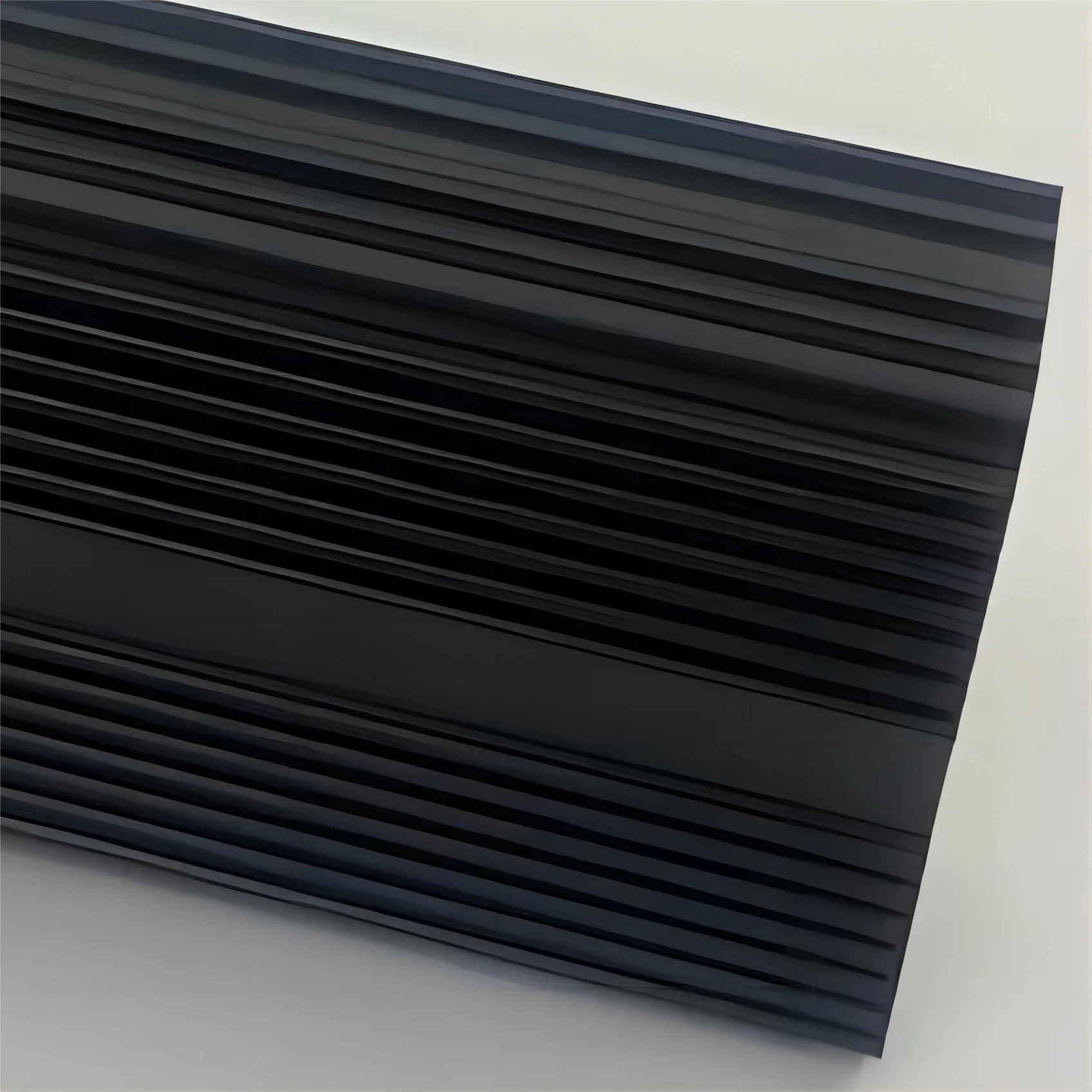

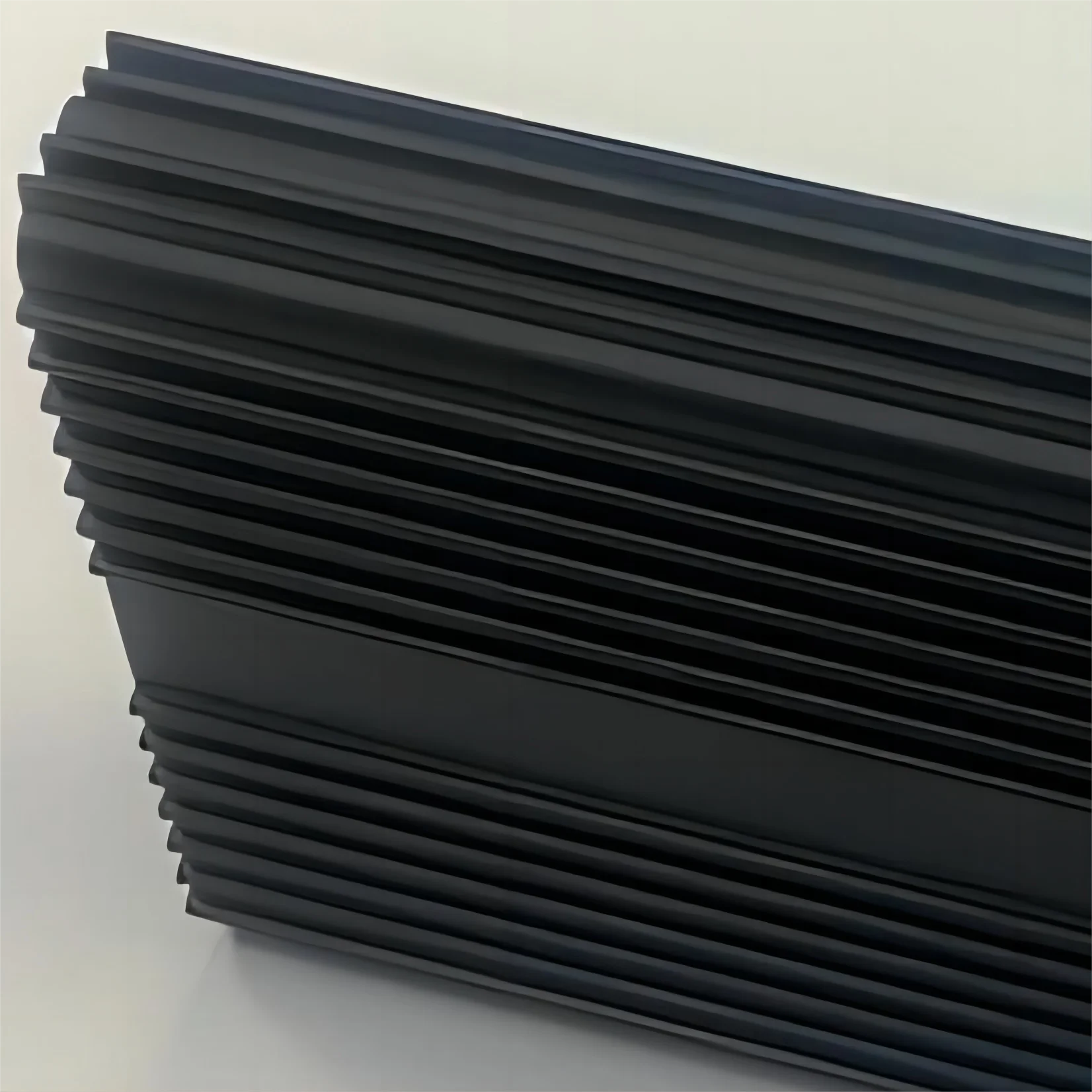

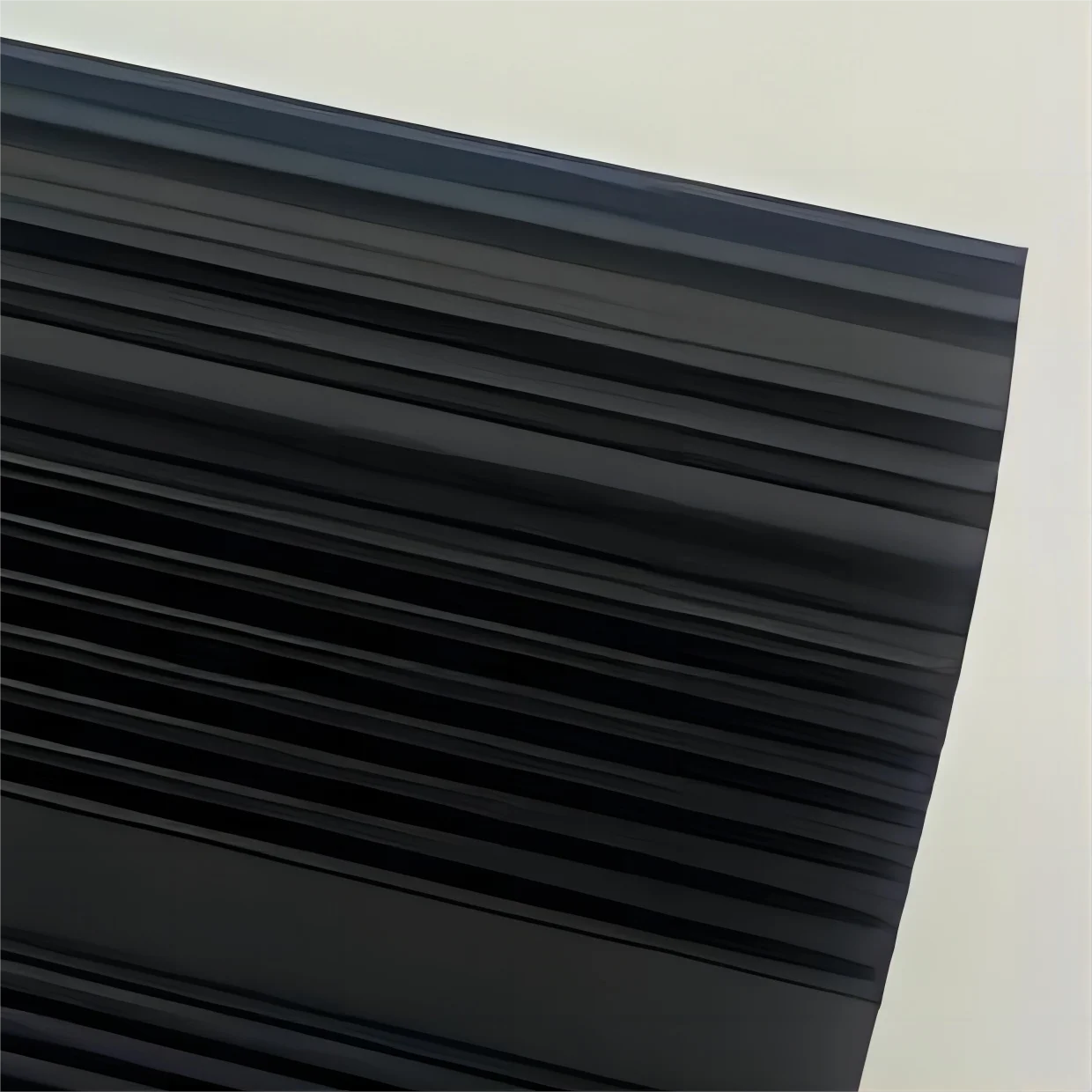

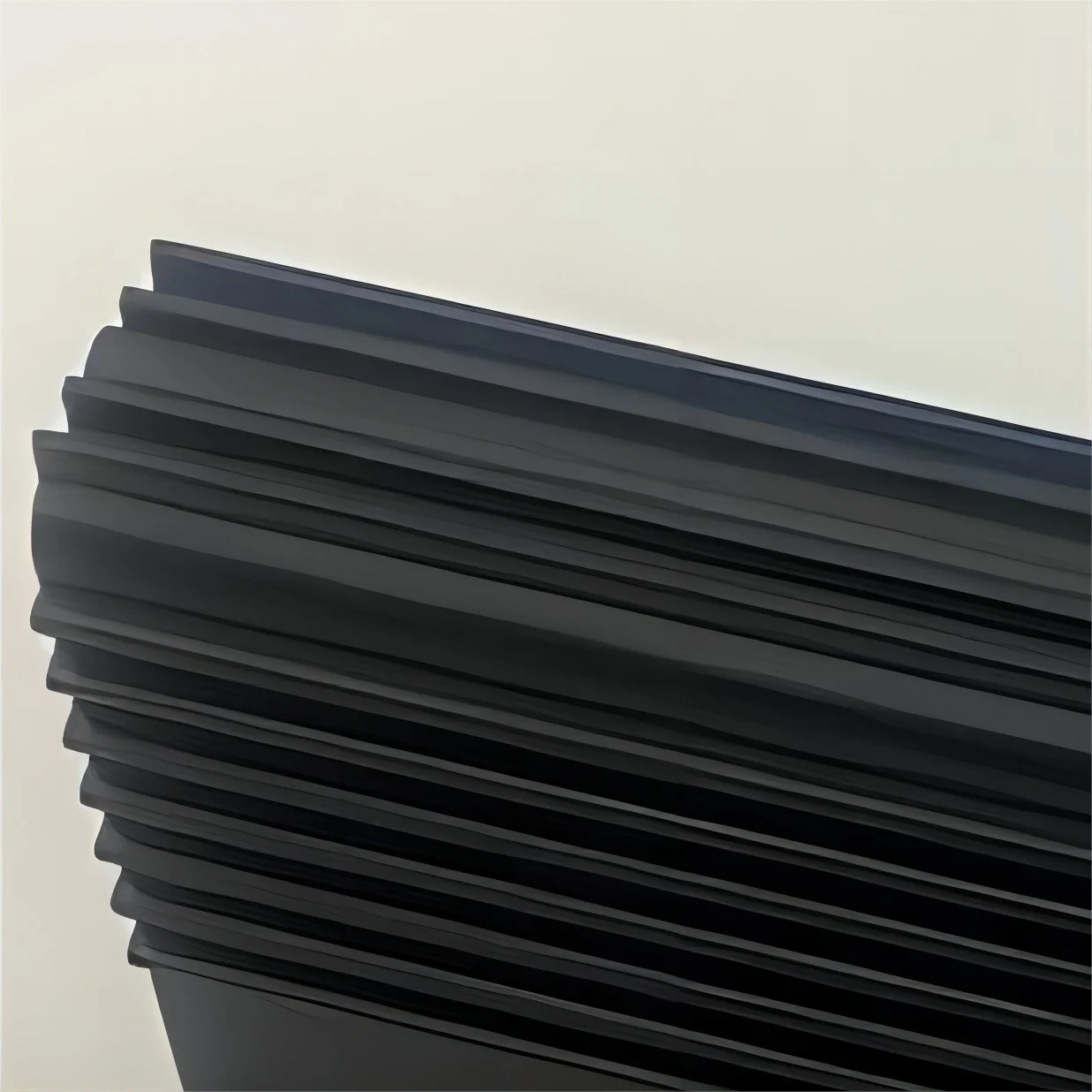

KGI New Arrival Aluminum Extrusion Heatsink with Black Anodized

- Категория: >>>

- Поставщик: Dongguan Kinggold Industry Co. Ltd.Dongguan Ltd.

Сохранить в закладки 1601244753363:

Описание и отзывы

Характеристики

Products Description

Aluminum Extrusion Heatsink

Commodity Parameters:

Material: AL6061-T6

Finish: Black anodize

Production Process: Aluminum extrusion

Packaging: PVC bag- carton- pallet

Application: Electronic parts

Material Characteristics: SGS, ROHS, REACH compliant

Tips: All products of KGI can be customized, and a variety of materials, finish, packaging and specifications are available.

