Изготовленная на заказ пластмассовая форма Pla Preform с системой самоблокировки 8 полостями для банок широким горлышком

- Категория: >>>

- Поставщик: TAIZHOU HANGXIANG PLASTIC MOULD CO. LTD.

Сохранить в закладки 1601243079357:

Описание и отзывы

Характеристики

Product Description

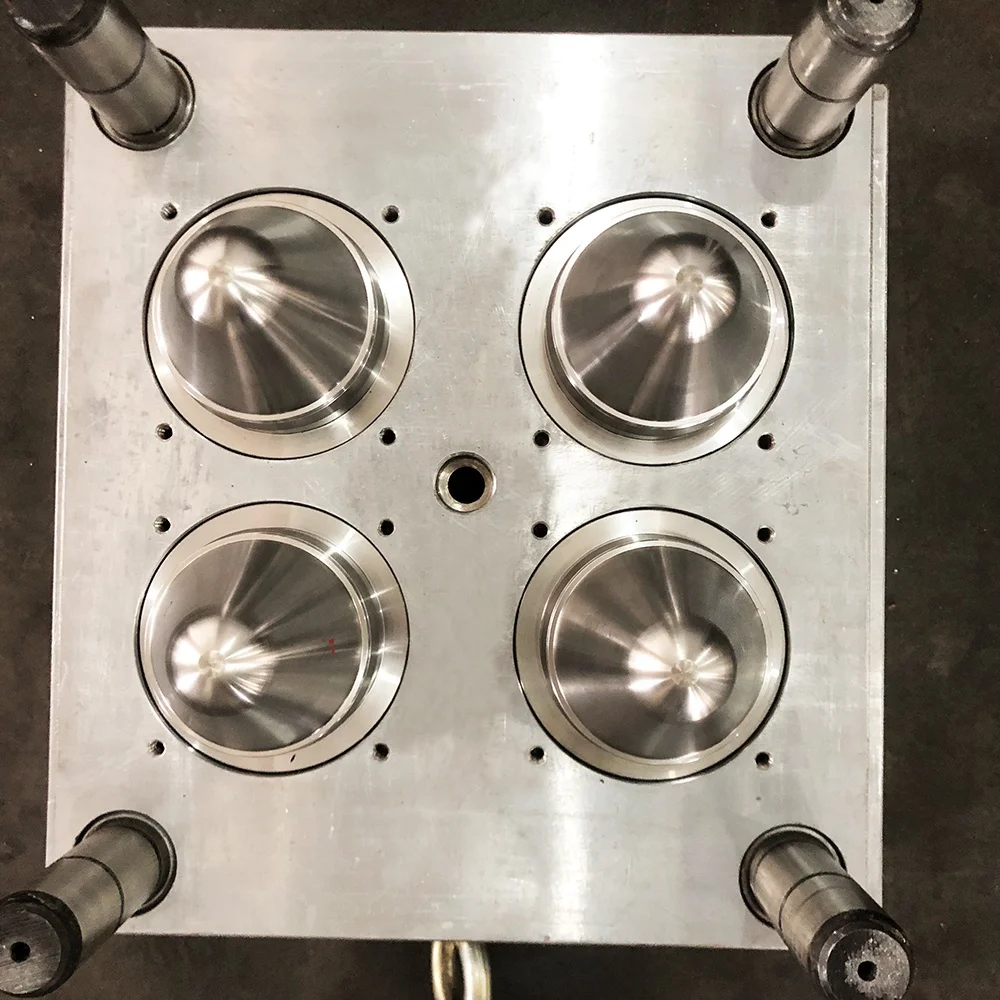

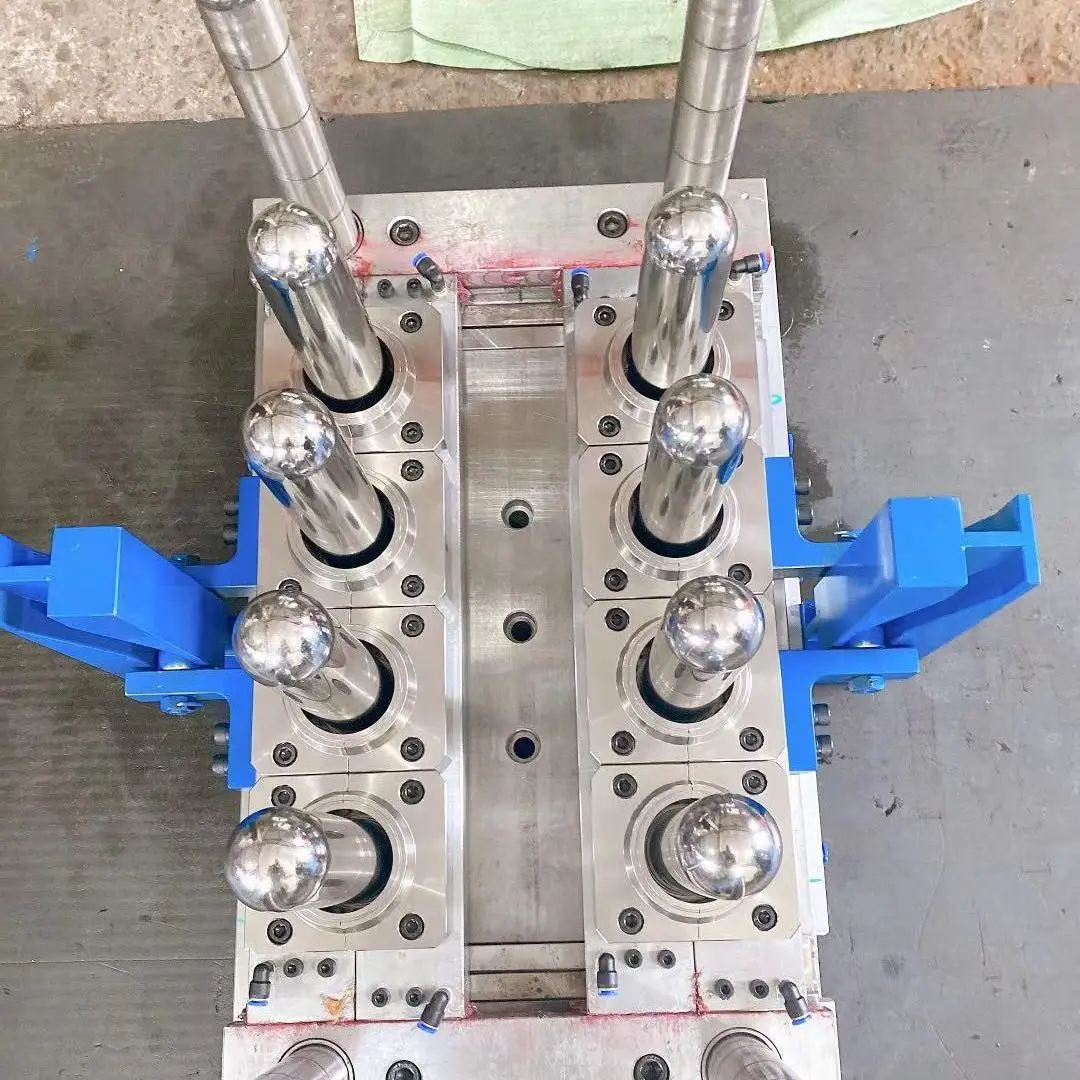

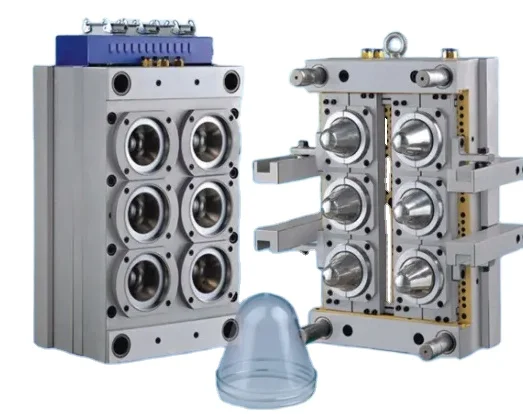

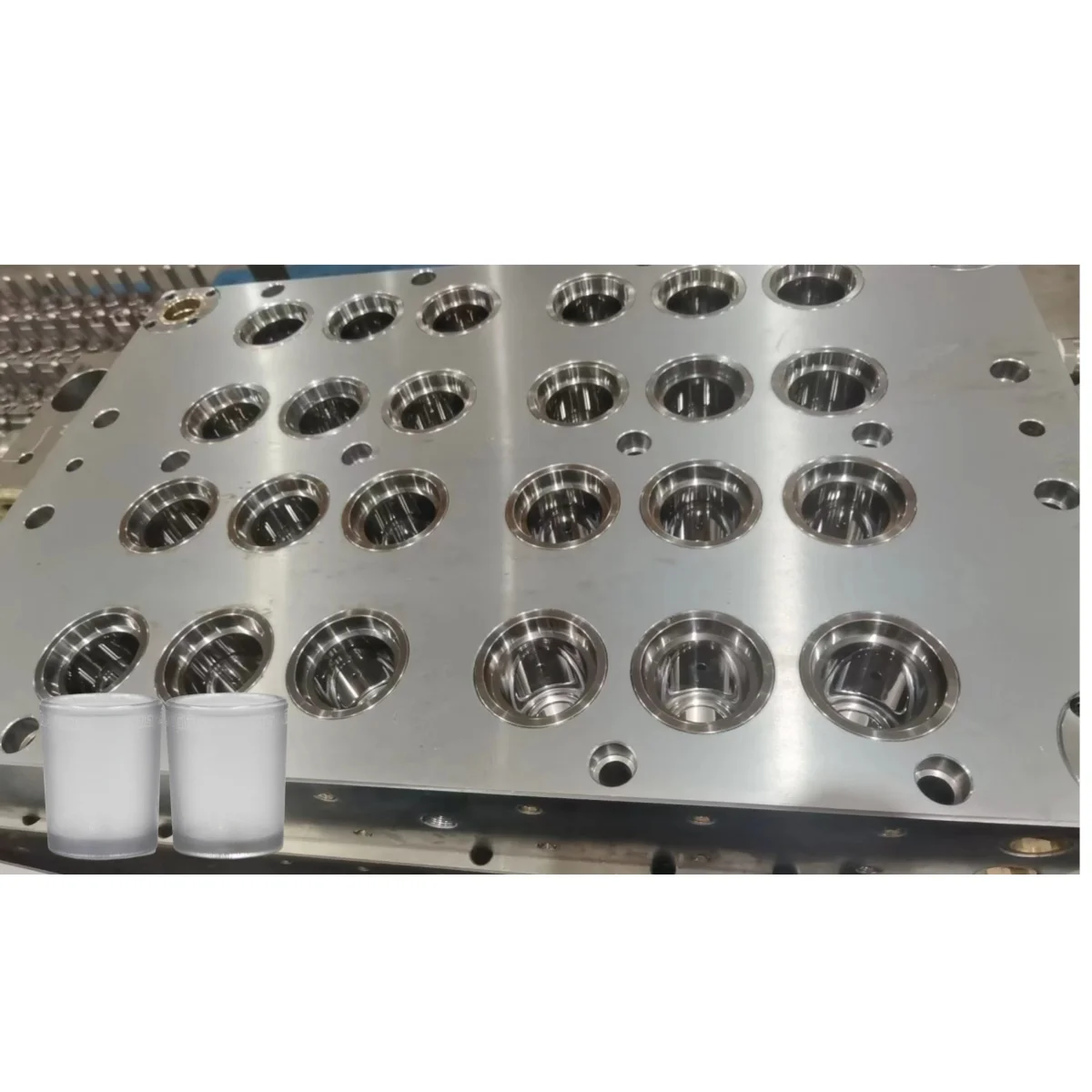

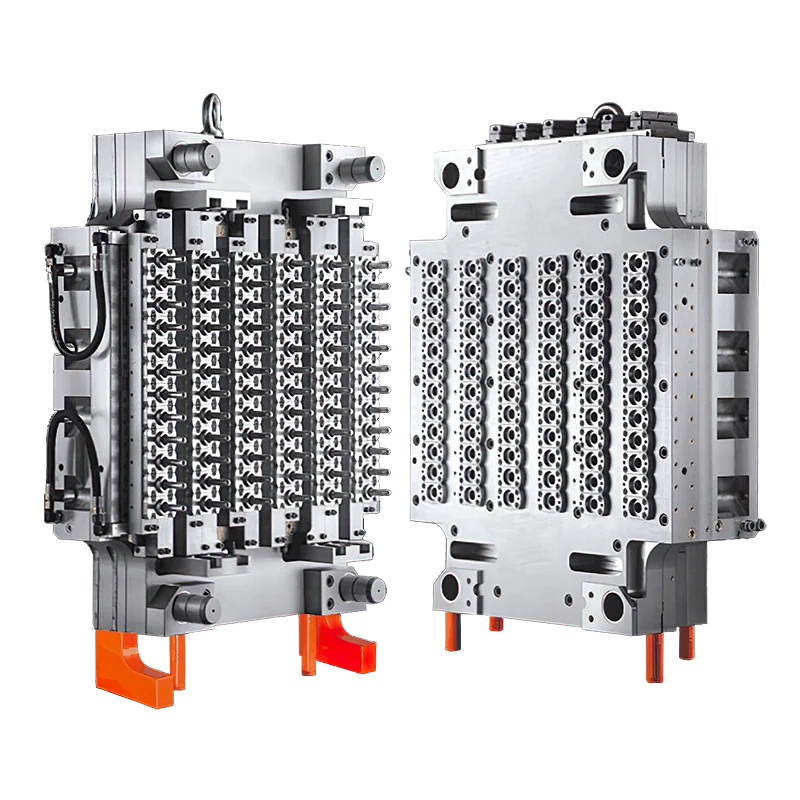

Custom Design Make Pet Plastic Pla Preform Mold With 8 Cavity Self Lock System For Wide Mouth Jar Bottle Preforms

1,PET jar preform mould

2, We have normal, self-lock and pin valve gate hot runner preform mould for choice

3, P20 + S136 stainless steel for mould material

4, 1 year warranty time, whole life technology support

Product Name | Jar preform mould |

Cavity/Core/Screw Material | S136 |

Mould Plate | P20 |

Mould Life | 2 million shots |

Type | Normal, self lock, pin valve gate |

Tail | Short tail, long tail, no tail |

Dimension | 620*380*480mm (40g preform) |

Weight | 690kg |

More Proucts

Company Profile

Taizhou Hangxiang Plastic Mould Co., Ltd

We designs not only preform with standard neck size for water preform, carbonated drink preform and oil preform, also design preform of special shape responding to customer’s request. We adopts a wide range of computer-aided engineering service from design conception to the finished products to make customer satisfied.

Our preform injection mold adopts an advanced valve-gate unit, which is used to control the mold’s injection hole open & close on each cavity. Reliable sealing function, smoothing moving, low thermal expansion rate, and long using life are its main features.

The patent designed rectifying device is equipped to rectify the preform thickness during preform production. The preform thickness can be adjusted below 0.05mm.

Preform injection mold adopts specially designed hot runner system to achieve ideal and prompt heating effect for preform production. Lager flowing channels of such hot runner system ensures the mold to produce preform with lower injection pressure, which reduces mold’s each part’s wear & tear and maintenance cost, and also saves electric energy.

Manufacturing

Sample Room Display

Packing&Transportation

8 Cavity Hot Runner Preform Mould

1. Outside package: Export standard wooden case for both preform mould and temperature controller

2. Inner package: Stretch waterproof film & Each Mold painted anti-rust oil.

3. Spare parts together with the mold shipment.

2. Inner package: Stretch waterproof film & Each Mold painted anti-rust oil.

3. Spare parts together with the mold shipment.

Certifications

FAQ

1. Are you factory or trading company?

We are mould factory with import and export right.

2. Where is your factory located?

4. How to get firm price of mould?

Please kindly supply below information:

We are mould factory with import and export right.

2. Where is your factory located?

We are located in Huangyan, Taizhou city, Zhejiang Province, China.

40 minutes from Taizhou Luqiao Airport, 20 minutes from Taizhou West Station.

You can come to us by train from Shanghai, about 2.5 hour; by air plane from Guangzhou, about 1.5 hour.

3. How about quality control in your factory?

Qualiy wins the market. It's our belief.

We have professional engineers to control the quality. Whole of us do the following procedures:

A) Design Optimize control

B) Mould steel hardness Inspection

C) Mould assembly Inspection

D) Mould trial test and samples Inspection before shipment

4. How to get firm price of mould?

Please kindly supply below information:

A) Preform sample or 2D/3D drawing (DWG, DXF, STEP, IGS and X_T files), and we have designer too.

B) Mould cavity

C) Normal, self lock or pin valve gate

D) No tail, short tail or long tail

E) Special requirements about mould material etc

5. What's the main product of your factory?

5. What's the main product of your factory?

A) Preform mould

B) Injection mould

C) Bottle blow mould

Any inquiry, please feel free to contact us at sales@hxmolds.com and Wechat/whatsapp +8613967628276.

6. How about production time?

A) For normal preform mould, usually 20-25 working days

B) For self lock preform mould, usually 25-30 working days

C) For pin valve preform mould, usually 30-35 working days

Production time is based on mould cavity. And we can reduce production time with quality warranty, when you have urgent order.

7. How about payment terms?

A) Alibaba trade assurance order

A) Alibaba trade assurance order

B) T/T, L/C, D/P

C) Western Union, Moneygram, Paypal

D) 20%-50% as deposit, balance will be paid before shipment.

8. what services can you provide?

8. what services can you provide?

A) We can suggest and design preform based on your bottle idea;

B) Video calling to inspect mould processing

C) Mould testing before shipment

D) Free sample and express to you for quality checking

E) Mould warranty time: usually 1 year from your receive date

F) Whole life technology support for both mould, bottle blowing and injection moulding machine.

Похожие товары

Широкогорлая независимая самоблокирующаяся форма для преформ домашних животных 110 мм, формы для преформ шеи/ПЭТ 315 мл

59 343,79 ₽ - 107 897,80 ₽

8 емкостей, ПЭТ-банка, форма для производства широкой горловины с клапаном, Запорная система для гаек и бутылок для конфет

Заводская 24 полости штифт клапан ворота горячий бегун 38 мм Шея 14 г Чжэцзян Taizhou Huangyan ПЭТ Преформа пластиковая литьевая форма

Многоразовая посуда пластиковая чашка для домашних животных форма на заказ

1 402 671,40 ₽ - 1 618 467,00 ₽

24 полости, 28/pco Шея 35 грамм форма для преформ/28/pco

323 693,40 ₽ - 3 236 934,00 ₽

Изготовленная на заказ форма для преформ для бутылок с 8 полостями форма для преформ для домашних животных для производства преформ для домашних животных

431 591,20 ₽ - 647 386,80 ₽

Пластиковая форма для литья под давлением

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $