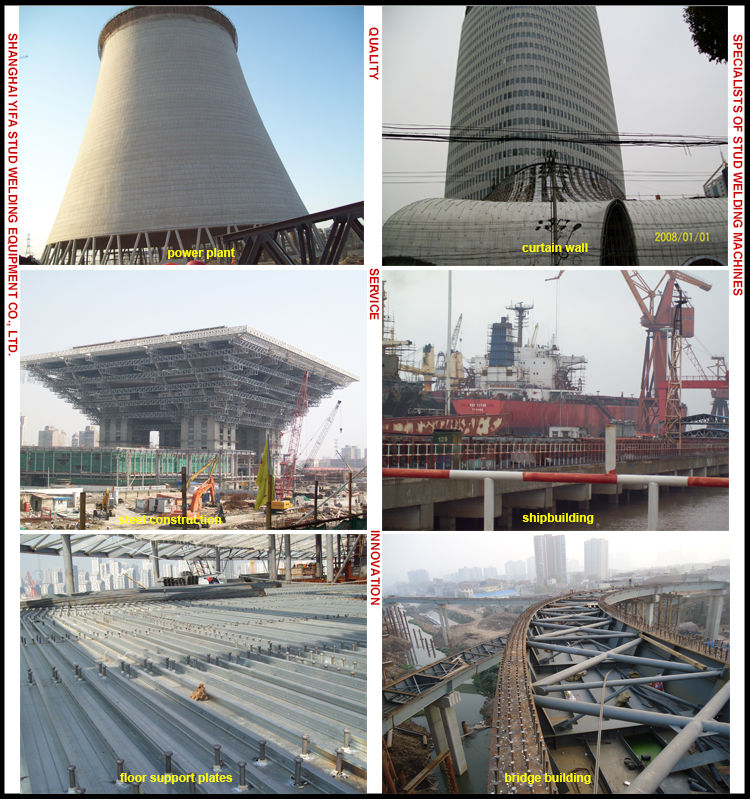

4. Our welding machines for m6 welding pin in construction sites

5. Welding machine for m6 welding pin applications

(1) Mother materials and welding effects

Carbon steel, low alloy steel, copper etc. materials with arc weldability. Welding in the workpiece surface of oxide layer, oil slick, priming paint or electroplate. After welding, no deformation, no convex, downward position welding, vertical position welding, overhead position welding, all position welding.

(2) Applicable welding projetcs

Kiln, boiler, shipbuilding, power plant, chemical engineering, mechanical equipment, various pipeline, vessel, bucket, vehicle manufacturing etc. thickness ≥ 3mm, welding M4mm—M36mm pins, studs, pin bolts, special-shaped pins, corrugated pins, anchoring parts etc. similar studs and bolts.

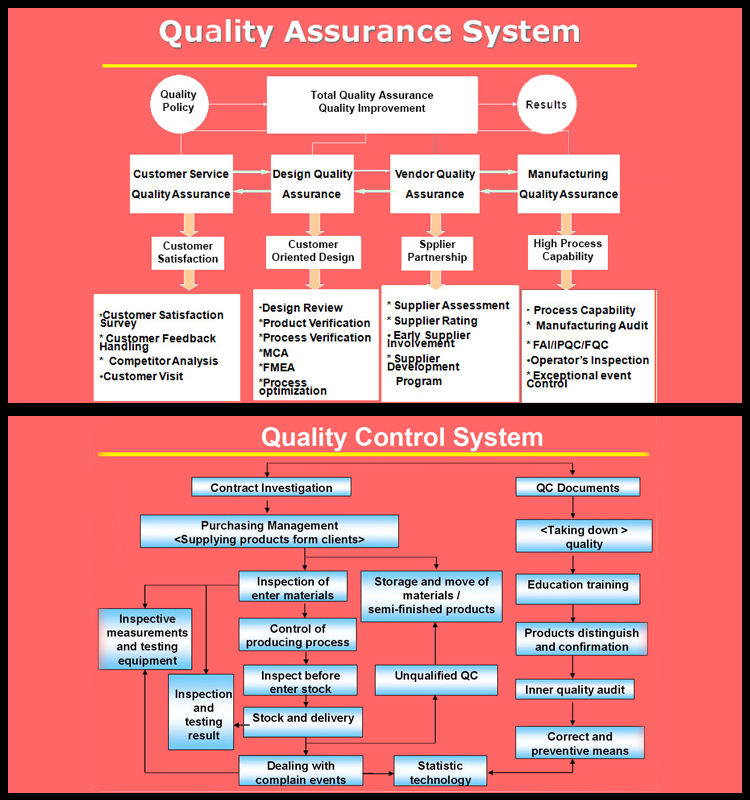

6. Quality Assurance and Quality Control System, Production Workflow

As professional manufacturer of stud welding machines, welding torches and accessories, we possess special quality assurance and quality control system, and advanced production lines and complete workflows including high-quality raw materials purchasing, assembling, testing, packaging and delivery etc.

7. Welding machine for m6 welding pin operation

(1) Locate the welder in a reliable, clear and safe site;

(2) Connect the earth cable, lengthening cable, torch, chuck, pressing plate, ferrule and stud;

(3) Open power suply to observe digital welding voltage, current and time meters;

(4) Adjust welding voltage, time and current, lifting height, extending length, chuck, grip, ferrule and stud

(5) Trial welding to test whether all the parameters are correctly adjusted or not. If not, reset your welding parameters.

(6) Begin to weld studs in your sites

1. Packaging

(1) Outer package: sturdy plywood cases accessible to pallet.

(2) Inner package: welding machines covered by bubble covers and inside fixed by battens with nails; matched welding guns and other accessories packed by corrugated cartons.

(3) Container loading: 31 sets for 20GP, and 65 sets for 40GP.

(4) The package can be designed according to clients' requirements.

2. Shipping

(1) Loading Port: Shanghai, China

(2) Delivery terms: CIF, FOB C&F etc. based on Incoterms 2010.

(3) Delivery time: 5 working days for the stock, 20 working days for the new, from the receipt of down payment and the actual delivery time depend on your order.

(4) Other shipping terms can be negotiated.

1. Free Operation Instructions

Detailed operation and maintenance manual are offered. Free telephone, online, video conference are available to you.

2. Guarantee

The seller guarantee the machine is new (or unused) and the guarantee period will be given 2 years from shipment date. During this period, the seller will provide free maintenance and free spare parts that caused by the machine’s quality. Parts damaged because of mishandling and consumable parts are not covered by any warranty.

3. Overseas Adjusting and Training Service

The seller will send the technician to buyer for installing and adjusting the machine and training the workers if the buyer invited.

4. Factory Visit by Free Accommodation

You are welcome to visit our factory, your accommodation fees shall be on our accout in case your purchasing agreement are concluded.

Похожие товары

Производитель распродажа Электрический сварочный аппарат цена TIG/MMA-200A Электрический Инвертор портативное оборудование для дуговой сварки

Высококачественная высокомощная сварная машина 250A MMA сварочная машина ZX7 Сварщики

RSN7-1000 сварочный аппарат металла бренда YIFA

MMA-300 сварочные аппараты высокой мощности 120A 220V портативные машины для дуговой сварки

Низкая стоимость небольшой Cnc плазменной резки CUT-120CNC низкочастотной Cnc чугунной стали плазменной резки металла

CUT-120CNC/160CNC/200CNC плазменный дуговой резак

ЧПУ Интегрированная машина Внешний воздушный насос промышленного класса CUT-120NCN плазменной резки 380 В оптовая продажа

Новые поступления

Новинки товаров от производителей по оптовым ценам