Commodity Parameters:

Material: AL6061-T6

Finish: Black anodize

Production Process: Aluminum extrusion

Packaging: PVC bag- carton- pallet

Application: Electronic parts

Material Characteristics: SGS, ROHS, REACH compliant

Tips: All products of KGI can be customized, and a variety of materials, finish, packaging and specifications are available.

Recommend Products

Company Details

About KGI

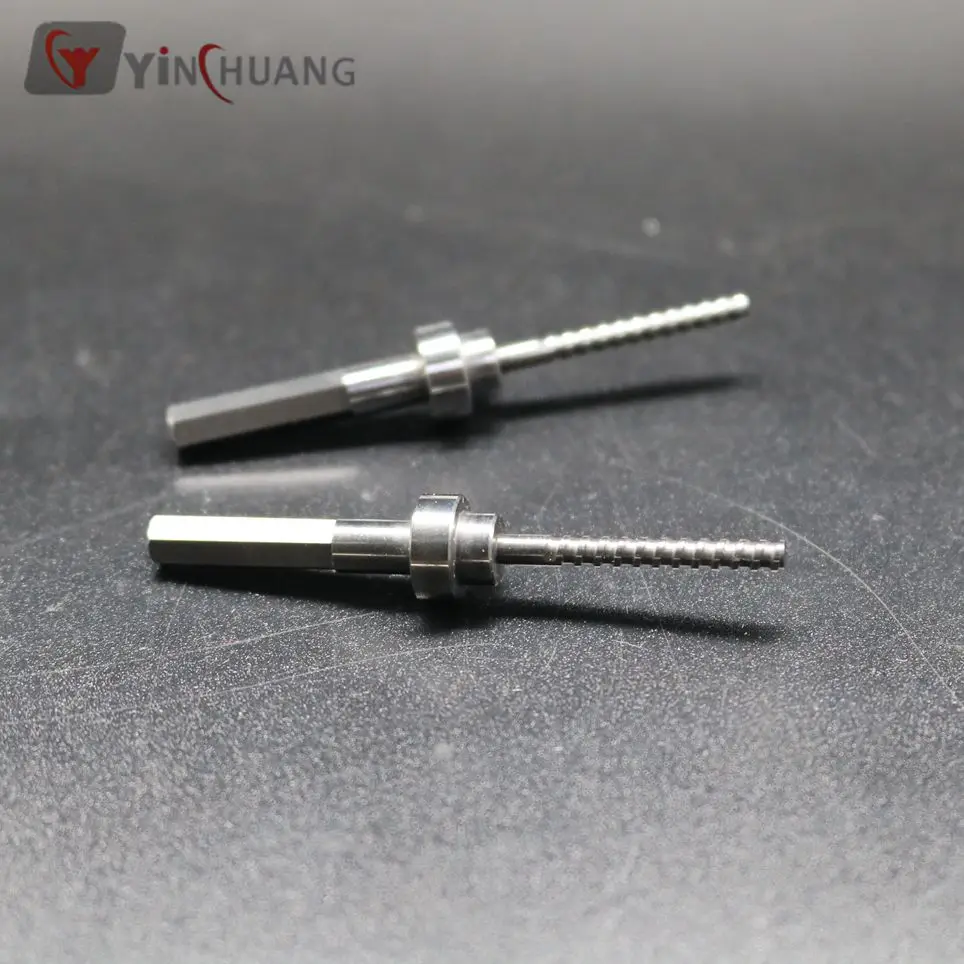

Dongguan Kinggold Industry Co., Ltd called KGI for short, which was founded in 2003 and located in the "world factory" Dongguan.The factory covers an area around 12000㎡ and is a comprehensive industrial enterprise committed to diversified development.Relying on 20+ years of experience in stamping parts production and management , KGI has invested and integrated all kinds of supply chains to provide customers with industry-wide services, such as CNC machining, zinc&aluminum die casting, aluminum extrusion, sheet metal, spring, plastic &silicone, finished and semi-finished products assembling,etc. KGI is always committed to provide global customers with customized one-stop solutions from product R&D, mold manufacturing, production and procurement, assembling, testing, packaging to transportation and exportation.

Factory Tour

KGI has independent stamping workshop and CNC machining workshop, dedicates to the production of various precision stamping parts and CNC lathe parts, such as all kinds of bending and deep drawing shields, standard shields, precision shrapnels, contact plates, clips, non-standard terminals, CNC lathe parts, automatic lathe parts, etc. All molds are developed,designed and produced independently,we also brought in a small laser cutting machine for rapid prototyping to meet the client’s test demand in the initial phase of the project.

Stamping Workshop

With more than 20sets of imported and domestic stamping machines available, our daily output could reach millions of pieces.

CNC Workshop

Our CNC machining workshop is wholly owned in house, which can produce both CNC lathing parts and automatic lathing parts.

Tooling Workshop

All the toolings are fully designed and produced by KGI. We also brought in a small laser cutting machine for rapid prototyping.

Packaging Workshop

The quality controls for all our diversified parts are performed in house. All the parts are 100% checked before shipping.

Testing Equipment

In order to meet the needs of diversified products, KGI is equipped with perfect quality inspection equipment, such as CMM machine, 2.5D automatic image measuring instrument, Japan imported KEYENCE measuring instrument, film thickness tester, salt spray test machine, colorimeter and other testing equipment.

Certificate

Customer Photos

FAQ

Q1. Can I buy the product showed above directly?

No, all the products showed on our website are only for showing our production capability and cannot be sold directly. And the prices are also for reference, please contact us for actual prices.

Q2. Are you a factory or trade company?

We are a direct factory, located in Dongguan, China.

Welcome to visit our factory.

Q4. How about your quality?

♦We have got ISO9001:2015 and IATF16949 certificates.

♦We will make the operation instruction once the sample is approved.

♦We will 100% inspect the products before shipment.

Q5. How long should we take for a quotation?

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days.

Q6. What is your payment term?

Mold: 50% prepaid, balance after sample approval; Mass production: 40% prepaid, balance T/T before shipment.

KGI and the whole sales team warmly welcome your RFQ and visit!

No, all the products showed on our website are only for showing our production capability and cannot be sold directly. And the prices are also for reference, please contact us for actual prices.

Q2. Are you a factory or trade company?

We are a direct factory, located in Dongguan, China.

Welcome to visit our factory.

Q3. How about the lead time?

Mold: 2-4 weeks; Mass production: 3-4 weeks

Mold: 2-4 weeks; Mass production: 3-4 weeks

Q4. How about your quality?

♦We have got ISO9001:2015 and IATF16949 certificates.

♦We will make the operation instruction once the sample is approved.

♦We will 100% inspect the products before shipment.

Q5. How long should we take for a quotation?

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days.

Q6. What is your payment term?

Mold: 50% prepaid, balance after sample approval; Mass production: 40% prepaid, balance T/T before shipment.

KGI and the whole sales team warmly welcome your RFQ and visit!

Похожие товары

Втулка из спеченного железа, пропитанная маслом, бронзовая втулка, втулка 29,05*20,15*30 мм

5,11-10,21 ₽

98010898 S1730S-L16P-MA 16-портовый гигабитный POE Неуправляемый коммутатор доступа S1700

Детали карбида вольфрама компоненты обработка

Запчасти для станков SMT JUKI MTC MTS шаговый двигатель 103H7523-7051 40045057 400-45057

Вулканизирующий пресс вулканизирующий резиновый силиконовый станок для резиновой этикетки

Сделано в Китае, индивидуальный листовой металл, Штампованный корпус из мягкой стали

343,00-392,30 ₽

Бамбуковый мобильный беспроводной источник питания Защита окружающей среды грецкий орех кленовый USB литий-полимерный аккумулятор блок 10000 мА

1,10-2,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $